What Are the Examples of Automated Assembly?

Introduction: The Revolution of Automated AssemblyThe future of automation is not just evolving—it is undergoing a revolutionary shift that will redefine how we think about human-machine collaboration in one of the most critical areas: assembly. As the founder of Humanoid and a veteran with over a decade in tech entrepreneurship, I’ve witnessed firsthand how advanced technologies transform industries—especially how they’re reshaping automated assembly, a cornerstone of manufacturing that’s long struggled with inefficiency, labor gaps, and rigidity.For context, the U.S. manufacturing sector faces a crisis that makes automated assembly not just a “nice-to-have,” but a necessity. Deloitte and the Manufacturing Institute project that by 2033, the industry will need 3.8 million […]

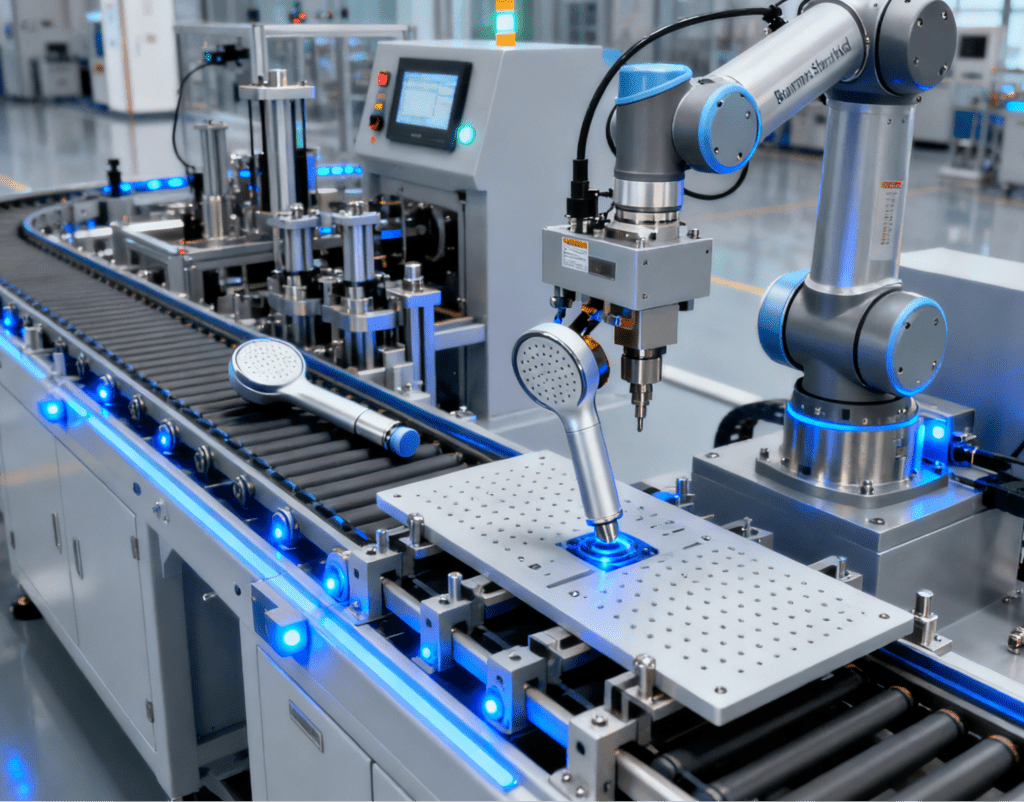

A torque-controlled screwdriver integrates with the robot to fasten the flange to the base’s drainage port

The torque is customized by material: 1.8-2.2 N·m for acrylic bases (to avoid cracking) and 2.5-3.0 N·m for FRP bases (to ensure tight sealing). A pressure sensor monitors the flange’s compression on the gasket—ensuring the gasket is compressed to 30-40% of its original thickness (the optimal range for water tightness). Edge trim bonding: For bases requiring edge sealing, a servo-driven glue dispenser applies a continuous, uniform bead of waterproof glue (width 3-5mm, thickness 2mm) along the base’s edge. A heating plate (temperature 60±5℃) then presses the trim strip onto the glue, with pressure controlled at 10-12N to ensure firm bonding without deforming the base. Multi-Dimensional Quality Detection Unit: Guarding […]

China’s Smart Manufacturing Shines Again! Lenovo Group Lights Up the First Chinese “Lighthouse Factory” in the Americas

On September 16, the World Economic Forum (WEF) and McKinsey officially announced the latest list of “Lighthouse Factories,” with Lenovo Group’s Monterrey manufacturing base in Mexico successfully ,becoming the first “Lighthouse Factory” by a Chinese enterprise in the Americas. This milestone demonstrates Lenovo’s continuously evolving strength in its global expansion, marks another leap in its smart manufacturing and global supply chain capabilities, and showcases the powerful capability of Chinese smart manufacturing to be rebuilt overseas, setting a model for Chinese enterprises in digital transformation and intelligent upgrading abroad. Lenovo Group’s manufacturing base in Monterrey, Mexico, established in 2008, covers an area of about 40,000 square meters with two […]

Amlogic Acquires Xinmai Micro for RMB 316 Million, Target Company’s First-Half Revenue Only RMB 680,000

RMB 316 Million Acquisition of Xinmai Micro: The Logic Behind Acquiring a Low-Revenue Target Recently, Amlogic announced its plan to acquire 100% equity of Xinmai Micro Semiconductor (Jiaxing) Co., Ltd. for a total consideration of RMB 316 million in cash. Public records show that Xinmai Micro Semiconductor was established in Zhuhai in August 2021 and relocated to Jiaxing, Zhejiang in January 2025 under its current name. Despite generating only RMB 680,000 in revenue in the first half of 2025, the company has developed rapidly since its establishment, completing three rounds of financing totaling hundreds of millions of yuan within the past year. Investors include renowned institutions such as Walden […]

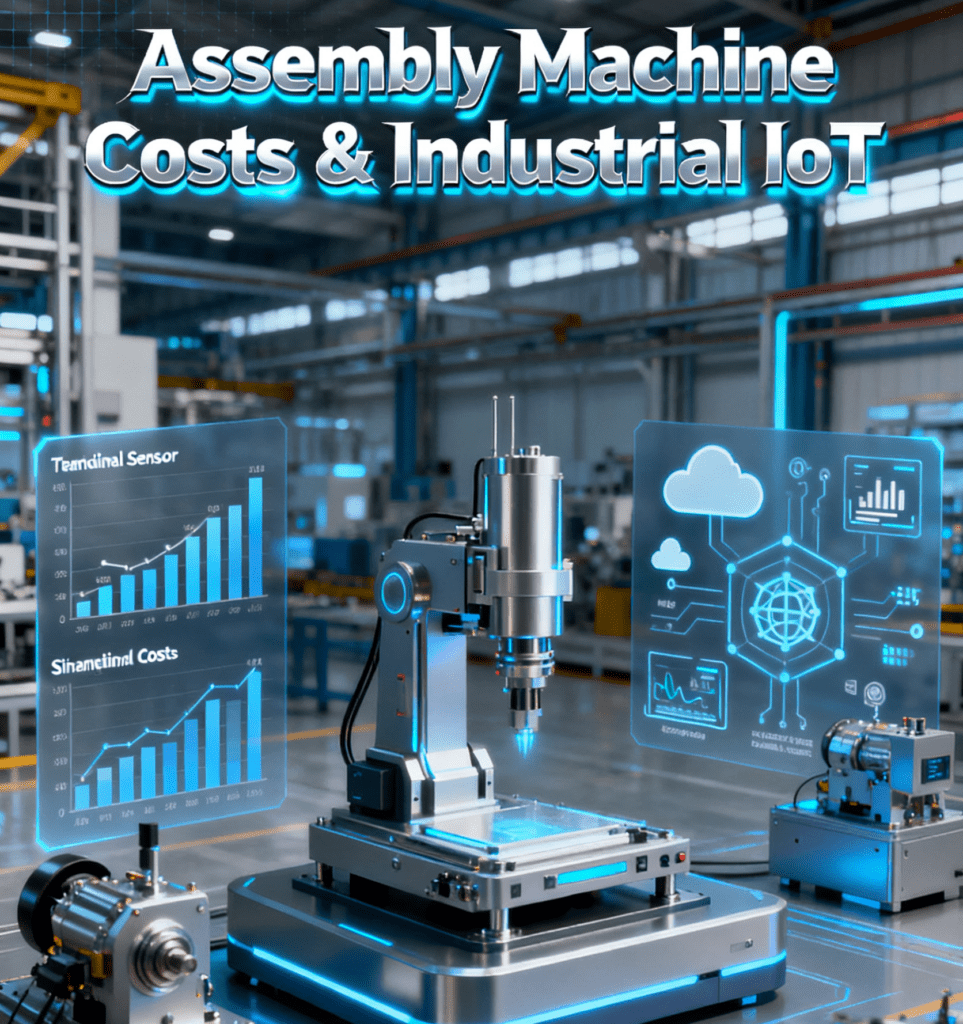

How Much Does an Assembly Machine Cost?

The cost of an assembly machine varies dramatically based on its automation level, complexity, industry use case, and integration with IoT technologies—ranging from tens of thousands to millions of dollars. To provide clarity, here’s a breakdown of common tiers: Semi-Automatic Assembly Machines: Ideal for small-batch production (e.g., manual loading with automated fastening). Costs typically range from $20,000 to $100,000. Examples include tabletop screw-driving machines for electronics or basic conveyor-based part-fitting systems. Fully Automatic Assembly Machines: For high-volume, repeatable tasks (e.g., automotive component assembly or smartphone chip soldering). These integrate robotic arms, vision systems, and inline inspection, costing $100,000 to $500,000+. A fully automated EV battery module assembler, for instance, often […]

What is an Automatic Assembly System?

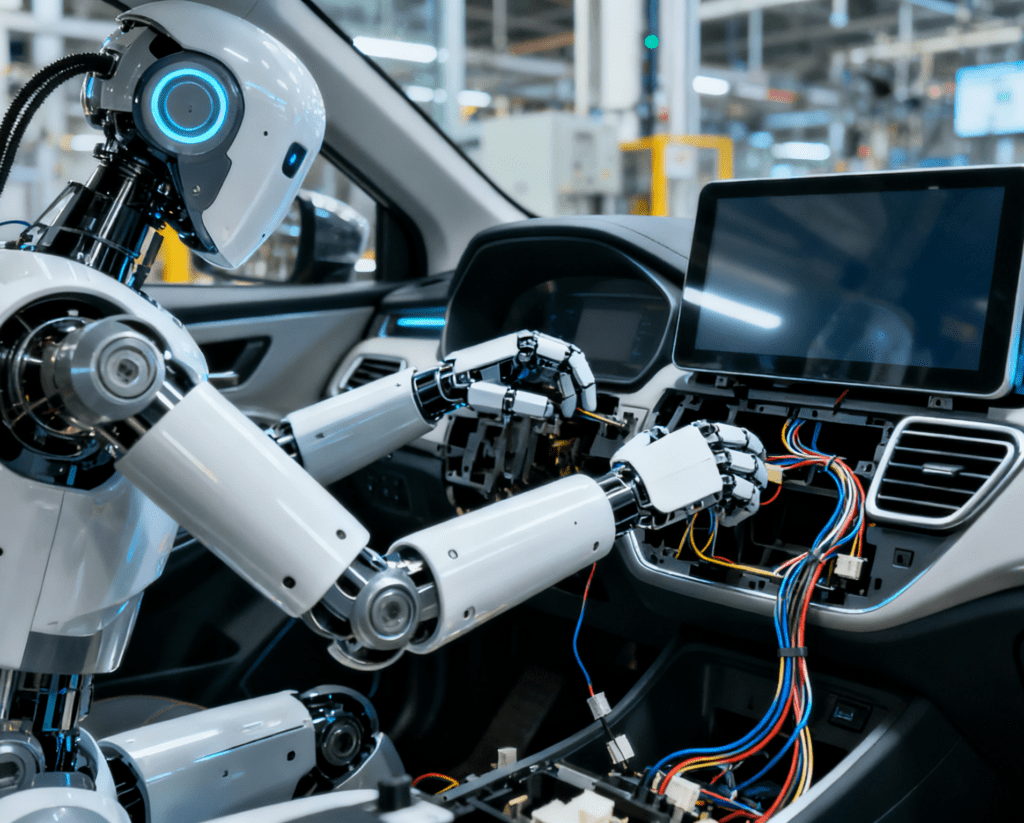

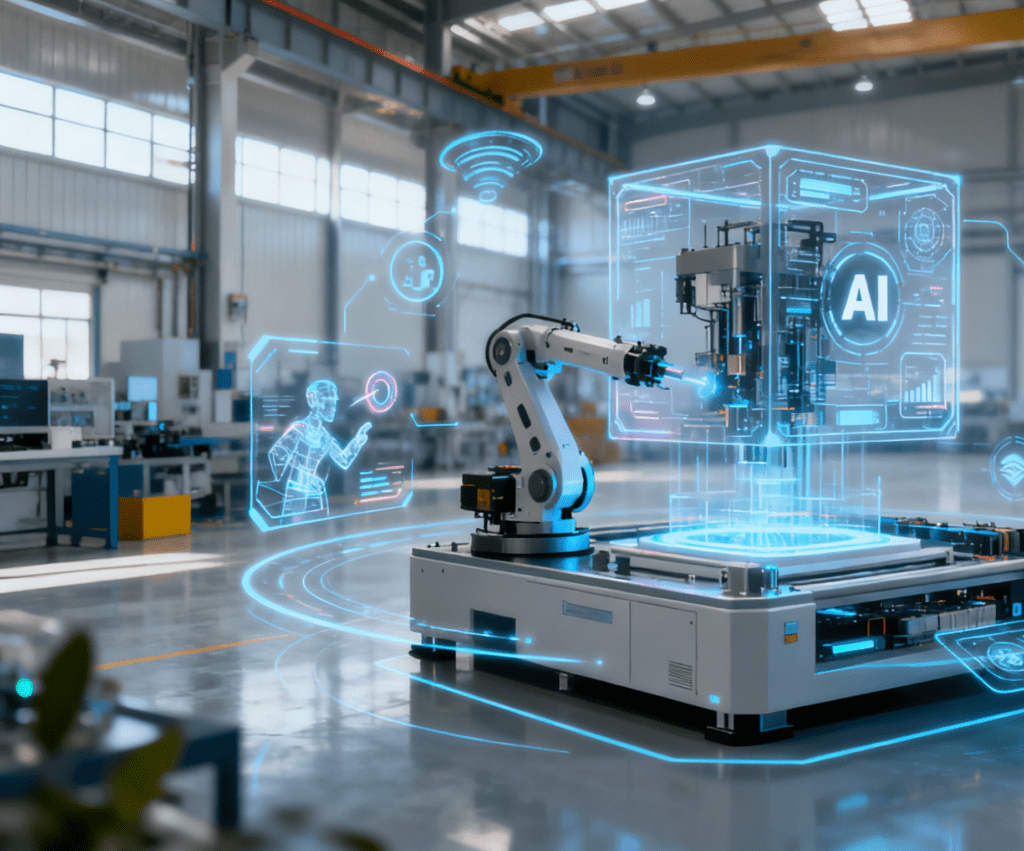

From Robotic Arms to Smart Factories: The Technology Transforming Modern Manufacturing Automatic assembly refers to the use of mechanized and automated equipment to perform various functions in an assembly line or unit. An automatic assembly system carries out a series of automated operations to combine multiple components into a single entity, which can be either a final product or a sub-assembly. It also provides a systematic method for assembling goods that can be completed at least partially without human intervention. In the current era of global smart manufacturing, efficiency, precision, and large-scale production have become the keys to enterprise competitiveness. The automatic assembly system is the core […]

Pillow-type vacuum packaging machine

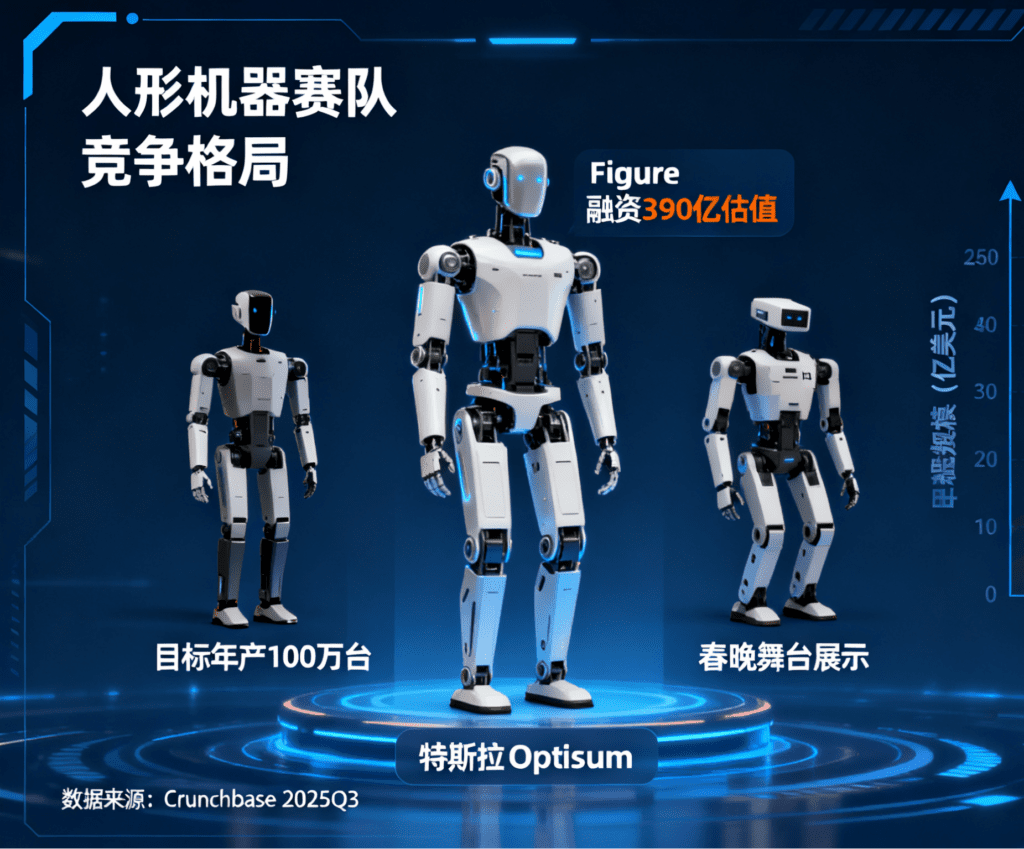

Humanoid Robot Startup Figure AI Raises $1 Billion, Valuation Jumps to $39 Billion

September 17 news, according to foreign media reports, humanoid robot startup Figure AI has raised $1 billion in funding, with the company’s valuation soaring to $39 billion. Figure CEO Brad Adcock announced the news. The $1 billion comes from a Series C round led by Parkway Venture Capital, with participation from heavyweight companies including Nvidia, Salesforce, T-Mobile, and Intel. Figure stated that this funding will drive the expansion of its AI platform Helix and BotQ manufacturing system. The funds will be used primarily for three purposes: Scale humanoid robot applications in homes and commercial operations Figure is expanding BotQ’s manufacturing capacity and real-world deployment to enable robots […]

2025 Yunqi Conference Sneak Peek: These Are the New AI Highlights This Year

“Cloud-Intelligence Integration · Carbon-Silicon Symbiosis”: Guests from 50 Countries + 3 Main Forums, Outlining the Blueprint for AI-Industry Integration As reported on September 16, the 2025 Yunqi Conference will be held in Yunqi Town, Hangzhou, from September 24 to 26. Alibaba Cloud has officially announced the agenda for the main forums at the opening ceremony. With the core theme of “Cloud-Intelligence Integration · Carbon-Silicon Symbiosis”, the three-day conference will not only feature three main forums—”Yunqi Outlook”, “Yunqi Technology”, and “The Immeasurable Value”—to discuss the latest trends in AI, cloud computing, and industrial applications, as well as release core technological products, but also plan over 110 themed sessions focusing on […]

Global Technology News Roundup: AI Investments, Chip Development, and Smart Hardware Innovation

Microsoft, NVIDIA and other tech giants plan over $40 billion in new AI investments in the UK Microsoft announced on Tuesday its plan to invest $30 billion in the UK by 2028 to build its AI infrastructure. This includes $15.5 billion for capital expansion and $15.1 billion for UK business operations. The company stated this investment will enable collaboration with British cloud computing firm Nscale to create the UK’s “largest supercomputer,” equipped with over 23,000 advanced GPUs. NVIDIA, Google, OpenAI, and Salesforce have also announced multibillion-dollar investment plans in the UK, bringing the total new investment to over $40 billion. Musk: AI5 chip design evaluation this Saturday, AI, […]

AI, IoT, and Edge Computing Powering Digital Banking Transformation

Forrester Research’s report “The Future of Digital Banking Experience” reveals how artificial intelligence (AI), the Internet of Things (IoT), and edge computing will completely transform digital banking over the next decade. Analysts believe that as financial institutions evolve these technologies from mere supporting tools to expected experiences and ultimately to agent experiences, trust and transparency will be crucial in driving consumer adoption. Key innovations are reshaping the banking landscape. AI-powered virtual assistants will enhance customer interactions, delivering multimodal, intuitive, and emotionally aware banking experiences. Financial institutions will leverage AI to provide customized insights, while IoT-driven intelligence will enable embedded finance and deliver real-time financial advice based on […]

Empowering the Sanitary Ware Industry with Intelligent Automation

In the sanitary ware industry, the bathroom shower head — a daily-se product closely tied to quality of life — has evolved from a single-function “water outlet tool” to a multi-scenario product integrating constant temperature control, water-saving atomization, and intelligent sensing. However, behind this product upgrade, the traditional manual assembly mode has long been a bottleneck restricting industry development: manual installation of components such as shower heads, hoses, interface valves, and gaskets often faces problems like inconsistent torque (leading to water leakage), misaligned assembly (affecting water flow uniformity), and low efficiency (a skilled worker can only assemble 80-100 units per day). With the surge in market demand for personalized shower […]