Application and Advantages of Precision Intelligent Machining Technology in the Production of Medical Parts

In today’s medical industry, precision intelligent machining technology has become an important means to ensure the quality of medical parts. With its high precision, efficiency and flexibility, this technology is widely applied to the production of various medical device accessories. It can not only meet stringent dimensional and shape requirements, but also realize complex structural design, laying a solid foundation for the innovation of medical devices. Through real-time monitoring, potential errors in the intelligent machining process can be timely identified and corrected, thus ensuring the consistency and reliability of products. In addition, the combination of advanced materials and surface treatment processes also enables medical parts to exhibit excellent wear and […]

Precision Manufacturing & Machining: The Core Driving Force Empowering the Production of High-Precision Medical Devices

In the field of healthcare, the quality of high-precision medical devices is directly tied to the accuracy of clinical diagnosis and the safety of surgical treatment. The machining precision, stability and reliability of their core components are the decisive factors for device performance. Leveraging its distinctive technical advantages, CNC machining technology has become the core support for manufacturing high-precision medical devices. It fundamentally resolves the precision bottlenecks and quality challenges that are insurmountable with traditional machining methods, providing a solid guarantee for the high-quality development of the medical device industry. Precision Error Control: Upholding the Safety Bottom Line of Medical Devices High-precision medical devices impose far stricter precision […]

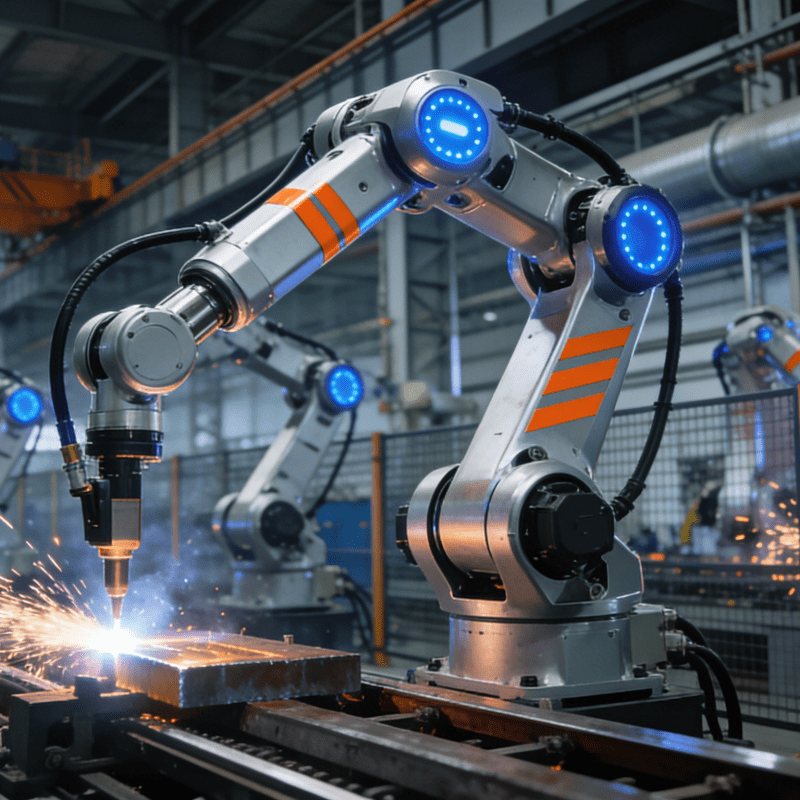

Precision Manufacturing and Machining Centers: Driving the Upgrade of Precision Machining and Empowering the Development of High-end Manufacturing

Against the backdrop of the manufacturing industry’s transformation towards high precision, high efficiency and high flexibility, precision machining has become a key indicator for measuring the core competitiveness of enterprises. As the core equipment in this field, machining centers, by virtue of their integrated machining capabilities, superior precision control and stable production performance, are gradually replacing traditional machining equipment and emerging as the cornerstone of intelligent manufacturing that underpins the development of high-end sectors such as aerospace, automotive manufacturing and medical devices. Machining Centers: The Core Carrier of Precision Machining The core demands of precision machining are controllable precision, stable efficiency and manufacturability of complex components. By integrating […]

Core Process System of Precision Manufacturing & Machining: Empowering Precision and Efficiency for Precision Component Machining

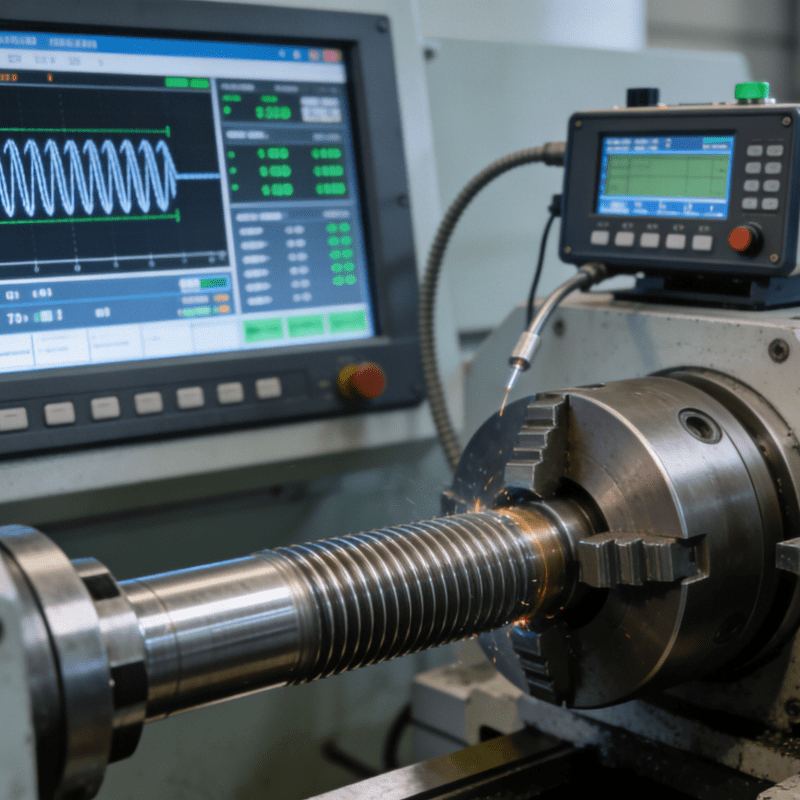

In high-end manufacturing, aerospace, electronic equipment and other fields, the dimensional accuracy and surface quality of precision components directly determine the performance of end products. As a core technical means to achieve precision component machining, precision machining relies on digital control and accurate execution capabilities, and provides support for the stable batch production of precision components through standardized and modular process combinations. The selection and execution quality of its processes directly affect the precision qualification rate, structural integrity and operational reliability of precision components. The following will analyze the core processes of precision machining and their practical impacts in detail. Turning Process: The Cornerstone of Precision for Shaft-type Components […]

Precision Machining of Pipe Threads: An Efficient Technical Solution for Precision Connection Applications

Pipe threads are the core structure for the connection of pipeline systems, and their machining quality directly determines the tightness, pressure-bearing capacity and service life of pipelines. Against the backdrop of the manufacturing industry’s transformation towards precision and high efficiency, precision machining of pipe threads, with its standardized and automated technical characteristics, has gradually become the mainstream choice for pipe thread production across various industries. This paper objectively analyzes the core value of pipe thread precision machining from three dimensions: technical definition, application scenarios and process advantages. Pipe thread precision machining refers to a technical method that leverages computer numerical control systems (intelligent manufacturing) combined with specialized precision machining […]

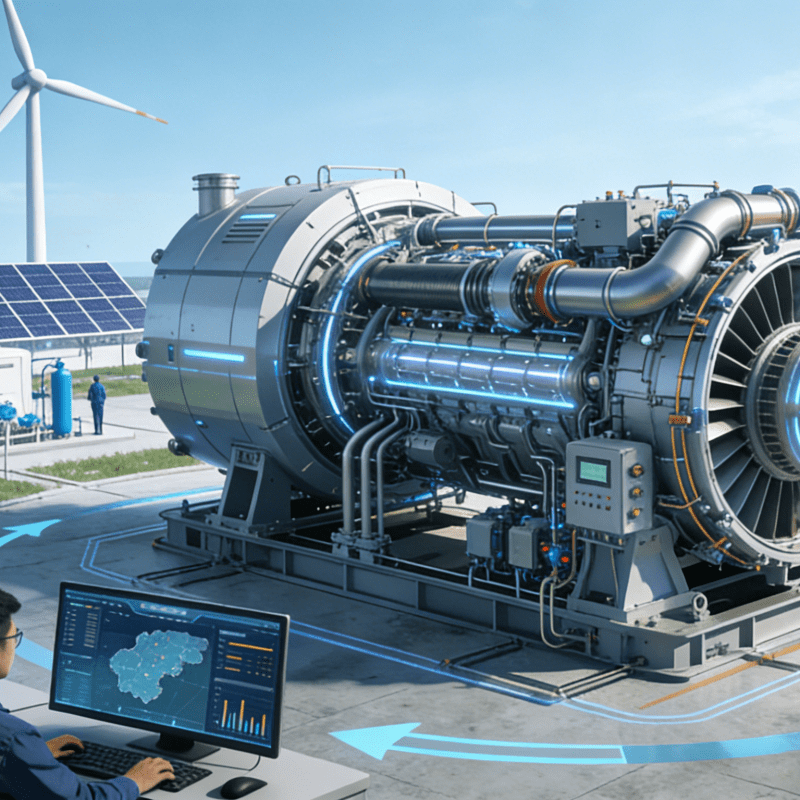

The World’s First 30 MW-class Pure Hydrogen Gas Turbine Put into Operation

Reported by CCTV News on December 28th, the world’s first independently developed 30 MW-class pure hydrogen gas turbine in China — Jupiter-1 — has successfully achieved pure hydrogen power generation and maintained stable operation. This marks the official materialization of the world’s first 30 MW-class demonstration project of the Power-to-Hydrogen-to-Power cycle, turning the blueprint into reality. Integrating wind power, photovoltaic power and water electrolysis hydrogen production systems, the project has built an energy recycling mode of “green electricity for green hydrogen production, and green hydrogen re-converted to electricity”, which effectively addresses the problem of absorption and utilization of surplus electricity generated from new energy sources. Through multiple iterations […]

Promoting the Orderly Development of Anthropomorphic Interactive Services of Artificial Intelligence and Guiding the Responsible Innovation of Artificial Intelligence

Breakthroughs in artificial intelligence (AI) technology are driving human-computer interaction to evolve from functional assistance to emotional and personalized engagement. While reshaping the social interaction model, such evolution has also given rise to a series of new risks and challenges. These risks feature concealed transmission characteristics, which may infringe upon citizens’ rights and interests, and even undermine social ethical order and the foundation of public trust. The lack of effective governance will seriously hinder the sound development of AI and damage social public interests. Against this backdrop, the formulation of the Interim Measures for the Administration of Anthropomorphic Interactive Services of Artificial Intelligence (Draft for Comments) (hereinafter referred to as […]

From Stage Backup Dancers to AI Shop Managers: A New Era of Human-Robot Collaboration Has Dawned

Humanoid Robots Shine on Concert Stages with Stunning Performances Recently, the world’s first robotic concert stage made a stunning debut at the Chengdu stop of Wang Leehom’s “The Best Place” concert tour. The robots performing as backup dancers on stage were Unitree G1 humanoid robots, which made a dazzling appearance on the day and stole the spotlight throughout the show. We specially watched the live performance footage and saw six humanoid robots deliver an electrifying performance on stage, moving in perfect sync with the rhythm of the music. Their perfectly coordinated movements and precise, powerful rhythm timing, paired with human dancers performing alongside them, created a spectacular stage show; […]

SYNDA Launches the Industry’s First Industrial Embodied Intelligent Robot

On December 29th, SYNDA, as a pioneer in the industry, officially unveiled SYNDA R1, the industry’s first embodied intelligent robot purpose-built for industrial scenarios. Its launch represents more than just the debut of a single product; it marks a strategic leap for SYNDA — evolving from a key player in industrial robotics and motion control to a pivotal enabler of the embodied intelligence industry. Starting with this milestone, SYNDA has taken the lead in kicking off the large-scale deployment and industrial integration of embodied intelligence, setting an industrial-grade benchmark for the industrialization of embodied robots, and injecting definitive impetus into the in-depth evolution of the manufacturing sector for a […]

Key Milestones Achieved for a Batch of Methanol Dual-Fuel Vessel Projects in China

Recently, a batch of construction projects for methanol dual-fuel vessels in China’s shipbuilding industry have successfully reached key milestones, demonstrating the steady improvement of Chinese shipbuilders’ capability in the systematic supply of green ship types. DSIC Tianjin’s First-Built Methanol Dual-Fuel Large Container Vessel Triumphantly Completes Sea Trial Recently, the first methanol dual-fuel 15,000 TEU container vessel built by DSIC Tianjin for CMA CGM Group of France has successfully completed the sea trial with methanol fuel and returned to port smoothly. The sea trial fully verified the advanced methanol dual-fuel power system of the vessel. All performance indicators of the vessel have met the design requirements, and its […]