アサヒ、オールスタイン、エスコ、コングスベルグがオープンハウスでフレキソ自動化を発表

In an industry grappling with a critical shortage of skilled labor and escalating demands for efficiency, four leading players are joining forces to redefine the future of flexographic printing. Asahi Photoproducts, Allstein, Esko, and Kongsberg PCS have announced a groundbreaking collaboration, set to debut next-level flexo automation at an exclusive open house event in Herford, Germany, on October 7, 2025. This joint showcase not only addresses pressing workforce challenges but also positions flexography as a formidable competitor to rotogravure, particularly in markets where gravure has long dominated. A Response to Industry Pressures: Automation as a Strategic Imperative The global printing industry has been sounding alarms about the dwindling pool of […]

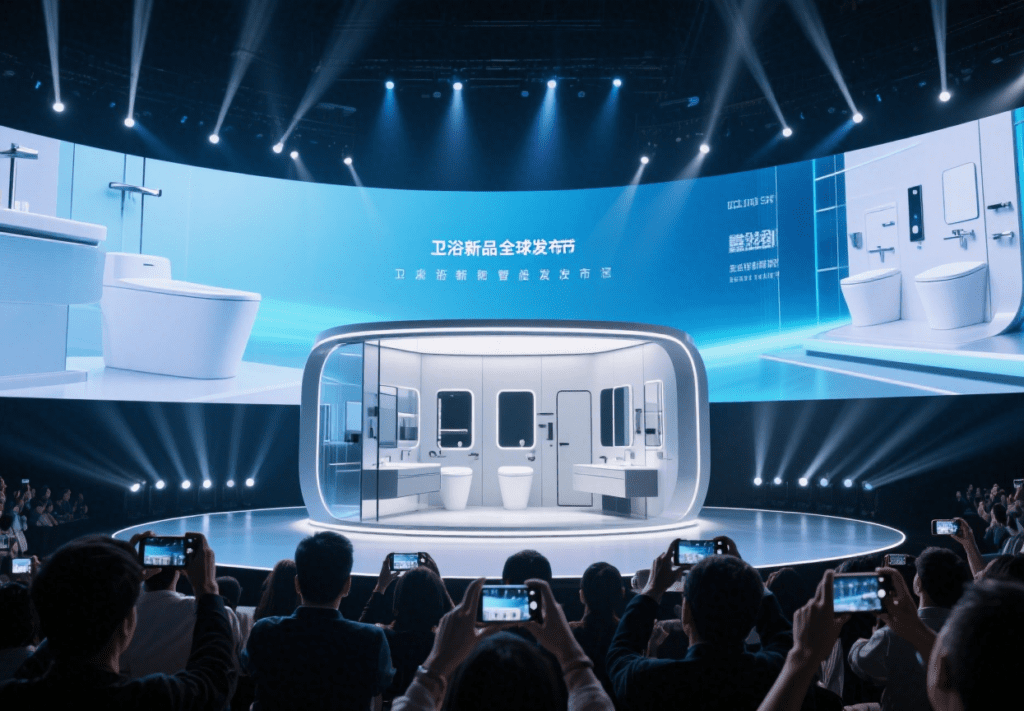

衛生陶器業界の次の10年を再定義する「バスルームシーン」の世界初公開

As the current hottest science and technology, AI is reconstructing industrial development and the world pattern. On May 26, the “AI Awakens New Scenes” 2025 Jiumu Technology Innovation Conference was held in Shanghai. Jiumu Group globally premiered two scene brands, “Jiumu AI BATH” and “Xiaomu YOUNG BATH”, which attracted widespread attention in the industry. At the conference, He Fan, Dean of the China Institute for Development Research at Shanghai Jiao Tong University and author of Variables, delivered a keynote speech entitled Where Do the Innovation Advantages of China’s Manufacturing Industry Come From, which conducted in-depth interpretations on technology and transformation of China’s manufacturing industry, as well as the resilience and […]

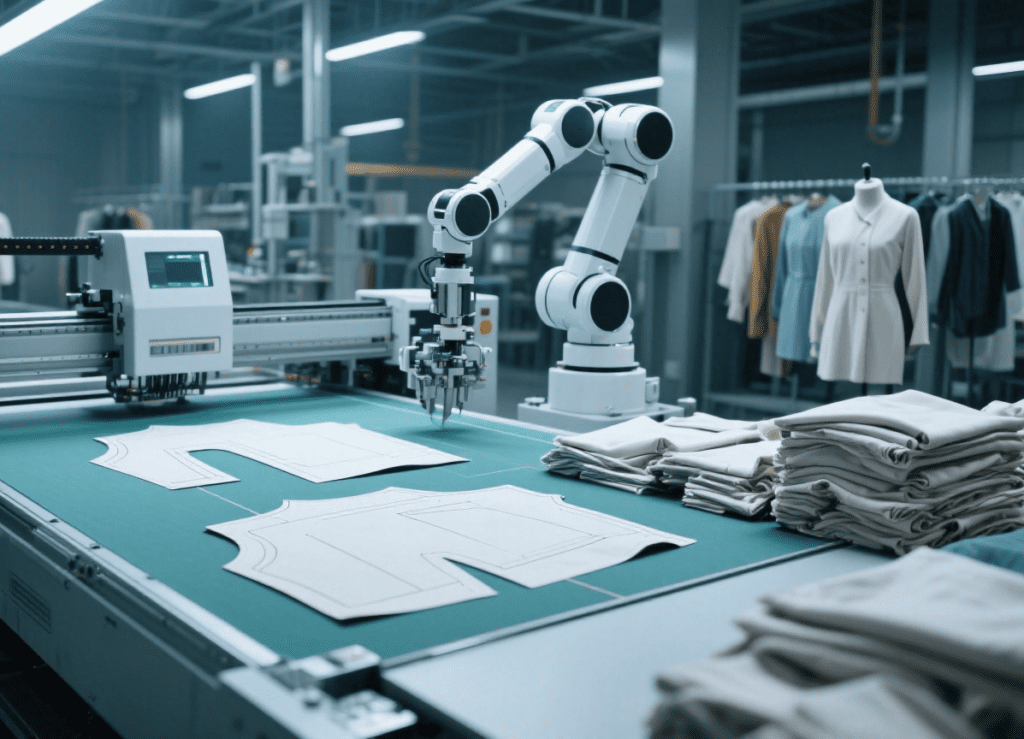

フレキシブル製造におけるロボットと自動化機器の利点と応用について

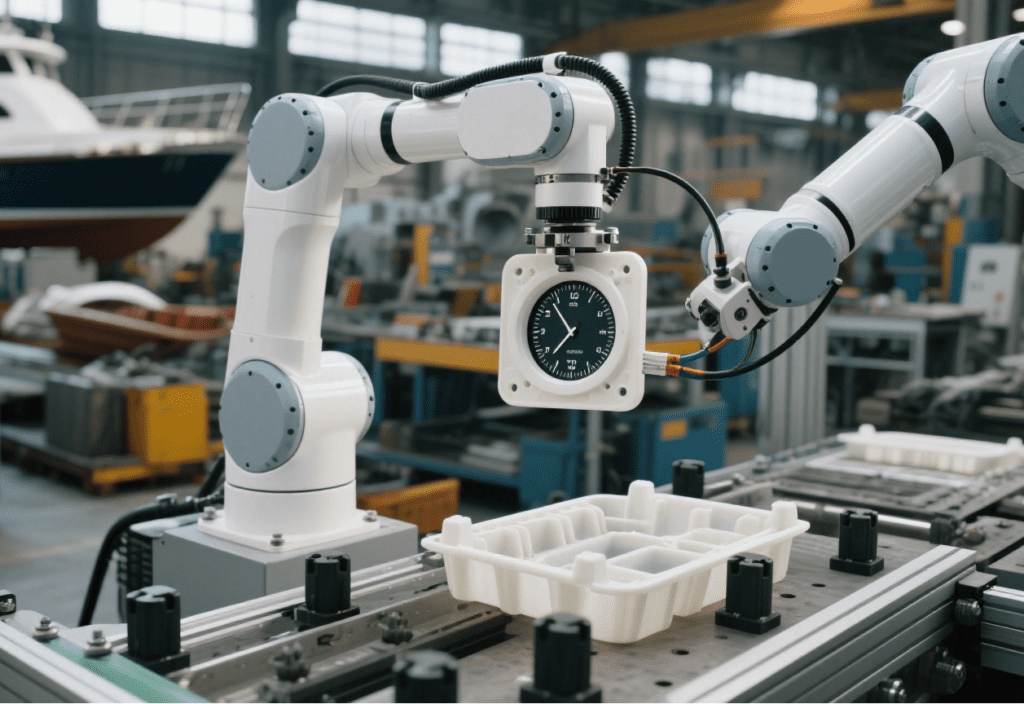

Against the backdrop of increasingly fierce global competition in the manufacturing industry, flexible manufacturing, as an emerging production model, is gradually becoming an important way for enterprises to improve efficiency and reduce costs. However, the realization of flexible manufacturing faces many challenges, such as complex production processes, high flexibility requirements, severe mixed production, and rising labor costs. With the continuous development of industrial technology, robots and automated equipment are playing an increasingly important role in the field of flexible manufacturing. Automated mechanisms based on technologies such as robots and modules are becoming key technologies to realize unmanned and intelligent production. Advantages of Robots and Automated Equipment in Flexible Manufacturing Automated […]

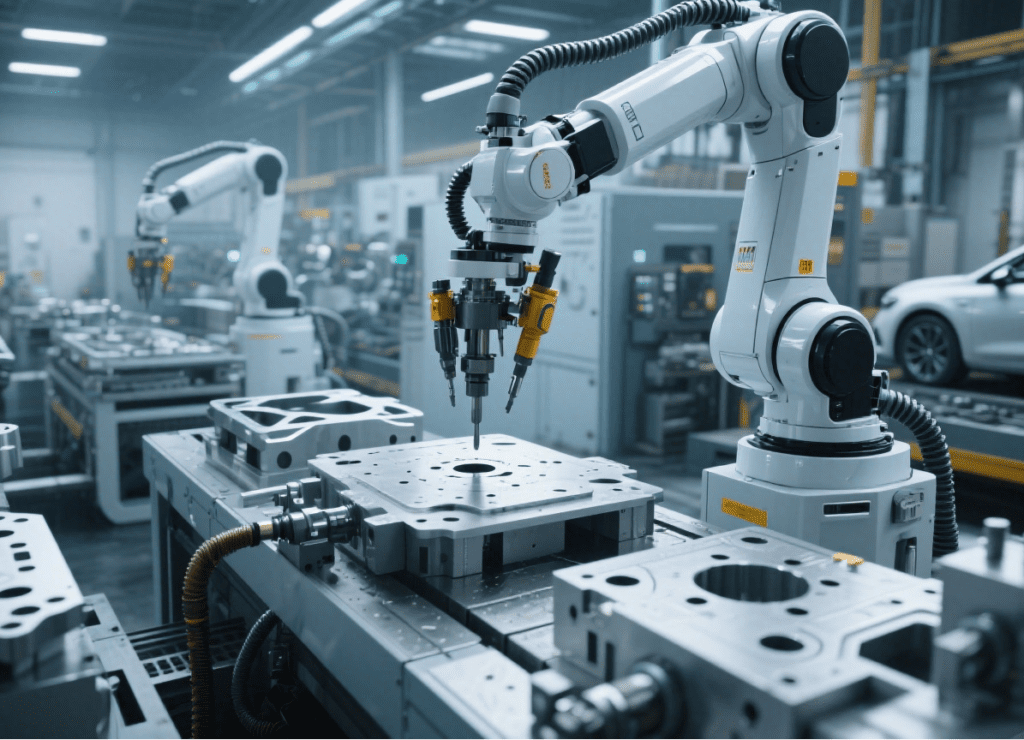

精密機械加工の柔軟性コードを解読する

China is a major global manufacturer of precision mechanical components. According to third-party data, as of the end of April 2025, the total number of enterprises related to precision manufacturing in China has reached more than 87,900. Most of these are small and medium-sized enterprises, which generally face bottlenecks in improving Overall Equipment Effectiveness (OEE), as well as systemic challenges such as difficulty in technical inheritance, high delivery pressure, and tight cost control brought by multi-variety, small-batch orders. In this report, Xinhua News Agency reporters visited Sun Hung Kai’s Suzhou factory to explore their path of technological breakthrough and value leap. Starting Point: Building a Flexible Production Line with Fastems […]

自動化された柔軟な生産を理解する

In traditional manufacturing, “profits thinner than paper” are a pain point for many enterprises. Production waste leads to soaring costs, slow response to market changes, and repeated missed profit opportunities. Today, with changing market demands and the rise of personalized customization, the manufacturing industry is facing unprecedented pressure. At this point, flexible production, as an innovative model, has emerged. It focuses on the flexibility and adaptability of production systems, enabling rapid responses to market changes. This article will take you through an in-depth analysis of its definition, technical support, challenges, and implementation strategies, opening a new “monetization” path for traditional manufacturing enterprises. Flexible Production: From “Rigid Inflexibility” to “Dynamic […]

TRUMPF Flex Cell Flexible Bending Automation Solution: Full-Function Integration, Empowering Efficient Production

In the field of metal processing, the automation of bending processes has long been a pain point for small and medium-sized enterprises. Traditional automation equipment occupies a large area, is complex to debug, and struggles to handle small-batch, multi-variety order demands. The new rapid-movement bending unit Flex Cell launched by TRUMPF, with “full-function integration” as its core breakthrough, forms a compact automation system with the TruBend 7050 bending machine, redefining the efficiency standards of flexible bending. This solution can not only be deployed within a few hours but also, with its “compact size” of 10 square meters, bring 24-hour uninterrupted high-efficiency production capacity to the workshop, making it an ideal […]

AI-Powered Upgrade: Xiamen’s Kitchen and Bath Industry Embarks on a New Chapter of High-Quality Development

In recent years, the kitchen and bath industry has faced challenges such as a shrinking real estate market, rising raw material prices, and intensified fluctuations in the international market. It is transitioning from incremental expansion to stock optimization. Xiamen is one of the representative production areas for high-end manufacturing of global kitchen and bath products. Currently, many enterprises are breaking through and transforming by innovating sales models, strengthening product research and development, and expanding brand influence, driving the steady development of the industry. In the exhibition hall of Gold Home Furnishing, staff demonstrated a developing Feiliu AI home decoration design intelligent system. By simply importing a floor plan or real […]

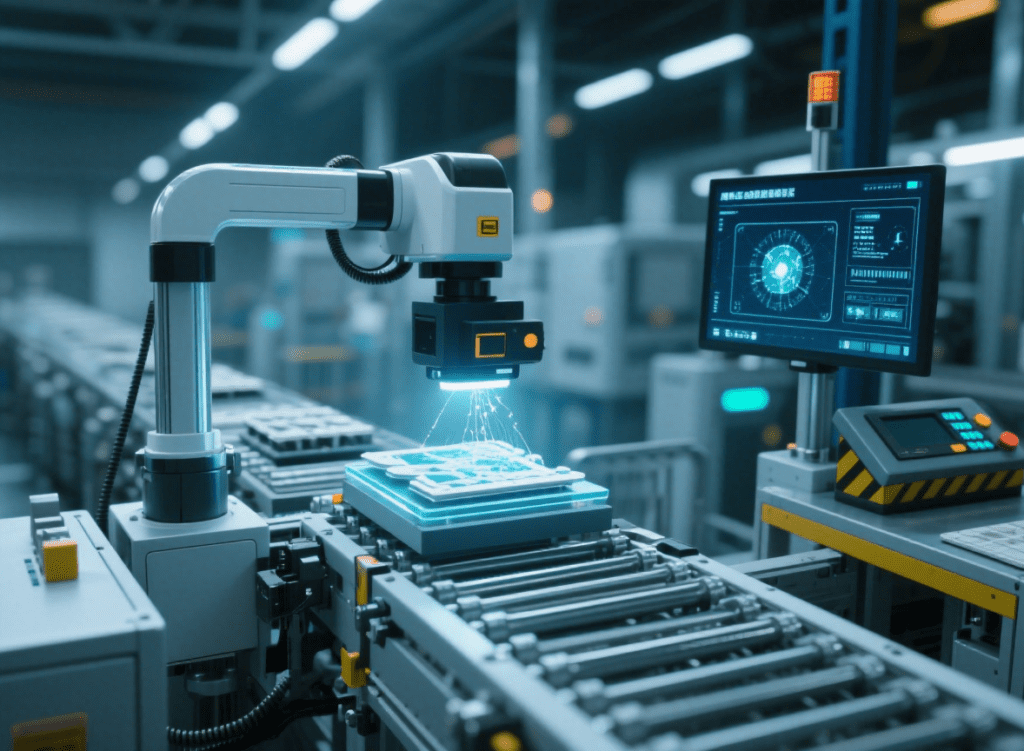

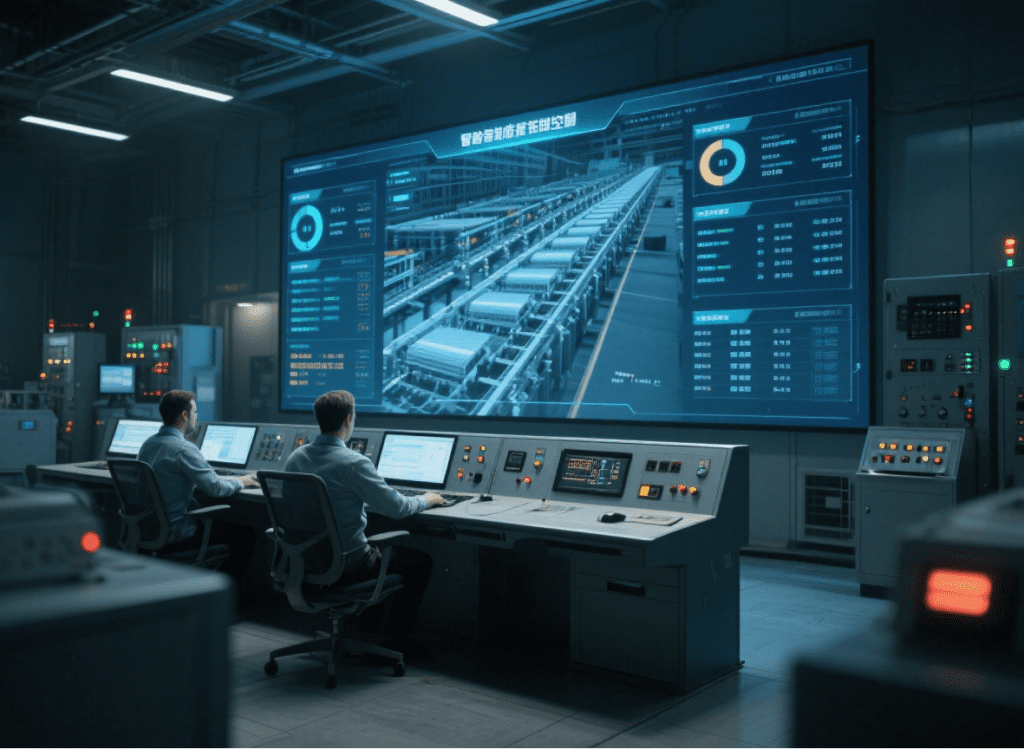

China Embraces the Wave of Intelligentization: Rise of “Lighthouse Factories”, Unmanned Factories and Smart Factories

In recent years, China has accelerated the in-depth integration of artificial intelligence and manufacturing, promoting the construction of a number of digital workshops and smart factories. Today, in many factories across China, a large number of industrial robots and fully automated production lines have emerged. These futuristic and technology-filled production scenes have become hot topics among many foreign media. Intelligent Manufacturing Transforms Chinese Factories Recently, the intelligent production scenes of factories in many parts of China have attracted the attention of Brazil’s Forum magazine website: In the factory of Aptiv Central Electric (Shanghai) Co., Ltd., robots, CNC machine tools and AGVs (Automated Guided Vehicles) are busy working. The CNC machine tools, […]

Research Report on the Development Trend and Future Investment Trends of the Sanitary Ware Industry

1, Introduction to Sanitary Ware Products With the improvement of people’s living standards and the change of consumption concepts, people’s requirements for the home environment are increasing. As the most private space in the home environment, the decoration and supporting facilities of the bathroom are closely related to the quality of family life. Therefore, sanitary ware products have attracted more and more attention from consumers, becoming indispensable daily necessities, and are widely used in various buildings such as family residences, hotels, office buildings, and commercial centers. Sanitary ware products can be divided into two categories: sanitary facilities and sanitary accessories. Sanitary facilities mainly include shower rooms, bathroom cabinets, bathtubs, toilets, […]

電子部品自動ローディング組立機

小型化、精度、スピードが成功を決定づける、変化の激しい電子機器製造の世界において、電子部品自動ローディング組立機は変革をもたらす力として登場しました。これらの特殊システムは、部品の取り扱いと組立の間のギャップを埋め、0.1mmのマイクロチップから5mmのコネクタに至るまで、小さく繊細な電子部品を扱う際の特有の課題に対処します。組立ワークフローへの部品のローディングを自動化し、複雑な接合作業をサブミリメートルの精度で実行することで、これらの機械は、民生用電子機器から車載用半導体に至るまで、さまざまな業界における生産性、信頼性、拡張性を再定義しました。この記事では、これらのシステムの技術、用途、影響を探り、私たちの生活を動かすデバイスの製造をどのように可能にしているかに焦点を当てます。[…]

自動ローディング機能付き射出成形部品自動組立システム

精度、スピード、スケーラビリティが市場のリーダーシップを定義する現代の製造業において、自動ローディング機能を備えた射出成形部品自動組立システムは効率の要となっています。この統合ソリューションは、自動組立の精度と自動ローディングのシームレスな材料フローを融合し、繊細で不規則な形状から大量生産の大量需要まで、射出成形部品の取り扱いに特有の課題に対処します。単なる機械の集合体ではなく、人間の介入を最小限に抑えて未加工のプラスチック部品を完成品に変換する同期されたエコシステムであり、自動車から医療機器に至るまでのさまざまな業界の生産性を再定義します。システムの定義:コア目的と範囲射出成形部品自動組立システム […]

Automatic Injection – Molded Part Feeding And Assembly

精度と効率が競争力を左右する複雑な製造チェーンにおいて、自動射出成形部品供給・組立システムは、原料プラスチックと完成品をつなぐ重要な架け橋となっています。射出成形部品の自動供給とロボット組立を組み合わせたこの統合プロセスは、0.5mmの極小電子コネクタから大型自動車ハウジングまで、プラスチック部品の取り扱い方に革命をもたらしました。エラーが発生しやすい手作業による取り扱いを、ロボット、センサー、ソフトウェアの同期システムに置き換えることで、射出成形部品(軽量、壊れやすい、または不規則な形状であることが多い)の供給、位置合わせ、組立を微視的な精度で行うことができます。医療機器から民生用電子機器に至るまで、プラスチック部品が製品の大部分を占める時代において、この自動化は単なる利便性ではなく、[…]