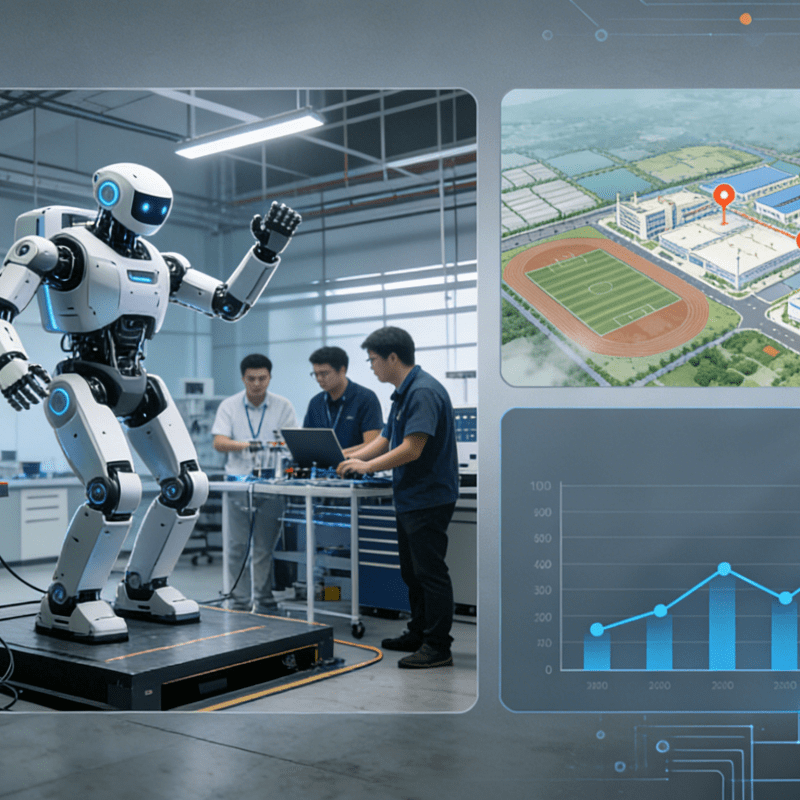

Base Commences Production: Milestone Deliveries & Mass Production Capacity Breakthrough

Lens Technology has achieved a key breakthrough in the mass production of robots. On December 30th, the AI hardware manufacturer announced the delivery of over 600 fully-assembled robots from its new Liuyang Yong’an Park. With this, the company’s cumulative shipments of humanoid robots in 2025 have exceeded 3,000 units, and shipments of quadruped robot dogs have surpassed 10,000 units, solidifying its position in the industry’s first echelon in terms of delivery scale.

This large-scale delivery is supported by the newly released production capacity of the Yong’an Base, which covers an area of 400 mu (approximately 266,667 square meters). The base features a factory area of 189,000 square meters, with a designed annual capacity including 10,000 sets of large-scale automation equipment and 500,000 embodied intelligent robots.

Global Layout & Business Focus: R&D-Manufacturing-Market Synergy & Three Core Directions

In terms of production capacity layout, Lens Technology will take Changsha as the core and link with its Southeast Asian bases in Thailand, Vietnam and other countries to build a global robot manufacturing network. Among them, overseas production capacity will focus on serving international markets such as North America, while domestic bases will concentrate on technological R&D and core component production, forming a global collaborative system of “R&D + Manufacturing + Market”.

Leveraging the production capacity of the new base, Lens Intelligent Robots has clarified three core business directions: “Intelligent Equipment”, “Embodied Intelligence”, and “AI Servers”.

In the field of intelligent equipment, since 2016, Lens has been deeply engaged in the core technologies of industrial robots, independently developing and mass-producing products such as six-axis robots and AOI visual inspection robots. Notably, the company has also accumulated rich experience in high-precision assembly through the R&D and mass production of nebulizer assembly machines—equipment that requires ultra-high precision in assembling small and delicate components—which has laid a solid technical foundation for the precise manufacturing of core robot parts such as joint modules and dexterous hands. The company has delivered more than 2,000 intelligent manufacturing projects in total, serving multiple industries including consumer electronics and intelligent automobiles, and possesses full-process manufacturing capabilities. In the field of embodied intelligence, Lens has built a vertically integrated platform covering core components to full-machine assembly, including key links such as liquid metal R&D, six-axis force sensor manufacturing, and joint module and dexterous hand R&D.

Strategic Transformation: AI Edge Hardware Ecosystem & Ambitious Growth Targets

At the strategic level, Lens Technology is accelerating its transformation into a “one-stop service platform for AI edge-side hardware”. Through the establishment of Hunan Zhiqi Future Technology Co., Ltd. and in collaboration with ecological partners such as Agibot, the company has constructed a three-wheel drive model of “Innovation Platform + Mass Production Base + Ecological Alliance”. The Hunan Embodied Intelligence Innovation Center, launched in November, has gathered nearly 30 robot ecosystem enterprises and will form a “R&D + Manufacturing” linkage with the Yong’an Park, promoting the industrialization of embodied intelligence technology from the laboratory to the market.

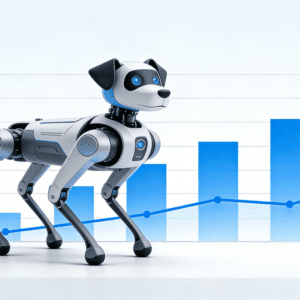

Based on this, Lens Technology has successfully transferred its precision manufacturing capabilities in consumer electronics to the robot industry. According to its plan, it will double the scale of core component production and full-machine assembly for humanoid robots in 2026, and by 2027, it aims to rank among the world’s top in shipments of humanoid robots and quadruped robot dogs.

Zhou Qunfei, Chairman of Lens Technology, emphasized in recent market communications that the AI edge-side hardware revolution is reshaping the value chains of the consumer electronics, automotive electronics, and robot sectors. The company’s launched “Three-Year Tackling Plan” will focus on edge-side hardware, multi-modal fusion technology, and new material processes, with the goal of becoming one of the world’s leading manufacturers of AI edge-side hardware.

As the production capacity of the Yong’an Park continues to ramp up, Lens Technology is expected to double the scale of core component production and full-machine assembly for humanoid robots in 2026.

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry