Artificial Intelligence and Machine Learning: Reshaping the Intelligent Genes of Manufacturing Systems

Artificial Intelligence and Machine Learning: Reshaping the Intelligent Genes of Manufacturing Systems Driven by breakthroughs in deep learning algorithms and the precipitous decline in computing costs, artificial intelligence (AI) is upgrading from an auxiliary tool to the core engine of manufacturing systems. Data from the China Academy of Information and Communications Technology shows that the global industrial AI market reached $48 billion in 2023, with a compound annual growth rate of 38%. Its value penetrates the entire lifecycle from design and R&D to after-sales service, propelling manufacturing from “labor-intensive” to “algorithm-intensive”. 一、Design End: Generative AI Usher in the Era of Innovation Democratization The battery module design revolution at Tesla’s Berlin […]

Industrial Internet of Things (IIoT): Deconstructing the Universal Data Nervous System of Smart

Industrial Internet of Things (IIoT): Deconstructing the Universal Data Nervous System of Smart Manufacturing In the wave of the Fourth Industrial Revolution, the Industrial Internet of Things (IIoT) is weaving discrete industrial equipment and isolated production systems into a real-time interactive intelligent network through its disruptive connectivity. Data from the McKinsey Global Institute shows that by 2030, IIoT technologies could create over $10 trillion in new value for global manufacturing. Its core lies in building a closed-loop ecosystem of “device interconnection-data flow-intelligent decision-making,” driving factories to leap from an “experience-driven” to a “data-driven” paradigm. 一、Device Interconnection: Evolution from “Dumb Terminals” to “Intelligent Agents” General Electric (GE) realized the “digital awakening” […]

The Technological Revolution and Industrial Applications of Assembly Machines: The Evolution from Rigid Production to Intelligent Flexibility

The Technological Revolution and Industrial Applications of Assembly Machines: The Evolution from Rigid Production to Intelligent Flexibility Introduction: When Watch Movements Meet Assembly Robots — The Ultimate Game of Precision and Efficiency In the movement assembly workshop of a top Swiss watch factory, traditional craftsmen took 3 hours to assemble 68 parts of a complex movement with a yield rate of only 92%. However, the newly introduced micro-nano assembly robot, through force-controlled servo (±0.01N pressure control) and atomic force microscope vision, achieves 0.001mm-level precision assembly, reducing the time per movement to 45 minutes and increasing the yield rate to 99.8%. This is not just a leap in efficiency but a […]

Future Outlook for Non-Standard Automation Equipment: The Ultimate Evolution from “Customized Tools” to “Intelligent Ecosystems”

Future Outlook for Non-Standard Automation Equipment: The Ultimate Evolution from “Customized Tools” to “Intelligent Ecosystems” Introduction: When Equipment “Thinks, Collaborates, and Evolves”—The Ecosystem Revolution in a New Energy Factory A lithium battery production line at a CATL base is a scene that subverts tradition: Equipment Interconnection: The pole piece laminator detects abnormal diaphragm tension and automatically synchronizes data with the coating machine, which adjusts the slurry viscosity in real time. Autonomous Decision-making: The AI model on the inspection line identifies a trend of poor tab welding and proactively dispatches robots to fine-tune parameters, nipping defects in the bud. Self-Evolution: The production line runs virtual simulations at night, optimizing parameters based […]

Global Opportunities and Challenges of Non-Standard Automation Equipment: Key Points for Cross-Border Project Implementation and Localization Adaptation Strategies

Global Opportunities and Challenges of Non-Standard Automation Equipment: Key Points for Cross-Border Project Implementation and Localization Adaptation Strategies Introduction: From “Blocked Overseas Expansion” to “Localization Breakthrough”—The Pain and Rebirth of a Company’s EU Certification A new energy equipment manufacturer in Shenzhen first entered Europe by providing a “pole piece sorter” for a German battery factory. However, due to failing the CE-LVD low voltage directive certification (motor insulation class not meeting standards), the equipment was detained at the Port of Rotterdam for 30 days, resulting in not only a €150,000 port detention fee but also missing the customer’s production window. Learning from this, the company spent 18 months establishing a global […]

The Sustainable Development Path of Non-Standard Automation Equipment: Green Design, Energy Consumption Optimization, and Full Life Cycle Management

The Sustainable Development Path of Non-Standard Automation Equipment: Green Design, Energy Consumption Optimization, and Full Life Cycle Management Introduction: When “High Energy Consumption” Becomes an Elimination Criterion —— The Environmental Protection Transition Pain of an Auto Parts Factory The non-standard stamping line of an auto mold factory in Jiangsu has a single equipment power of 150kW·h, with annual power consumption exceeding 1.2 million kWh, and electricity expenses accounting for 18% of production costs. After the EU Carbon Border Adjustment Mechanism (CBAM) came into effect in 2024, its export products were subject to a 12% tax surcharge, causing profits to plummet. Learning from this pain, the enterprise invested 3 million RMB […]

The New Paradigm of Human-Machine Collaboration in Non-Standard Automation Equipment: The Efficiency Revolution from “Machine Replacement” to “Human-Machine Integration”

The New Paradigm of Human-Machine Collaboration in Non-Standard Automation Equipment: The Efficiency Revolution from “Machine Replacement” to “Human-Machine Integration” Introduction: When a Robotic Arm “Crushes” Sponge —— The Collaboration Dilemma and Breakthrough of Traditional Automation In an automotive seat factory, a ¥2 million robotic arm attempted to grasp memory foam pads but caused indentation defects in 20% of pads due to rigid grippers unable to sense pressure. When manual intervention was needed for correction, 3 collision accidents occurred because the robotic arm lacked safety sensors. Eventually, a traditional automated production line with “human-machine isolation” required 8 workers to “guard” it, achieving only 30% efficiency improvement over pure manual labor. This […]

Selection Guide for Non-Standard Automation Equipment: 5 Dimensions and 30 Evaluation Indicators for Clients

Selection Guide for Non-Standard Automation Equipment: 5 Dimensions and 30 Evaluation Indicators for Clients Introduction: The Price of Choosing the Wrong Equipment —— Lessons from “800K Investment” to “Two Years of Idleness” A smart home enterprise in Zhejiang customized an “intelligent lock detection line”. Due to blindly choosing a low-cost supplier (ignoring core technical maturity), the equipment had issues such as “poor multi-model compatibility” (only adapting to 30% of products), “unstable detection accuracy” (15% missed detection rate), and “after-sales response exceeding 72 hours” after delivery. It was eventually forced out of use, with the 800K investment wasted. Selecting non-standard equipment is a multi-dimensional game of “technology + business + risk”. This article constructs 5 […]

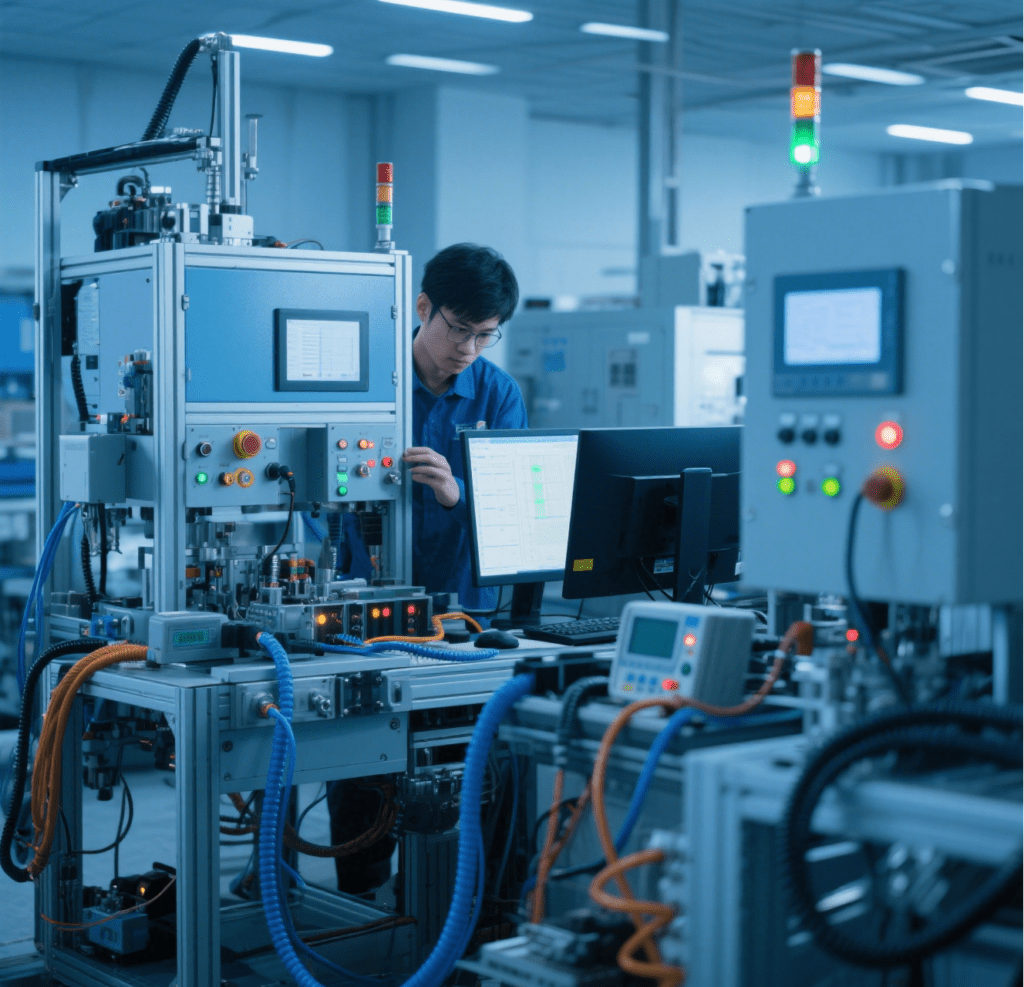

Technical Breakthroughs of Non-Standard Automation Equipment: 5 Core Technologies and Future Evolution Directions

Technical Breakthroughs of Non-Standard Automation Equipment: 5 Core Technologies and Future Evolution Directions Introduction: When Precision Demands Break Through the “Human Eye Limit”—How Technology Reshapes the Boundaries of Non-Standard Equipment In new energy battery production, the alignment precision of pole piece lamination needs to be controlled within ±0.02mm (about 1/3 of a human hair), a physical limit for traditional mechanical positioning. A leading battery enterprise introduced “binocular vision guidance + force-controlled servo” technology, using algorithms to rectify lamination deviations in real-time, increasing the yield rate from 92% to 99.8%. This confirms a fact: the core competitiveness of non-standard automation essentially lies in the “dimensionality reduction strike” of technological breakthroughs. This article […]

The Cost Black Hole of Non-Standard Automation Equipment: 6 Out-of-Control Links and 12 Cost-Reduction Strategies

The Cost Black Hole of Non-Standard Automation Equipment: 6 Out-of-Control Links and 12 Cost-Reduction Strategies Introduction: Non-Standard Projects Devoured by Costs —— A Warning from “Budget 800K” to “Final Accounts 1.5M” A new energy enterprise in Suzhou customized a “lithium battery pole piece sorter” with an original budget of 800,000 RMB, but the final accounts reached 1.5 million RMB—requirement changes caused mechanical structure rework (+250K), customized sensor premiums (+180K), supply chain delays increasing labor costs (+120K), and debugging overruns (+150K)… The “cost black hole” of non-standard equipment is devouring enterprises’ return on investment. This article decomposes 6 out-of-control links and presents 12 implementable cost-reduction strategies, making non-standard equipment truly “valuable […]

The Complete R&D Process of Non-standard Automation Equipment: 18 Key Nodes from Requirement Decomposition to Delivery Acceptance

The Complete R&D Process of Non-standard Automation Equipment: 18 Key Nodes from Requirement Decomposition to Delivery Acceptance Introduction: The “Out-of-Control Dilemma” and Breakthrough Logic in Non-standard R&D In a “pole ear laser welding machine” project of a new energy enterprise in Dongguan, misunderstandings in requirements (failing to clarify the “oxygen-free welding chamber” requirement), supply chain delays (custom welding head procurement cycle exceeding 60 days), and debugging loss (on-site debugging taking 45 days, accounting for 40% of the total cycle) extended the R&D period from 12 months to 15 months, with costs exceeding the budget by 40%. This case exposes the core pain point of non-standard R&D: the uncertainties brought by […]

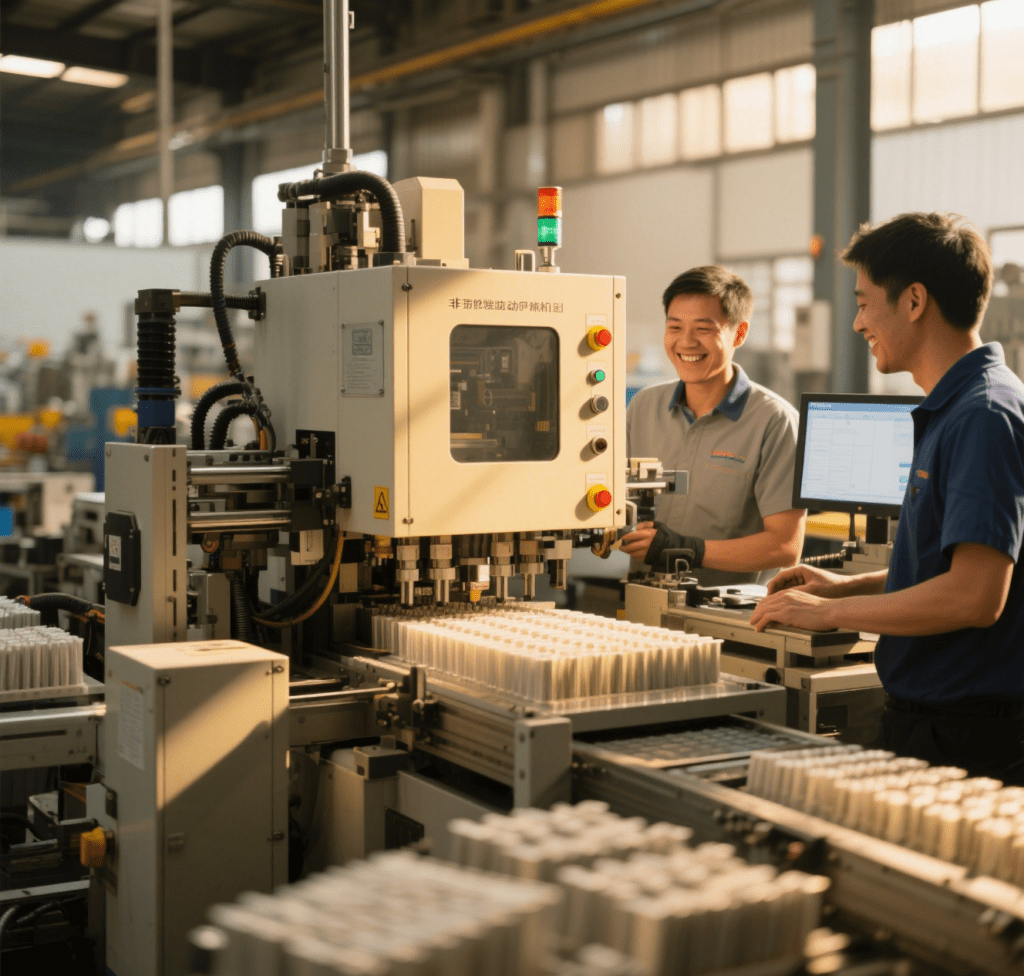

Non-standard Automation Equipment: The Breakthrough Code for Customized Production —— In-depth Deconstruction from Requirement to Value

Non-standard Automation Equipment: The Breakthrough Code for Customized Production —— In-depth Deconstruction from Requirement to Value Introduction: When Standard Equipment Fails, How Does Non-standard Equipment Rescue the Situation? In the workshop of a 3C OEM factory in Shenzhen, the production of a new folding-screen phone frame hit a deadlock: the surface contour tolerance was only ±0.03mm. Traditional standard punching machines couldn’t adapt to the complex curvature due to fixed molds, causing the yield rate to plummet to 78% and extending the order delivery cycle by 15 days. Eventually, a set of non-standard automatic punching lines broke the dilemma—through “flexible molds + visual guidance + servo pressure control”, the yield rate […]