A Historic Breakthrough in Space Metal 3D Printing

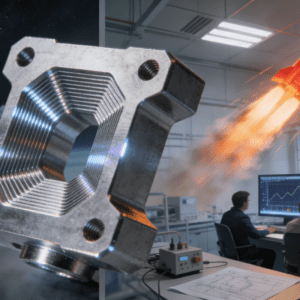

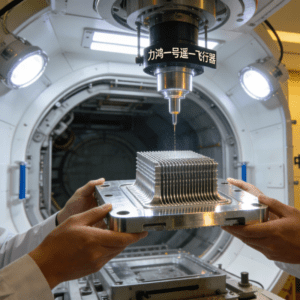

January 23 News – The Zhongke Aerospace Lihong-1 Yao-1 vehicle, carrying the recoverable scientific experiment payload for microgravity metal additive manufacturing independently developed by the Institute of Mechanics, Chinese Academy of Sciences (CAS), has successfully completed a metal additive manufacturing experiment in space.Following the complete success of the mission, the payload was safely recovered, and a handover ceremony was held at the Institute of Mechanics on January 22.This mission marks China’s first recoverable scientific experiment on space metal additive manufacturing conducted on a rocket platform. It signifies that China has successfully fabricated metal components using additive manufacturing technology (i.e., 3D printing) in the microgravity environment of space, with the overall technology reaching a world-class level.This major breakthrough will strongly drive the development of China’s space manufacturing technology and provide critical support for the construction of space infrastructure in the future.

Core Technological Breakthroughs & Experimental Data Acquisition

It is reported that during the mission, the research team made breakthroughs in a series of key technologies for metal additive manufacturing under microgravity conditions, including the stable transport and forming of materials, closed-loop control of the entire process, and highly reliable payload-rocket synergy.After the experiment, the payload module was smoothly landed and recovered via a parachute system.Researchers have successfully obtained process data of metal additive manufacturing in the space microgravity environment (including dynamic characteristics of the molten pool, material transport, solidification behavior, etc.), as well as parameters such as the forming accuracy and mechanical properties of metal components manufactured via space additive manufacturing. These achievements have accumulated valuable experimental data for the rapid iteration of China’s space metal additive manufacturing technology.The mission also marks the official transition of China’s space metal additive manufacturing from the ground-based research phase to a new phase of space engineering verification.

Strategic Significance & Prospects for Extraterrestrial Missions

Researcher Jiang Heng, leader of the payload R&D team, stated that mastering space metal 3D printing technology can significantly enhance the autonomy of on-orbit maintenance and expansion of spacecraft, reduce reliance on ground supply. It can also break through the size and production capacity limitations of traditional rocket launches, drive the transformation of spacecraft manufacturing from “manufactured on Earth for use in space” to “manufactured in space for use in space” and even “manufactured in space for use on Earth”, and support the realization of space missions shifting from “Earth-dependent” to extraterrestrial self-sufficiency.In long-term missions such as space station expansion, deep space exploration and extraterrestrial base construction, in-situ manufacturing capabilities will play an irreplaceable role.