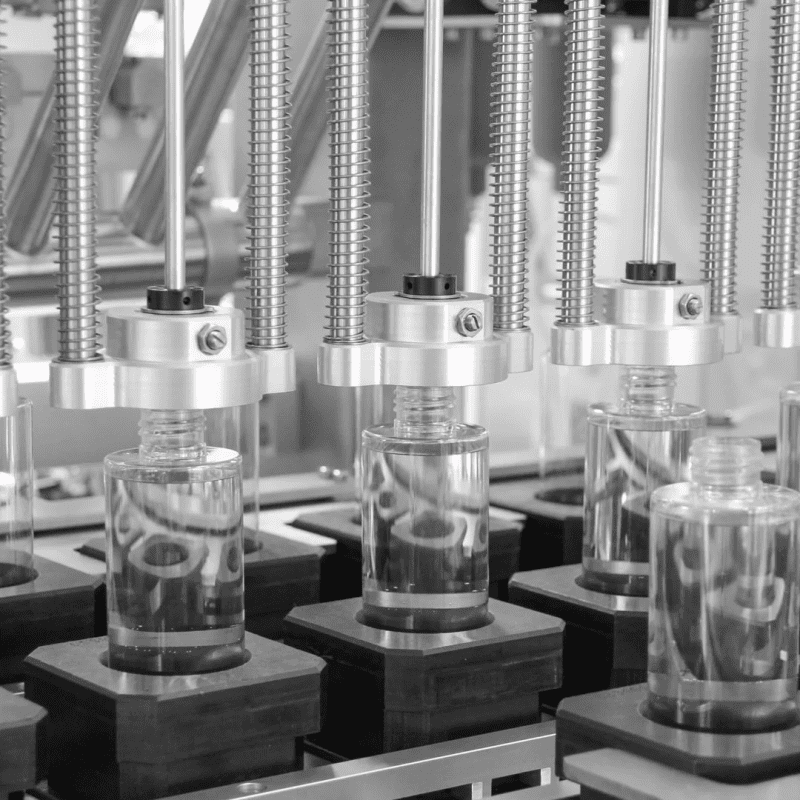

Non-Standard Perfume Sprayer Assembly Equipment for Any Production Line

Perfume sprayer assembly requires high precision and flexibility, as perfume manufacturers often have diverse production lines, product specifications, and workshop layouts. Standard assembly equipment cannot adapt to these personalized needs, leading to low efficiency, poor compatibility, and wasted investment. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing specializes in non-standard perfume sprayer assembly equipment, designed to fit any production line and solve the customization pain points of cosmetics and perfume enterprises. Customized Design to Match Diverse Production Needs Every perfume manufacturer has unique requirements—different sprayer sizes, assembly processes, output targets, and even workshop space constraints. Ruizhi’s non-standard perfume sprayer assembly equipment abandons the one-size-fits-all model. […]

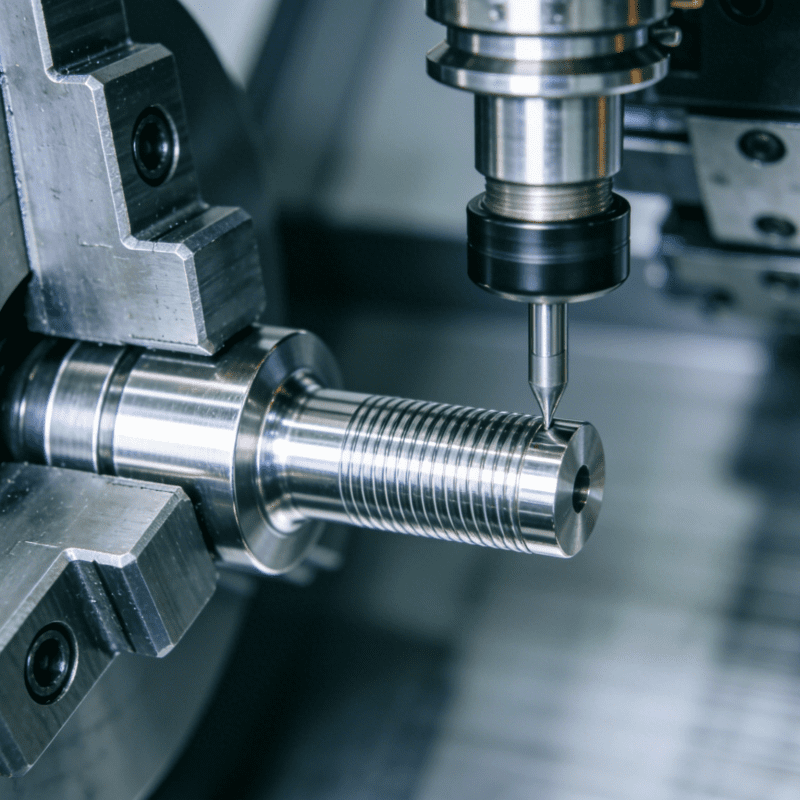

Precision Machining of Medical Stainless Steel: Pain Point Solutions and High-Efficiency Processing Strategies

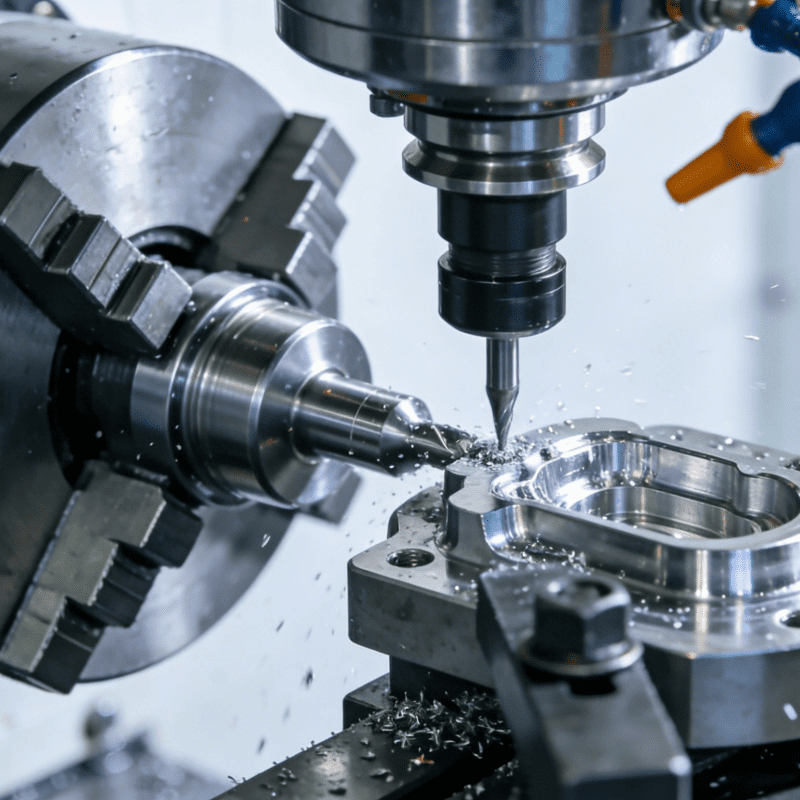

In medical devices and life sciences, precision stainless steel components are core parts that ensure equipment performance and safety. Examples include precision mating teeth of surgical instruments and fluid connectors for life science analyzers. Their dimensional errors must be controlled at the micron level, and they must feature excellent corrosion resistance and biocompatibility. The quality of these parts directly affects the performance of medical devices and patient safety, making them highly valued in the industry. However, traditional stainless steel machining methods often fail to meet high-end requirements. Many manufacturers face problems such as rapid tool wear, substandard surface roughness, and low processing efficiency. How can these bottlenecks be broken […]

Perfume Sprayer Assembly Machine: Solve Your Production Pain Points

Perfume sprayers are core components of fragrance products, and their assembly quality directly affects product sealing, usability, and brand reputation. However, many cosmetics and perfume manufacturers face stubborn pain points in sprayer assembly—low efficiency, high error rates, and poor adaptability to diverse specifications. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has developed high-performance perfume sprayer assembly machines, targeting these pain points to help enterprises optimize production and reduce operational burdens. Solve Low Efficiency Pain Points with Automated Assembly Manual assembly of perfume sprayers involves small components like pumps, nozzles, and caps, which is time-consuming and labor-intensive. A single worker can only assemble 40-60 units per […]

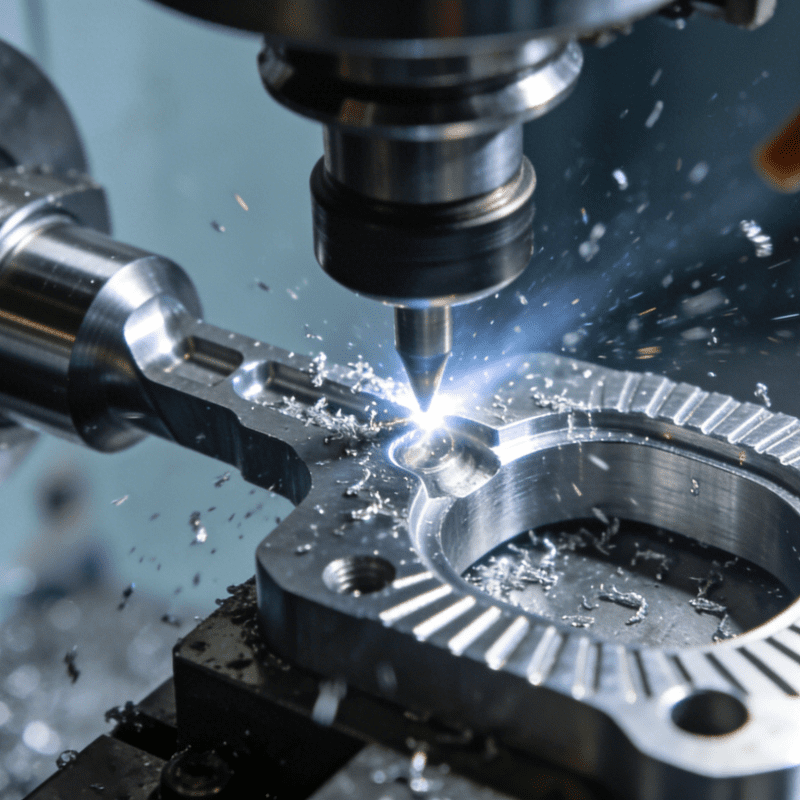

Key Technical Applications of 5-Axis Precision Machining Centers in the Manufacturing of Precision Medical Parts

5-axis precision machining centers play an indispensable role in the production of high-precision medical parts. Especially when facing complex-structured, ultra-high-precision medical device components—such as orthopedic implants or core parts of precision surgical tools—traditional machining methods are often inadequate. The core advantage of such equipment lies in its powerful multi-axis simultaneous motion capability, enabling machining on multiple complex surfaces of a part at the same time. Most processes can be completed in a single clamping setup. This not only greatly reduces the risk of accumulated errors caused by repeated fixturing, but also enables stable and efficient machining of difficult-to-cut materials such as medical titanium alloy and special stainless steel. […]

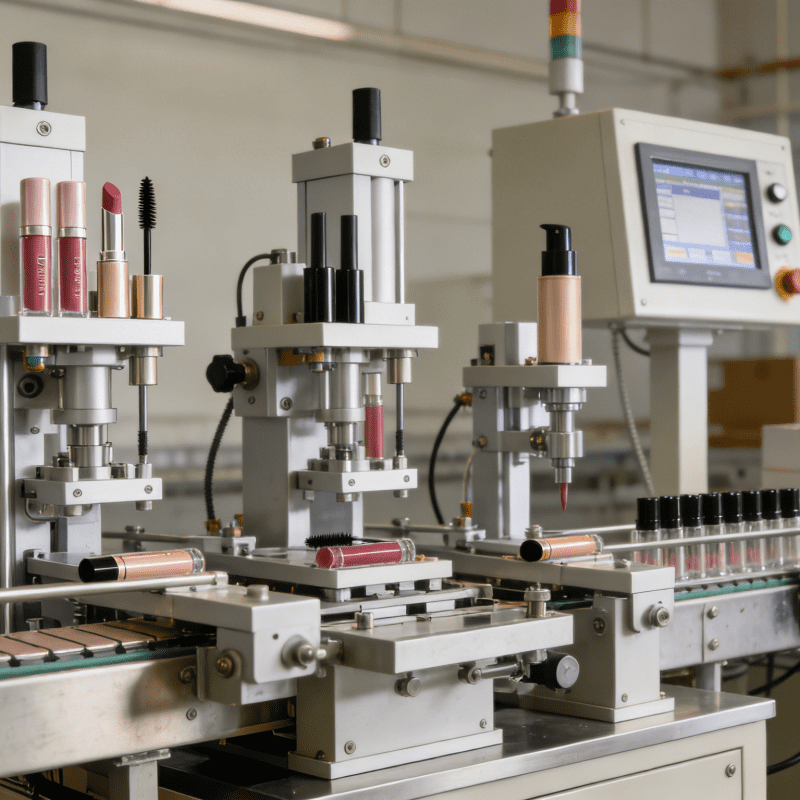

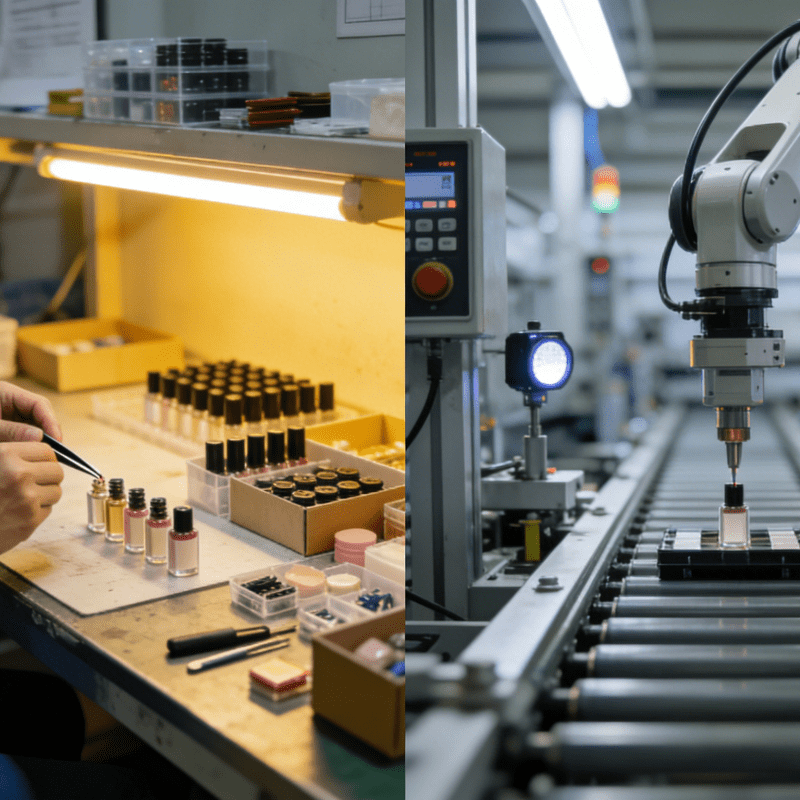

Non-Standard Cosmetics Assembly Equipment for Any Production Line

The cosmetics industry is defined by diverse product types, frequent upgrades, and unique production needs—factors that make standard assembly equipment ineffective for many manufacturers. Whether you run a small batch workshop or a large-scale production plant, flexible and customized solutions are essential to stay competitive. As a professional non-standard automation provider, Ruizhi Intelligent Manufacturing specializes in non-standard cosmetics assembly equipment, designed to seamlessly adapt to any production line, solving pain points and boosting operational efficiency for cosmetics enterprises worldwide. Customized Design to Fit Unique Production Demands Unlike one-size-fits-all standard equipment, Ruizhi’s non-standard cosmetics assembly equipment is tailored to your specific needs. We fully consider your product specifications (lip […]

How Cosmetics Assembly Machines Improve Production Efficiency

In the fast-paced cosmetics industry, production efficiency directly determines a manufacturer’s market competitiveness. Manual and semi-automatic assembly methods are no longer able to keep up with the growing demand for large-scale production and high-quality standards. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has helped numerous cosmetics enterprises optimize their production processes with advanced cosmetics assembly machines. This article explores three key ways these machines boost production efficiency, bringing tangible value to cosmetics factories. Higher Production Speed Than Manual Assembly Manual assembly of cosmetics components—such as lip gloss tubes, mascara wands, and spray pump heads—is time-consuming and prone to fatigue. A single worker can only assemble […]

Full Coverage of Various Surface Finishes to Meet the Differentiated Needs of Intelligent Processing for Metal and Plastic Parts

This article explores the application of various surface finishing processes in the intelligent processing of metal and plastic parts. The selection of these surface treatments not only affects product quality and appearance but also directly responds to diverse market demands. Based on the characteristics of different materials, technologies such as spraying, anodizing, and electroplating each have unique advantages that effectively improve the durability and aesthetics of parts. In response to the growing demand for customization in the market, manufacturers can flexibly apply these processes to meet consumers’ pursuit of personalized products. By choosing the right surface treatment method, enterprises can enhance product competitiveness and better respond to market challenges. […]

Why Is 5-Axis Machining Ideal for Medical Parts? An Analysis of Core Advantages of Multi-Axis Motion

5-axis machining technology offers undeniable advantages in the manufacturing of medical parts. It enables high-precision machining of complex geometries while effectively improving production efficiency. Through multi-axis simultaneous motion, 5-axis machining can complete cutting in multiple directions in a single clamping setup, reducing errors caused by repeated fixturing. This feature is especially suitable for the medical industry, which has extremely strict requirements for part precision and consistency. In addition, the flexibility of 5-axis machining equipment allows faster responses to diverse design requirements, supporting the rapid launch of new products. Together, these advantages enhance the quality and efficiency of medical part production, helping manufacturers better meet market demands. Advantages of 5-Axis […]

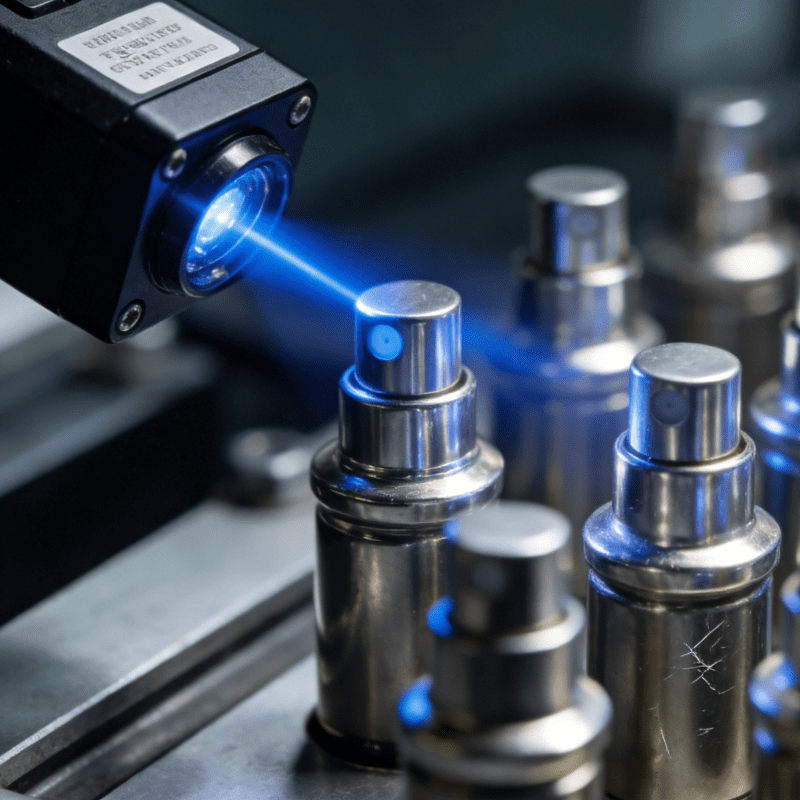

Why Choose Automatic Spray Pump Assembly for Cosmetic Production

In the competitive cosmetic industry, product quality, production efficiency, and brand reputation are crucial to standing out. Spray pumps are widely used in skincare, makeup, and personal care products, and their assembly quality directly affects product sealing, usability, and consumer experience. Traditional manual or semi-automatic spray pump assembly can no longer meet the high standards and large-scale production needs of cosmetic enterprises. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing explains why cosmetic manufacturers should choose automatic spray pump assembly equipment to optimize production and gain market advantages. Ensure Consistent Quality to Meet Cosmetic Industry Standards Cosmetic products have strict requirements for safety and quality, and […]

Joint Construction of an Embodied Intelligent Robot Manufacturing Base

On January 30, Binzhou City, Shandong Province, held a centralized signing ceremony for strategic emerging industry projects. The People’s Government of Bincheng District signed a cooperation agreement with Shanghai Kepler Robotics Co., Ltd. (Kepler) for the Kepler (Binzhou) Robot Manufacturing Project. Li Yiming, Member of the Standing Committee of the Bincheng District Party Committee, Minister of the Organization Department and Secretary of the Political and Legal Affairs Commission, and Liu Tianying, Global Strategy Director of Shanghai Kepler Robotics Co., Ltd., signed the agreement on behalf of both parties.Hu Bo, Member of the Standing Committee of the Binzhou Municipal Party Committee and Vice Mayor, Yao Zhenxiang, Director of the Binzhou […]

Spray Pump Assembly Machine: Solve Manual Assembly Pain Points

Spray pumps are essential components in cosmetics, pharmaceuticals, and daily chemical packaging, with complex assembly processes involving pump cores, nozzles, springs, and caps. Traditional manual spray pump assembly is plagued by low efficiency, high error rates, and high labor costs, becoming a bottleneck for enterprises expanding production. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has developed a high-performance Spray Pump Assembly Machine, which precisely addresses the pain points of manual assembly and helps enterprises achieve efficient, stable, and intelligent production. Replace Manual Labor to Solve Low Efficiency & High Labor Cost Pain Points Manual spray pump assembly requires multiple workers to complete tedious, repetitive steps, […]

Major Breakthroughs Achieved in Brain-Computer Interface

The proposals for the 15th Five-Year Plan have explicitly listed Brain-Computer Interface (BCI) as one of the six future industries, marking its upgrade from cutting-edge technological exploration to a new engine of national economic growth. At present, China’s BCI industry is developing in a pattern of multi-point advancement and characteristic competition. Many regions are actively seizing this strategic emerging track through systematic policy guidan ce, platform construction, and ecosystem cultivation. So, what types of machine tools and equipment are needed to support the industrialization of this emerging sector? Major Breakthrough According to Chinadaily.com.cn, a research team led by Chang Honglong and Ji Bowen at Northwestern Polytechnical University recently announced a key breakthrough […]