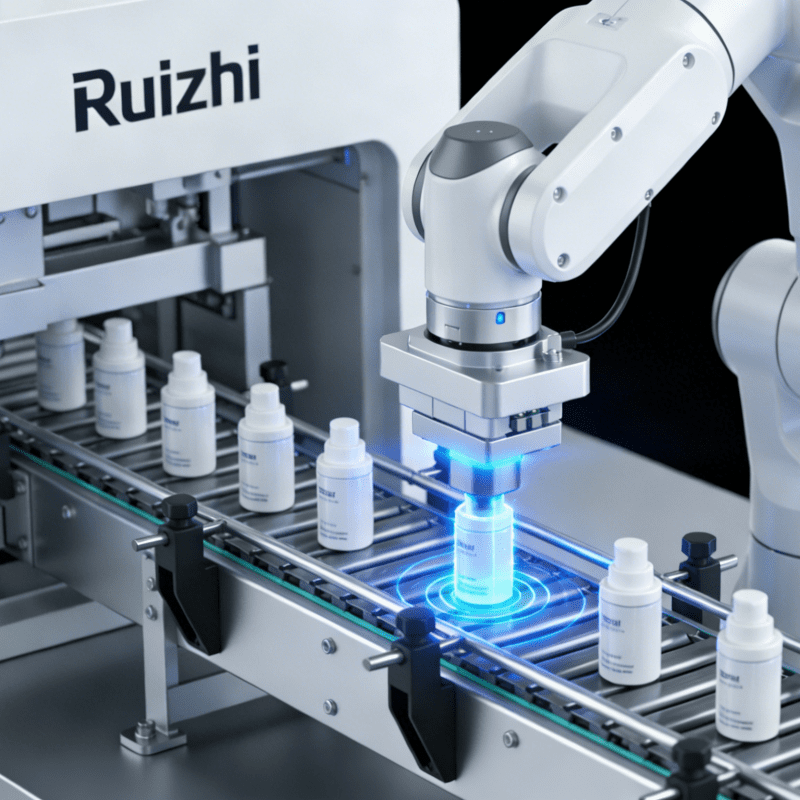

Manual Lotion Pump Assembly Is Costly?

Lotion pumps are essential packaging for daily chemical and cosmetic products, but many enterprises are trapped in the high cost of manual assembly. From labor wages to rework losses caused by low efficiency and high defects, manual assembly has become a heavy burden affecting profitability. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, offers efficient lotion pump assembly machines to replace manual operations, helping enterprises achieve substantial cost reduction and efficiency improvement. The Hidden Costs of Manual Lotion Pump Assembly: Beyond Labor Wages The high cost of manual assembly is not just about direct labor wages. Firstly, low efficiency leads to opportunity costs: A worker can only […]

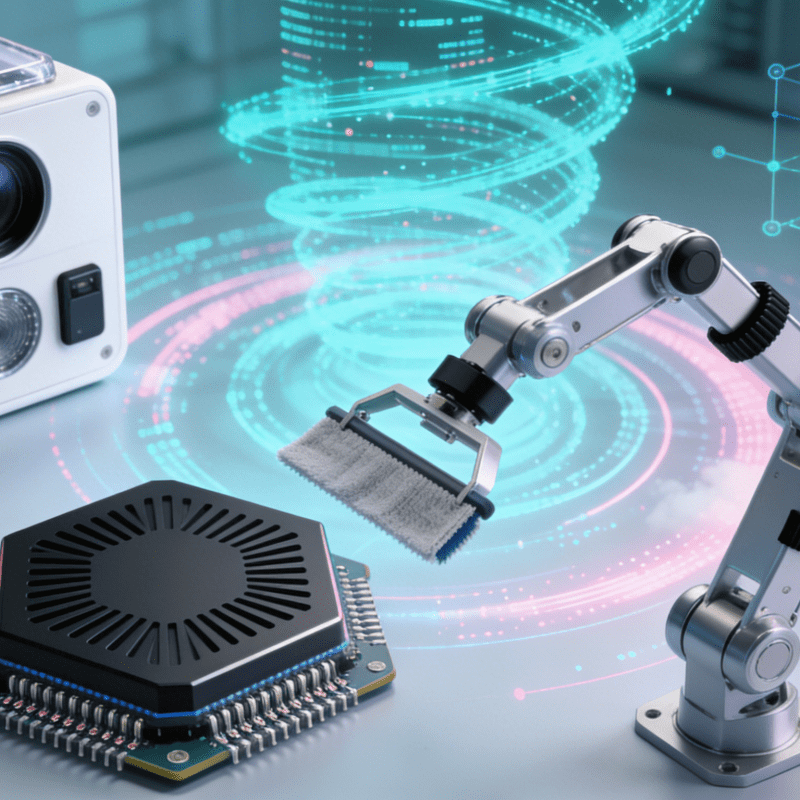

Chinese Robot Vacuums Sweep the Global Market

January 11 News – According to CCTV Finance, as one of the world’s most influential tech events, the 2026 Consumer Electronics Show (CES) in Las Vegas, USA, featured a concentrated display of cutting-edge technologies in the smart home sector, with a focus on household cleaning devices. Among the exhibits, a number of new robot vacuum models integrated with artificial intelligence made their debut. Several new products launched by Chinese companies are now “equipped with movable components, capable of aerial operations, and empowered with intelligent decision-making”. These robot vacuums boast core technical capabilities such as perception, decision-making, and execution, demonstrating the in-depth application of embodied intelligence in household scenarios. […]

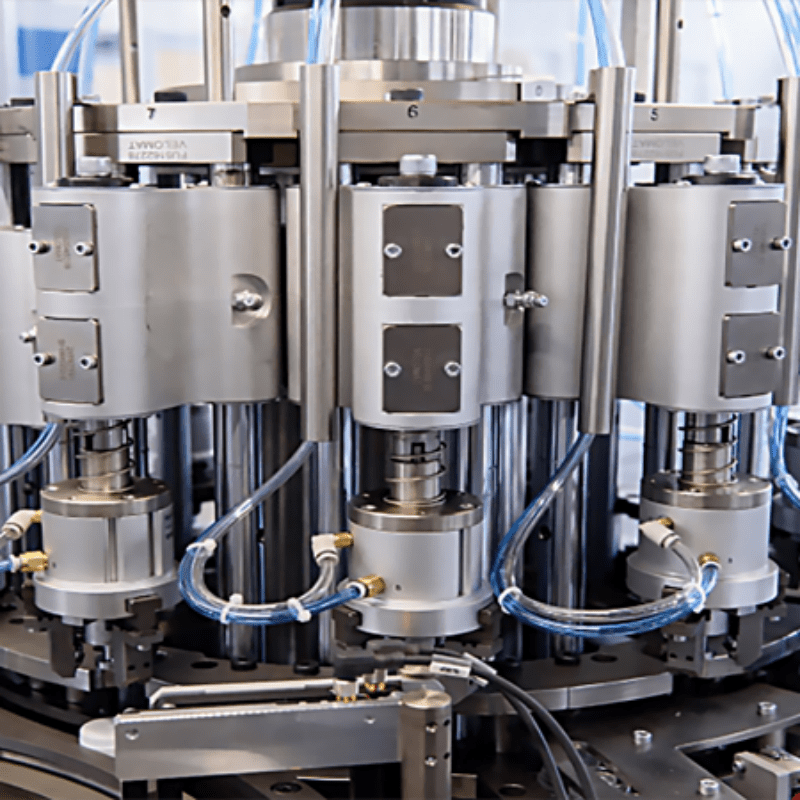

Efficient Lotion Pump Assembly Machine

Lotion pumps are core packaging components in the daily chemical and cosmetic industries, with their assembly efficiency directly affecting enterprise production capacity and market supply speed. Traditional manual assembly or standard automation equipment often faces bottlenecks such as low output, slow model switching, and high labor costs. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, has launched an efficient lotion pump assembly machine, which breaks through efficiency limitations and helps enterprises achieve lean production upgrading. Industry Pain Points: Efficiency Bottlenecks Plaguing Lotion Pump Assembly At present, lotion pump assembly in the daily chemical industry is troubled by obvious efficiency problems. Manual assembly relies on manual coordination of […]

The “Air Lala” Has Arrived! Tianma-1000 Unmanned Transport Aircraft Successfully Completes Maiden Flight

January 11 News – According to Xinhua News Agency, the Tianma-1000 unmanned transport aircraft, independently developed by Xi’an Aisheng Technology Group Co., Ltd. of China North Industries Group Corporation, successfully completed its maiden flight test on the same day. All flight data of the Tianma-1000 performed excellently, marking a complete success for its first flight. As introduced, the Tianma-1000 is like an “air freight hauler”, integrating multiple functions such as logistics transportation, emergency rescue, and material delivery. It is China’s first mid-altitude low-cost transport platform that achieves “adaptation to complex plateau terrain, ultra-short takeoff and landing, and rapid switching between cargo transport/airdrop dual modes”. This aircraft model can […]

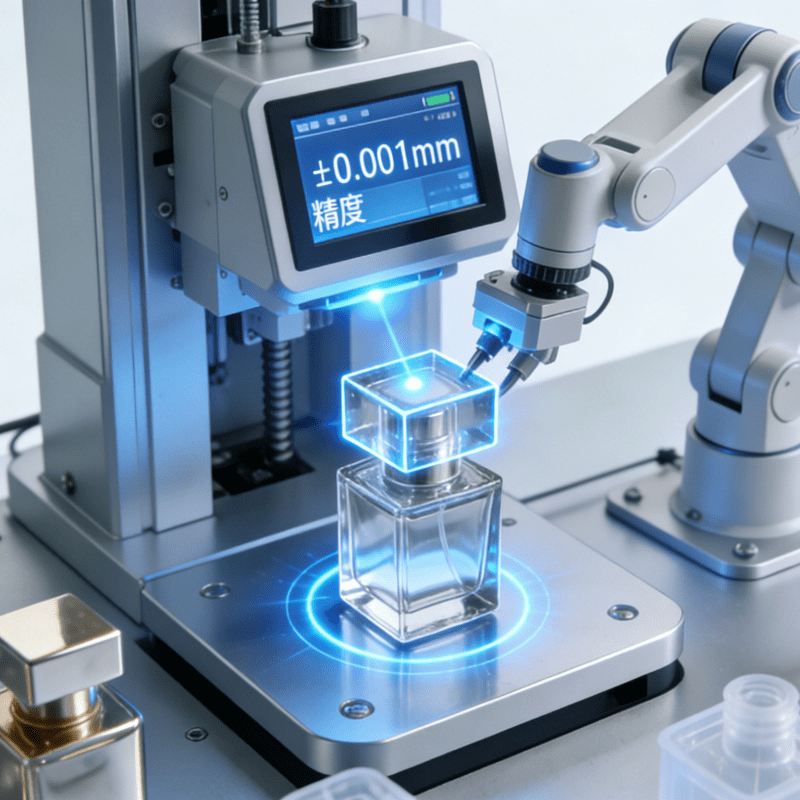

High Defect Rate in Perfume Cap Assembly?

For luxury perfume brands, the assembly quality of perfume caps directly determines product value and brand reputation. A high defect rate—such as uneven fitting, scratches, or leakage—not only increases production costs but also damages consumer trust. Many perfume manufacturers are plagued by defect rates exceeding 3% in cap assembly, yet struggle to find effective solutions with manual operations or standard equipment. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, targets this pain point with high-precision custom perfume cap assembly machines, helping enterprises achieve a significant reduction in defect rates. Why Is the Defect Rate of Perfume Cap Assembly So High? The high defect rate in perfume cap […]

LONGi Hydrogen Energy’s First European Electrolyzer Shipment Successfully Completed

At the start of the new year, LONGi Hydrogen Energy successfully delivered its first electrolyzer system for water electrolysis in Europe. The delivered equipment consists of a 5MW alkaline water electrolysis hydrogen production system. Tailored to the application demands of the European market, the project has been systematically and forward-looking configured across product compliance, engineering design, and delivery service sectors. This delivery marks a critical step for LONGi Hydrogen Energy from market layout to practical implementation in Europe, leveraging verifiable engineering equipment capabilities to support Europe’s real-world needs for green transition. Stringent Compliance Design Ensures Long-Term Stable Operation of Customer Projects The equipment is strictly manufactured in accordance […]

High-Precision Custom Perfume Cap Assembly Machine

For the luxury perfume industry, the perfume cap is not only a protective component but also a key part of brand image. Its assembly quality, such as fitting precision and appearance consistency, directly affects product grade and consumer trust. However, the diverse shapes, materials, and process requirements of high-end perfume caps make standard assembly equipment difficult to meet production needs. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, launches a high-precision custom perfume cap assembly machine, tailored to solve the pain points of high-end perfume packaging assembly. Industry Pain Points: The Dilemma of High-Precision Assembly for Custom Perfume Caps High-end perfume caps often feature complex structures, such […]

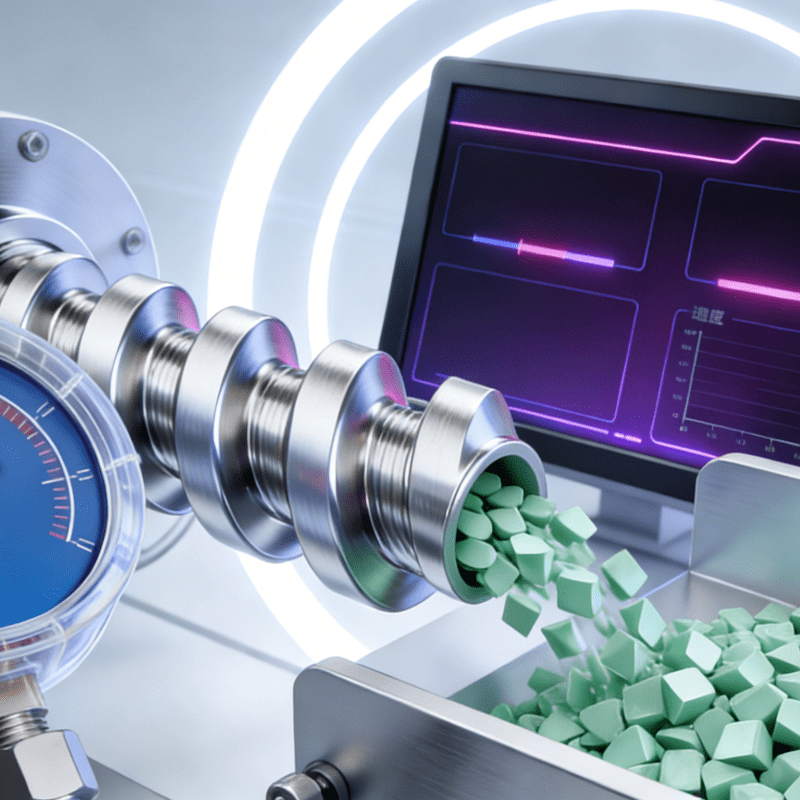

Unstable Pelletizer Extrusion? Precisely Adjust Rotational Speed and Temperature for Rapid Stable Production

In plastic pelletizing production, chronic issues such as melt pressure fluctuations, unstable output, and uneven pellets occur frequently. These problems not only disrupt continuous production but also directly compromise product quality and profitability. The key to solving these issues lies in the precise control of process parameters. This article focuses on two core aspects—temperature and rotational speed/feeding—and shares a set of actionable optimization methods to help you achieve rapid and stable production. Temperature Control Start with Material Characteristics and Lock Down Key Die Head Parameters The temperature profile must be precisely matched to material properties instead of simply applying generic templates. Taking a commonly used Φ150mm screw as […]