Core Technologies: Algorithms and Control Principles

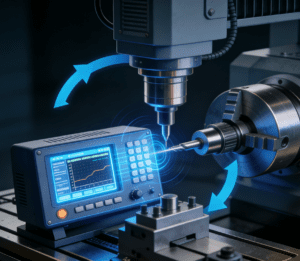

Precision machining with digital control is a method that uses digital technology to achieve precise control over the mechanical machining process. By virtue of advanced algorithms and control systems, it enables accurate positioning of machining tools, precise control of motion trajectories, and real-time adjustment of machining parameters, thereby ensuring that the processed parts possess extremely high precision and quality.

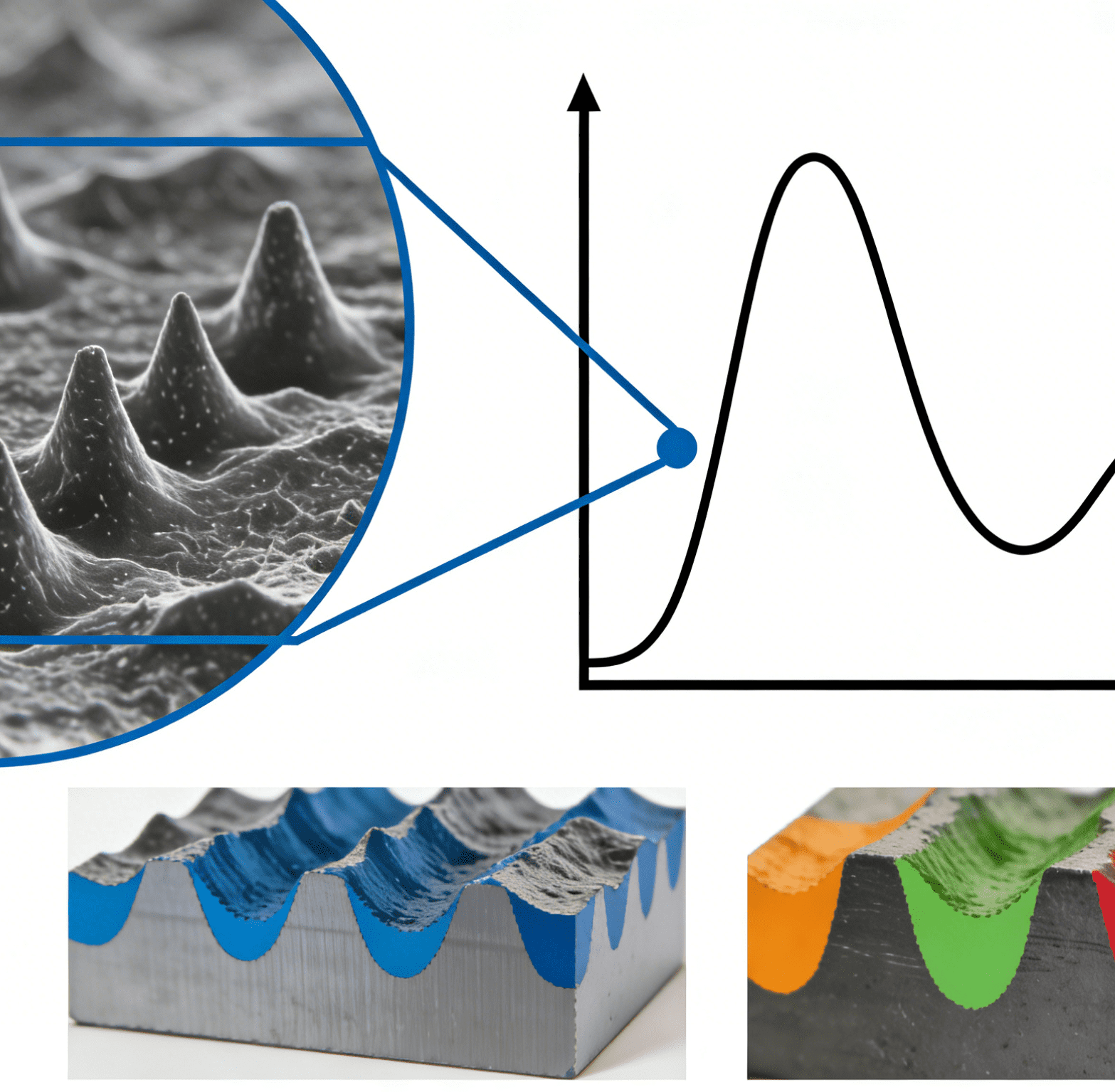

The underlying algorithms are the core of precision machining with digital control. These algorithms mainly include path planning algorithms, interpolation algorithms, and error compensation algorithms. Path planning algorithms are responsible for determining the motion trajectory of machining tools on the workpiece to achieve precise machining of the workpiece. Interpolation algorithms are used to generate a series of intermediate positions between two known positions, allowing machining tools to move smoothly and thus improving machining quality and efficiency. Error compensation algorithms conduct real-time monitoring and analysis of errors generated during the machining process, and then adjust machining parameters to reduce errors and enhance machining precision.

In terms of control principles, precision machining with digital control mainly adopts closed-loop control systems. Such control systems use sensors to monitor various parameters in the machining process in real time, such as position, speed, and acceleration, and feed these parameters back to the controller. The controller compares the feedback information with preset target values, then calculates control signals and drives actuators to adjust the machining process, ensuring that the process is always in a stable and precise state.

Industry Application: Empowering Medical Device Manufacturing

As a leader in the field of precision mechanical machining, Arie Precision Machinery has profound technical accumulation and rich practical experience in digital control machining. Its digital control machining system adopts advanced algorithms and control principles, capable of providing high-quality machining services for the medical device and parts industry.

The importance of precision machining with digital control in the medical device and parts industry is self-evident. For example, in the manufacturing of dental equipment and supplies, high-precision parts are the key to ensuring the performance and safety of dental devices. Through precision machining with digital control, it is possible to produce ultra-high-precision parts such as dental drills and crowns, whose dimensional accuracy and surface quality directly affect the effect of dental treatment and patients’ comfort.

Similarly, precision machining with digital control plays a vital role in the manufacturing of medical devices. Medical devices usually require extremely high precision and reliability to ensure patients’ safety and treatment outcomes. Digital control machining enables the production of high-precision medical device parts such as surgical instruments and implants, whose quality is directly related to patients’ lives and health. Beyond that, Arie Precision Machinery also applies its core digital control machining technologies to the optimization of 生物指標組立機—by leveraging path planning algorithms and closed-loop control systems, the company realizes automatic and high-precision assembly of core components like biological indicator carriers and culture media tubes, ensuring the consistency of assembly precision and avoiding cross-contamination risks caused by manual operation, which is critical for the accuracy of biological sterility testing in medical scenarios.

Challenges and Innovation Directions

However, precision machining with digital control also faces several challenges. Firstly, the algorithms are highly complex and computationally intensive, requiring high-performance computers and control systems for support. Secondly, there are many sources of errors in the machining process, such as tool wear and uneven workpiece materials, which necessitate continuous error compensation and optimization. In addition, the cost of digital control machining systems is relatively high, which may be unaffordable for some small-sized enterprises.

To address these challenges, researchers and engineers are constantly conducting technological innovation and optimization. On the one hand, they are committed to developing more efficient and accurate algorithms and control principles to improve the performance and efficiency of digital control machining. On the other hand, they are striving to reduce the cost of digital control machining systems, making them more accessible and easier to apply.

Precision machining with digital control is an advanced machining technology, and its underlying algorithms and control principles are the key to achieving high-precision machining. Continuous exploration and innovation by enterprises like Arie Precision Machinery in this field have provided strong support for the development of sectors such as the medical device and parts industry. With the continuous advancement of technology, it is believed that precision machining with digital control will play an increasingly important role in more fields.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine