Defining AI Risks: The Hidden Battleground of Global Competition

The Paradox Amid Consensus: From Risk Warnings to the Norm of Competition Risk dominates current discussions on artificial intelligence governance. This July, Geoffrey Hinton, a dual laureate of the Nobel Prize in Physiology or Medicine and the Turing Award, delivered a speech at the World Artificial Intelligence Conference in Shanghai. The title remained the one he has repeatedly used since leaving Google in 2023: “Will Digital Intelligence Replace Biological Intelligence?” He emphasized once again that artificial intelligence may soon surpass humanity and threaten our survival. Scientists and policymakers from China, the United States, European countries, and beyond nodded in grave agreement. However, beneath this superficial consensus lies a […]

AgiBot Expands to Fujian Province

On September 8, AgiBot established Fujian Jufu Technology Co., Ltd. in Fuzhou New Area, with a registered capital of 10 million yuan. Chen Zhaoxiang, head of AgiBot’s Ecosystem Cooperation Department, serves as the legal representative. Equity analysis shows that Jufu Technology is owned by AgiBot Innovation (Shanghai) Technology Co., Ltd. (65%), Fuzhou New Area Guidance Fund (25%, indirectly held through Song Chaoqun’s SPV), and Fujian industrial investor Lin Jie (10%). Notably, this marks AgiBot’s first inclusion of a local government fund as a shareholder. “3+1” High-Value Business Scope Jufu Technology focuses on the core industrial chain of humanoid robots, covering three core areas and one supporting business: […]

This IoT communication product supplier completes angel round financing

Dianju Wulian secures 10 million yuan in angel round financing, focusing on technological R&D and market expansion Recently, Dianju Wulian (Shenzhen Dianju Wulian Innovation Technology Co., Ltd.) completed an angel round of financing worth 10 million yuan, with Suzhou Jishiyu Investment as the investor. It is reported that this round of financing will be mainly used to strengthen technological research and development, expand the product matrix, and accelerate market implementation, further consolidating its leading position in the field of ad-hoc network communication. Company profile: Focusing on MESH ad-hoc network technology, with products covering multi-field applications Founded in 2020 and headquartered in Shenzhen, Guangdong Province, Dianju Wulian has […]

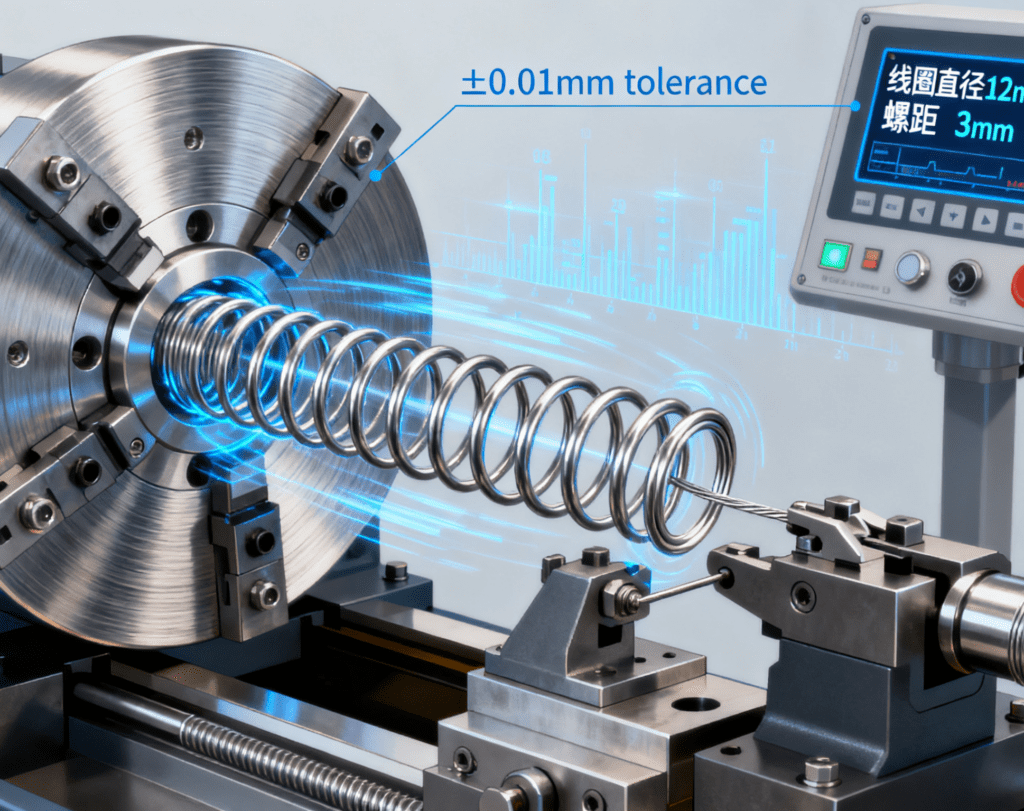

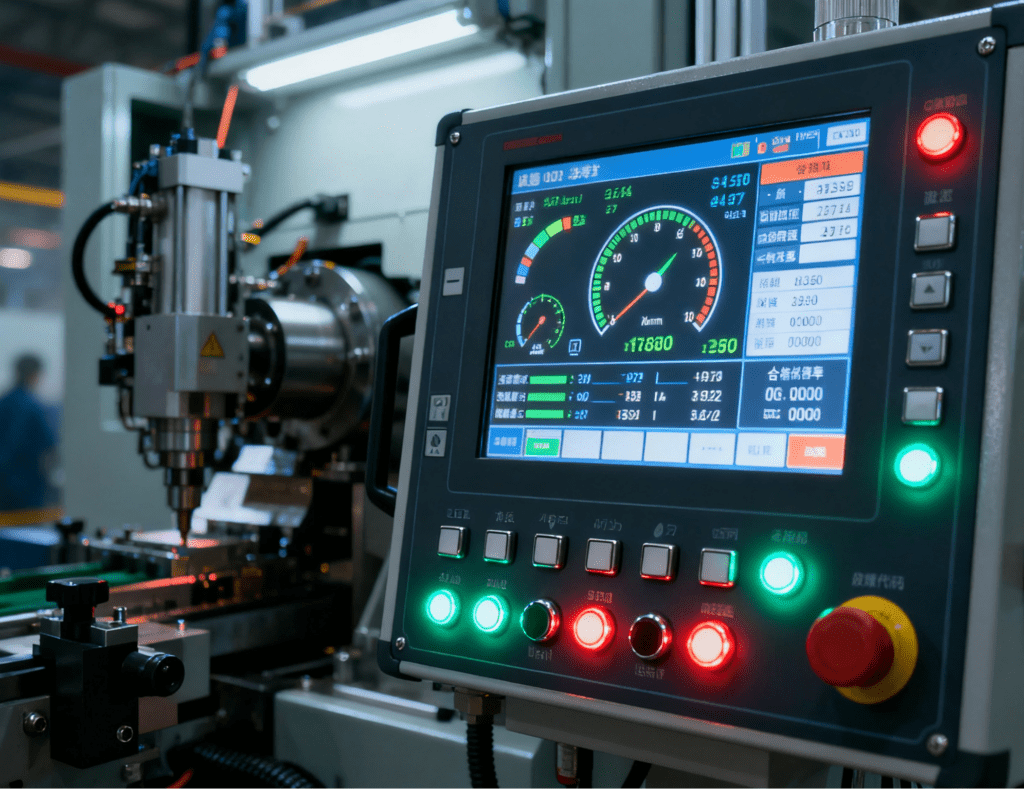

The Backbone of Precision in Spring Manufacturing

Springs, those unassuming yet indispensable components, are the silent enablers of countless machines and devices—from the suspension systems of cars to the buttons on our smartphones, from medical devices to industrial machinery. Behind every reliable spring lies a manufacturing process that demands meticulous precision, consistency, and efficiency. Enter automatic spring equipment—a category of advanced machinery that has revolutionized how springs are designed, produced, and integrated into modern products. What is Automatic Spring Equipment? Automatic spring equipment encompasses a range of specialized machines engineered to automate the entire lifecycle of spring production, from wire forming to finishing, inspection, and even assembly. Unlike manual or semi-automatic systems, these machines operate […]

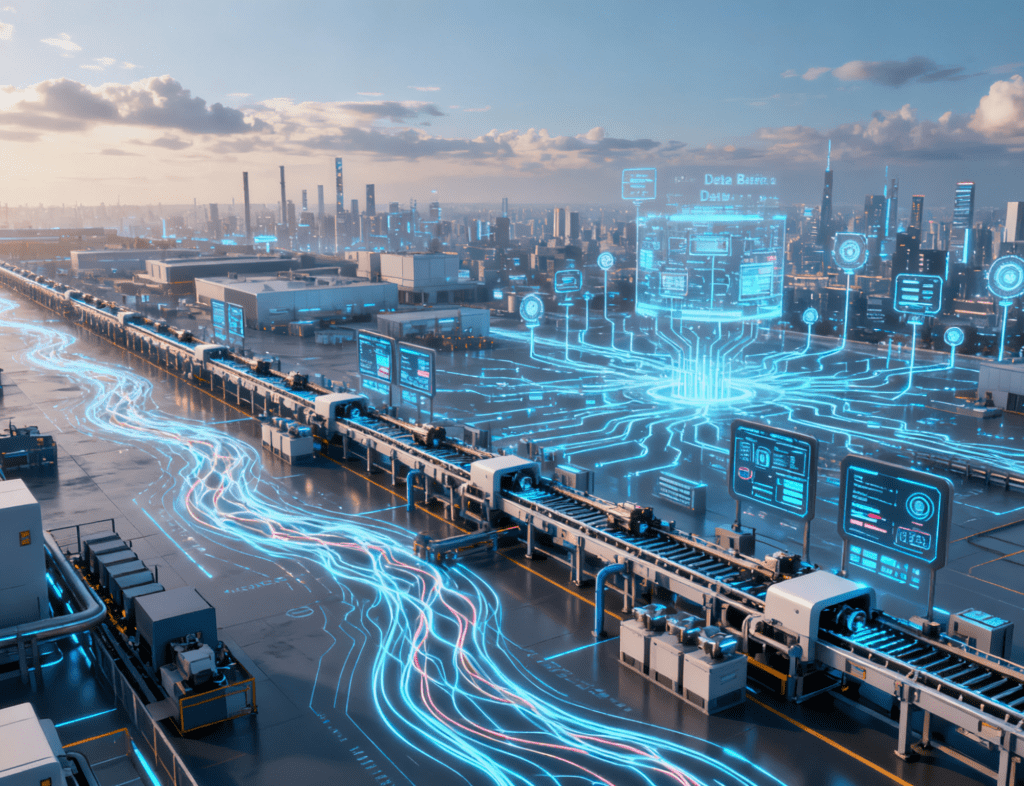

Cisco Data Fabric: Turning Machine Data into AI-Ready Intelligence

In the era of artificial intelligence, the ability to harness machine data—from sensors, networks, and systems—has become a defining factor for enterprise innovation. At Splunk .CONF 2025 in Boston, Cisco unveiled a game-changing solution: the Cisco Data Fabric. Built on the Splunk platform, this revolutionary architecture aims to transform how organizations manage, analyze, and leverage machine data at scale, turning it into a powerful fuel for AI applications. Redefining Machine Data for the AI Era Machine data is the lifeblood of modern businesses, encompassing sensor readings, factory metrics, network logs, and app events—yet unlocking its value for AI has long been hindered by complexity, high costs, and scalability […]

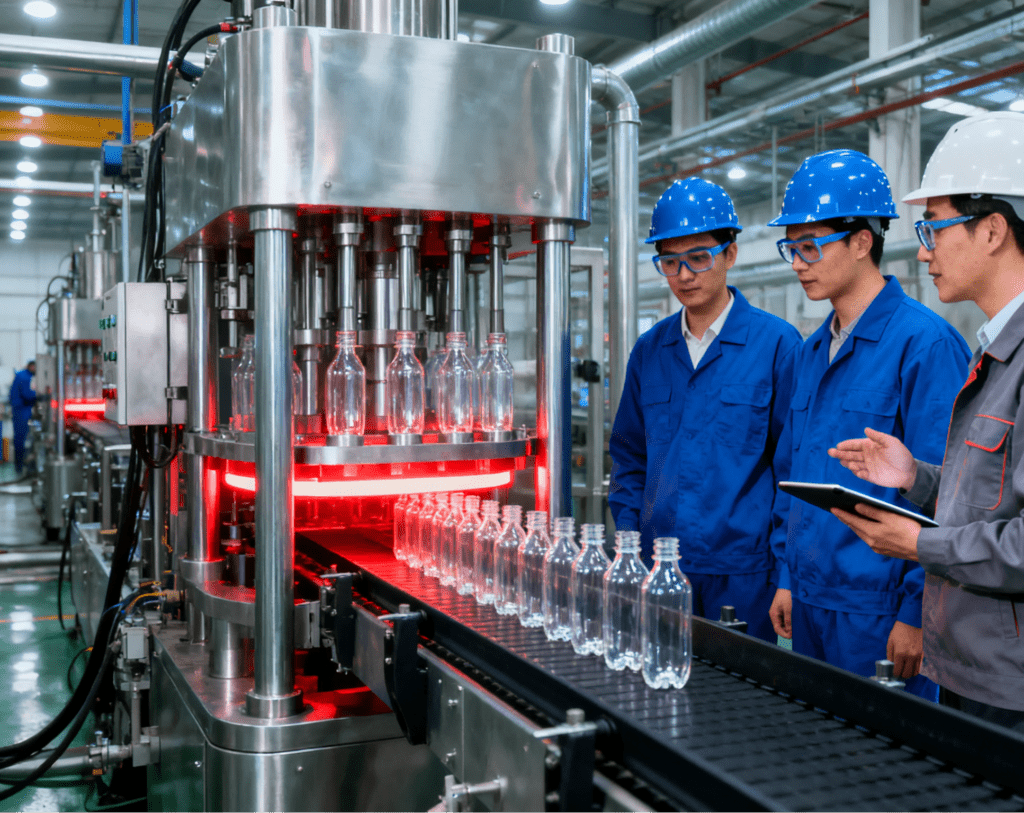

Wang Li and His Delegation from China Packaging Federation Visit Packaging Enterprises in Shenzhen and Foshan for Research and Exchange

To gain an in-depth understanding of the new trends in green and low-carbon development and the new demands for standardization in the packaging industry, and to promote high-quality development of the industry, from September 8th to 10th, Wang Li, Chief Engineer of China Packaging Federation, led a team to Shenzhen and Foshan. They conducted research and exchanges on standardization work with four key packaging manufacturers, including Shenzhen Tongchan Lixing Technology Group Co., Ltd., Foshan Huaxin Hengfeng Polyester Packaging Co., Ltd., Foshan Nanfang Packaging Co., Ltd., and Shenzhen Shensaier Co., Ltd. Shenzhen Tongchan Lixing Technology Group Co., Ltd. During their visit to Shenzhen Tongchan Lixing Technology Group Co., Ltd., […]

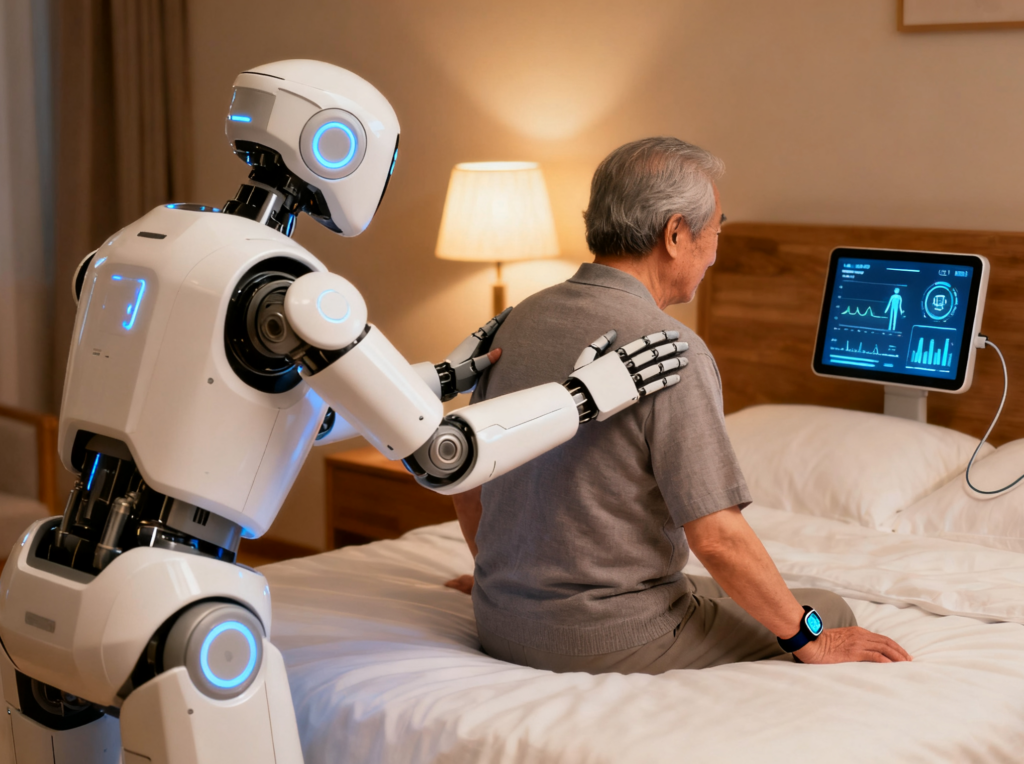

Elderly Care Service Robots Break Into “Elderly People’s Bedsides”

Recently, the General Office of the Ministry of Industry and Information Technology and the General Office of the Ministry of Civil Affairs announced the list of pilot projects for paired research and development and scenario application of intelligent elderly care service robots. The list includes a total of 32 intelligent elderly care service robot projects focusing on 10 types of application scenarios such as emotional companionship, rehabilitation support, daily care, transfer assistance, walking assistance, toileting and incontinence care, and bathing assistance. For example, the key technology research and pilot application of intelligent emotional companionship robots, and the paired research and scenario application of intelligent physiotherapy and rehabilitation robots. Each project has one leading unit and multiple participating units.

Convergence Lecture Series Presents ‘How to Thrive in the Age of AI’

The First Lecture Focuses on Ways to Survive in the AI Era The inaugural Convergence lecture series kicks off with a timely exploration of how artificial intelligence is reshaping our world—and how we can equip ourselves to thrive in careers and lives amid automation. The Speaker Analyzes the Core Advantages of Humans in the AI Era “How to Thrive in the Age of AI” features Po-Shen Loh, a social entrepreneur, inventor, and mathematics professor at Carnegie Mellon University. Loh will delve into a paradox of our automated era: as AI takes over routine tasks, human strengths like creative problem-solving, sound judgment, and empathetic communication only grow more […]

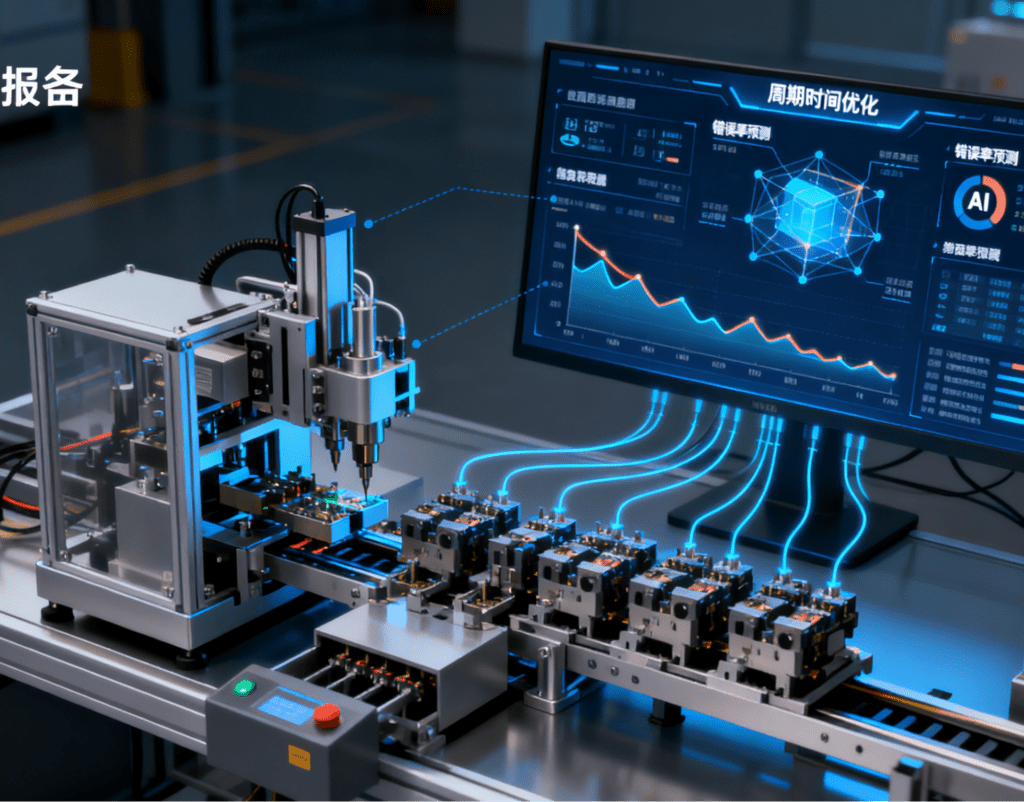

Revolutionizing Precision Assembly in Industrial Production

In the intricate landscape of modern manufacturing, where precision and efficiency are paramount, the automatic spring white disc machine has emerged as a silent workhorse, redefining how small but critical components are assembled. This specialized automated system, designed to streamline the pairing of springs with white discs—common in industries ranging from automotive to electronics—combines mechanical precision, intelligent control, and adaptive technology to meet the demands of high-volume, high-accuracy production. The Core Function: Marrying Precision with Speed At its heart, the automatic spring white disc machine is engineered to perform a deceptively simple yet technically demanding task: aligning, inserting, and securing springs into white disc components with minimal human […]

The Energy Race Fueling Artificial Intelligence: A Fact Check

The rapid expansion of artificial intelligence (AI) is driving a surge in global electricity demand, with the United States at the center of a growing challenge: powering the data centers and infrastructure that enable AI’s advancement. As AI models grow larger and more complex, their hunger for energy has sparked a race to secure reliable, scalable power—raising questions about sustainability, grid capacity, and international competition. The Growing Energy Appetite of AI Data centers, the backbone of AI operations, already consume a significant share of U.S. electricity. According to an analysis from Berkeley Lab, these facilities currently account for about 4.4% of all U.S. electricity use. This figure is […]

Another pharmaceutical company crosses over into semiconductors!

On September 7th, Sunflower released an important announcement stating that the company is planning to acquire a controlling stake in Zhangzhou Xipu Material Technology Co., Ltd. (hereinafter referred to as “Xipu Materials”) and a 40% equity stake in Zhejiang Beide Pharmaceutical Co., Ltd. (hereinafter referred to as “Beide Pharmaceutical”) by issuing shares and/or paying cash, while also planning to raise supporting funds. This transaction is still in the planning stage. As of the disclosure date of this announcement, the valuations of Xipu Materials and Beide Pharmaceutical have not been finally determined. Based on preliminary calculations, this transaction is expected to constitute a major asset reorganization as stipulated in the […]

Why is Data Quality the Cornerstone of AI Success?

In today’s era where artificial intelligence (AI) is gradually becoming the core of corporate strategy, a fact is increasingly clear: the effectiveness of AI depends on the quality of the data behind it. Whether it is driving business automation, optimizing operations, or developing competitive advantages, if the underlying data is flawed, the value of AI will be greatly diminished. The Importance of Data Quality The ancient adage “garbage in, garbage out” still holds true in the AI era. The performance of an AI model depends on the training data and operational data it receives. If the input data is incomplete, inaccurate, or inconsistent, the output results will […]