Huawei Releases World’s Most Powerful Supernode and Cluster

Atlas Series Supernodes and Clusters Debut: Million-Card-Scale Computing Power Sets New Global Record At the Huawei Connect 2025 conference in Shanghai, Huawei’s Deputy Chairman and Rotating Chairman Xu Zhijun delivered a keynote speech, affirming the core view that “computing power is the key to artificial intelligence.” Based on China’s chip manufacturing processes, Huawei officially released the world’s most powerful computing supernode and cluster products. The Atlas 950 SuperPoD and Atlas 960 SuperPoD supernodes support 8,192 and 15,488 cards respectively, leading in all key metrics including card scale and total computing power. The Atlas 950 SuperCluster and Atlas 960 SuperCluster, built on these supernodes, achieve computing power scales exceeding […]

EIR and Tencent Cloud Sign Strategic Cooperation: Exploring Intelligent Implementation of Humanoid Robots in Elderly Care Scenarios

Cloud-Enterprise Collaboration: Tencent Cloud’s Technological Empowerment to Build a Humanoid Robot Ecosystem Recently, EIR (Sichuan Embodied Humanoid Robot Technology Co., Ltd.) and Tencent Cloud officially entered into a strategic cooperation, focusing on deep collaboration in cloud computing support and the implementation of elderly care scenarios. In the future, Tencent Cloud will leverage its world-leading cloud computing infrastructure and audio-visual technology to provide EIR with three key supports: high-performance computing power guarantee, data intelligence analysis capabilities, and cloud-based collaborative control technology. The goal is to jointly build an open, intelligent, and secure humanoid robot ecosystem, helping robots achieve breakthroughs in autonomous learning efficiency, scene adaptation capabilities, and cluster collaboration, thereby […]

Factory-Carton-Automatic-Packaging-Machine

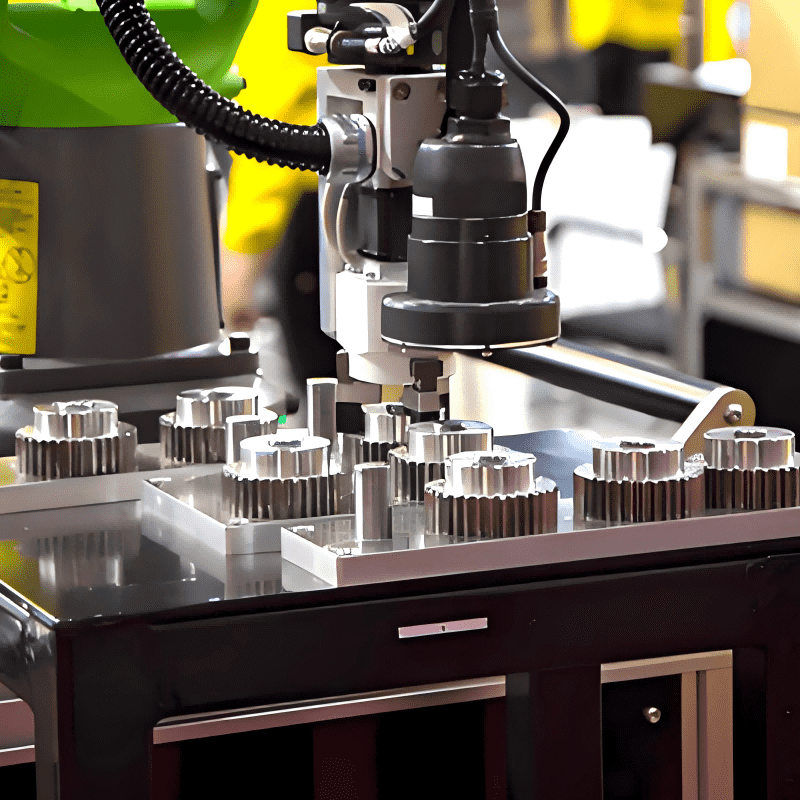

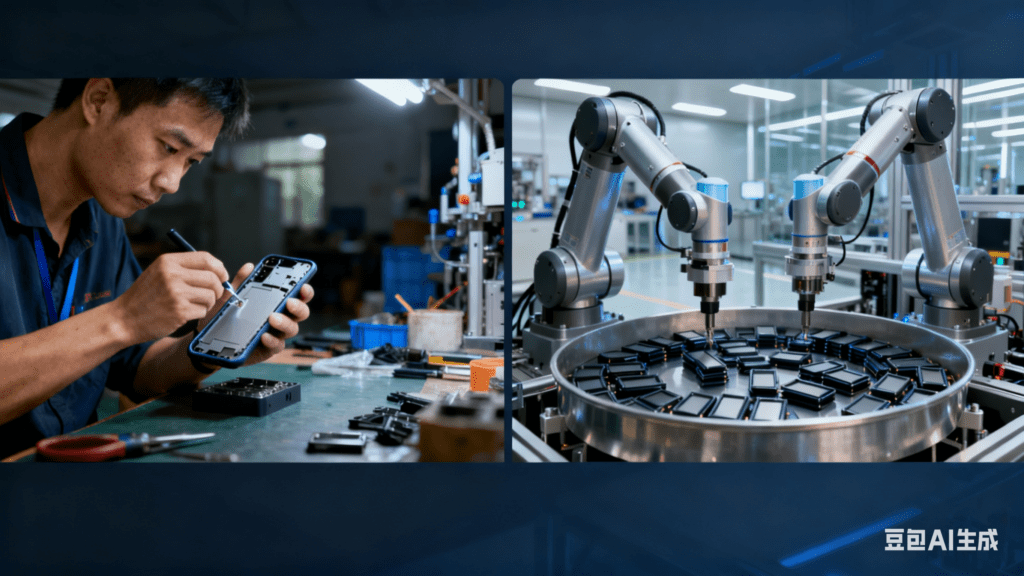

The Core Engine Driving Manufacturing Automation Upgrade

In the wave of global manufacturing transformation, hardware parts—such as screws, nuts, buckles, and terminals—are the “building blocks” of almost all industrial products. However, the traditional manual feeding and assembly of hardware parts have long been plagued by low efficiency, high error rates, and heavy labor dependence, becoming a bottleneck restricting the production rhythm of enterprises. Against this backdrop, Automatic Hardware Part Feeding And Assembly technology has emerged as a key solution to break through this bottleneck, integrating precision machinery, intelligent sensing, and automated control to reshape the production mode of the hardware manufacturing industry. The Technical Logic of Automatic Hardware Part Feeding And Assembly: From “Precision Delivery” to “Intelligent […]

The “Last Centimeter” of Humanoid Robots: Chinese Players Break Through

The bottleneck preventing humanoid robots from moving from laboratories to factories and homes is not usually “can they walk,” but “can they grasp.” As the “nerve endings” of robots, dexterous hands account for about one-fifth of the total cost and directly determine whether a robot can pick up an egg, hold a cup steadily, open a bottle cap, or even perform minimally invasive surgery. This “hand” that integrates precision machinery, flexible electronics, and AI is truly the “last centimeter” in robot industrialization. As the humanoid robot boom intensifies, the dexterous hand industry stands at the threshold of large-scale development. But how to balance high versatility with low cost? Should […]

2025 Yunqi Conference Sneak Peek: These Are the New AI Highlights This Year

September 16 — The 2025 Yunqi Conference will be held from September 24 to 26 in Yunqi Town, Hangzhou. Today, Alibaba Cloud officially announced the main forum agenda for the opening ceremony. Theme and Scale This year’s Yunqi Conference, themed “Cloud-Intelligence Integration · Carbon-Silicon Symbiosis,” will span three days with three main forums and over 110 aggregated topics. More than 2,000 guests from over 50 countries are expected to attend. The exhibition area covers 40,000 square meters and is divided into three halls: Artificial Intelligence + Hall Computing Hall Cutting-Edge Application Hall Over 500 enterprises will showcase 3,500 exhibits. Main Forums and Speakers During the conference, the three main […]

Huawei Releases Top 10 Technology Trends for the Intelligent World 2035; Musk to Evaluate AI5 Chip Design

Microsoft, NVIDIA, and other tech giants plan to add over $40 billion in AI investment in the UK Microsoft announced on Tuesday its plan to invest $30 billion in the UK by 2028 to build its artificial intelligence infrastructure. The investment includes $15.5 billion for capital expansion and $15.1 billion for UK business operations. Microsoft stated this will enable collaboration with British cloud computing company Nscale to create the UK’s “largest supercomputer,” equipped with more than 23,000 advanced graphics processing units (GPUs). NVIDIA, Google, OpenAI, and Salesforce have also announced multibillion-dollar investment plans in the UK, with the total new investment exceeding $40 billion. Musk: AI5 Chip Design […]

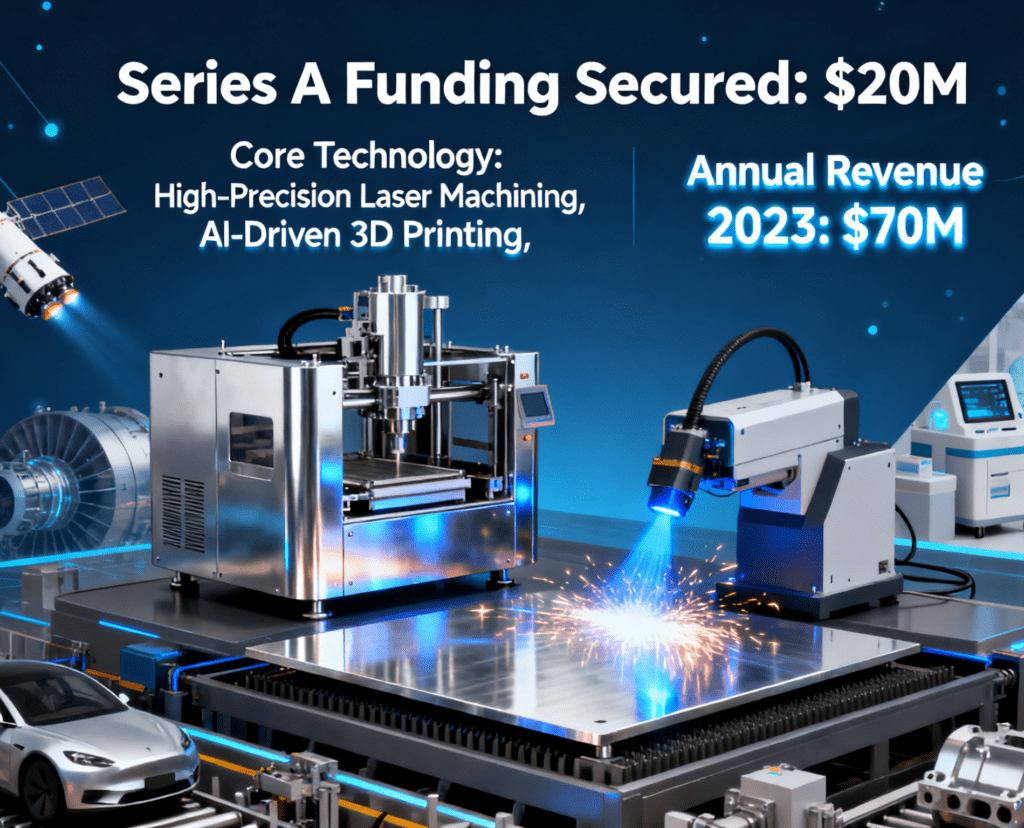

End-of-Year Revenue to Exceed RMB 70 Million! Why This Laser Company Secured Another Round of Funding?

Series A Financing Overview: Funds Allocated to R&D, Market Expansion, and Team Building Recently, Shenzhen Zhongzhi Xinying Precision Technology Co., Ltd. (referred to as “Zhongzhi Xinying”) announced the completion of its Series A financing, led by Ceyuan Ventures. The funds will be mainly used for technology research and development, market expansion, and team building to accelerate the company’s layout in the laser processing field. Notably, this financing round comes only about 8 months after the previous one. What strengths does this company possess? Why has it attracted capital interest? Tech & Product Portfolio: Diversified Laser Solutions for High-Tech & Civilian Industries Founded on September 18, […]

Humanoid Robot Startup Figure AI Raises $1 Billion, Valuation Soars to $39 Billion

September 17 news — According to foreign media reports, humanoid robot startup Figure AI has raised $1 billion in funding, pushing its valuation to $39 billion. Figure CEO Brad Adcock announced the news. The $1 billion comes from a Series C round led by Parkway Venture Capital, with participation from major companies including Nvidia, Salesforce, T-Mobile, and Intel. Figure stated that the funds will be used to expand its AI platform Helix and BotQ manufacturing system. Three Main Uses of Funding: Scaling Humanoid Robot Applications to Homes and Businesses Figure is expanding BotQ’s manufacturing capacity and real-world deployment to enable robots to assist with household […]

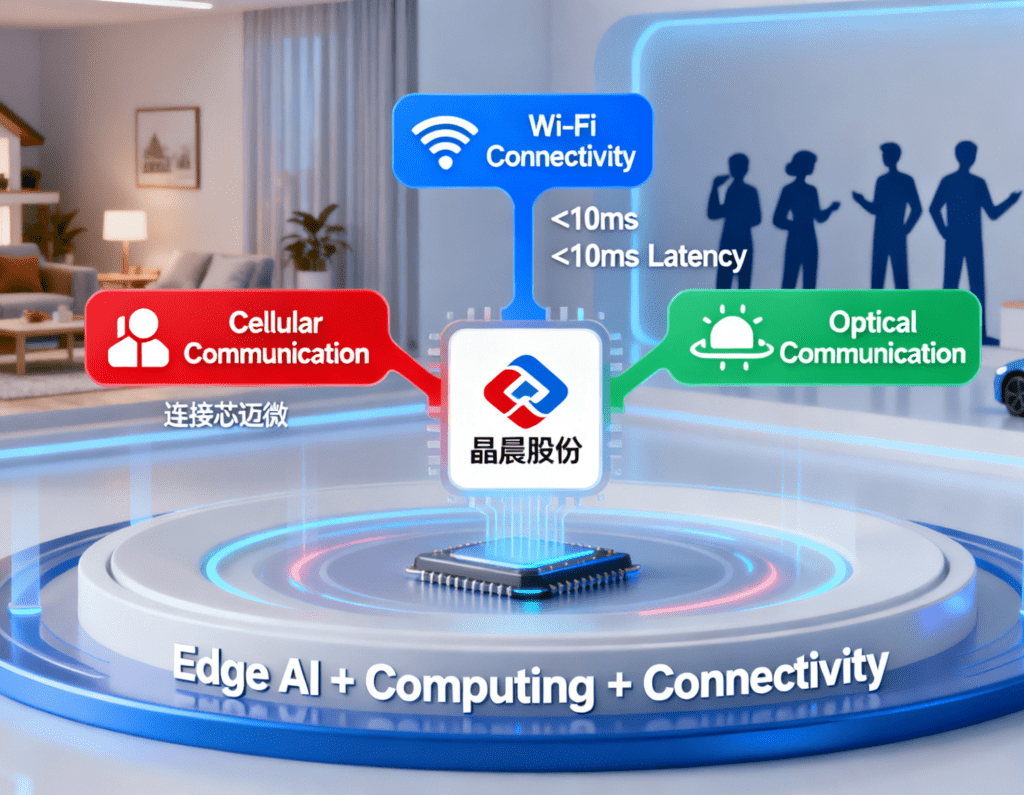

Amlogic Acquires Xinmai Micro for RMB 316 Million; Target Company’s H1 Revenue Only RMB 680,000

Merger & Acquisition Core: RMB 316 Million Cash Purchase of 100% Equity in Xinmai Micro, Targeting Communication Technology Breakthroughs Recently, Amlogic announced its plan to acquire 100% equity in Xinmai Micro Semiconductor (Jiaxing) Co., Ltd. for a total consideration of RMB 316 million in cash. Public records show that Xinmai Micro Semiconductor was founded in Zhuhai in August 2021, and relocated to Jiaxing, Zhejiang in January 2025 under its current name. Since its establishment, the company has developed rapidly, completing three rounds of financing totaling several hundred million yuan within the past year. Investors include well-known institutions such as Walden International, Legend Capital, and CCV (China Creation Ventures). […]

The Revolution in Connecting Component Production

In automotive interiors, 3C electronics, smart homes, and other fields, fasteners (snap-fit connectors) serve as low-cost, easy-to-operate connecting components that provide core functions such as structural fixation and part assembly. From tiny phone case fasteners to heavy-duty automotive door panel fasteners, applications span from precision electronics to heavy industry. However, traditional manual fastener assembly has long suffered from low efficiency, poor precision, and inconsistent quality. In one washing machine panel assembly line, workers could only produce 600 units per person per day with a defect rate of 2.8%, requiring additional quality inspection personnel to address issues like missing or reversed installations. As manufacturing transitions toward flexibility and intelligence, […]

CATL: Sodium-Ion New Passenger Vehicle Battery to Start Mass Supply Next Year

Global Launch of CATL NaXin: Full Temperature Range Operation & Core Advantages Over Lithium-Ion Batteries According to reports, in April this year, CATL launched the world’s first large-scale mass-produced sodium-ion battery — CATL NaXin, which includes two product categories: “NaXin power battery” and “NaXin-24V heavy-duty truck starting and storage integrated battery.” Both products can operate in a full temperature range from -40°C to +70°C. On September 17, CATL stated on an interactive platform that although the energy density of sodium-ion batteries is slightly lower than that of lithium-ion batteries, they have greater advantages in low-temperature performance, carbon footprint, and safety. Technical Performance & Market Fit: 175Wh/kg Energy […]