Uncovering the Secret Behind Efficient Production Lines: The Value of Custom Non-Standard Automated Equipment

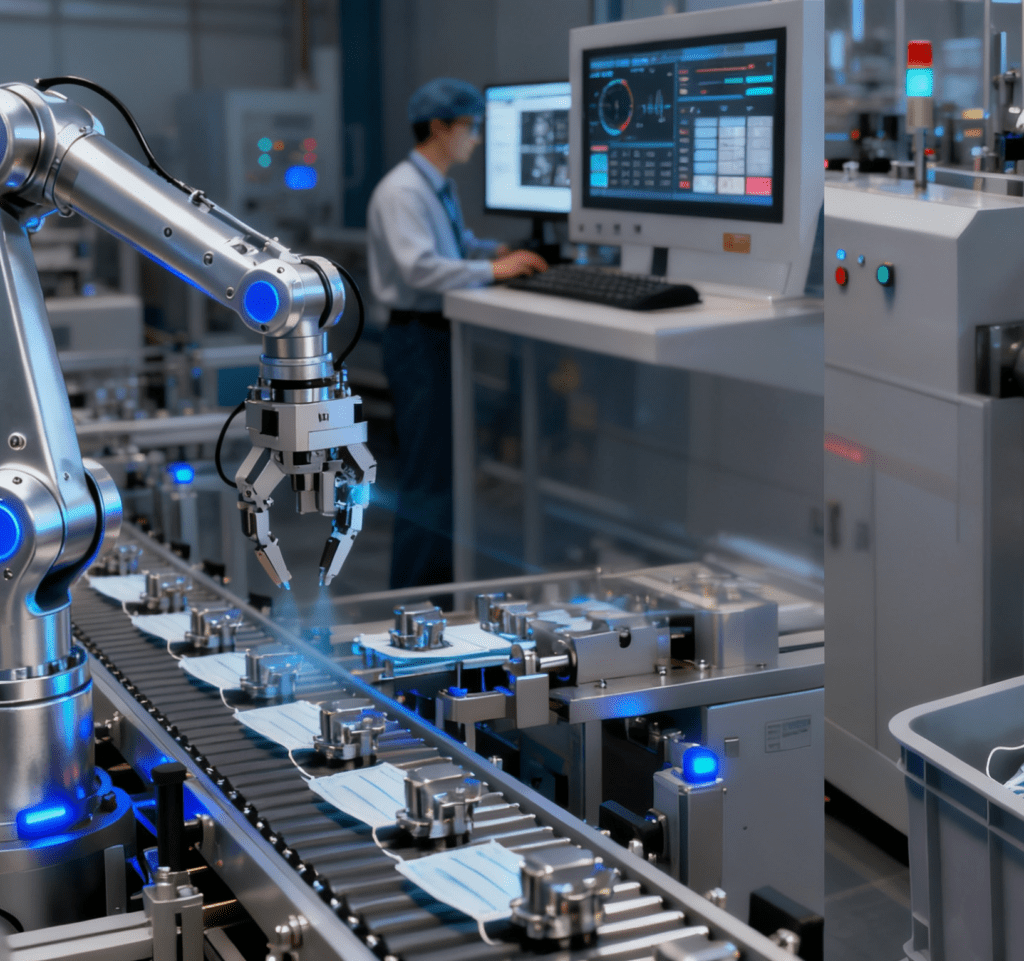

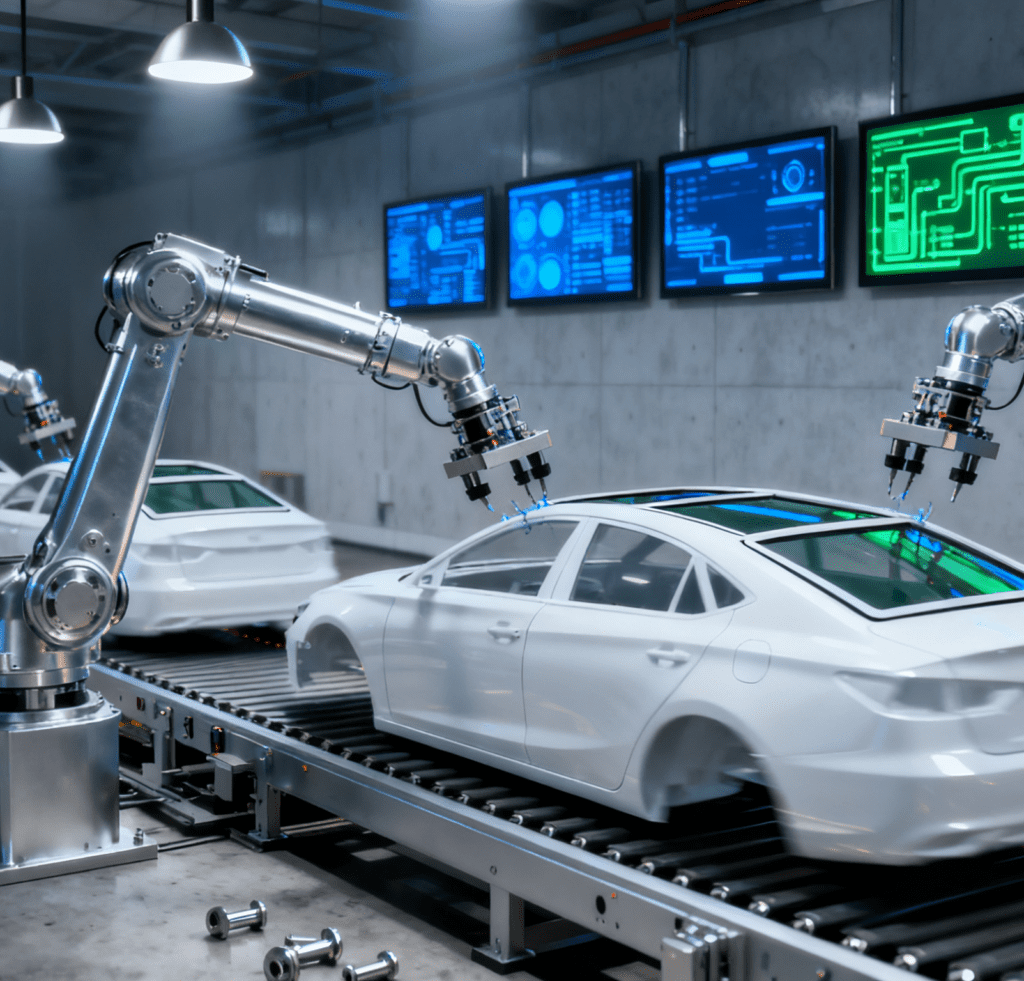

In the process of the manufacturing industry’s transformation towards intelligence and flexibility, the customization of non-standard automated equipment is no longer merely a technical choice, but a strategic decision. Behind every efficient production line lies an often-overlooked “invisible engine” — the customization of non-standard automated equipment. These mechanical devices, tailored to the unique needs of enterprises, are redefining the competitive boundaries of the manufacturing industry. In today’s increasingly fierce manufacturing competition, enterprises’ pursuit of production efficiency has entered an intense stage. From precision component processing to large-scale assembly, solutions like custom non-standard CNC Lathe Automatic Loading & Unloading Systems have become a key force in breaking bottlenecks, as they address […]

Pilz: Addressing New Challenges in Industrial Cybersecurity with One-Stop Solutions

In today’s era of rapid development in industrial automation, the importance of machine safety is self-evident. However, have you realized that focusing solely on “safety” in the traditional sense is no longer sufficient? We are in an era of transformation—epitomized by innovative manufacturing frameworks like the New Ford Universal EV Production System—where intelligent, interconnected production lines demand that machine safety be closely integrated with industrial cybersecurity to provide comprehensive protection for personnel, equipment, and data. As automakers and manufacturers worldwide adopt modular, scalable production systems (such as Ford’s universal EV platform) to boost efficiency and flexibility, the interconnection of machinery, data sharing across production nodes, and remote operation capabilities have […]

Thermal Efficiency Reaches 48%! Chery’s European Brand Launches New Engine

On October 24th, according to reports from overseas automotive media, Omoda & Jaecoo (a European-focused brand under Chery) unveiled an internal combustion engine with an ultra-high thermal efficiency of 48% at the 2025 International User Summit. Although electrification remains the core direction of Chery Group’s long-term strategy, Omoda & Jaecoo is also investing heavily in the optimization of traditional internal combustion engines. The brand believes that hybrid power will still be the most practical path to reducing global energy consumption in the next few years. In practical use, every 1 percentage point increase in thermal efficiency can reduce fuel consumption by approximately 2.5%. Compared with the current industry […]

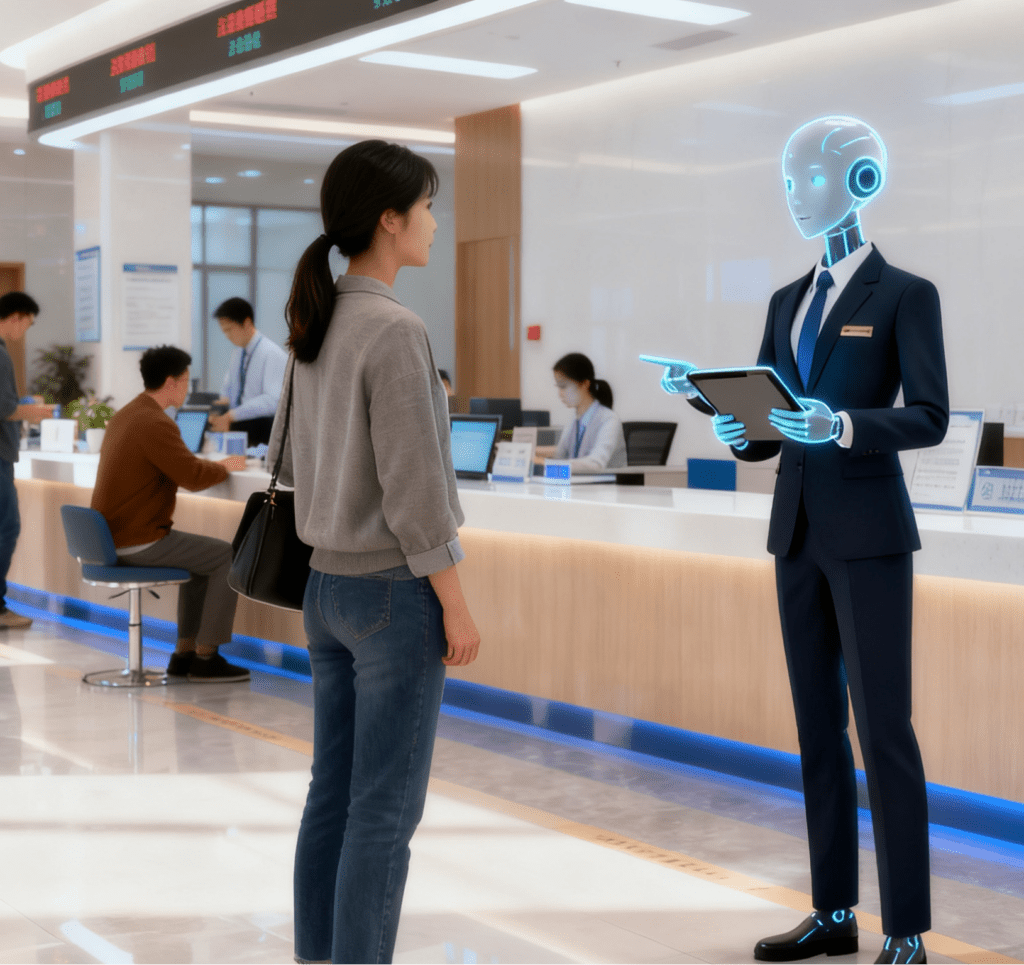

“Zero-Threshold” Creation Arrives: The Digital Human Industry “Stands” at the Critical Point of Large-Scale Development

During this year’s Double 11 shopping spree, JD.com launched the “Zero-Frame Start” digital human mini-program, which attracted widespread attention from merchants and users. In particular, its “Everything Has a Soul” campaign opened up AI digital human technology to merchants and ordinary users, enabling “zero-threshold” creation for all and unleashing the convenience and popularization potential of digital human technology. Digital humans have become one of the key future industrial directions fostered at the national level. This technology, once only a concept in science fiction, has now moved from sci-fi to reality and been widely applied in various fields such as e-commerce, finance, healthcare, culture and entertainment, education, and government services. […]

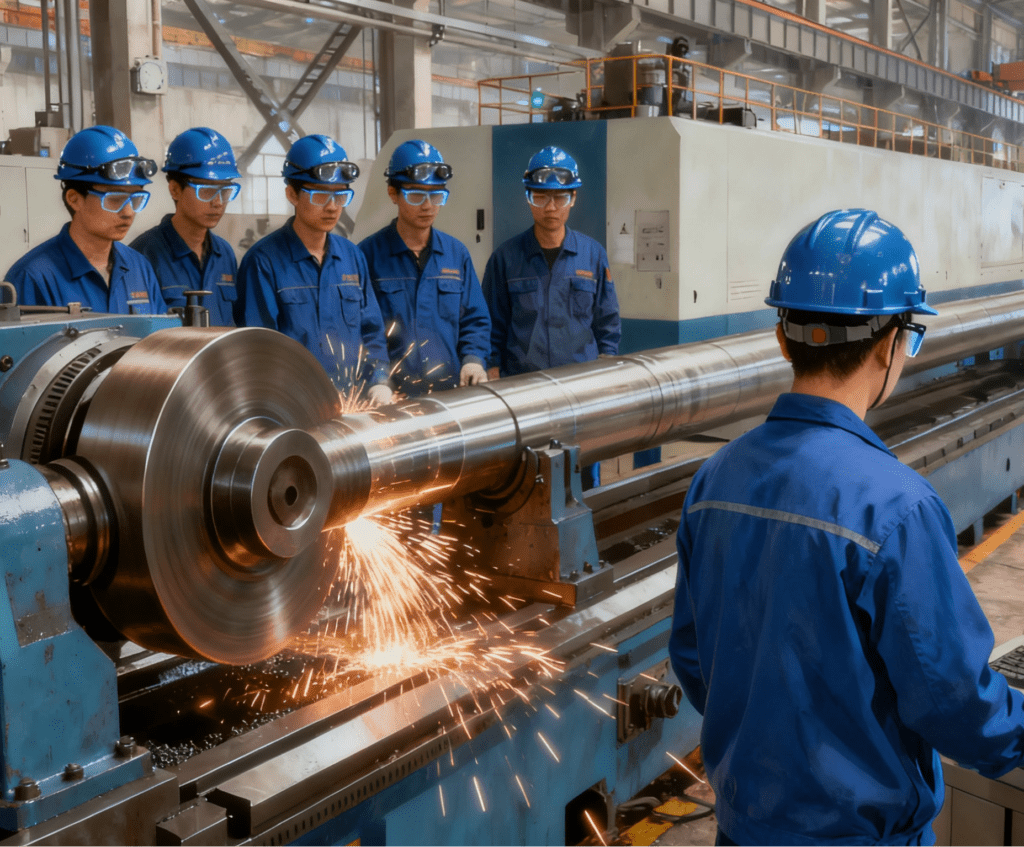

Dalian Rubber & Plastics Solves High-Precision Machining Challenge of Ultra-Long and Ultra-Thin Mandrels

Technological Breakthrough Dalian Rubber & Plastics Co., Ltd., a subsidiary of Dalian Heavy Industry Equipment Group, has developed four sets of new synthetic resin extrusion granulation units for a domestic petrochemical enterprise. As a core project this year, these units boast extremely high technological standards and market value. To meet the performance requirements of the units and effectively produce qualified special resin particles, the units adopt ultra-long, ultra-thin mandrels with an ultra-large length-to-diameter ratio. High-precision machining of such special mandrels has long been recognized as a major challenge in the industry, posing significant difficulties for Dalian Rubber & Plastics. Core Challenges: Ultra-Large Aspect Ratio and Incoming Material Warpage […]

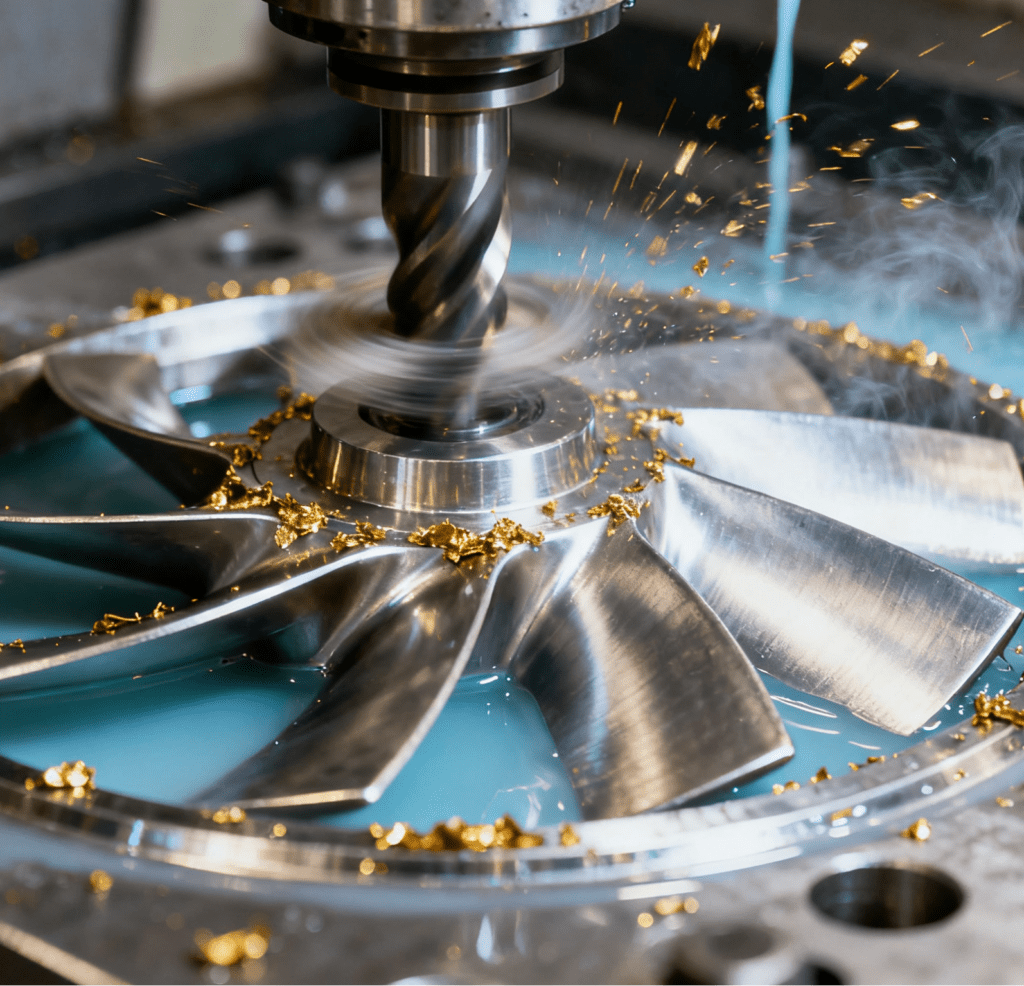

Implementation Plan of Multi-Axis CNC On-Machine Measurement and Adaptive Machining Integration Technology

In modern manufacturing, the requirements for machining accuracy and efficiency of complex parts are becoming increasingly stringent, and the traditional step-by-step measurement and machining methods can hardly meet the demands. The multi-axis CNC on-machine measurement and adaptive machining integration technology is precisely the key solution to address this challenge. This technology skillfully integrates a high-precision measurement system directly into a 5-axis CNC machine tool, enabling real-time monitoring of the workpiece status during the machining process. Through intelligent algorithms for real-time analysis of the collected data, the system can dynamically adjust the subsequent machining path, realizing a true closed-loop control of “measurement-feedback-compensation”. This closed-loop control mode is the core to improve […]

RoboSense Enters Strategic Cooperation with ASENSING

Official Announcement of Strategic Cooperation: Jointly Developing Multi-Modal Sensor Fusion Solutions RoboSense and ASENSING officially announced the establishment of a strategic cooperation. Under this cooperation, the two parties will deeply integrate RoboSense’s strengths in the field of lidar perception with ASENSING’s expertise in precision inertial navigation. They will jointly develop multi-modal sensor fusion solutions for areas such as embodied intelligence and industrial robots, pushing the performance boundaries of robot perception systems in complex scenarios and accelerating their large-scale full-scenario implementation and application. Notably, the multi-modal sensor fusion solutions co-developed by the two parties will also simplify the practical operation of end users—for example, in industrial robot deployment, the integrated […]

Deepening Medical Precision Machining, Safeguarding Life and Health with Precision

In today’s rapidly developing medical industry, from minimally invasive surgical instruments to implantable medical devices, the performance of every core component is directly related to patients’ life safety and treatment outcomes. The foundation of all this relies on the high-standard machining of precision medical parts. Compared with ordinary industrial precision parts, precision medical parts not only need to meet strict dimensional tolerances but also take into account special requirements such as biocompatibility and corrosion resistance stability. This makes “precision machining” no longer a mere technical indicator, but a core link that bears medical responsibilities. Taking the end effector parts of surgical robots as an example, their motion precision directly […]

5-Axis Machining Center: A Practical Tool Unlocking New Heights in Precision Machining

In the field of precision manufacturing, “millimeter-level precision” can no longer meet the demand. From aero-engine blades and medical device artificial joints to complex cavities of automotive molds and microstructures of electronic components, all require “micron-level” machining precision. However, the traditional machining mode has long been trapped by three major challenges: complex parts require multiple clamping operations, leading to accumulated precision errors; switching between multiple processes wastes a lot of production time; and machining at special angles requires custom fixtures. The 5-axis machining center, with its core capabilities of “multi-axis linkage, one-time forming, and stable high-precision output”, has become a key piece of equipment to break through these bottlenecks. […]

German Auto Parts Supplier Webasto Reaches Restructuring Agreement with Banks

According to Bloomberg reports, German auto parts supplier Webasto has secured unanimous approval from all stakeholders for a restructuring agreement. Under the agreement, its shareholders will transfer a large number of their shares to a trustee. To strengthen operational efficiency amid restructuring and mitigate the impact of rising production costs, Webasto has been upgrading its core production lines for automotive roof and heating systems with automatic loading and unloading equipment. This equipment integrates robotic arms, conveyor systems and intelligent sensing technology to realize unmanned operation in raw material feeding, semi-finished product transfer and finished product stacking, reducing manual labor costs by about 25% while cutting down loading-unloading errors that lead to […]

German Auto Parts Supplier Webasto Reaches Restructuring Agreement with Banks

According to Bloomberg reports, German auto parts supplier Webasto has secured unanimous approval from all stakeholders for a restructuring agreement. Under the agreement, its shareholders will transfer a large number of their shares to a trustee. Notably, as Webasto focuses on optimizing core production capabilities amid restructuring—especially for high-precision auto components like automotive roof systems and heating system parts—it has continued to invest in key manufacturing equipment such as the High Precision Visual Inspection Labeling Machine. This machine integrates advanced machine vision technology to automatically detect surface defects, dimensional deviations, and assembly accuracy of auto parts, while synchronously completing high-precision labeling of product information (e.g., batch numbers, quality certifications). It […]

2025 Yangtze River Delta International Chemical Industry Exhibition to Kick Off Soon, Jointly Exploring a New Future for the Industry

Nanjing, an ancient capital, is set to host a grand event that will lead the future of the industry – the 2025 Yangtze River Delta International Chemical Industry Exhibition. With the theme of “Innovation-Driven Green Transformation · Collaborative Creation of the Chemical Industry’s Future”, the exhibition will be held at Nanjing Airport International Expo Center from November 4 to 6. Breaking away from the framework of traditional exhibitions, this event focuses on building a platform for enterprise connection and cooperation. By integrating industry resources, reconstructing the cooperative ecosystem, promoting technological innovation, and unlocking collaborative development mechanisms, it will deeply explore the core value of high-quality industrial development and inject strong […]