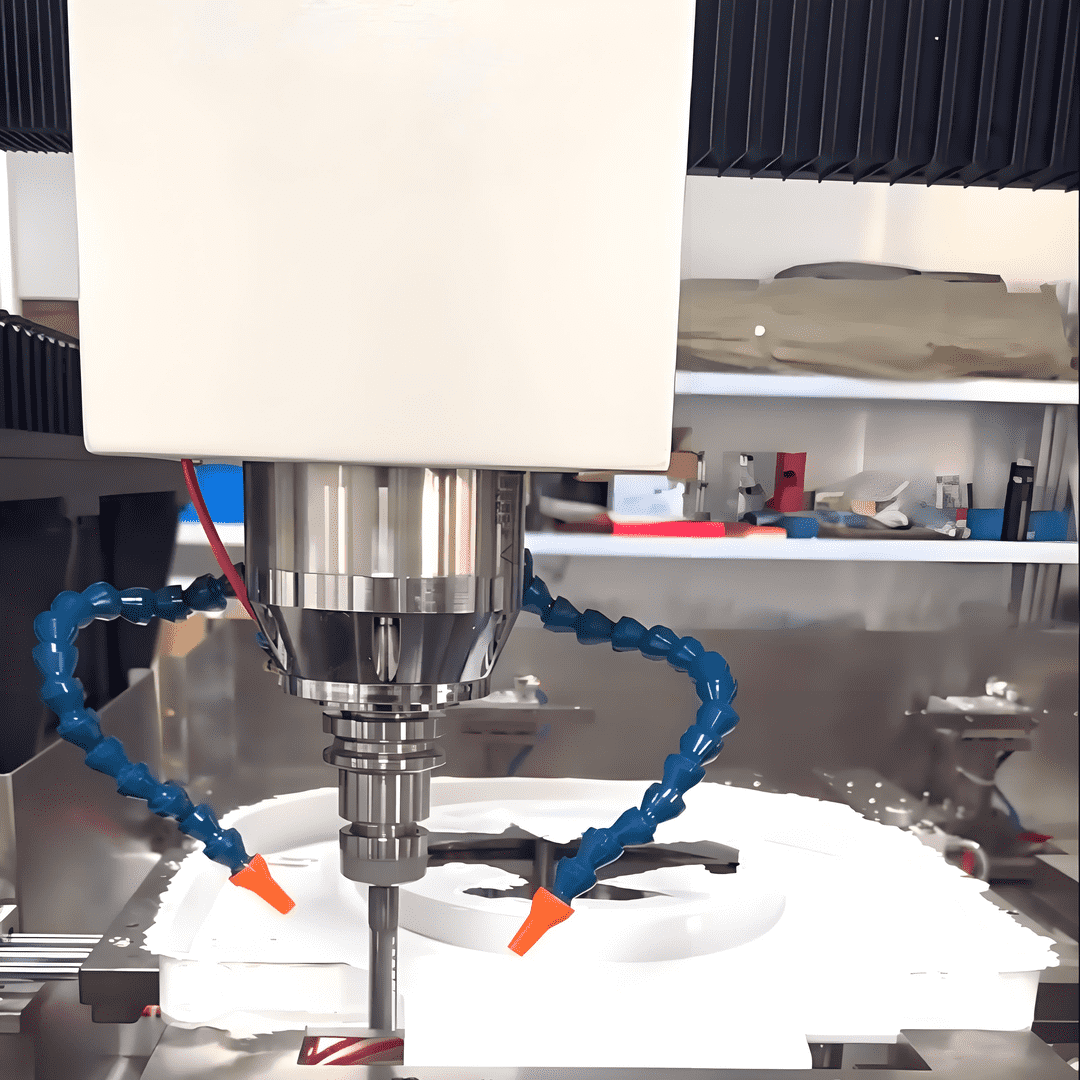

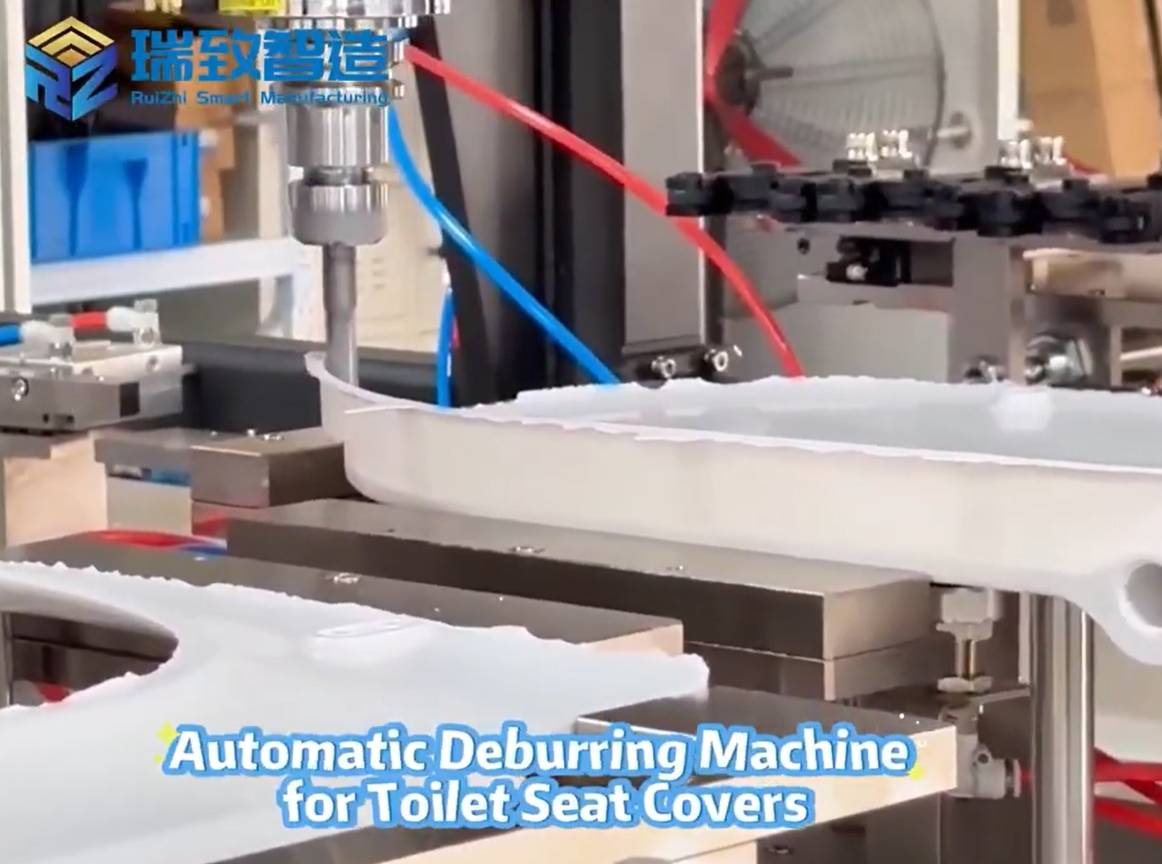

便座カバー用自動バリ取り機

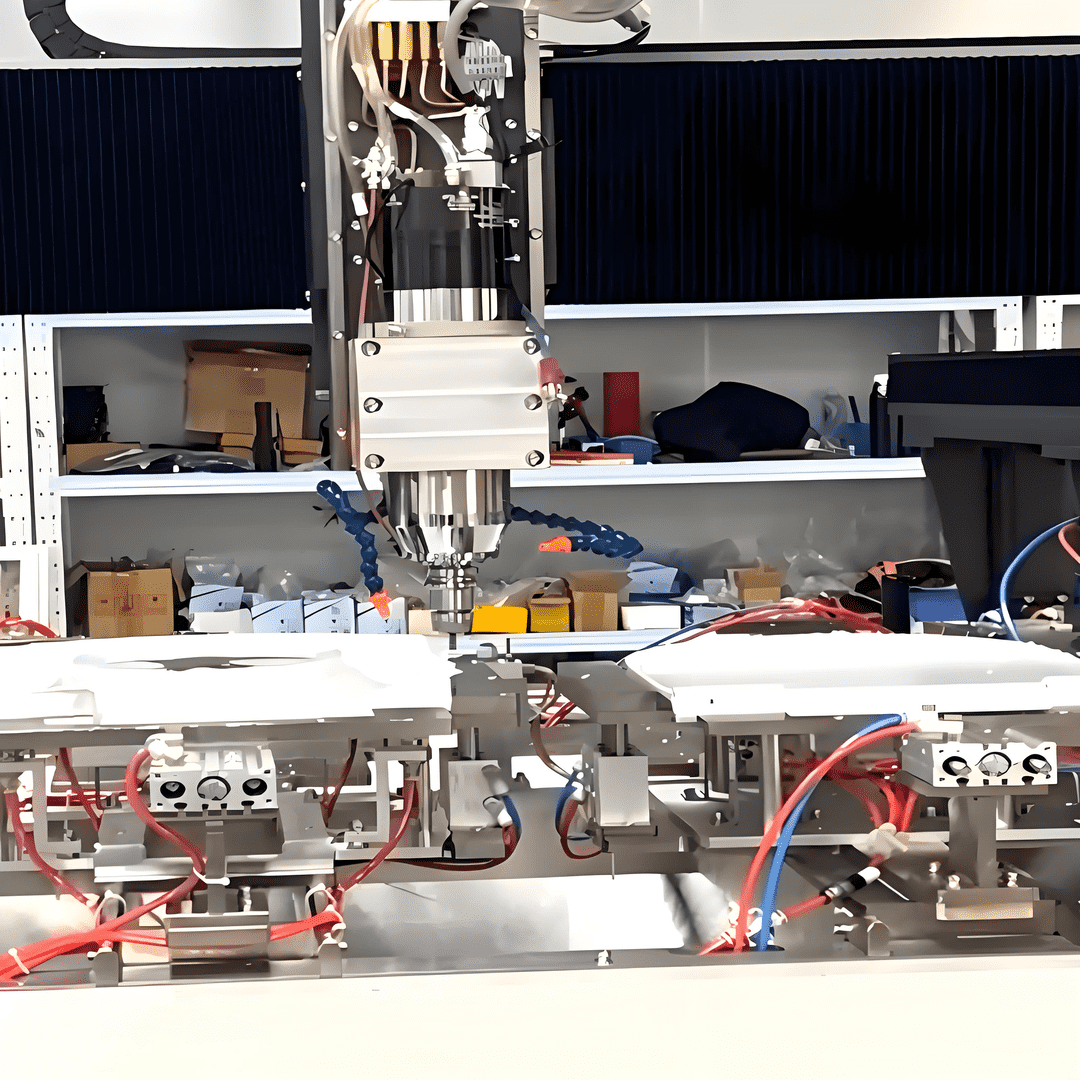

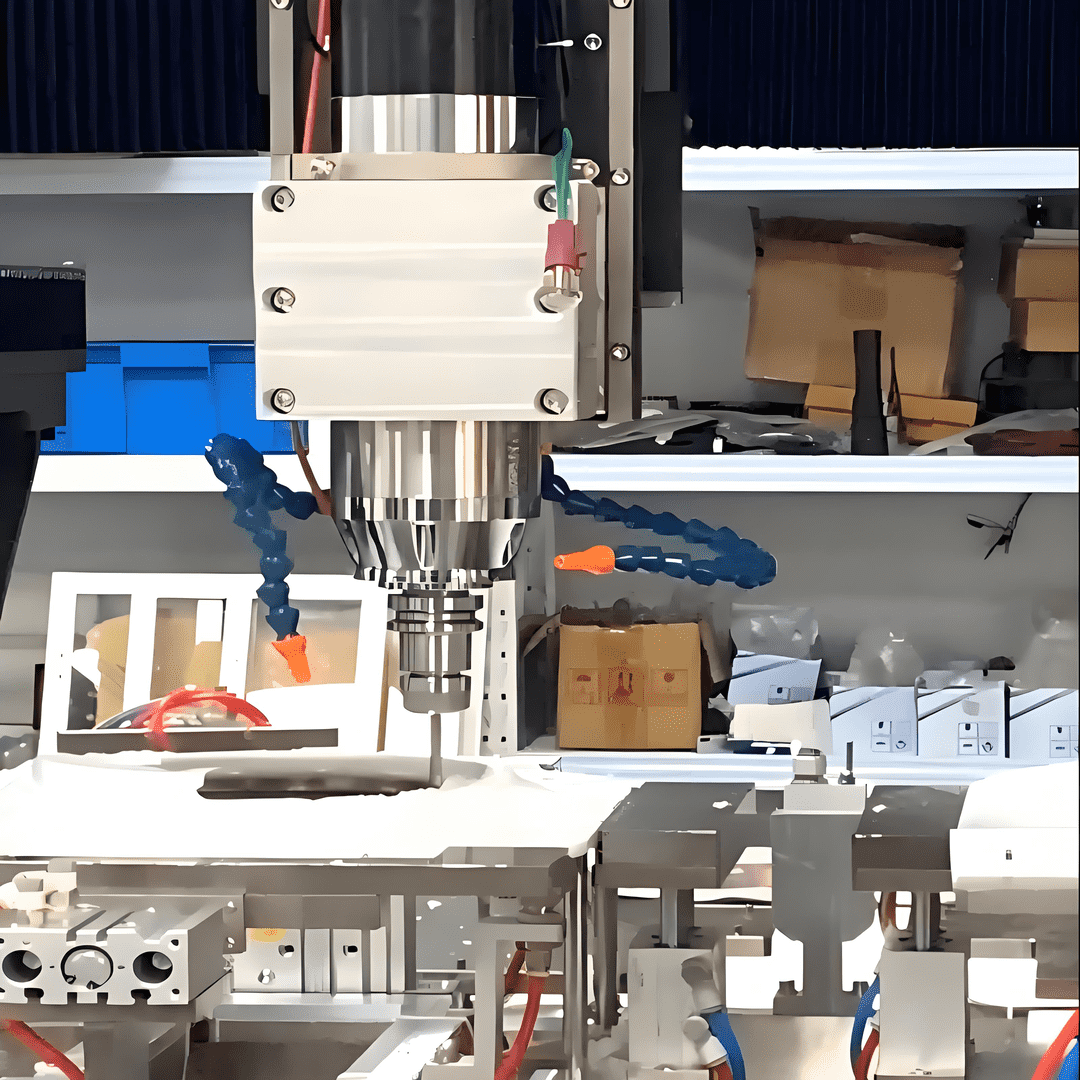

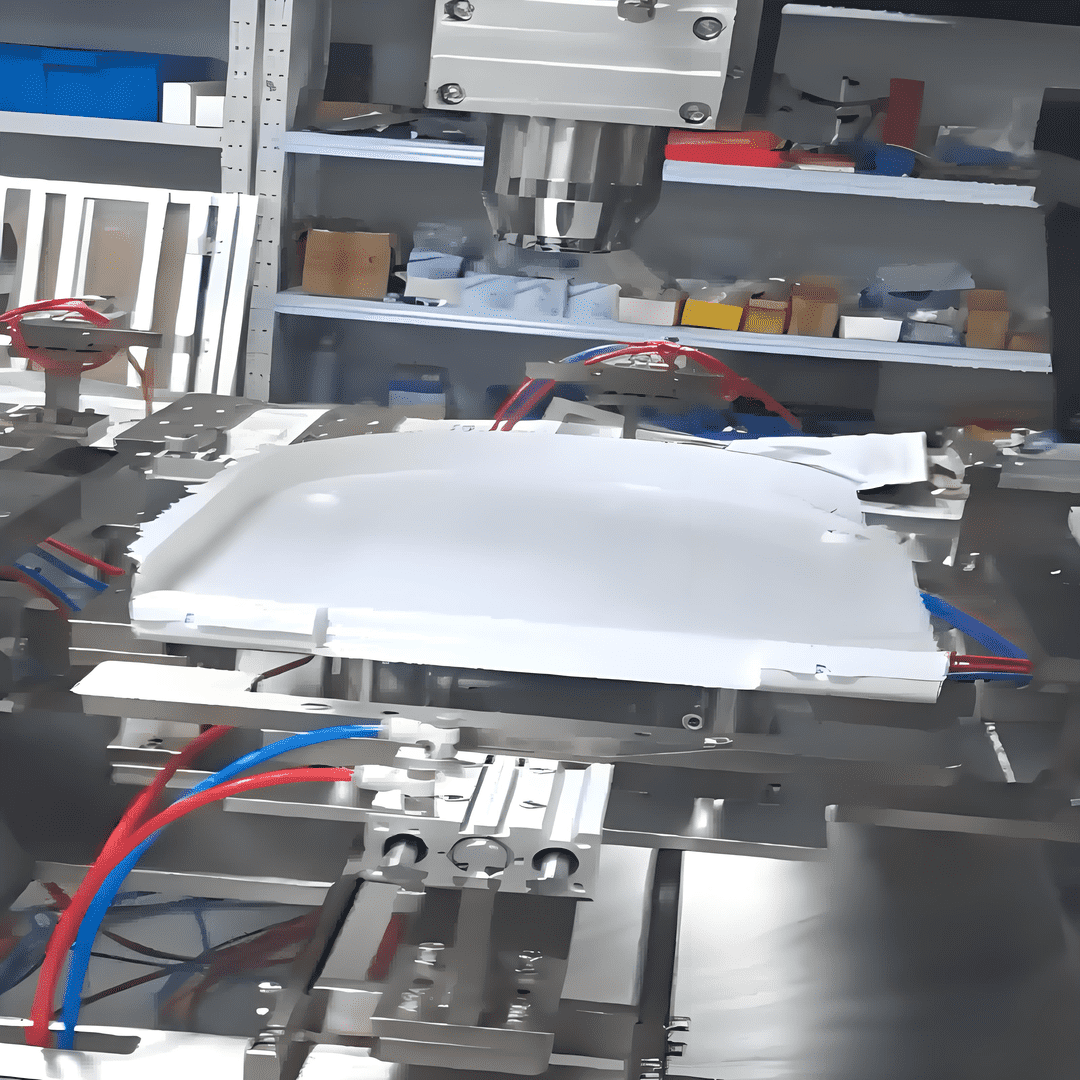

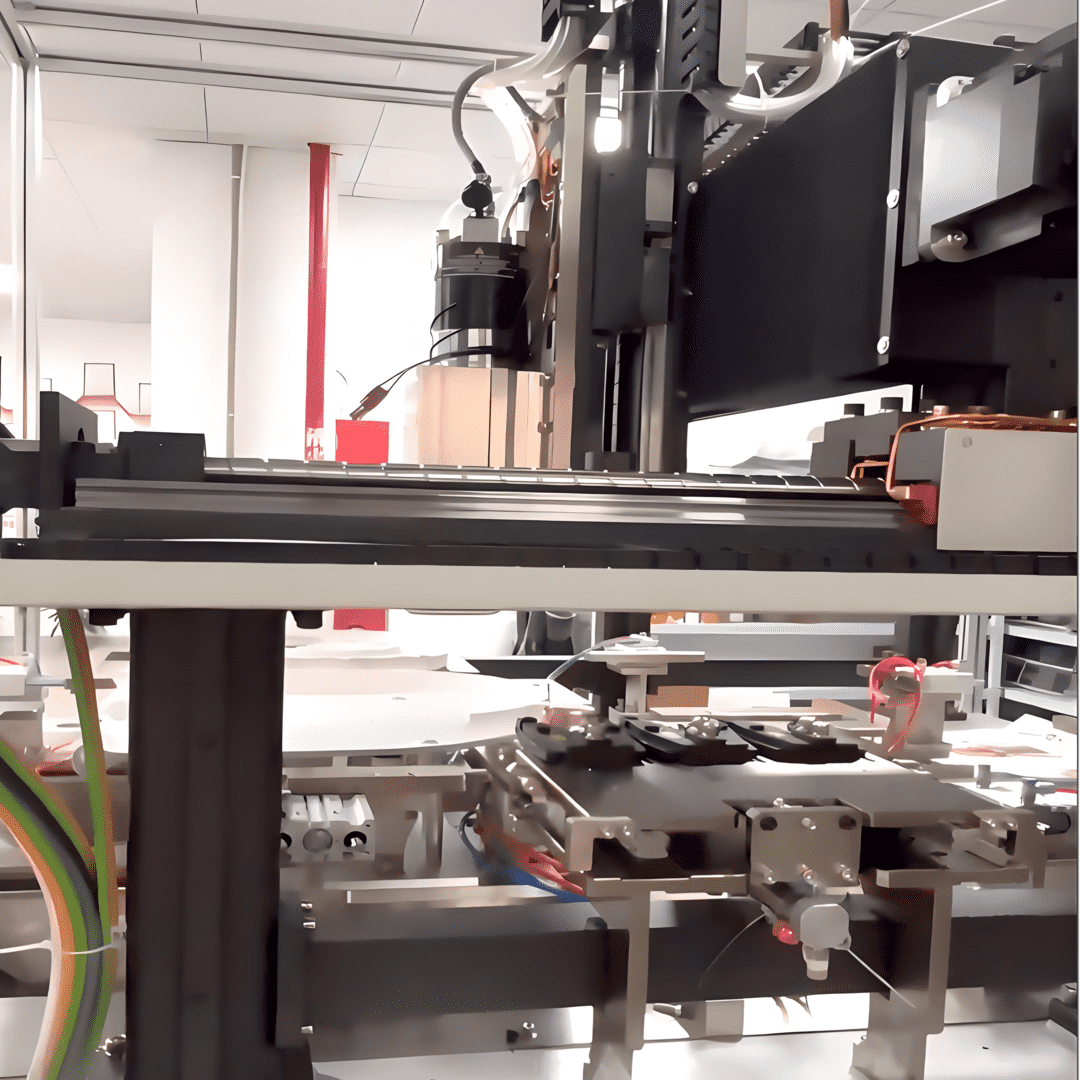

This equipment uses a six-axis robot for automatic loading/unloading, efficiently removing large flashes from lids and seat rings, then shaping them at the station. Connected to 4 vertical injection molding machines, it cuts labor by 2-3 workers vs. traditional methods, reducing costs. With fully automated processes (removal, trimming, shaping, collection), it ensures seamless, high-efficiency production. Key Keywords: Flexible Production, High Precision It supports multi-model production (subject to evaluation), enabling quick 10-20 min model switches to meet market needs. Boasting 99.5%+ qualification rate, low failure, and easy maintenance, it’s a top choice for sanitary ware firms to boost efficiency and competitiveness.

| Components Qty | 7 parts |

| Cycle Time | 4.0 sec/pc |

| Pneumatic Parts | SMC |

| OEE | 80% |

| First Pass Yield | 98% |

| Standard Parts Brand | Panasonic, Mitsubishi, SMC, Keyence, Omron |

| Requested Operators | 2 operators |

| Certificate | CE |

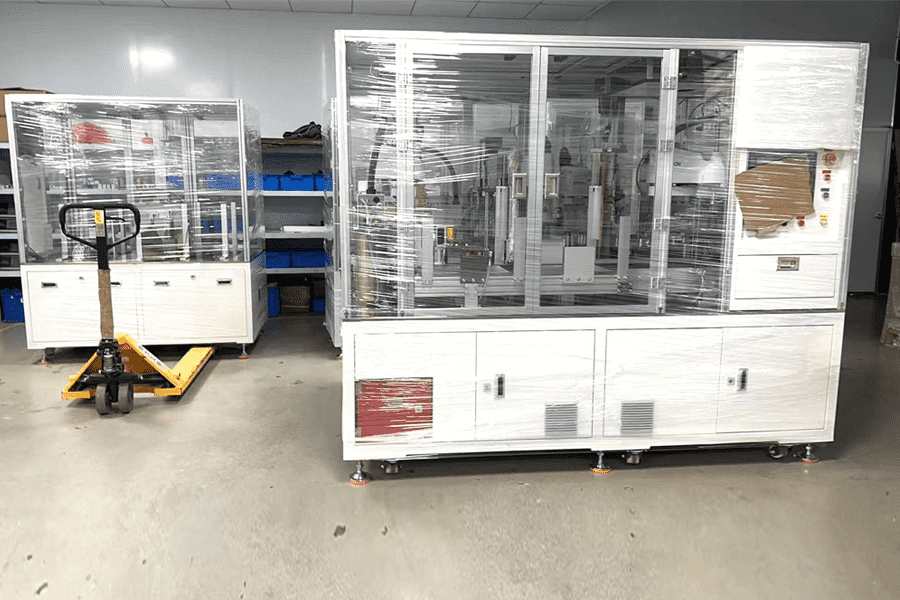

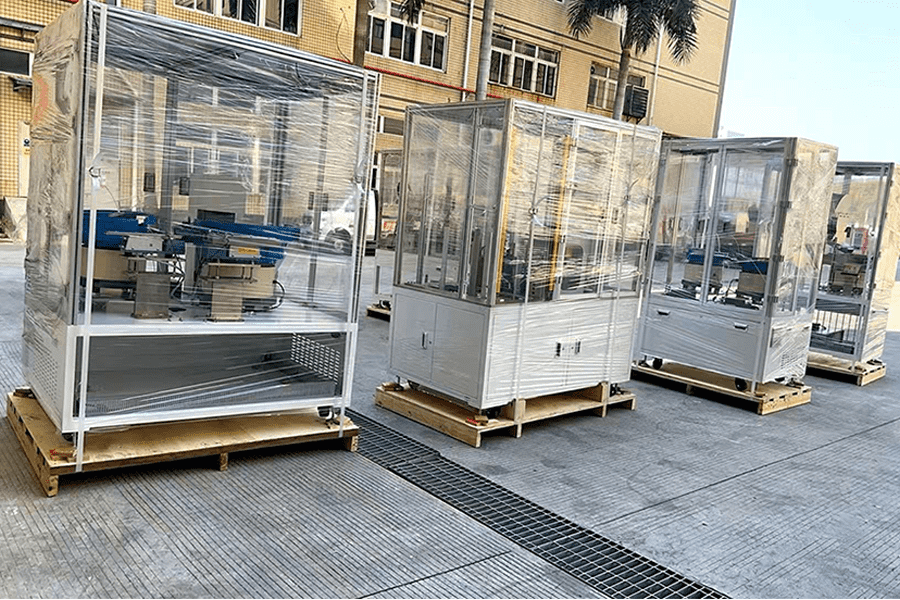

After the equipment has been assembled and debugged, we will select suitable packaging materials to properly protect the equipment. This will effectively safeguard it against impacts, moisture, and ensure it is firmly secured, guaranteeing that the equipment arrives at its destination intact.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Respond to defects within 4 hours.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project’s on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer’s technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.