IBG Flaw Detection Machine

IBG Flaw Detection Machine is a high-precision automatic non-destructive testing solution for automotive, hardware, aerospace, and medical device manufacturing. This intelligent inspection equipment uses advanced eddy current and sensing technology to quickly identify internal cracks, pores, material defects, and structural abnormalities with high accuracy. It realizes fully automatic detection, replacing manual inspection to reduce errors and improve efficiency. With stable performance, easy operation, and high compatibility, it supports various metal components and precision parts. The system provides real-time data recording, alarm prompts, and seamless production line integration, helping manufacturers strengthen quality control, ensure product safety, and meet strict industry standards. IBG Flaw Detection Machine is the ideal choice for reliable, efficient, and intelligent flaw inspection in modern automated production.

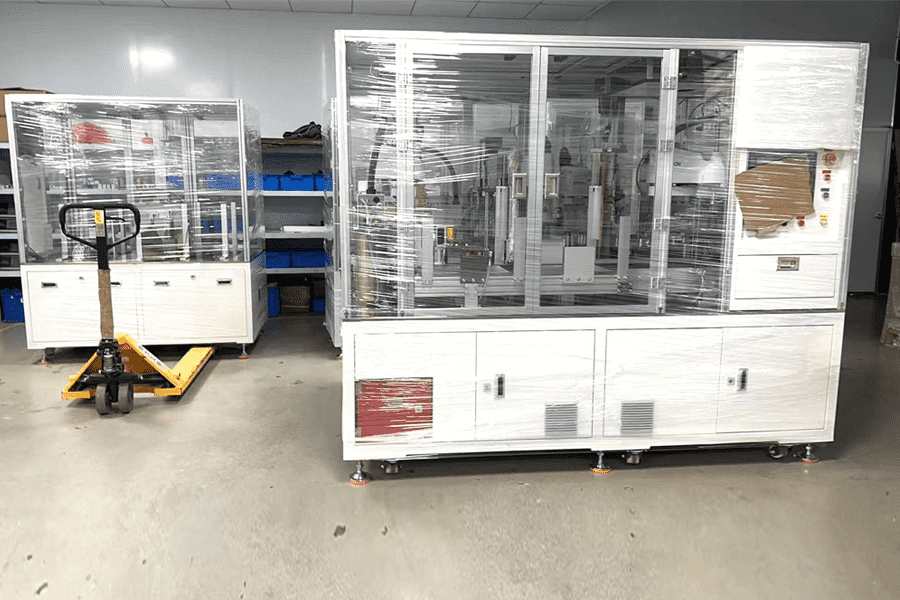

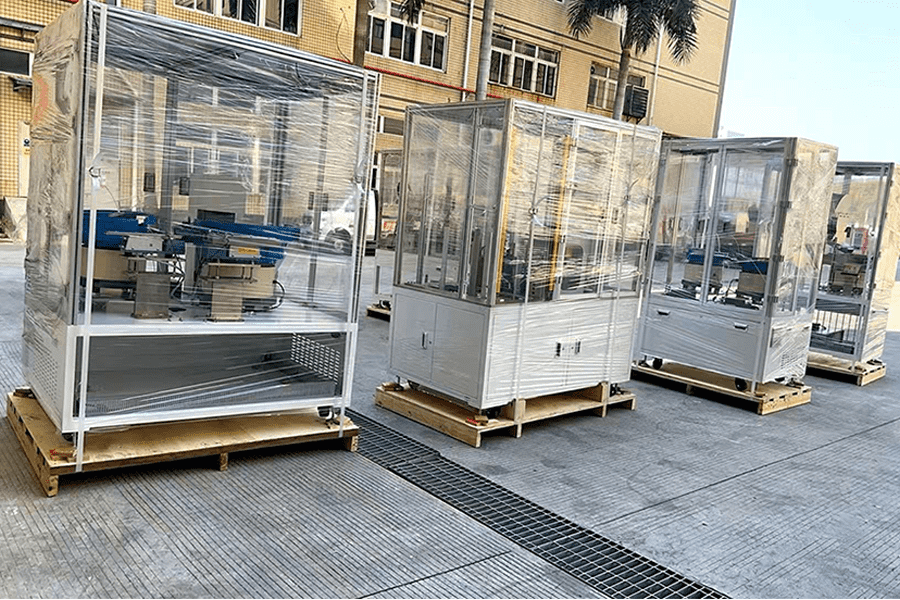

After the equipment has been assembled and debugged, we will select suitable packaging materials to properly protect the equipment. This will effectively safeguard it against impacts, moisture, and ensure it is firmly secured, guaranteeing that the equipment arrives at its destination intact.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Respond to defects within 4 hours.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

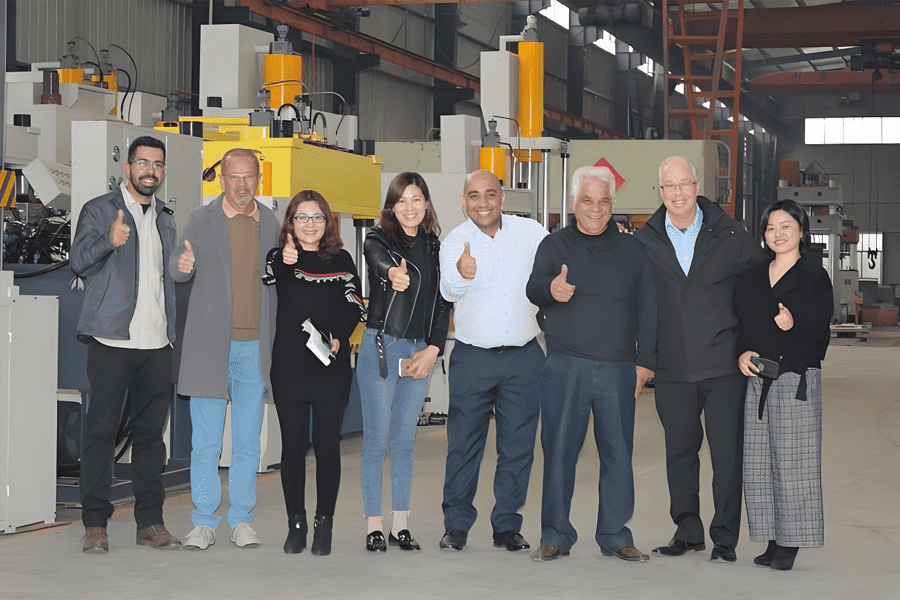

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project’s on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer’s technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.