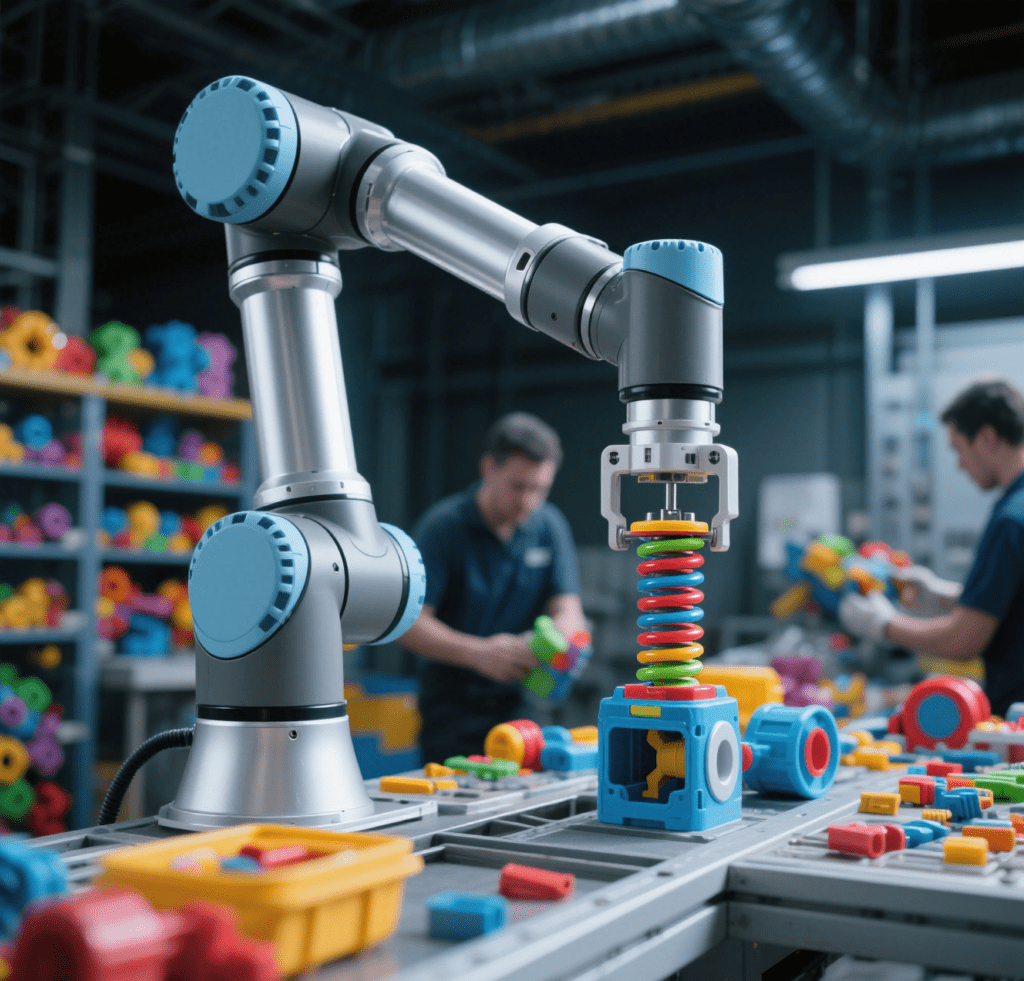

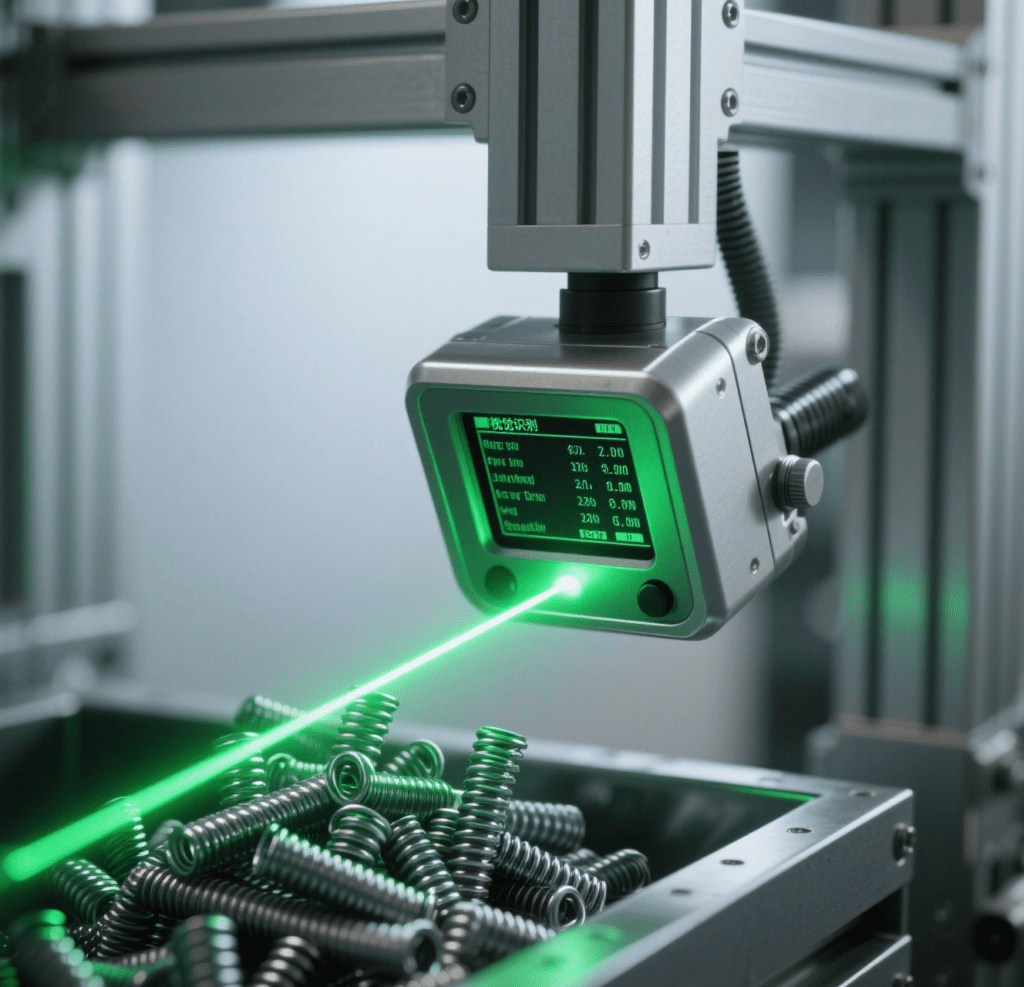

6-Axis Robotic Spring Pick-and-Place System: Mastering Precision in Elastic Component Handling

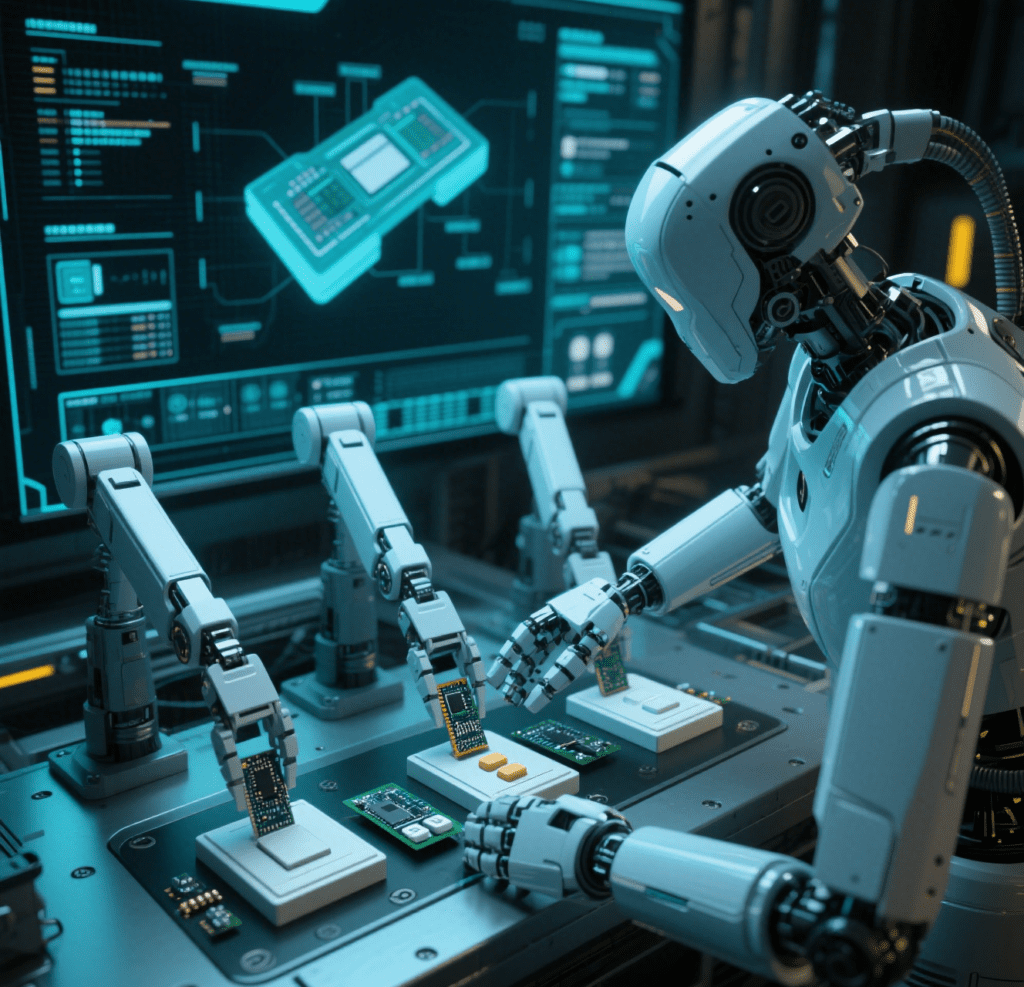

6-Axis Robotic Spring Pick-and-Place System: Mastering Precision in Elastic Component Handling In industries where tiny, elastic components dictate product performance—think automotive suspensions, electronic switches, or medical device actuators—handling springs is a delicate dance of force, precision, and adaptability. Manual pick-and-place operations struggle with inconsistent grip force (leading to deformation or slippage), while 4-axis robots falter with 3D orientation challenges. Enter the 6-Axis Robotic Spring Pick-and-Place System—a versatile solution engineered to tackle these complexities. By combining full 3D dexterity, intelligent force control, and adaptive vision, this system transforms spring handling from a high-risk bottleneck into a streamlined, error-free process. Why 6-Axis? The Imperative for Elastic Component Dexterity Springs are inherently complex: their […]

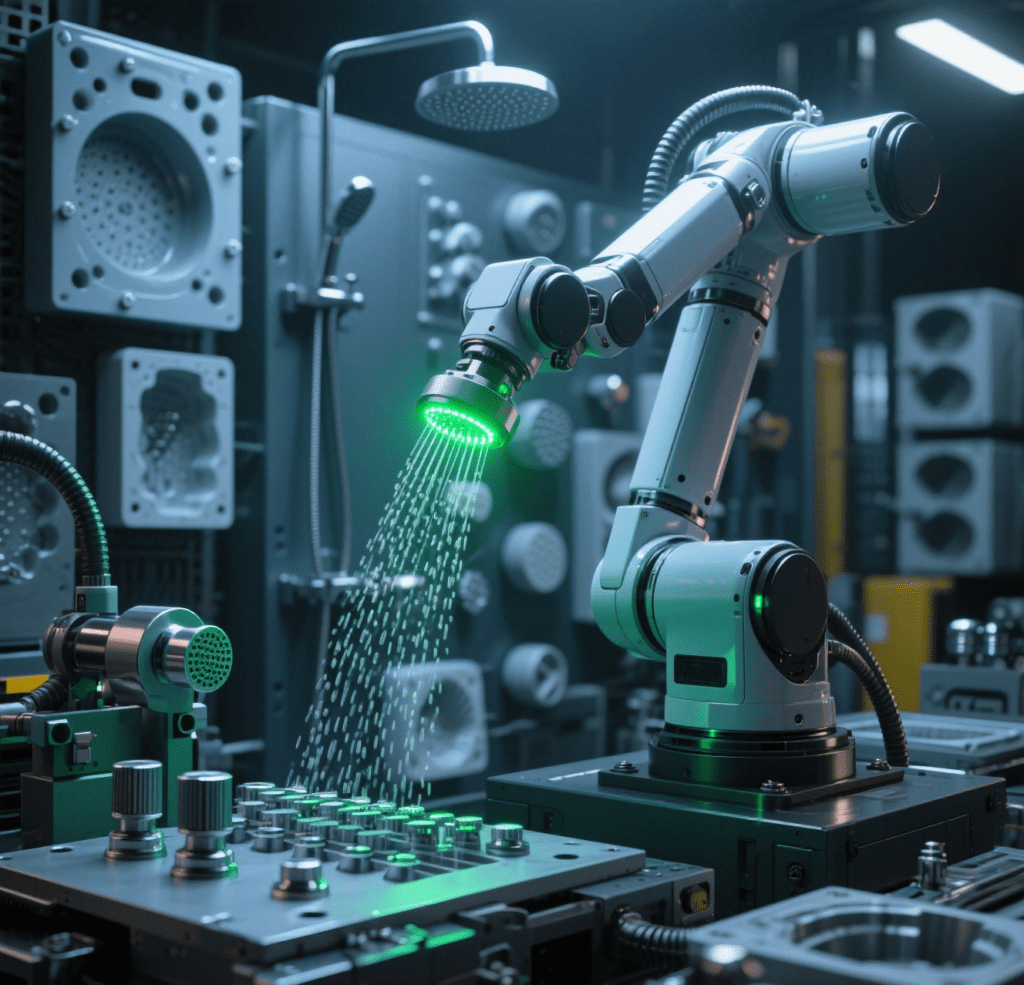

6-Axis Robotic Showerhead Loading/Unloading System: Mastering Complexity in Manufacturing

6-Axis Robotic Showerhead Loading/Unloading System: Mastering Complexity in Manufacturing In the intricate world of showerhead production—where curved surfaces, threaded connectors, and varied geometries demand precise handling—manual loading/unloading is a bottleneck riddled with inefficiencies. Human operators struggle with repetitive motions, inconsistent positioning, and the risk of ergonomic injuries, while traditional 4-axis systems fall short in managing the 3D complexity of showerhead designs. Enter the 6-Axis Robotic Showerhead Loading/Unloading System—a versatile solution engineered to tackle these challenges with unmatched dexterity, adaptability, and speed. Designed for 卫浴 factories, plumbing manufacturers, and assembly lines, this system transforms a once-laborious process into a streamlined, high-precision operation. Why 6-Axis? The Necessity of Full 3D Dexterity Showerheads are […]

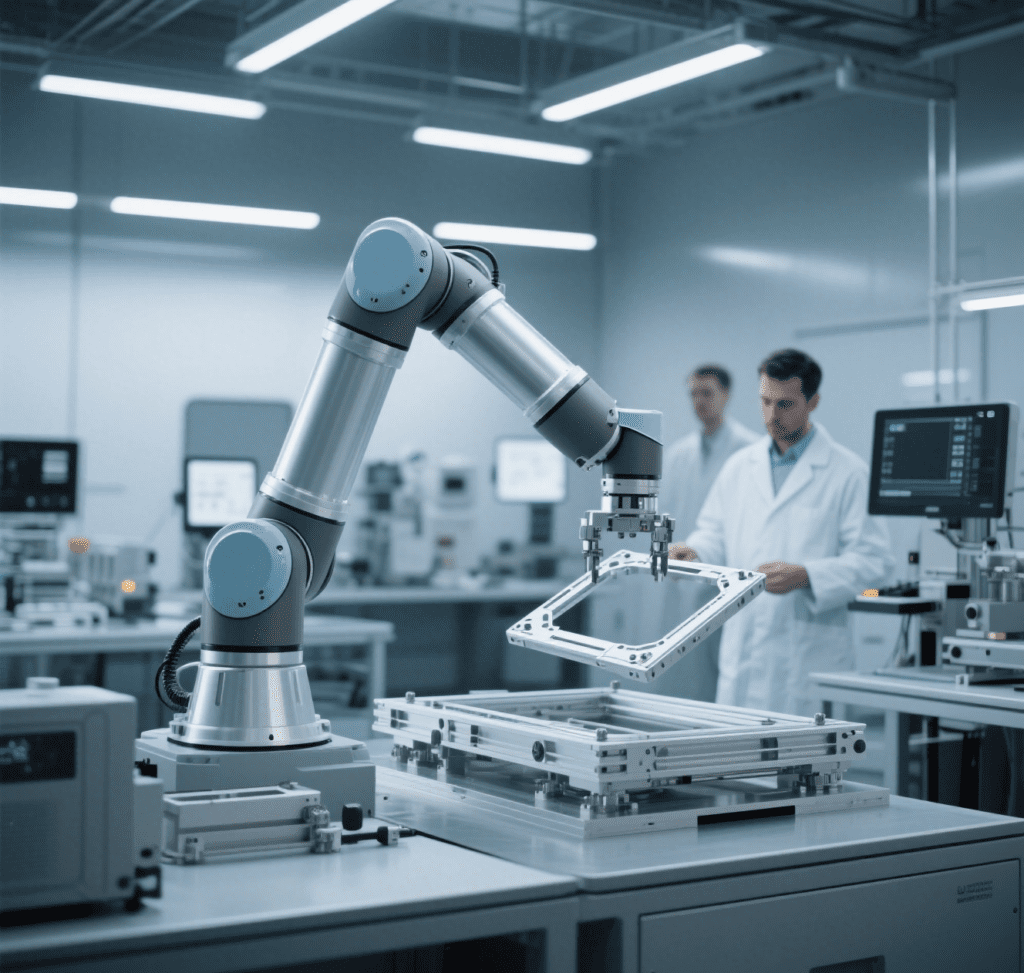

4-Axis Robotic Frame Pick-up System: Revolutionizing Precision Material Handling in Manufacturing

4-Axis Robotic Frame Pick-up System: Revolutionizing Precision Material Handling in Manufacturing In modern manufacturing, the efficient and precise handling of frames—whether for display panels, circuit boards, or industrial structures—is a make-or-break process. Manual frame picking is slow, error-prone, and risky for workers, while traditional automation often struggles with varying frame sizes, weights, and fragility. Enter the 4-Axis Robotic Frame Pick-up System, a SCARA-based solution engineered to address these challenges with unmatched speed, adaptability, and precision. Designed for industries ranging from consumer electronics to heavy machinery, this system transforms frame handling into a streamlined, reliable, and future-ready operation. Why 4-Axis for Frame Pick-up? The Perfect Balance of Speed and Control Four-axis SCARA […]

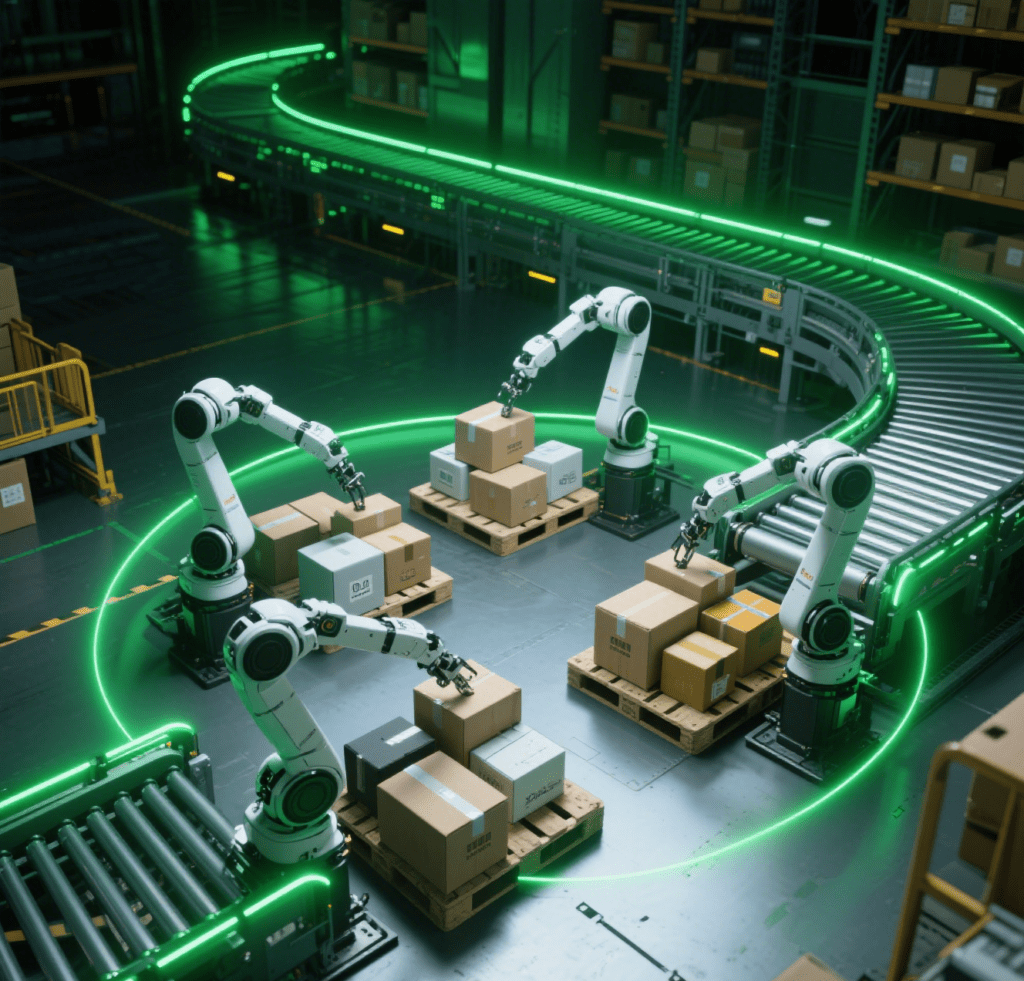

4-Axis Robotic Tray Loading System: Redefining Efficiency in Automated Material Handling

4-Axis Robotic Tray Loading System: Redefining Efficiency in Automated Material Handling In the fast-paced world of modern manufacturing, the seamless loading of components into trays is the unsung hero of streamlined production. Whether in electronics, automotive, or pharmaceuticals, manual tray loading is a bottleneck—prone to errors, slow, and labor-intensive. Enter the 4-Axis Robotic Tray Loading System, a SCARA-based solution designed to transform this critical process. By merging high-speed motion, precision positioning, and intelligent adaptability, this system eliminates inefficiencies, boosts quality, and future-proofs production lines for high-mix, high-volume environments. The 4-Axis Advantage: Engineered for Speed and Precision Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for planar material handling, making them […]

4-Axis Robotic Tray Loading System: Optimizing Precision and Speed in Material Handling

4-Axis Robotic Tray Loading System: Optimizing Precision and Speed in Material Handling In modern manufacturing and logistics, the efficient loading of components into trays is a critical bottleneck. Whether dealing with delicate electronic parts, automotive components, or pharmaceutical products, manual tray loading is slow, error-prone, and costly. Enter the 4-Axis Robotic Tray Loading System—a SCARA-based solution designed to streamline material handling with unmatched speed, precision, and adaptability. This system transforms tray loading from a labor-intensive task into a high-speed, automated process, addressing the demands of high-mix, high-volume production. Why 4-Axis for Tray Loading? The Geometry of Efficiency Four-axis SCARA robots excel in planar motion tasks, making them ideal for tray loading: Rigid […]

4-Axis Robotic TV Panel Screw-Fixing System: Redefining Precision in Large-Screen Assembly

4-Axis Robotic TV Panel Screw-Fixing System: Redefining Precision in Large-Screen Assembly In an era where TVs are racing toward larger sizes (up to 110”) and slimmer profiles (as thin as 6mm), the assembly process—especially screw-fixing panels to frames—has become a high-stakes balancing act. One misaligned screw can crack a panel, one loose screw can cause screen flickering, and one slow cycle can bottleneck an entire production line. Enter the 4-Axis Robotic TV Panel Screw-Fixing System—a SCARA-driven solution engineered to master these challenges with surgical precision, blistering speed, and unmatched adaptability. Why 4-Axis? The Perfect Match for Planar Screw-Fixing Four-axis SCARA robots are not just faster than their six-axis counterparts for flat-surface […]

4-Axis Robotic Small Product Assembly System: Mastering Miniature Manufacturing Challenges

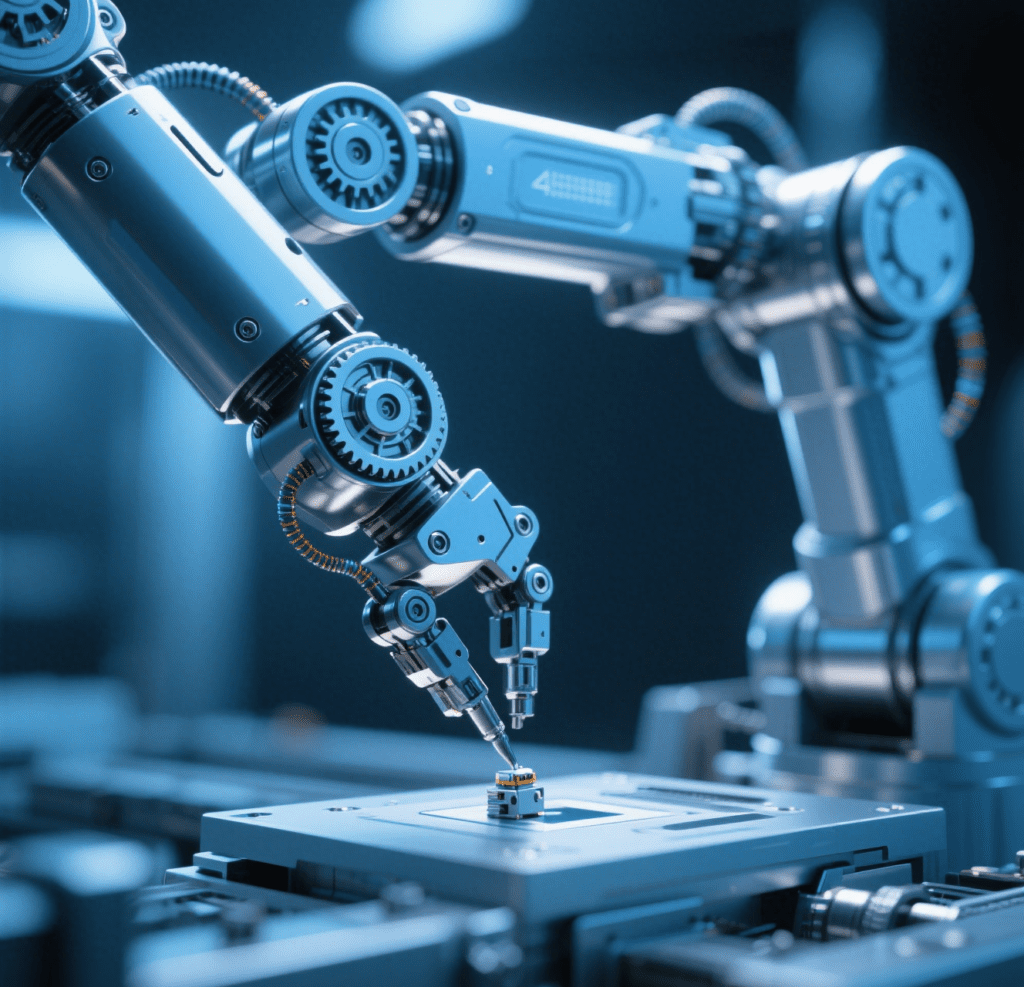

4-Axis Robotic Small Product Assembly System: Mastering Miniature Manufacturing Challenges In the intricate landscape of small-scale production—where components shrink to millimeters and assembly tolerances demand micron-level precision—traditional methods falter. Manual labor, prone to fatigue and inconsistency, struggles to meet the pace of high-volume, high-precision demands. Six-axis robots, while versatile, introduce unnecessary complexity and cost for planar tasks. Enter the 4-Axis Robotic Small Product Assembly System—a SCARA-driven solution engineered to conquer the unique hurdles of miniature assembly. The 4-Axis Edge: Engineered for Planar Excellence Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for fast, precise planar motion. Here’s why they outperform alternatives in small-part assembly: 1. Speed Redefined With a rigid […]

4-Axis Robotic Assembly System: Revolutionizing Efficiency in Smart Manufacturing Automation

4-Axis Robotic Assembly System: Revolutionizing Efficiency in Smart Manufacturing Automation In the era of Industry 4.0, traditional assembly systems struggle to keep pace with the demands of high-mix, low-volume production. Characterized by slow cycle times (15–30 seconds per part), limited flexibility, and high labor costs, these systems fail to address the agility required in modern manufacturing. The 4-Axis Robotic Assembly System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and modular tooling to enable seamless automation across electronics, automotive, and medical device industries. I. Core Technical Architecture: Speed Meets Precision The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis […]

4-Axis Robotic Injection Molding Part Removal System: Revolutionizing Post-Molding Automation

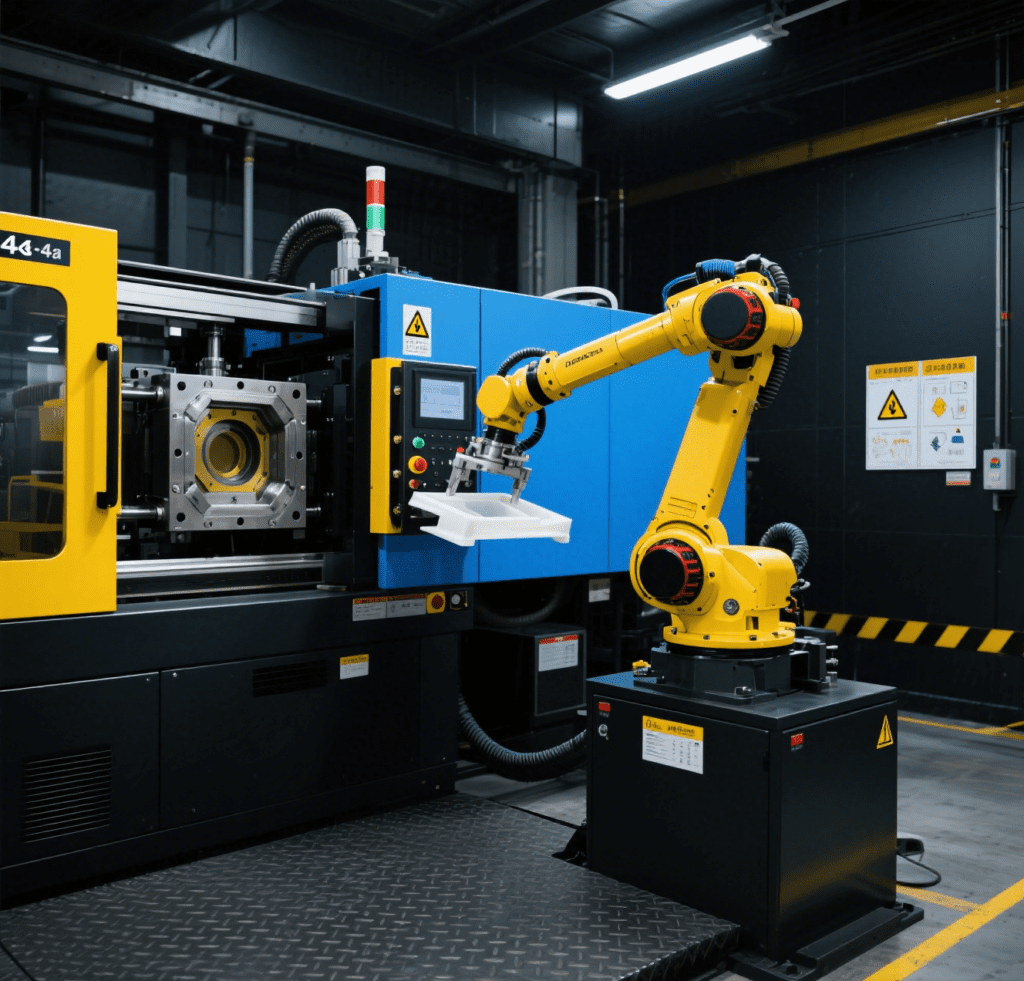

4-Axis Robotic Injection Molding Part Removal System: Revolutionizing Post-Molding Automation In the high-volume landscape of injection molding, traditional part removal methods—ranging from manual extraction to basic mechanical arms—face critical limitations: slow cycle times (15–30 seconds per part), inconsistent handling (±0.5mm positioning errors), and high risk of part damage. The 4-Axis Robotic Injection Molding Part Removal System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive gripping to streamline post-molding operations in automotive, electronics, and medical device manufacturing. I. Core Technical Architecture: Speed Meets Precision The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis Robotic Manipulation Powered by SCARA […]

4-Axis Robotic Automated Assembly Line: Redefining Efficiency in Smart Manufacturing

4-Axis Robotic Automated Assembly Line: Redefining Efficiency in Smart Manufacturing In the era of Industry 4.0, traditional assembly lines struggle to keep pace with the demands of high-mix, low-volume production. Characterized by slow cycle times (15–30 seconds per part), limited flexibility, and high labor costs, these systems fail to address the agility required in modern manufacturing. The 4-Axis Robotic Automated Assembly Line emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and modular tooling to enable seamless automation across diverse industries—from electronics to automotive. I. Core Technical Architecture: Speed Meets Flexibility The system’s modular design synergizes robotic precision with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis […]

4-Axis Robotic Vision-Guided Spring Placement System: Redefining Precision in Elastic Component Assembly

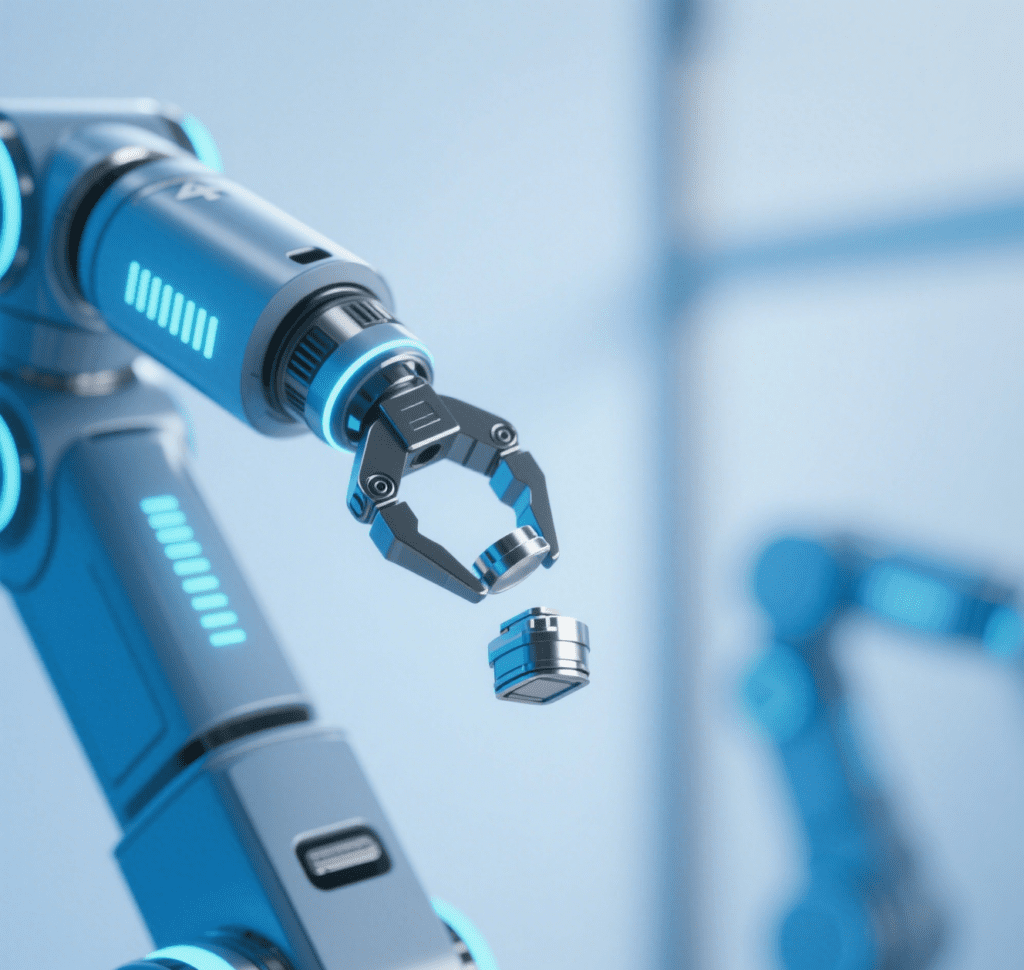

4-Axis Robotic Vision-Guided Spring Placement System: Redefining Precision in Elastic Component Assembly In the realm of precision manufacturing, spring placement for complex assemblies—ranging from automotive suspensions to microelectronics—demands unparalleled accuracy and repeatability. Traditional manual or semi-automated systems struggle with slow cycle times (10–20 seconds per spring), inconsistent positioning (±0.5mm errors), and limited adaptability to diverse spring geometries. The 4-Axis Robotic Vision-Guided Spring Placement System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive force control to enable micron-level precision in high-mix, high-volume production. I. Core Technical Architecture: Speed Meets Surgical Precision The system’s modular design synergizes robotic agility with intelligent perception, comprising three interdependent subsystems: 1. […]

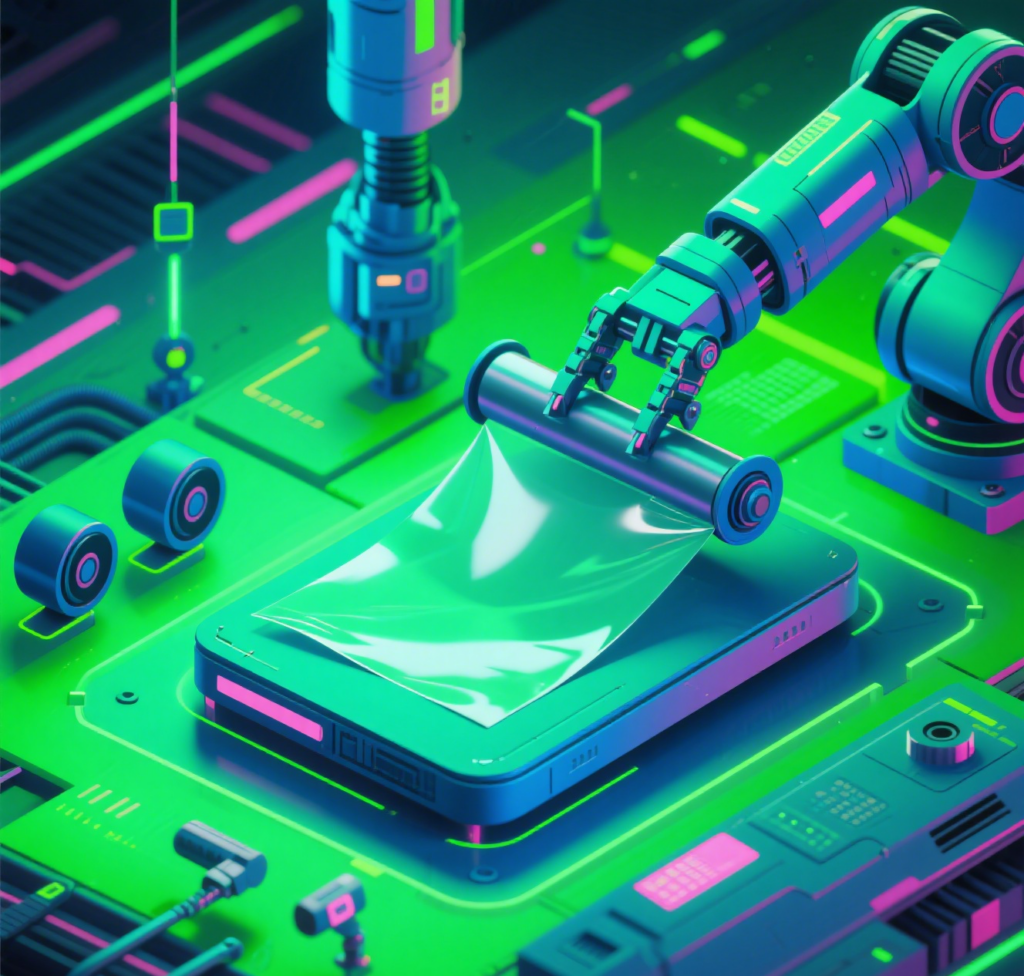

4-Axis Robotic Automatic Film Laminating System: Revolutionizing Precision Surface Treatment in Manufacturing

4-Axis Robotic Automatic Film Laminating System: Revolutionizing Precision Surface Treatment in Manufacturing In the era of high-precision manufacturing, film lamination for delicate components—ranging from smartphone displays to solar panels—demands unparalleled accuracy and consistency. Traditional manual or semi-automated laminating systems suffer from critical limitations: slow cycle times (20–40 seconds per part), inconsistent alignment (±0.5mm errors), and high risk of film wrinkles or bubbles. The 4-Axis Robotic Automatic Film Laminating System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive pressure control to enable micron-level precision in high-volume production across electronics, renewable energy, and medical device sectors. I. Core Technical Architecture: Speed Meets Micro-Precision The system’s modular design […]