Customized Baby Bottle Automatic Assembling Machine

The baby product industry is characterized by diverse specifications, strict safety requirements, and frequent product updates, making customized and flexible production a core demand for enterprises. Traditional standard baby bottle assembling equipment cannot adapt to non-standard production needs, leading to resource waste and low production efficiency. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing focuses on solving this pain point, launching the Customized Baby Bottle Automatic Assembling Machine to tailor exclusive automation solutions for baby product manufacturers. Fit Your Unique Production Needs Unlike standard equipment with fixed functions, our machine is fully customized based on your specific requirements. Ruizhi’s professional R&D team will adjust […]

Grinding Process: Enhancing Precision of Medical Equipment Parts to Ensure Patient Safety

In life science experiments, the precision of reagent dispenser components directly impacts the accuracy of experimental data. For medical devices, such as minimally invasive surgical instruments, the precision of their cutting edges is critical to patient safety during surgery. The manufacturing quality of these core components is a key factor for the competitiveness of the life science and medical industries. However, traditional grinding methods often suffer from excessive dimensional errors, especially for parts with complex curved surfaces where manual operations struggle to ensure consistency. Additionally, when processing hard materials like ceramics or cemented carbide, conventional equipment tends to cause uneven wear of the grinding wheel, leading to non-compliant surface […]

Revolutionize Baby Bottle Assembly

In the baby product industry, safety, precision, and flexibility are non-negotiable for baby bottle production. Traditional baby bottle assembly relies heavily on manual labor and disjointed equipment, leading to high error rates, slow production speeds, and difficulty adapting to small-batch & multi-variety demands—pain points that limit enterprise growth. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing is reshaping the industry with our Baby Bottle Automatic Assembling Machine, bringing a revolutionary change to traditional assembly processes. End Manual Dependency & Boost Efficiency Our revolutionary assembling machine integrates automatic feeding, bottle body fitting, nipple installation, cap screwing, leak detection, and blanking into one seamless unit. Unlike traditional manual […]

Igniting a New Frontier: The Future is Now – Shanghai Vigorously Cultivates and Develops Brain-Computer Interface

In an era of rapid technological advancement, Brain-Computer Interface (BCI) technology is transforming our lives and cognition at an unprecedented pace. Once confined to science fiction, this technology has now become a reality, bringing unprecedented opportunities and challenges to humanity. From helping paralyzed patients stand and walk again to enabling mind control of smart homes, the application scenarios of BCI are constantly expanding, and its development prospects are highly anticipated. However, behind these technological breakthroughs, BCI also faces numerous challenges, such as signal acquisition accuracy, biocompatibility, and ethical issues, all of which require careful consideration and resolution. BCI as a Key Future Industry According to Jiefang Daily’s news […]

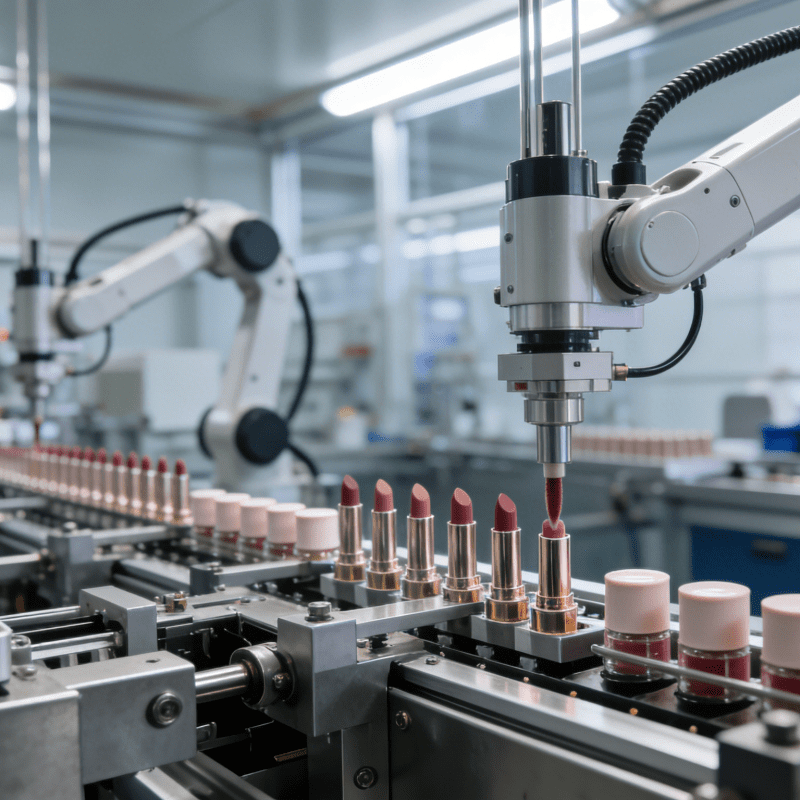

All-in-One Lip Gloss Applicator Assembly Machine for Small-Batch & Multi-Variety Production

The beauty industry is evolving rapidly, with small-batch and multi-variety production becoming a key trend to meet diverse consumer demands and fast market changes. However, traditional lip gloss applicator assembly faces bottlenecks: scattered processes, slow specification switching, and high labor costs, which fail to keep up with flexible production needs. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing launches the All-in-One Lip Gloss Applicator Assembly Machine, custom-built to solve these pain points and empower beauty enterprises with efficient, flexible production. Simplify Processes for Small-Batch Efficiency Unlike traditional separate equipment, our machine integrates automatic feeding, brush rod assembly, bottle fitting, cap screwing, leak detection, and blanking into […]

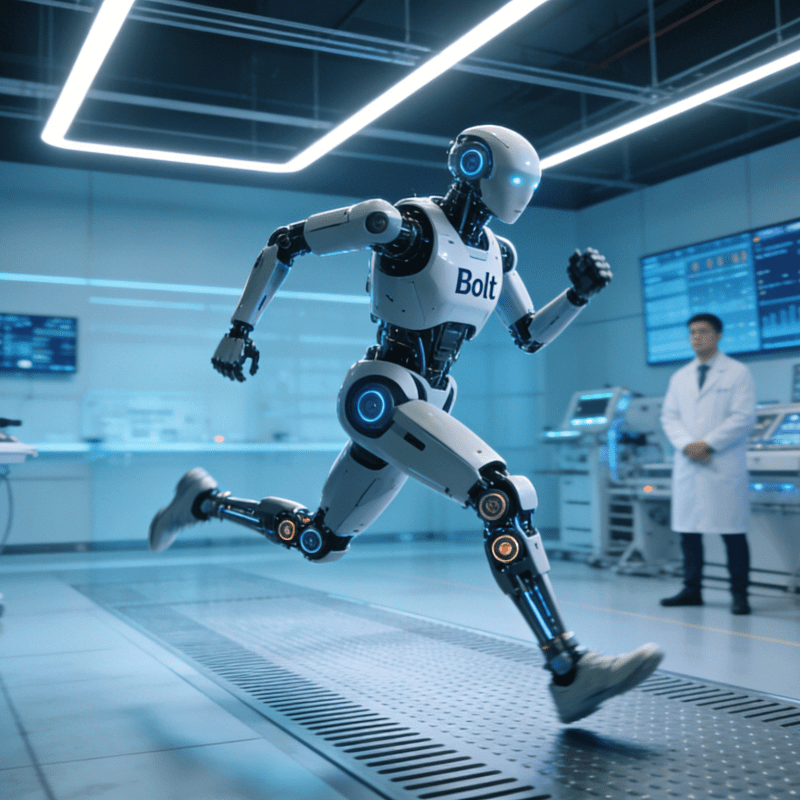

Chinese Self-developed Humanoid Robot “Bolt” Breaks the Global Record for Fastest Running

Bolt’s Groundbreaking Running Speed On February 2, 2026, the Humanoid Robot Innovation Institute of the International Innovation Center of Zhejiang University officially unveiled the full-sized humanoid robot Bolt. It is reported that the robot has set a new global record for the fastest speed among humanoid robots with a running speed of 10 meters per second (approximately 36 kilometers per hour), making it the fastest humanoid robot in the world. This achievement not only demonstrates China’s leading strength in the field of dynamic motion and control of robots but also marks a significant breakthrough in the engineering and practical application of high-speed humanoid robot technology. Technological Foundations & […]

All-in-One Lip Gloss Applicator Assembly Machine

In the fast-paced beauty industry, the efficiency and precision of lip gloss production directly determine market competitiveness. For beauty enterprises struggling with scattered assembly processes, high labor costs, and inconsistent product quality, Ruizhi Intelligent Manufacturing launches the All-in-One Lip Gloss Applicator Assembly Machine—a customized non-standard automation solution designed to reshape lip gloss applicator production. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing focuses on addressing the pain points of traditional lip gloss applicator assembly. Our all-in-one machine integrates multiple processes, reduces manual intervention, and ensures stable mass production, helping beauty enterprises achieve cost reduction, efficiency improvement, and quality upgrading. Simplify Processes, Boost Efficiency The core […]

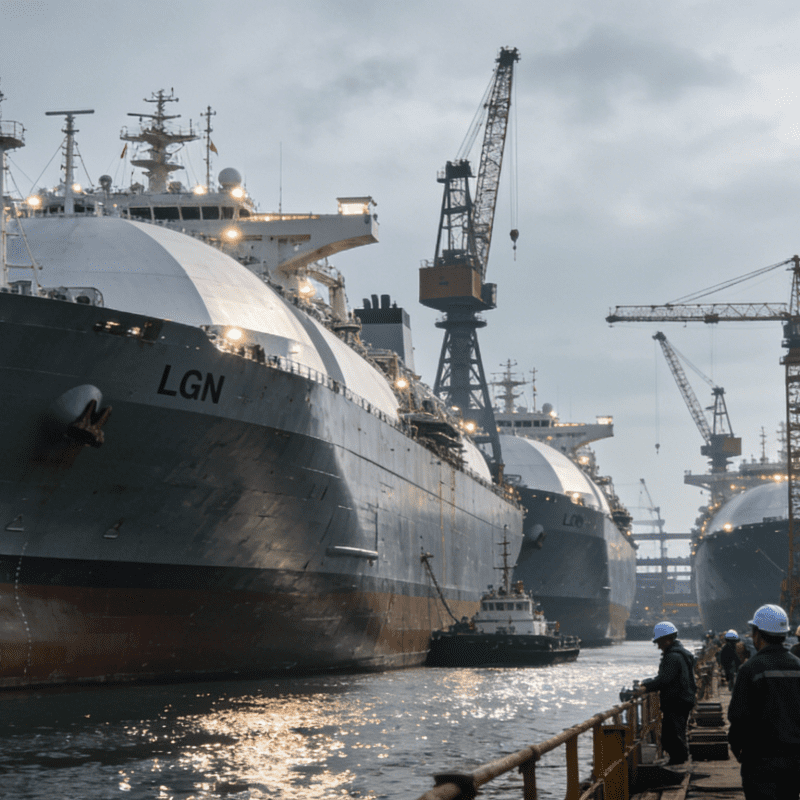

The international market share of China’s shipbuilding industry maintained its global leading position in 2025

16-Year Dominance Unbroken In 2025, China’s shipbuilding industry demonstrated strong resilience amid the complex and volatile global economic and trade environment. The three core indicators continued to lead the world comprehensively, further consolidating China’s status as the global shipbuilding center. From January to December 2025, China’s shipbuilding completion volume reached 53.69 million deadweight tons, representing a year-on-year increase of 11.4% and accounting for 56.1% of the world’s total. The new order volume stood at 107.82 million deadweight tons, a year-on-year decrease of 4.6%, accounting for 69.0% of the world’s total. By the end of December, the backlog of orders reached 274.42 million deadweight tons, up 31.5% year-on-year and […]