Operational Maintenance Strategies for Automation Equipment: The Secret to “Non-Stop” Production Lines

Operational Maintenance Strategies for Automation Equipment: The Secret to “Non-Stop” Production Lines In the competitive landscape of manufacturing, where “efficiency is paramount and costs are strictly controlled”, operational maintenance of automation equipment has evolved from a passive “repair-after-failure” model to a proactive preventive maintenance system. From vibration monitoring to oil analysis, and from AI early warning to digital twins, maintenance technologies are addressing industry challenges of “unplanned downtime, high maintenance costs, and efficiency losses” through three breakthroughs: “condition sensing + intelligent analysis + proactive intervention”, driving equipment management to shift from a “cost center” to a “profit engine”. I. Technical System of Intelligent Maintenance: Closed-Loop Innovation of Sensing, Analysis, and […]

Operational Maintenance Strategies for Automation Equipment: The Secret to “Non-Stop” Production Lines

Operational Maintenance Strategies for Automation Equipment: The Secret to “Non-Stop” Production Lines In the competitive landscape of manufacturing, where “efficiency is paramount and costs are strictly controlled”, operational maintenance of automation equipment has evolved from a passive “repair-after-failure” model to a proactive preventive maintenance system. From vibration monitoring to oil analysis, and from AI early warning to digital twins, maintenance technologies are addressing industry challenges of “unplanned downtime, high maintenance costs, and efficiency losses” through three breakthroughs: “condition sensing + intelligent analysis + proactive intervention”, driving equipment management to shift from a “cost center” to a “profit engine”. I. Technical System of Intelligent Maintenance: Closed-Loop Innovation of Sensing, Analysis, and […]

Application of Cobots: Redefining “Collaboration” Models in Workshops

Application of Cobots: Redefining “Collaboration” Models in Workshops Against the backdrop of exploding demand for “human-machine collaboration” in manufacturing, collaborative robots (cobots) have transitioned from concepts to large-scale applications, emerging as the core solution to resolve the contradiction between “precision operations and human-machine safety”. From electronic component assembly to automotive interior polishing, and from medical device manufacturing to food sorting, cobots have broken through the traditional “human-machine isolation” production model through three breakthroughs: “force-control safety + intelligent interaction + flexible adaptation”, redefining workshop “collaboration” rules and propelling manufacturing into an era of “human-machine integration”. I. Technical Core of Human-Robot Collaboration: Three-Dimensional Breakthroughs in Safety, Flexibility, and Intelligence The essence of […]

Warehouse Logistics Automation Solutions: Reconstructing the Speed Code of E-commerce Fulfillment

Warehouse Logistics Automation Solutions: Reconstructing the Speed Code of E-commerce Fulfillment Against the backdrop of explosive e-commerce growth and deep integration with intelligent manufacturing, warehouse logistics automation has transformed from a “cost center” to an “efficiency engine,” becoming the core solution for enterprises to crack the challenges of “warehouse congestion, labor shortages, and fulfillment delays.” From AGV cluster scheduling to intelligent sorting systems, from automated storage and retrieval systems (AS/RS) to last-mile delivery, automation technologies are redefining the “speed ceiling” of logistics fulfillment through three breakthroughs: “flexible scheduling + intelligent algorithms + digital twin,” driving the industry’s leap from “labor-driven” to “intelligent operation.” I. Technical System of Warehouse Logistics Automation: […]

New Energy Production Line Automation: Driving Efficiency Revolution in Lithium Batteries and Photovoltaics

New Energy Production Line Automation: Driving Efficiency Revolution in Lithium Batteries and Photovoltaics Driven by the “dual carbon goals” and the wave of energy transition, new energy production line automation has become the core engine for industries like lithium batteries and photovoltaics to break through “capacity bottlenecks, precision barriers, and safety risks”. From lithium battery cell lamination to photovoltaic module string welding, and from pole piece cutting to glass packaging, automation technologies are reconstructing the “efficiency ceiling” of new energy manufacturing through three breakthroughs: “micron-level control + intelligent detection + digital twin”, promoting the industry’s leap from “scale expansion” to “quality upgrading”. I. Technical Characteristics of New Energy Automation: Industry […]

Food Packaging Automation Upgrades: End-to-End Innovation from “Productivity Efficiency” to “Safety Protection”

Food Packaging Automation Upgrades: End-to-End Innovation from “Productivity Efficiency” to “Safety Protection” Driven by the food industry’s characteristics of “high-frequency consumption and safety-first”, food packaging automation equipment is no longer just a tool to boost production capacity, but a core barrier building a safety line “from production line to dining table”. From beverage filling to snack sorting, cold chain packaging to ready-to-eat food sealing, automation technologies are 破解 the industry dilemma of “difficulty balancing efficiency and safety” through three breakthroughs: “high-speed precision + aseptic design + intelligent detection”, redefining food manufacturing’s “quality standards”. I. Technical Characteristics of Food Packaging Automation: Industry Adaptation in Three Dimensions Requirements for automation equipment in […]

Innovation in Medical Automation Equipment: Dual Breakthroughs in Compliance and Efficiency

Innovation in Medical Automation Equipment: Dual Breakthroughs in Compliance and Efficiency Under the strict requirements of “high precision, high compliance, and high safety” in the medical industry, medical automation equipment is no longer just an “efficiency tool” but a core infrastructure critical to patient safety and enterprise compliance. From reagent filling to surgical instrument assembly, and from sterile packaging to in vitro diagnostics (IVD) production lines, automation technologies are 破解 the industry challenge of “difficulty in balancing efficiency and compliance” through “micron-level precision control + full-process traceability + aseptic design”. I. Technical Barriers of Medical Automation: Industry Specificity in Three Dimensions Requirements for automation equipment in medical scenarios far exceed […]

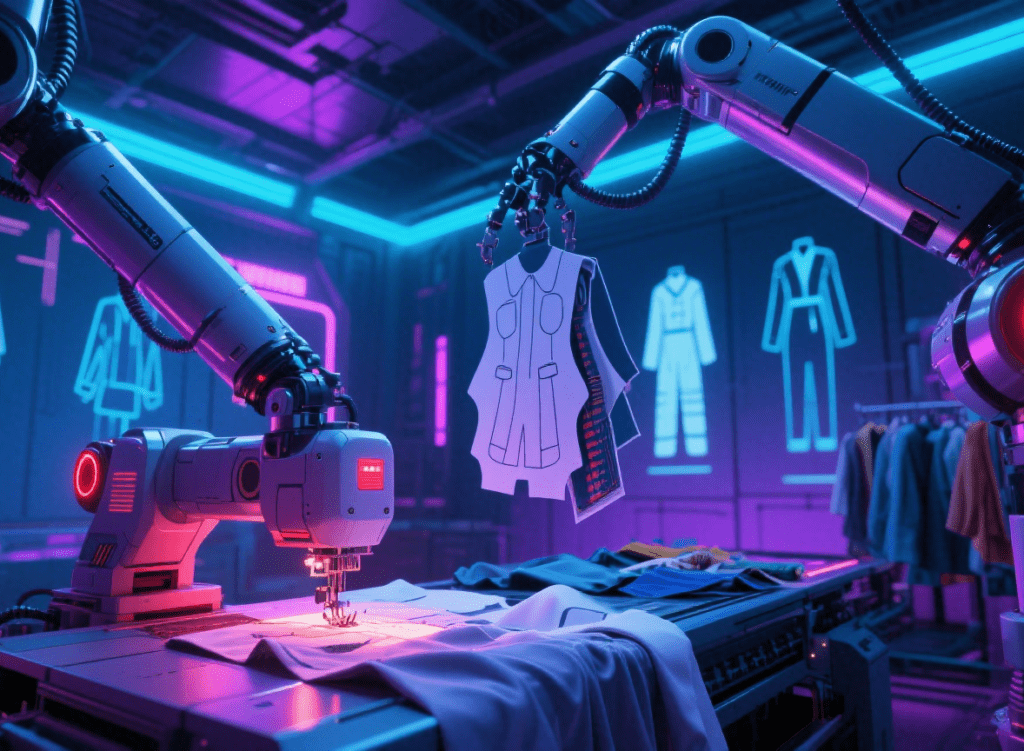

Flexible Automation Production Line Design: Cracking the Dilemma of Multi-Variety Production

Flexible Automation Production Line Design: Cracking the Dilemma of Multi-Variety Production In today’s manufacturing landscape where “multi-variety, small-batch” production has become the norm, the concept of “one production line = N products” is no longer a vision but a survival necessity. The core of a flexible automation production line lies in its “modular architecture + intelligent scheduling,” enabling the line to “transform”—efficiently producing single products, quickly switching between varieties, or even conducting mixed-flow production in the same period. From 3C electronics to automotive parts, medical devices to home goods, flexible lines are redefining the boundaries of “economies of scale.” I. Design Logic of Flexible Production Lines: Hardware “Detachable” + Software […]

Intelligent Visual Inspection System: Equipping Automation Equipment with “Smart Eyes”

Intelligent Visual Inspection System: Equipping Automation Equipment with “Smart Eyes” In automated production lines, “seeing accurately” is the prerequisite for “doing correctly”. The breakthrough of intelligent visual inspection systems has evolved equipment from “blind execution” to “precise perception”—through technologies like 3D structured light and AI defect recognition, it achieves millimeter-level precision inspection within milliseconds, even identifying subtle defects invisible to the human eye. From cracks in electronic chips to medical packaging seals, and from food foreign objects to new energy battery flaws, visual inspection is redefining the “quality defense line”. I. Technological Revolution: Dual Breakthroughs from “Seeing” to “Understanding” The core of intelligent visual inspection lies in the collaborative innovation […]

Industrial Robot Integration Applications: Unlocking the Code for Production Line Automation Upgrades

Industrial Robot Integration Applications: Unlocking the Code for Production Line Automation Upgrades In the new normal of “multi-variety, small-batch” manufacturing, upgrading production line automation is no longer just about “replacing humans with machines.” Instead, it achieves deep integration of hardware, software, and processes through industrial robot integration applications, constructing flexible and efficient production systems. From automotive parts to 3C electronics, and from injection molding to welding, robot integration is redefining the “evolution path” of production lines. I. Technical Architecture of Robot Integration: A Collaborative Revolution of Hardware, Software, and Processes Industrial robot integration is not a “solo operation” of robotic arms but a complex systems engineering: 1. Hardware Layer: Precise […]

The Embryonic Form of Future Factories: How Flexible Automatic Assembly Equipment Defines the Next-Generation Manufacturing Paradigm

The Embryonic Form of Future Factories: How Flexible Automatic Assembly Equipment Defines the Next-Generation Manufacturing Paradigm Introduction As Tesla’s Giga Press die-casts 70 parts into a single vehicle body component, and Siemens’ AMAPOLA project achieves “zero-drawing” autonomous production, flexible automatic assembly equipment is breaking through its positioning as an “efficient execution tool” and evolving into the core engine defining the next-generation manufacturing paradigm. This article delves into the frontiers of technological testbeds, analyzes three disruptive directions—”autonomous decision-making systems,” “bio-manufacturing integration,” and “resilient manufacturing networks”—and combines cases such as Airbus’ “Future Factory” and Boston Dynamics’ robot clusters to reveal the manufacturing revolution from “flexible production” to “intelligent evolution”—the future factory is […]

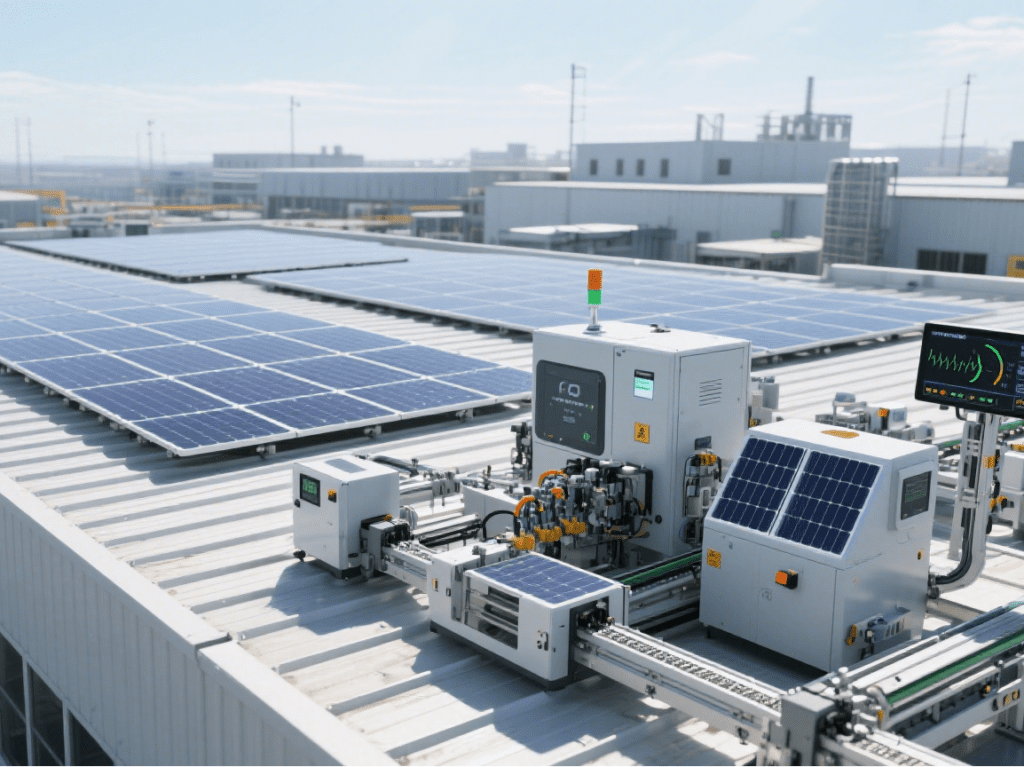

The New Dimension of Sustainable Manufacturing: How Flexible Automatic Assembly Equipment Empowers Green Production

The New Dimension of Sustainable Manufacturing: How Flexible Automatic Assembly Equipment Empowers Green Production Introduction Against the backdrop of the “Double Carbon” goals and the rise of ESG (Environmental, Social, Governance) investment, manufacturing is shifting from “efficiency-first” to “dual-drive of green and efficiency.” With core advantages of “precise control, rapid model switching, and resource reuse,” flexible automatic assembly equipment has become a key solution to address traditional manufacturing pain points of “high energy consumption, excessive waste, and difficult recycling.” This article explores three dimensions—energy optimization, material saving, and circular production—combined with industry practices in photovoltaics, lithium batteries, and electronic recycling, revealing how flexible equipment transforms “green manufacturing” from a concept […]