SIA Shanghai: Experience the cutting-edge intelligent manufacturing solutions and directly connect with over 1,000 exhibitors for supply and demand matching!

Against the backdrop of the accelerated transformation of intelligent manufacturing, the SIA Shanghai International Intelligent Factory Exhibition & Industrial Automation and Robotics Exhibition (hereinafter referred to as “SIA”) is ready to kick off spectacularly at the National Exhibition and Convention Center (Shanghai Hongqiao) from July 29 to 31, 2025! How will this industry event, which gathers global wisdom and cutting-edge technologies, redefine the future of industrial manufacturing? Let’s unlock the highlights of the exhibition in advance! With the theme of “Digital Intelligence Empowers · Intelligent Manufacturing for the Future”, this exhibition covers an area of 60,000 square meters, gathering more than 1,000 exhibitors including Han’s Laser, Hiwin (Taiwan), THK, Dongguan […]

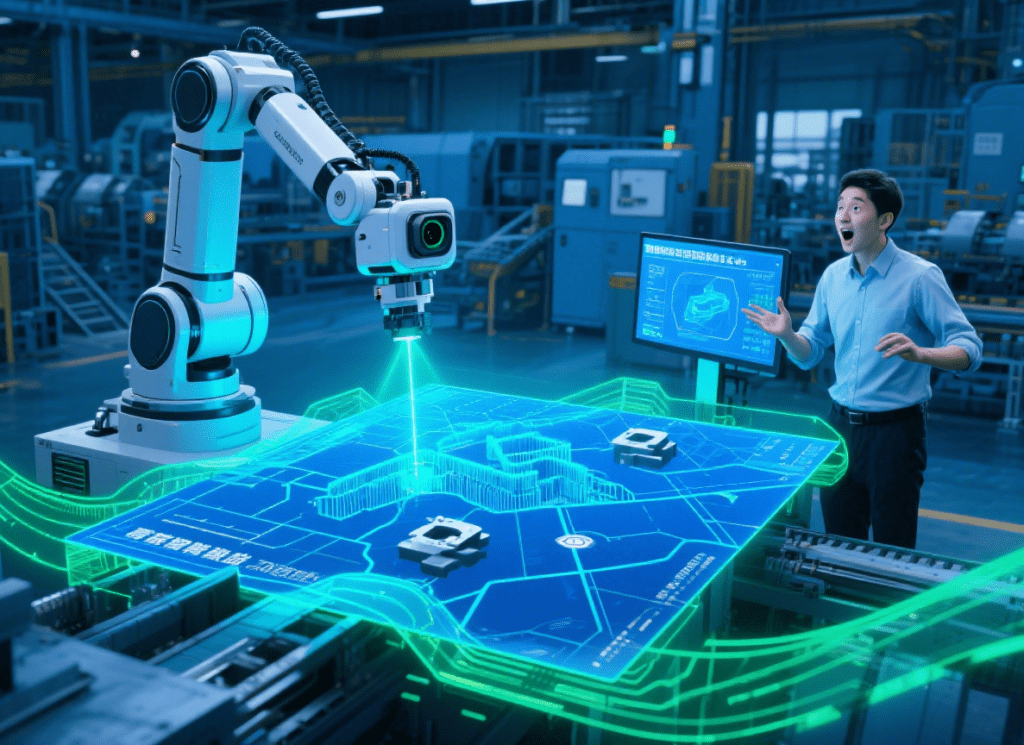

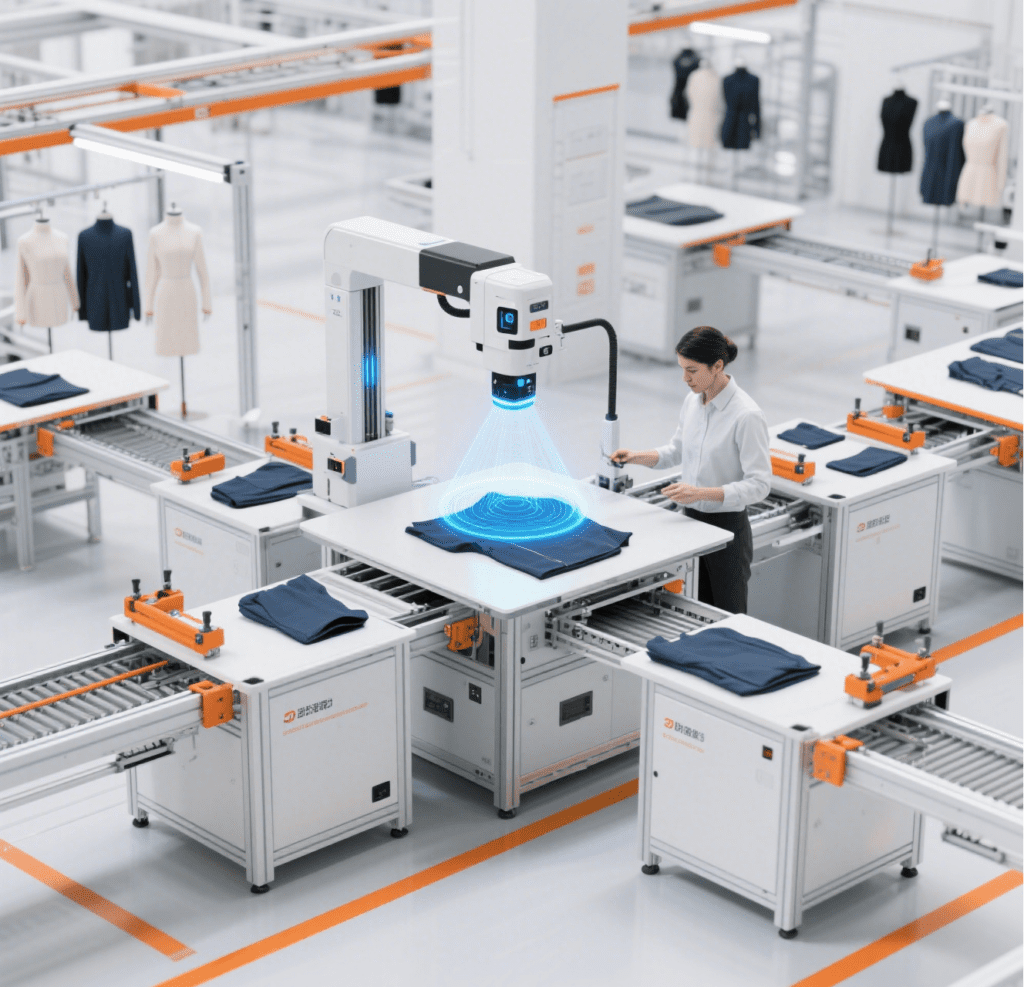

Multimodal Perception Technology for Industrial Robots: Reconstructing the Future of Flexible Manufacturing with AI-driven Vision and Tactility

Lead: In the field of industrial automation, robots are evolving from “repetitive executors” to “intelligent decision-makers”. By virtue of the embodied intelligent industrial robot multimodal perception technology, Fuwei Intelligence breaks through the limitations of traditional single sensors. It endows robots with “human-like tactile sensation” and environmental adaptability by integrating multi-dimensional perception capabilities such as vision, force perception, and lidar, providing revolutionary solutions for scenarios such as flexible manufacturing and precision assembly. In the field of industrial automation, robots are evolving from “repetitive executors” to “intelligent decision-makers”. By virtue of the embodied intelligent industrial robot multimodal perception technology, Fuwei Intelligence breaks through the limitations of traditional single sensors. It endows robots […]

ABB Launches PoWa Collaborative Robot Series in China

Lead: Building on its 30-year leadership in China’s robotics industry, ABB has launched a new series of collaborative robots, primarily targeting China’s rapidly growing general industrial sectors, including consumer goods and electronics manufacturing. The new PoWa collaborative robot series is built for compact environments, especially suitable for tasks with extremely high requirements for speed, collaboration, and efficiency, including applications such as rapid pick-and-place, palletizing, machine tending, arc welding, and screw driving. “The Chinese collaborative robot market is experiencing explosive growth, and customer needs have evolved from simply pursuing speed and payload to a comprehensive consideration of 极简 operation, compact space, and high performance,” said Sami Atiya, President of ABB’s Robotics […]

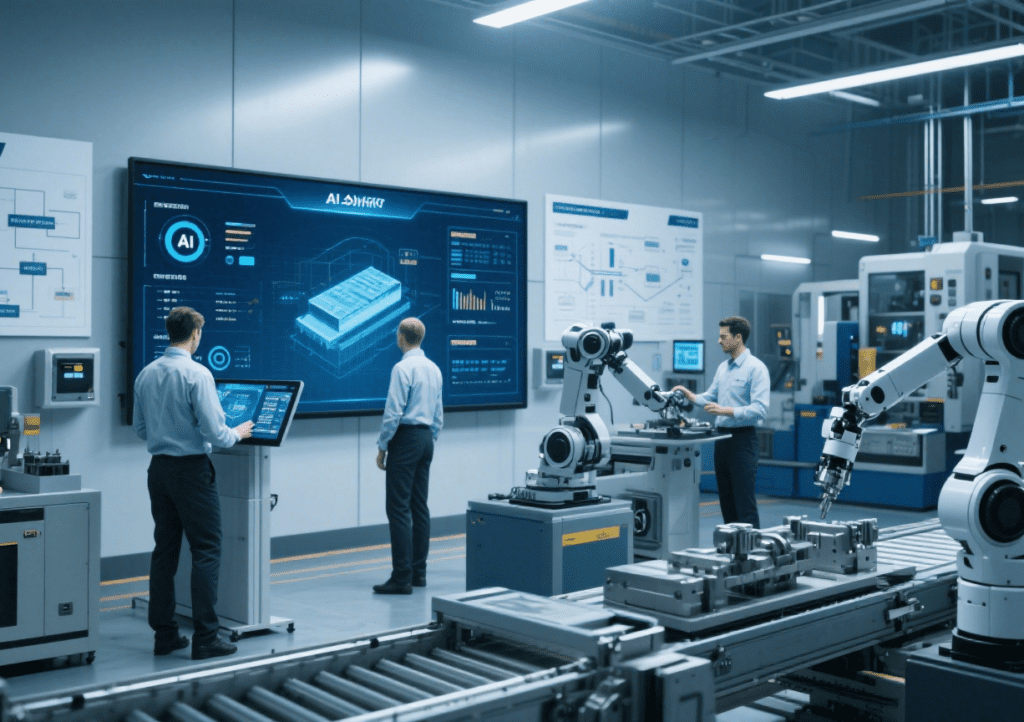

Enhancing Workshop Production Efficiency with Artificial Intelligence

Introduction: At the forefront of the Artificial Intelligence (AI) revolution, concerns have arisen about whether AI will replace human labor. However, upon careful consideration, applying AI to component manufacturing does not mean completely replacing personnel and processes with automation; on the contrary, AI can double efficiency and enhance production performance by strengthening existing systems. At the forefront of the Artificial Intelligence (AI) revolution, concerns have emerged regarding whether AI will replace human workers. Nevertheless, upon closer inspection, the application of AI in component manufacturing does not signify the complete replacement of personnel and processes with automation; instead, AI can multiply efficiency and improve production effectiveness by enhancing existing systems. Take […]

Chinese Team Unveils World’s First Programmable All-Optical Signal Processing Chip

Lead: On July 10th, according to scitechdaily, a Chinese research team consisting of institutions such as Huazhong University of Science and Technology, Shanghai Jiao Tong University, University of Electronic Science and Technology of China, and Nankai University has successfully developed the world’s first programmable single-chip All-Optical Signal Processing (AOSP) chip. It supports optical filtering, signal regeneration, and logical operations, breaking the limitation of traditional silicon photonics that require “optical-electrical-optical (O-E-O)” conversion. This allows data to remain in an optical signal state from input to output, moving towards a new high-speed computing architecture without the need for switches. On July 10th, according to scitechdaily, a Chinese research team composed of Huazhong […]

From Manual Programming Rules to AI Visual Perception: Unsupervised Detection Sparks a Boom in Product Quality Control

In the long evolution of manufacturing, product quality control has always been the core lifeline. In the early days, the maintenance of this lifeline was highly dependent on “manual programming rules”. Engineers, as designers of precision instruments, had to convert every possible product defect into machine-recognizable logical instructions. In the field of visual inspection, this meant writing complex judgment codes for specific product dimensions, colors, scratches, or shape abnormalities, with rules that were both strict and rigid. Of course, manual programming rules are not without advantages. Their strength lies in controllability, but when faced with product model changes, light variations, or unforeseen defect forms, engineers need to repeatedly debug the […]

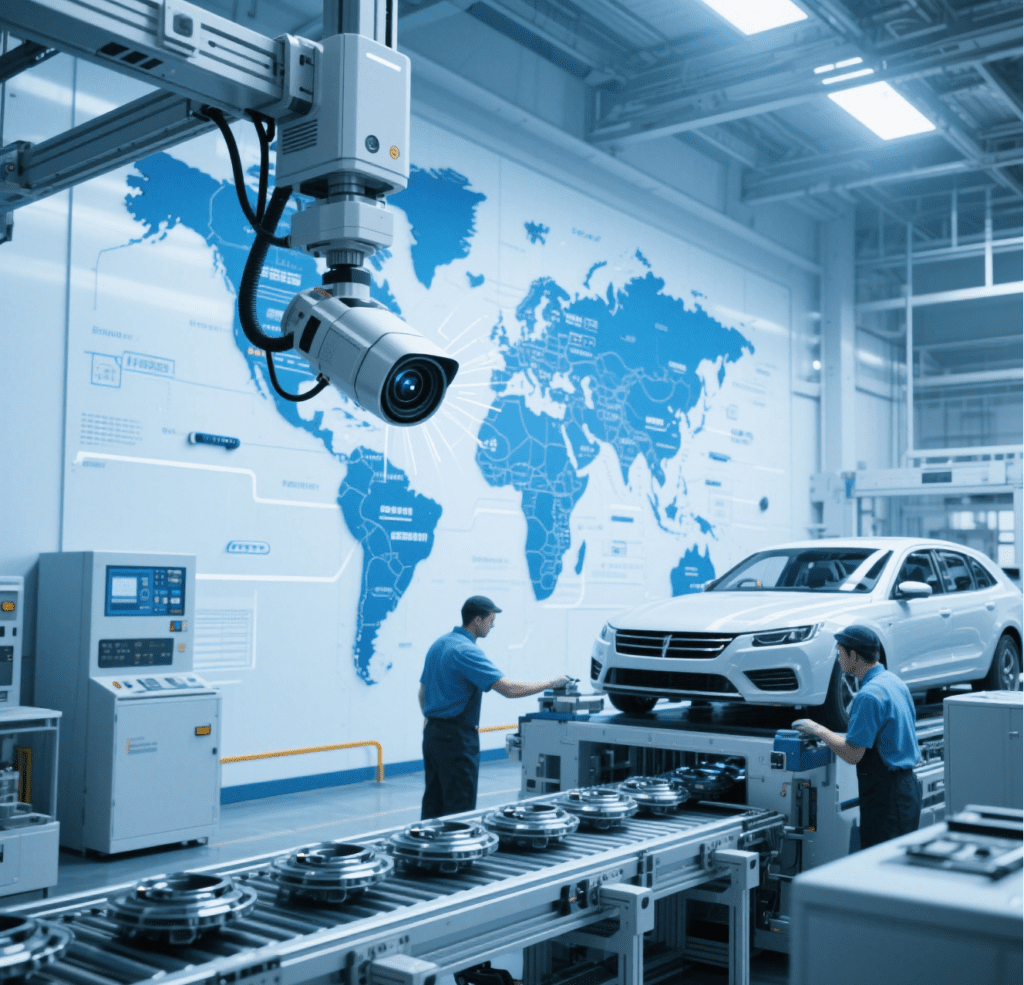

Another Revolution in Production Lines: Intelligent Industrial Control Machine Vision Systems Restructure the Global Industrial Chain

In an era where artificial intelligence technology dominates headlines, production lines are undergoing another profound revolution. The essence of this transformation lies in “data defining manufacturing” — ing the physical world with digital models through intelligent machine vision systems, and driving the industrial chain to shift from cost orientation to value innovation. The evolution history of machine vision is a microcosm of industrial automation evolving from “mechanical arms” to “smart eyes”. Around 2000, machine vision technology began to enter the Chinese market. In the first decade, its development was relatively slow. However, after 2012, driven by the booming development of domestic 3C, lithium battery, photovoltaic and other industries, as well […]

New technological achievements industrial production automation

New technological achievements empower industrial production automation: Intelligent upgrading leads the new future of manufacturing Driven by the wave of the Fourth Industrial Revolution, the global manufacturing industry is undergoing a profound transformation from mechanization to intelligence and networking. Recently, Chinese technology enterprises in multiple fields have successively released breakthrough achievements in the field of industrial automation, covering core areas such as intelligent robots, industrial Internet platforms, and digital twin technologies, marking that China’s industrial production automation process has entered a new stage of “all-factor collaboration”. Robot cluster operations break through efficiency limits In an automobile parts factory in the Yangtze River Delta, the latest generation of collaborative robot clusters […]

Entering the Smart Factory to Build Flexible Production Lines and Tackle the “Impossible Triangle”

How can digitalization make automobile parts manufacturing plants smarter and more efficient? Stepping into the Shanghai Intelligent Factory of United Automotive Electronics Co., Ltd. (UAES), the “lights-out production line” for key new energy vehicle electronic control components operates efficiently. Precision machining processes are intelligently completed by robots, while driverless AGV carts navigate through the facility, handling materials, loading and unloading, and cooperating seamlessly with on-site staff. A set of data is even more intuitive: direct labor productivity increased by 21%, production and operation indirect staff efficiency rose by 28%, overall equipment efficiency (OEE) improved by 15%, design and engineering costs decreased by 21%, scrap rate reduced by 4%, inventory holding […]

The Flexible Smart Manufacturing Revolution: How AI Dynamic Scheduling Boosts Energy Storage Factory Changeover Efficiency by 60% and Breaks the 8-Minute Order Response Barrier

Thousands of customized orders pouring in simultaneously, with production lines completing dynamic restructuring in 53 seconds—not a sci-fi movie, but the daily reality of AI-powered smart energy storage factories. In a super factory for energy storage batteries in Jiangsu, real-time data streams flash across huge screens in the central control room. An urgent order enters the system, and the AI scheduling engine kicks into action instantly: 0.2 seconds to complete process analysis, 3.7 seconds to generate 128 scheduling plans, and 7 minutes and 48 seconds later, the production line has switched to manufacturing products of the new specification. The entire process requires no manual intervention, and changeover losses are nearly […]

Flexible Automation: A Bridge from Manual to Full Automation, Unveiling Its Key Role and Development Prospects!

Recently, reports on autonomous driving technology and automated equipment have been emerging constantly. Researchers predict that by 2025, there will be approximately 8 million unmanned or semi-unmanned vehicles on the road. However, this vision of full automation still has problems in practical applications where many local scenarios cannot be fully connected, making overall automation face risks such as local downtime or other issues. This also leads to discussions on the stability, characteristics, and future development prospects of flexible automation equipment. 01 Local Downtime: A Bottleneck for Overall Automation Fully automated equipment such as self-driving cars and automatic delivery vehicles need to go through the autonomous driving levels defined by SAE […]

Ultra-High Precision Turbine Blade Flexible, Efficient, and Intelligent Manufacturing Unmanned Workshop——Case Display of “Progress in China’s Intelligent Manufacturing Technology”

Entering the 21st century, intelligent manufacturing, as a new production method integrating a new generation of information technology with advanced manufacturing technology, has become the core driving force of the new round of industrial revolution. From automated production lines to intelligent robots, from big data analysis to the Internet of Things technology, and from machine learning to the application of artificial intelligence, intelligent manufacturing is constantly promoting traditional manufacturing into a new era of more intelligent, efficient, and sustainable manufacturing. From 2017 to 2024, the Intelligent Manufacturing Alliance of Chinese Societies (IMAC) continuously carried out the “Case Study on Progress in China’s Intelligent Manufacturing Technology” and selected a total of […]