Springs, those unassuming yet indispensable components, are the silent enablers of countless machines and devices—from the suspension systems of cars to the buttons on our smartphones, from medical devices to industrial machinery. Behind every reliable spring lies a manufacturing process that demands meticulous precision, consistency, and efficiency. Enter automatic spring equipment—a category of advanced machinery that has revolutionized how springs are designed, produced, and integrated into modern products.

What is Automatic Spring Equipment?

Automatic spring equipment encompasses a range of specialized machines engineered to automate the entire lifecycle of spring production, from wire forming to finishing, inspection, and even assembly. Unlike manual or semi-automatic systems, these machines operate with minimal human intervention, leveraging computer numerical control (CNC), robotics, and sensor technology to deliver high-volume, high-precision output.

Key types of automatic spring equipment include:

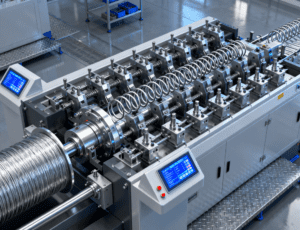

Automatic spring coiling machines: The workhorses of spring production, these machines shape metal wire (steel, stainless steel, copper, etc.) into coiled springs of varying sizes, pitches, and diameters.

Spring grinding machines: These refine the ends of coiled springs to ensure flatness and uniform length, critical for proper seating in assemblies.

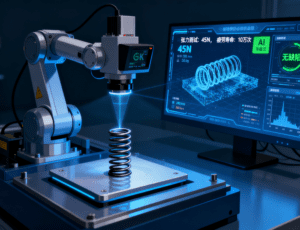

Spring testing machines: Equipped with load cells and displacement sensors, they validate spring performance (e.g., tension, compression, fatigue resistance) to meet industry standards.

Spring assembly machines: These integrate springs with other components (e.g., hooks, washers, or housings) in applications like automotive valves or electrical switches.

The Core Advantages: Why Automation Matters in Spring Production

Springs are often small, delicate, and require tight tolerances—even a fraction of a millimeter deviation can compromise their functionality. Automatic spring equipment addresses these challenges head-on, offering benefits that manual production simply cannot match:

- Unrivaled Precision and Consistency

Human hands, no matter how skilled, struggle to replicate the exactitude of automated systems. CNC-controlled spring coiling machines, for example, can shape wire with tolerances as tight as ±0.01mm, ensuring every spring in a batch performs identically. This consistency is vital for industries like aerospace, where a single faulty spring could have catastrophic consequences.

- Turbocharged Production Speed

Manual spring winding is slow and labor-intensive, limiting output to a few hundred pieces per hour. In contrast, advanced automatic coiling machines can produce thousands of small springs per hour, with some high-speed models exceeding 10,000 units per hour. This scalability allows manufacturers to meet tight deadlines and scale production in line with market demand.

- Reduced Waste and Cost

Automation minimizes material waste by optimizing wire usage and reducing errors. For instance, automatic feeding systems precisely measure and cut wire to the exact length needed, avoiding overages. Additionally, fewer defective springs mean lower scrap rates, while reduced labor costs (thanks to 24/7 operation with minimal oversight) drive down per-unit production expenses over time.

- Flexibility for Diverse Designs

Modern automatic spring equipment is highly adaptable. Operators can program machines to switch between spring types—coil, torsion, extension, or custom shapes—in minutes via user-friendly interfaces. This flexibility is a boon for manufacturers catering to niche markets or producing small-batch, specialized springs, such as those used in medical devices or robotics.

Innovations Driving the Next Generation of Spring Equipment

As manufacturing embraces Industry 4.0, automatic spring equipment is evolving with smarter, more connected features:

IoT Integration: Sensors embedded in machines monitor real-time data—temperature, vibration, wire tension—to predict maintenance needs, reducing unplanned downtime.

AI-Powered Quality Control: Machine vision systems, paired with artificial intelligence, inspect springs for defects (e.g., cracks, uneven coils) with greater accuracy than human inspectors, ensuring only flawless products move down the line.

Robotic Collaboration: Cobots (collaborative robots) work alongside automatic machines to handle secondary tasks, such as sorting finished springs or loading/unloading materials, further streamlining workflows.

Applications: Where Automatic Spring Equipment Shines

The impact of automatic spring equipment spans virtually every industry that relies on springs:

Automotive: Producing suspension springs, valve springs, and seat adjustment springs with consistent durability.

Electronics: Manufacturing tiny compression springs for switches, connectors, and battery contacts.

Medical Devices: Crafting precision springs for insulin pumps, surgical tools, and prosthetics, where biocompatibility and reliability are paramount.

Aerospace: Creating high-strength, heat-resistant springs for aircraft landing gear and engine systems, adhering to strict aviation standards.

Conclusion

Automatic spring equipment is more than just a tool—it is the cornerstone of modern spring manufacturing, enabling the precision, speed, and flexibility that define today’s industrial landscape. As technology advances, these machines will continue to evolve, pushing the boundaries of what’s possible in spring design and production. For manufacturers, investing in automatic spring equipment isn’t just about keeping up—it’s about leading the way in an era where quality and efficiency are non-negotiable.