Logistics Automation Equipment: An Efficiency Revolution from “Warehouse Sorting” to “Full-Link Intelligent Connection”

At 3 a.m., the automated sorting workshop of an e-commerce logistics center in Shanghai remains brightly lit: cross-belt sorters transport packages at a speed of 3 meters per second, the barcode recognition system completes information matching in 0.1 seconds, and the sorting accuracy remains stable at 99.98%; meanwhile, AGV robots independently plan paths through SLAM navigation technology, shuttling between dense shelves to accurately deliver goods to the review station — this scene vividly illustrates how logistics automation equipment is reshaping industry efficiency. Today’s logistics automation has long transcended the mechanical operations of a single link, forming an intelligent network covering the entire “inbound storage – storage – sorting – outbound – distribution” chain.

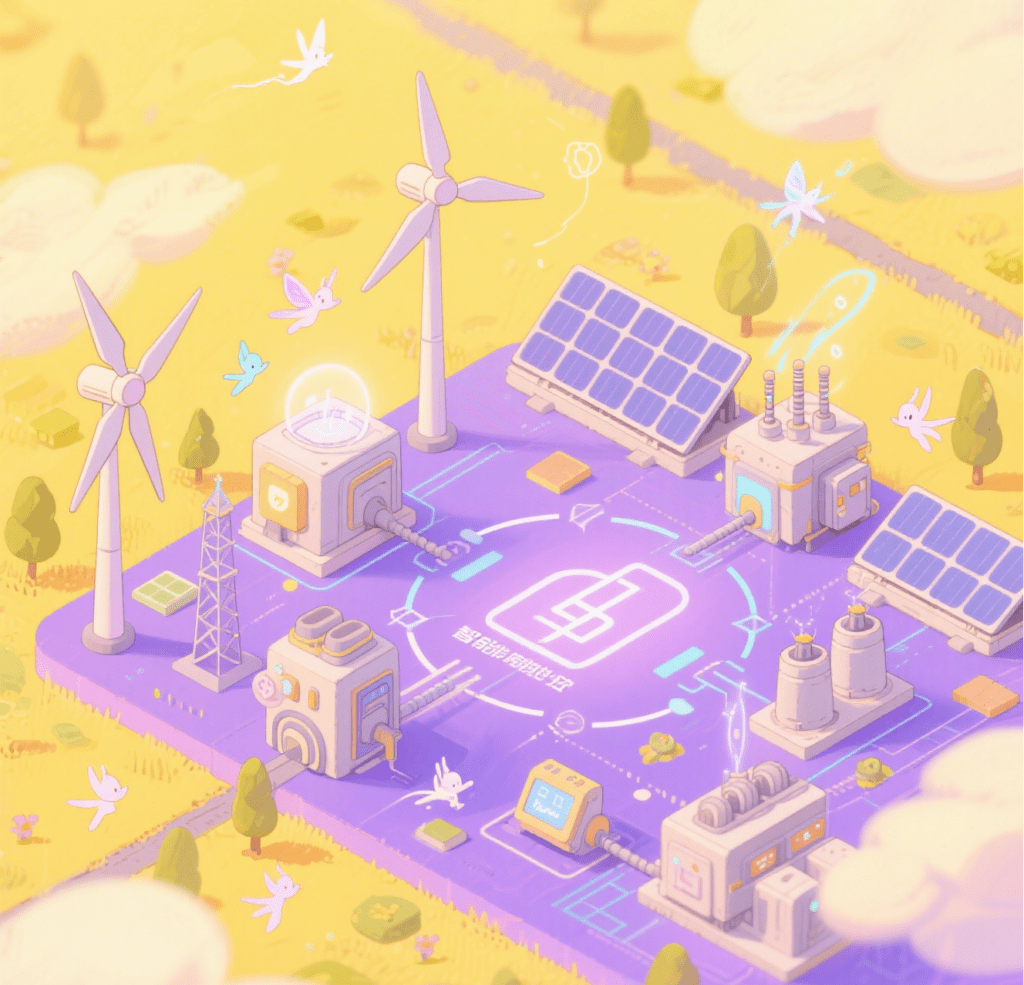

In-depth Penetration of Automation Equipment in the Energy Industry: A Leap from “Stable Supply” to “Intelligent Regulation”

In-depth Penetration of Automation Equipment in the Energy Industry: A Leap from “Stable Supply” to “Intelligent Regulation” At a large wind power base in Inner Mongolia, a group of inspection robots equipped with millimeter-wave radar are slowly climbing along the wind turbine tower. They can penetrate rain and fog to identify 0.2-millimeter cracks on the surface of the blades, and the data is transmitted in real time to the AI diagnostic system in the central control room. Meanwhile, hundreds of kilometers away in a photovoltaic power station, the automatic sun-tracking system adjusts the angle of the solar panels in real time according to the sun’s azimuth, increasing power generation by […]

Industrial Automation Equipment: The In-depth Evolution from “Single Machinery” to “Intelligent Ecosystem”

In the ultra-clean workshop of a semiconductor wafer factory in Shenzhen, an extremely precise automation scene is unfolding: a robotic arm grabs a 300mm-diameter silicon wafer with a repeat positioning accuracy of 0.001mm, and the pressure of the vacuum chuck is controlled at a critical value of 0.05 MPa to prevent damage to the wafer surface. All of this is carried out in an ISO Class 5 clean environment (where the number of particles with a diameter ≥ 0.1μm in each cubic meter of air is ≤ 100) — this is not a laboratory demonstration, but the daily operation of current industrial automation equipment in the field of precision manufacturing. […]

NHS’s Sustainability Revolution: Reimagining Healthcare for a Century to Come

NHS’s Sustainability Revolution: Reimagining Healthcare for a Century to Come As the backbone of Britain’s social fabric, the National Health Service (NHS) has long been a symbol of universal care—free at the point of need, rooted in equity. But today, this 75-year-old institution stands at a breaking point. Demand is soaring: an aging population, complex chronic illnesses, and post-pandemic backlogs have pushed waiting lists to record highs, while funding constraints and staffing crises threaten its ability to deliver on its promise. Lord Darzi’s 2024 investigation laid bare the urgency: the NHS is in “critical condition,” caught between outdated systems and a world that expects faster, more personalized, and more sustainable […]

Rockwell Automation: Harnessing AI to Forge a Sustainable Manufacturing Future

In the global race to tackle climate change, manufacturing stands at a critical crossroads. As one of the world’s most resource-intensive sectors—accounting for nearly a quarter of global energy consumption and 20% of carbon emissions—it faces immense pressure to reconcile production demands with planetary boundaries. Yet within this challenge lies opportunity: artificial intelligence (AI) is emerging as a transformative force, and Rockwell Automation is leading the charge to wield this technology for sustainable manufacturing. By integrating AI into industrial automation, the company is enabling factories worldwide to cut emissions, slash waste, and optimize resource use—proving that profitability and sustainability can thrive hand in hand.

Delta Hosts First “Industrial Automation Technology Conference” —— Driving Manufacturing Upgrading with Standardized Solutions

Delta Hosts First “Industrial Automation Technology Conference” —— Driving Manufacturing Upgrading with Standardized Solutions Currently, competition in the industrial market is intensifying, and the continuous upgrading of industries has brought many new opportunities. For industrial automation enterprises providing automation products and solutions, standing out in the new market competition requires not only rapid response but also comprehensive competition in technology and solutions. The recently launched “Delta Industrial Automation 2025 First Technology Conference” has given the answer. Technology-led growth will be the main direction for industrial automation enterprises in future competition, and solidifying technical solutions into standards and replicating them across industries will be the most effective way to use technology […]

Innovation Trends in the Global Tech World | The Integration of AI and Robotics Technology Accelerates at Full Speed – Observations from the 2025 Munich Automation Exhibition

Recently, reporters from Science and Technology Daily attended the biennial 2025 Munich Automation Exhibition, gaining a profound understanding of how automation technology is driving industrial transformation. The integration of artificial intelligence (AI) and robotics technology is accelerating across multiple fields. Several companies showcased new-generation humanoid robots, but based on on-site performances, there is still much work to be done in terms of technology and practical applications for humanoid robots. Making Automation Technology Smarter Automation is the backbone of modern production and an engine for innovation. Demonstrations by numerous exhibitors showed that machines are increasingly taking on tasks once considered too complex. For example, Intrinsic, a subsidiary of Google, has integrated AI into […]

The Future of Human-Machine Collaboration: Redefining “Labor Value” in Industrial Production

The Future of Human-Machine Collaboration: Redefining “Labor Value” in Industrial Production In the era of smart manufacturing, the anxiety of “machines replacing humans” is being supplanted by a new paradigm of “human-machine collaborative evolution”. Research by the International Labour Organization (ILO) shows that by 2030, human-machine collaboration roles in global manufacturing will grow by 45%. The value of labor is shifting from “repetitive operations” to “creative decision-making”, ushering in a golden age of “human wisdom + machine efficiency”. I. Role Reconstruction: Evolution from “Operator” to “Decision-Maker” The human-machine collaboration scenario in Amazon’s Phoenix warehouse is enlightening: Kiva robots undertake 90% of goods handling, freeing workers from physical labor (walking 20 […]

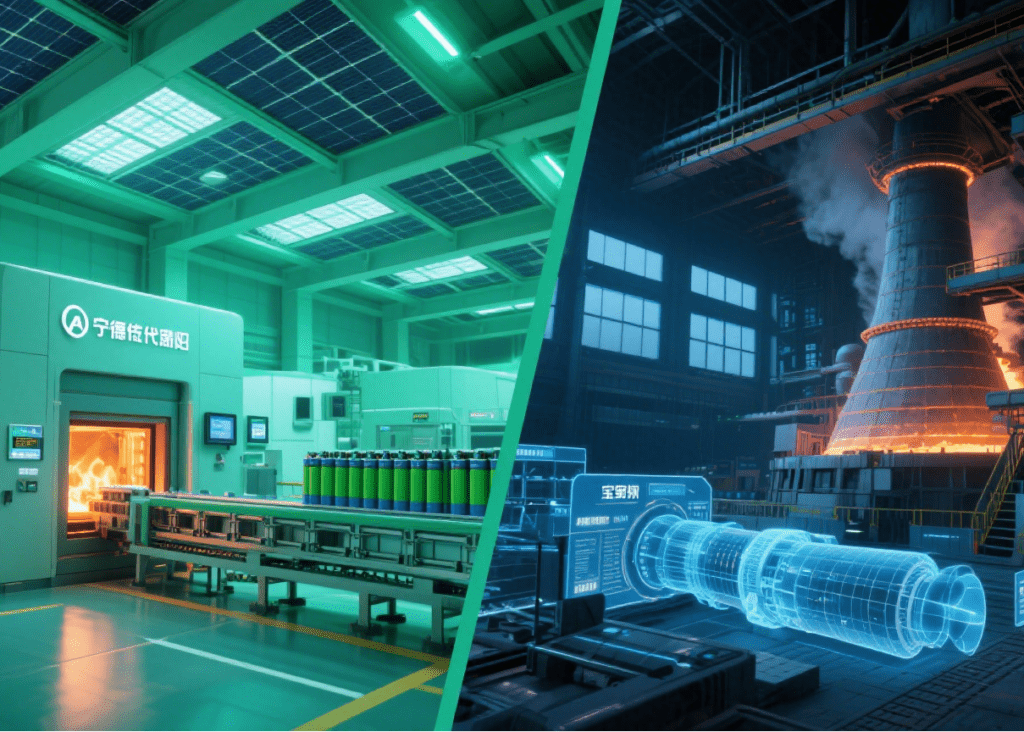

Green Smart Manufacturing: Finding the Optimal Solution Between Efficiency and Sustainability

Green Smart Manufacturing: Finding the Optimal Solution Between Efficiency and Sustainability Driven by the dual goals of “carbon peaking and carbon neutrality” and the ESG (Environmental, Social, Governance) philosophy, green smart manufacturing has evolved from an “enterprise responsibility” to a “core competitiveness”. A series of technological innovations are rewriting the traditional manufacturing image of “high energy consumption and high emissions”, achieving a win-win integration of economic and environmental benefits. 一、Technological Innovation: Full-Process Green Empowerment The lithium battery production line at CATL’s Liyang Plant sets a benchmark for green manufacturing: AI algorithms optimize the oven temperature curve in the coating process in real time, reducing energy consumption per unit by 22%; […]

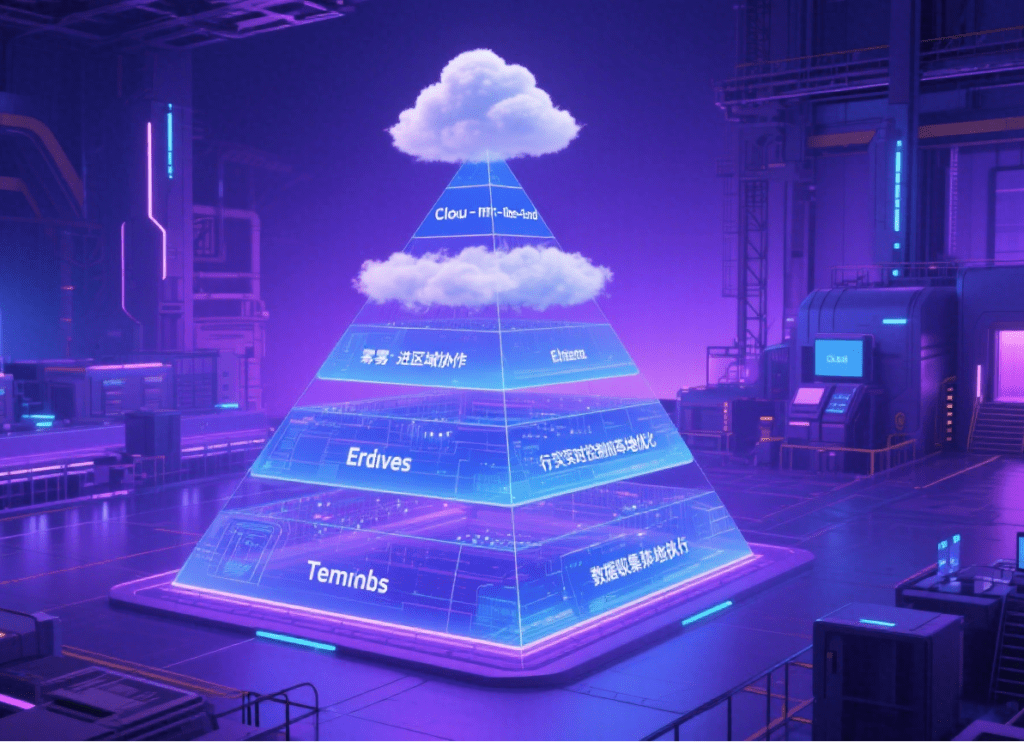

Edge Computing and Fog Computing: Enabling Intelligence to “Burst Locally” at Production Sites

Edge Computing and Fog Computing: Enabling Intelligence to “Burst Locally” at Production Sites In the “data (data )” of smart manufacturing, edge computing and fog computing are becoming key technologies to solve “cloud latency” and “data overload,” constructing a new “cloud-edge collaboration” computing architecture. Gartner predicts that by 2025, 75% of industrial data will be processed at the edge, with its value lying in making intelligent decisions “closer to the site and more responsive.” 一、Technical Essence: From “Distant Water Cannot Quench Near Thirst” to “Localized Resource Utilization” The intelligent warehousing system at Foxconn’s Shenzhen plant reveals the core advantages of edge computing: Each AGV robot is equipped with an edge […]

Flexible Manufacturing System (FMS): Cracking the Industrial Code for “Multi-Variety, Small-Batch” Production

Flexible Manufacturing System (FMS): Cracking the Industrial Code for “Multi-Variety, Small-Batch” Production Under the dual pressure of consumption upgrading and market segmentation, the Flexible Manufacturing System (FMS) has evolved from an “optional solution” to an “essential capability.” Its core value lies in using dynamic response capabilities to resolve the contradiction between “large-scale production” and “personalized needs.” Data from the International Academy for Production Engineering (CIRP) shows that enterprises adopting FMS have shortened product changeover time by an average of 75% and increased capacity utilization by 22%, reshaping the production paradigm of global manufacturing. 一、Technical Architecture: Triple Breakthroughs in Modularity, Intelligence, and Networking The FMS production line at Toyota’s Motomachi […]

Digital Twin: Constructing an Accurate Mirror System of the Real World

Digital Twin: Constructing an Accurate Mirror System of the Real World Digital twin technology, by creating virtual mappings of physical entities, enables real-time interaction and precise reflection between the physical and digital worlds. It has become the “digital rehearsal room” of smart manufacturing, driving the manufacturing industry from “trial-and-error by experience” to “precision prediction”. 一、Design Validation: Low-Cost Trial in the Virtual World Siemens’ digital twin system at the Amberg Factory in Germany sets an industrial benchmark: The virtual factory accurately replicates the operational logic of 1,250 devices and 300 conveyor belts. When planning to introduce a new PLC, engineers first simulate the collaborative effects of material flow, information flow, and […]