Powder Packaging Machine

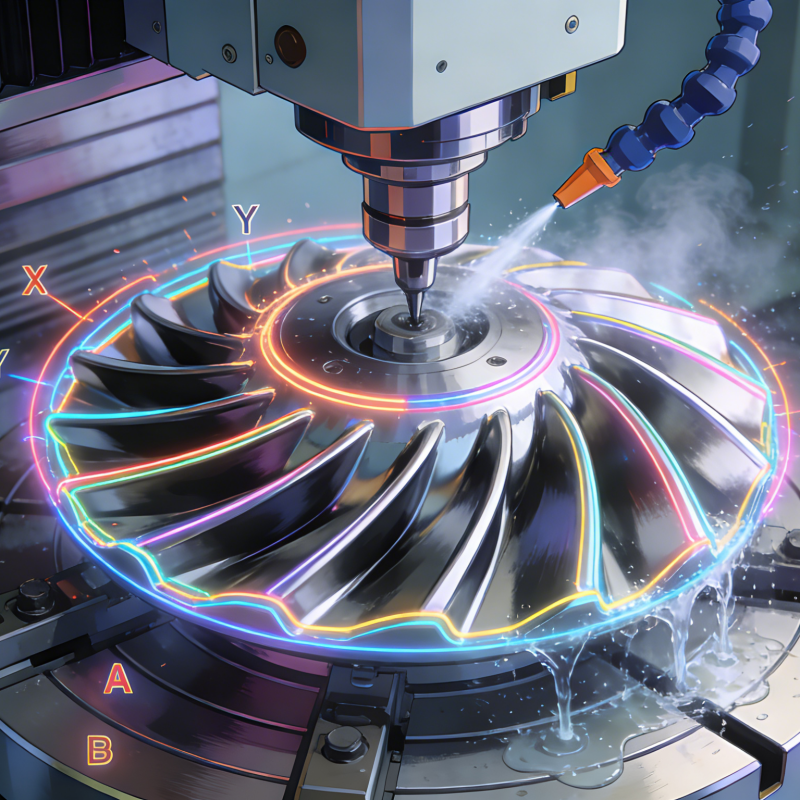

Micron-level Precision & Multi-axis Linkage: An Intelligent Production Management Solution

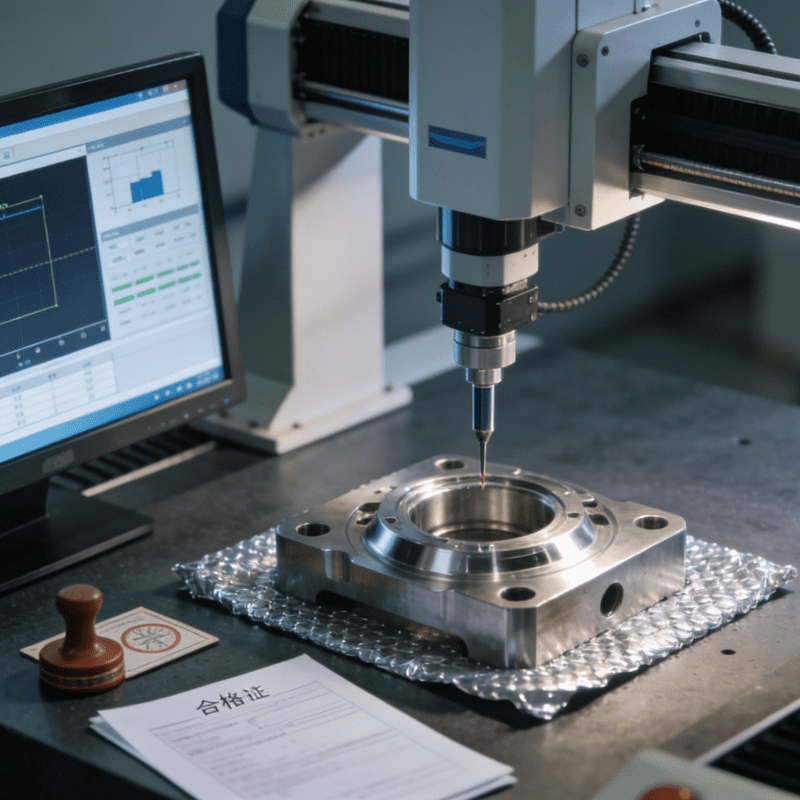

In the manufacturing of precision components, high-efficiency machining technology of CNC lathes plays a core role. This paper systematically introduces approaches to improve machining efficiency and quality, with a focus on three key areas: micron-level precision control to ensure impeccable dimensional accuracy of components, multi-axis linkage optimization for machining complex structural parts, and intelligent production management to achieve full-process monitoring. Through these elaborations, readers will gain practical insights to meet the stringent requirements for precision components in high-end industries. Next, we will delve into specific technical details in depth. Micron-level Precision Control Micron-level precision control is of paramount importance in the precision component machining of CNC lathes, which […]

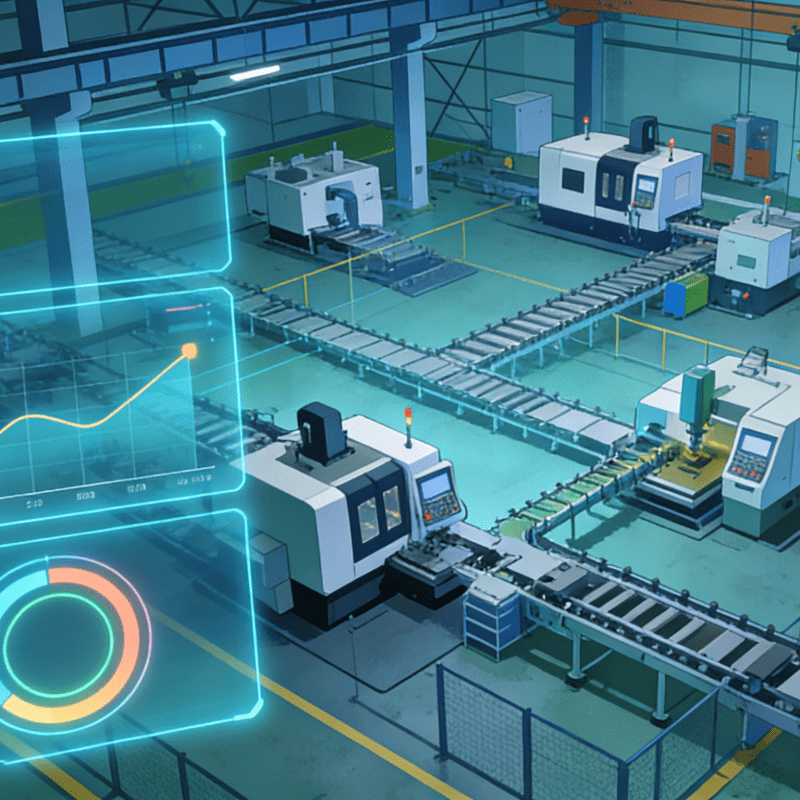

From Traditional Manufacturing to Smart Manufacturing: The Digital Transformation of Intelligent Machining

Against the backdrop of the accelerated evolution of the manufacturing industry, computer numerical control (CNC) intelligent machining, as a core link of precision manufacturing, is undergoing a profound transformation from traditional models to smart manufacturing. Driven by digital transformation, key technologies such as the Internet of Things (IoT) and Digital Twin have become pivotal driving forces, helping enterprises break down equipment silos and achieve efficient interconnection and real-time monitoring. Traditional intelligent machining is often limited by manual operations and low process visibility, while the intelligent transformation improves overall efficiency through data integration, laying a solid foundation for subsequent production optimization. Digital Twin Visualization Digital Twin technology provides core […]

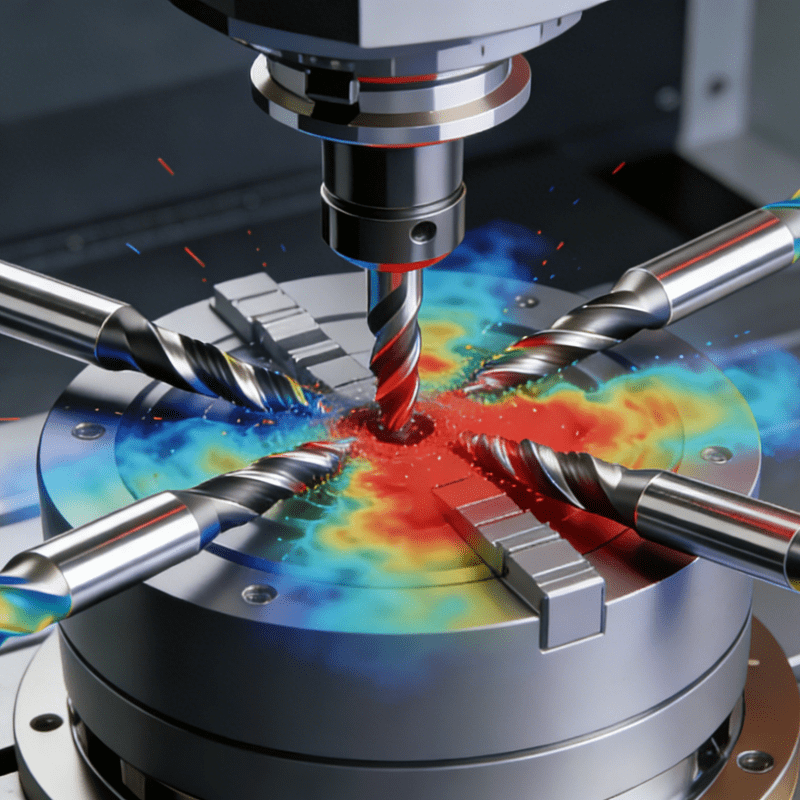

How to Fix Overshooting in Intelligent Machining? A 4-step Solution from Tool Selection to Parameter Adjustment

Overshooting and tool vibration are common issues in intelligent machining, which lead to reduced workpiece precision and tool damage. To address these challenges, this paper systematically introduces a 4-step solution. First, we explore precise tool selection strategies to help you choose suitable cutting tools and apply compensation methods. Second, we elaborate on key parameter optimization methods, including adjusting rotational speed, feed rate and depth of cut. Third, we discuss measures to improve clamping stability for a more reliable machining process. Finally, we provide practical and actionable improvement strategies that can be immediately applied to actual production work. Through these steps, you can gradually reduce vibration and the risk of overshooting, […]

3D Printing vs Intelligent Machining: Two Core Manufacturing Technologies, Which One Prevails?

In today’s rapidly evolving manufacturing sector, 3D printing and intelligent machining stand as two core digital manufacturing technologies, each boasting unique advantages and application scenarios. Understanding their fundamental differences is crucial for engineers, designers and procurement decision-makers alike. This paper delves into the key distinctions between these two technologies in practical applications, particularly in two common and critical stages: prototyping and low-volume production. By analyzing their respective working principles, material adaptability, cost structures and processing efficiency, we clearly outline the optimal selection path for different demand scenarios. This helps readers make more informed and efficient technological choices based on core factors such as cost, time, precision and complexity when faced […]

How Does Intelligent Machining Realize One-stop Processing of Rotational and Non-rotational Parts?

Turn-mill compound machining technology is gradually reshaping the landscape of modern manufacturing industry. It enables integrated turning and milling operations via intelligent CNC machining equipment, efficiently processing rotational parts (e.g., shaft-type components) and non-rotational parts (e.g., box-type components). This one-stop machining solution not only simplifies the production process, but also significantly improves processing efficiency and precision, while reducing costs and time waste. This paper explores in depth the core principles, innovative production strategies and practical application cases of this technology, helping readers fully understand its industrial value. Core Technology of Turn-mill Compound Machining The core advantage of turn-mill compound machining lies in its highly integrated processing capability. By […]

Medical Implant Devices: Micron-level Precision Achieved by Multi-axis Precision Machining

As the requirements for precision, efficiency and reliability in modern manufacturing continue to rise, CNC precision machining services have become a core technological pillar driving the development of high-end industries. Such services leverage advanced computer numerical control (CNC) technology to transform design drawings into high-precision physical components. Their core value lies in the ability to stably and efficiently achieve complex geometric shapes and extremely stringent tolerance requirements. Especially in critical fields such as aerospace key components, precision medical device implants, high-end optical instruments and complex industrial molds, CNC precision machining demonstrates irreplaceable advantages. Its scope of application covers the entire manufacturing cycle from rapid validation of initial prototypes to large-scale […]

Uncovering the Critical Role of Intelligent Machining in Medical Device Manufacturing

In the manufacturing of modern medical devices, the precision of core components is directly tied to the performance and safety of the equipment. As a core manufacturing method, intelligent machining technology plays a pivotal role in the production of these components. This paper systematically analyzes the application of intelligent machining in the medical field: first, it explores how precision manufacturing achieves micron-level accuracy requirements; second, it analyzes biocompatible machining processes to ensure material compatibility with human tissues; third, it elaborates on the aseptic control standards for medical materials; and finally, it discusses in depth the importance of quality control systems in safeguarding the overall manufacturing safety. Through the elaboration of […]

Empowering Developers to Unleash the Commercial Potential of Intelligent Agents in the Era of Personal AI

LTPC 2025 Kicks Off: Charting the Course for Human-Centric Super Intelligent Agents On December 26, 2025, the 2025 Lenovo Tianxi AI Ecosystem Partner Conference (LTPC 2025) was held at the Zhongguancun International Innovation Center in Beijing. With the theme of “Unite for Intelligent Agents, Co-create a New Ecosystem”, the conference explored the development of human-centric AI super intelligent agents. Aligned with this industrial trend, the conference clearly outlined the evolution path of Lenovo Tianxi AI from a mere assistant to a teammate with closed-loop execution capabilities. Through the strategic implementation of “One Core AI, Multi-terminal Deployment”, Lenovo is accelerating the universal access to personal AI, and building an open […]

The Third Session of the First Council of the Artificial Intelligence Industry Association Concludes Successfully

On the afternoon of December 28, 2025, the Third Session of the First Council of Sichuan Artificial Intelligence Industry Association was grandly held on the first floor of Building 7, Jingronghui, Chengdu Hi-tech Zone. Hosted by the Sichuan Artificial Intelligence Industry Association, this conference aimed to comprehensively summarize the work achievements of 2025, deploy key tasks for the next stage, further build industry consensus, integrate high-quality resources and stimulate innovation vitality, so as to boost the high-quality development of Sichuan’s artificial intelligence industry. More than 100 representatives from member units in the artificial intelligence field across the province, industry experts, scientific research institutions and media guests gathered together to discuss […]

Empowering Developers to Unleash the Commercial Potential of Intelligent Agents in the Era of Personal AI

LTPC 2025 Kicks Off: Charting the Course for Human-Centric Super Intelligent Agents On December 26, 2025, the 2025 Lenovo Tianxi AI Ecosystem Partner Conference (LTPC 2025) was held at the Zhongguancun International Innovation Center in Beijing. With the theme of “Unite for Intelligent Agents, Co-create a New Ecosystem”, the conference explored the development of human-centric AI super intelligent agents. Aligned with this industrial trend, the conference clearly outlined the evolution path of Lenovo Tianxi AI from a mere assistant to a teammate with closed-loop execution capabilities. Through the strategic implementation of “One Core AI, Multi-terminal Deployment”, Lenovo is accelerating the universal access to personal AI, and building an open […]