Topstar Global Open Day 2025: Beyond Humanoid Robots

On September 12, Topstar Global Open Day 2025 will grandly kick off in Dongguan, China. This Open Day will not only launch the “humanoid robot with process expertise” but also present a panoramic view of the “R&D + Manufacturing” dual bases, allowing global customers to intuitively experience Topstar’s solid strength as a world-leading intelligent equipment service provider. Adhering to the new vision of becoming a global leading intelligent equipment service provider, Topstar insists on building an intelligent hardware platform driven by core technologies. It synergizes efforts across three key links—high-precision component manufacturing, core process consolidation, and technology implementation & transformation—to provide one-stop intelligent solutions for global customers. On […]

China’s First AI Factory! Inspur AI Drives the Intelligent Transformation of Industries

Strategic Background: AI Becomes the Core Engine for Industrial Upgrading, Shandong Launches China’s First Large-Scale AI Factory As a strategic technology in the new round of scientific and technological revolution and industrial transformation, artificial intelligence (AI) has become a crucial engine for promoting industrial upgrading and fostering new productive forces. Relying on its solid industrial foundation, abundant data resources, and diversified application scenarios, Shandong Province is accelerating the layout of the AI industrial chain and striving to create new advantages for high-quality development. Recently, Inspur AI Factory, China’s first AI factory with industrialized, standardized, and large-scale production capabilities, has completed its physical construction and officially entered operation in Jinan, Shandong. […]

“AI +” Initiative Unlocks New Opportunities for Intelligent Development of the Manufacturing Industry

For manufacturing enterprises, with the introduction and implementation of the Opinions on Further Implementing the “AI +” Initiative (hereinafter referred to as the “Opinions”), it will bring far-reaching impacts on the intelligent development of enterprises. It will promote the intelligent linkage of all industrial factors and their application in all links, and drive the intelligent linkage of all industrial factors. The next one to two years will be a critical window period for the implementation of AI in all walks of life! Recently, the State Council issued the Opinions on Further Implementing the “AI +” Initiative, aiming to further promote the broader and deeper integration of AI with […]

Streamlining Precision in Modern Production Lines

In the intricate web of manufacturing, where efficiency and consistency define market competitiveness, the final steps of material handling—arranging, orienting, and packaging products—often become the make-or-break in meeting demand. Enter Automatic Material Arranging and Packaging Equipment:an integrated solution that merges robotics, machine vision, and adaptive controls to transform chaotic streams of parts into neatly organized, ready-to-ship packages. From tiny electronic components to bulk consumer goods, this technology is redefining how industries handle the critical transition from production to distribution. The Limitations of Manual and Semi-Automated Processes Traditional material arranging and packaging rely heavily on manual labor or rigid mechanical systems, both of which struggle to keep pace […]

Jiangsu Provincial Ship and Ocean Engineering Industry “Intelligent Transformation, Digital Upgrade, and Network Connection” Matching Event Held in Jingjiang

Event Background: Focusing on Industrial Upgrading Goals to Drive High-Quality Development of Clusters To earnestly implement the Jiangsu Provincial Three-Year Action Plan for Deepening Intelligent Transformation, Digital Upgrade, and Network Connection in Manufacturing (2025-2027) and the work deployment for the “1650” industrial system construction, strengthen collaboration among upstream and downstream links in the industrial chain, accelerate the intelligent transformation, digital upgrade, and network connection of the province’s ship and ocean engineering industry clusters, and expedite the development of an internationally competitive high-tech ship and ocean engineering equipment industry cluster, the Jiangsu Provincial Department of Industry and Information Technology (JIIT) held the Jiangsu Provincial Ship and Ocean Engineering Industry “Intelligent […]

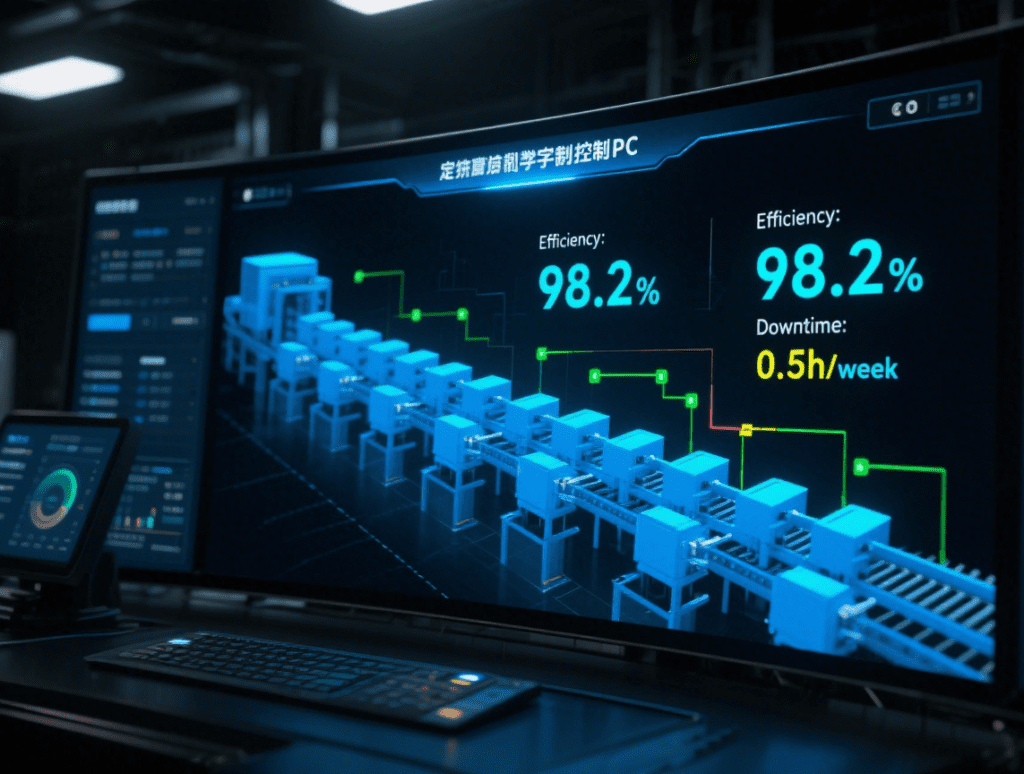

Automation Transforms EV Motor Manufacturing: Stator Lines Gain Speed via PC-Control Solutions

Automation Drives EV Motor Manufacturing Innovation Core Technologies Redefine Stator Production Efficiency PC-based control systems and flexible transport solutions are revolutionizing electric vehicle (EV) motor manufacturing—specifically slashing cycle times and ramping up efficiency for stator production lines, a critical link in EV powertrain assembly. GROB Leads Transformation with Custom Hairpin Production Solutions GROB-Werke GmbH & Co. KG, a Germany-based machine tool manufacturer headquartered in Mindelheim, is at the forefront of this transformation. A key player in high-volume EV production systems, the company recently delivered a sophisticated, custom-built solution for manufacturing hairpins—the core components that form stator winding rims in electric motors—for a major U.S.-based EV maker. […]

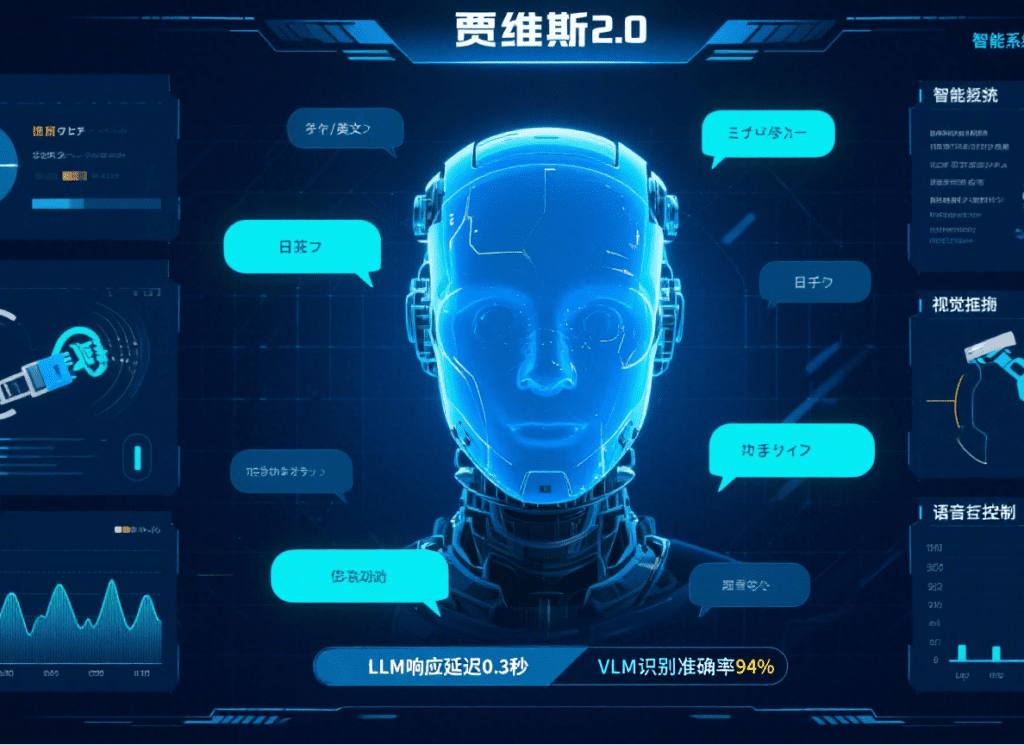

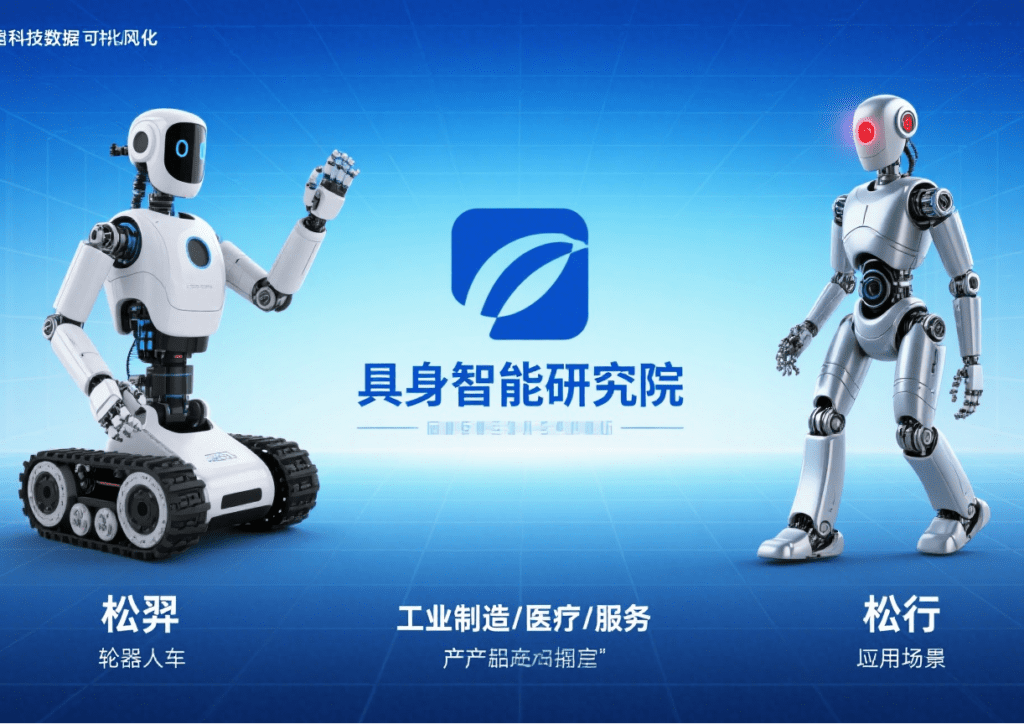

Puzhi Future Robotics: 200 Embodied Intelligent Robots to Roll Off the Production Line

On August 27, Junpu Intelligent announced that 200 embodied intelligent robots, covering two types (humanoid robots and wheeled robots), are about to roll off the production line at the factory of its subsidiary, Puzhi Future Robotics. Zhou Xingyou, Vice President of Joyson Group, Chairman of Junpu Robotics Research Institute, and Chairman of Puzhi Future Robotics, stated, “Next year, our production capacity will be expanded to 2,000 units to meet the demand for higher-volume production.” It is reported that Puzhi Future Robotics is a joint venture established in April this year by Junpu Humanoid Robot Research Institute and Zhiyuan. Its main business focuses on the production and R&D of […]

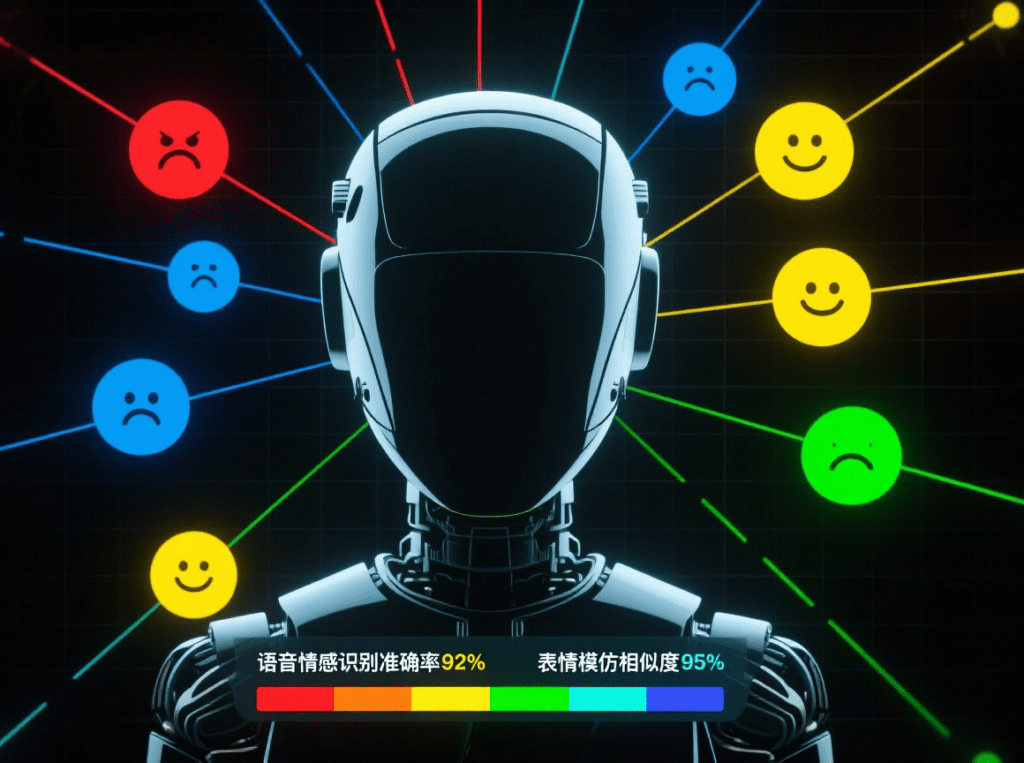

Not Just Building Robots, But Cultivating an Ecosystem: Fourier Intelligence Launches Emotional Robot GR-3

Recently, Shanghai Fourier Intelligence Co., Ltd. (hereinafter referred to as “Fourier Intelligence”) officially released its first full-size humanoid Care-bot GR-3 (hereinafter referred to as “GR-3”) in Beijing. This robot focuses on interactive companionship and features a “touchable” design. According to data compiled by the Smart Manufacturing Network, it has been nearly a year since the launch of Fourier’s previous humanoid robot GR-2 (hereinafter referred to as “GR-2”). GR-2 stands 175cm tall, weighs 63kg, and has a total of 53 degrees of freedom (DoF). The upgraded GR-3 is 165cm tall and weighs 71kg, with an increased 55 DoF in total—its torso DoF has been enhanced to support more human-like body […]

Half-Year Financial Report 2025 of “the First Listed Robotics Company” Released!

Recently, Siasun Robotics, known as “the first listed robotics company” in China, released its semi-annual report for 2025. The report shows that in the first half of the year, the company achieved an operating income of 1.66 billion yuan, a slight year-on-year decrease of only 0.07%, maintaining a basically stable revenue scale; its net profit attributable to shareholders of the listed company was -95.3582 million yuan, a year-on-year decrease of 54.32%; and its non-recurring net profit attributable to shareholders of the listed company was -122 million yuan, a year-on-year decrease of 12.66%. In terms of profitability, the company’s gross profit margin stood at 14.62%, also a slight decrease compared […]

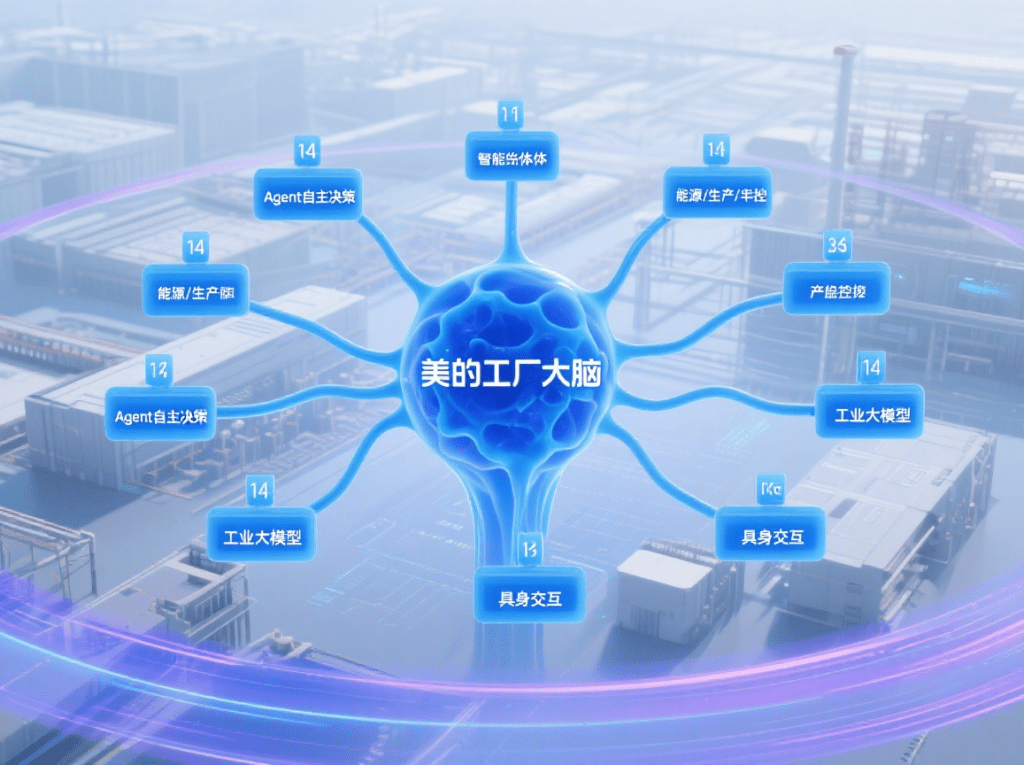

World Record Certification Awarded to the First Agent-Based Smart Factory

Midea’s Washing Machine Factory in Jingzhou has recently received the certification of “World’s Outstanding First Multi-Scenario-Covering Agent-Based Smart Factory” from WRCA (World Record Certification Agency), a London-based world record certification organization. This marks the official launch of the industry’s first agent-based smart factory. The factory’s 14 smart agents cover 38 core production business scenarios and achieve collaboration based on the “Midea Factory Brain”. By deeply integrating Midea’s manufacturing experience, large-model technology, and embodied robotics technology, the factory possesses end-to-end capabilities spanning perception, decision-making, execution, feedback, and continuous optimization. Practical results from the factory show that in multiple core manufacturing scenarios, smart agents complete tasks that traditionally take humans hours […]

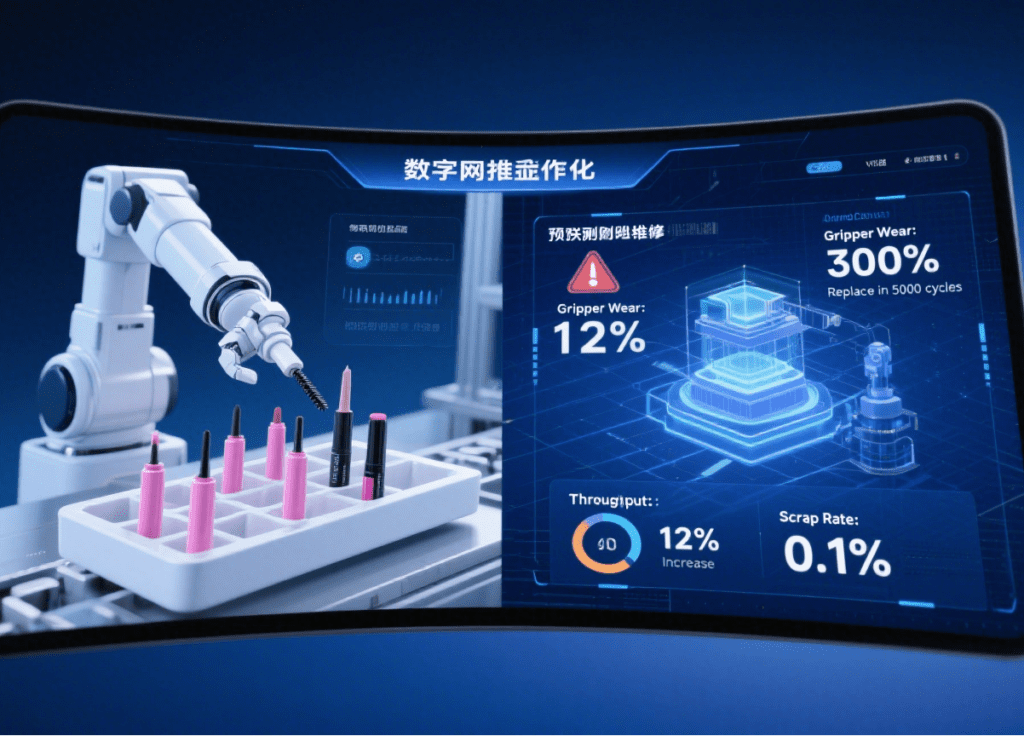

Revolutionizing Precision Handling in Modern Manufacturing

In the fast-paced world of modern manufacturing, where miniaturization and high-volume production dominate industries from electronics to pharmaceuticals, the demand for precise, efficient small product handling has never been greater. Enter the Robotic Small Product Tray Loading System—a technological marvel that combines robotic agility, advanced vision systems, and adaptive programming to transform how tiny components (think microchips, medical devices, or cosmetic applicators) are sorted, oriented, and loaded into trays. This automated solution is redefining productivity, accuracy, and scalability, addressing long-standing challenges in small-part manufacturing. The Need for Specialized Automation in Small Product Handling Traditional methods for loading small products into trays—often reliant on manual labor or rigid, one-size-fits-all […]

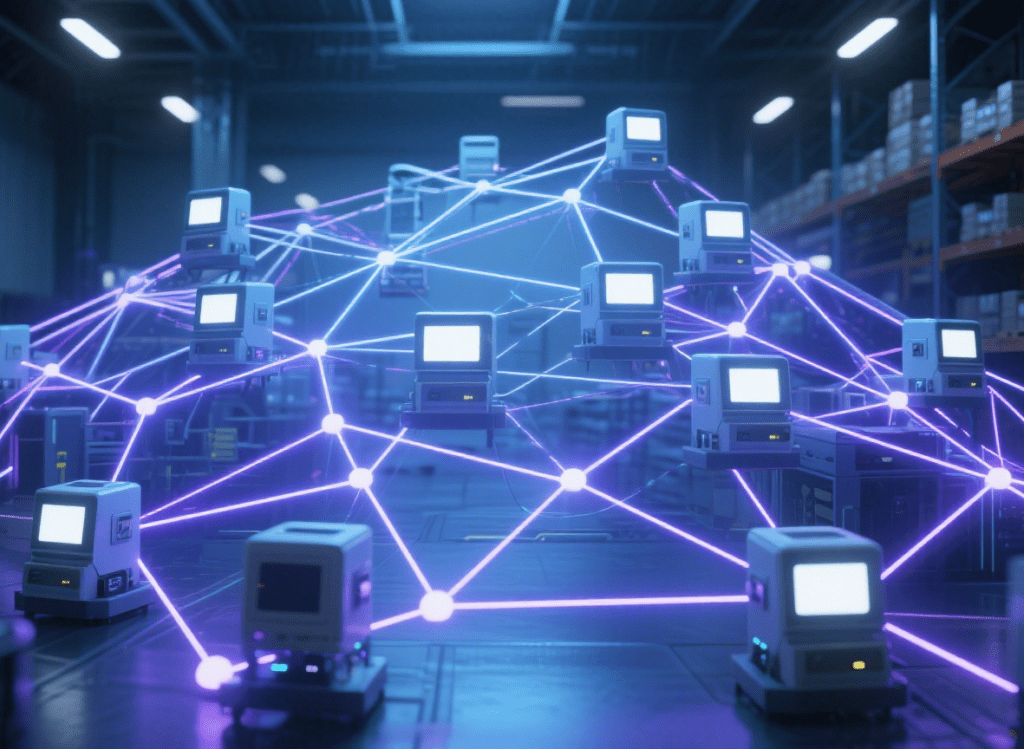

IoT Warehouse Automation: Necessity and Forward-Looking Solutions

In today’s logistics landscape, where global disruptions pose challenges to supply chain stability, warehouse operations must serve as a reliable backbone. The rapid development of enterprise Internet of Things (IoT) has turned this into a reality—not only for corporate giants but also for small and medium-sized enterprises (SMEs) striving to remain competitive. As of 2024, over 25% of warehouses have implemented some form of automation, a fivefold increase compared to a decade ago. This exponential growth is largely driven by IoT. Why? First, IoT perfectly aligns with speed—the core factor driving the adoption of warehouse technology. Second, consumer and business expectations have become more stringent, making precise control and […]