Process Analysis of Multi-Axis Simultaneous CNC Machine Tool Machining

Modern manufacturing has an increasingly high demand for the precision and efficiency of complex structural components, and the machining process of multi-axis simultaneous CNC machine tools plays a key role in this regard. This paper will systematically analyze the core connotation of this advanced machining technology, focusing on how to ensure the high-precision requirements of complex structural parts during the machining process. The paper will delve into its core technical principles, especially the application logic of advanced motion control strategies and various effective error compensation methods in actual production. Through the analysis of these core guarantee mechanisms, it aims to clearly present to readers the complete path of how […]

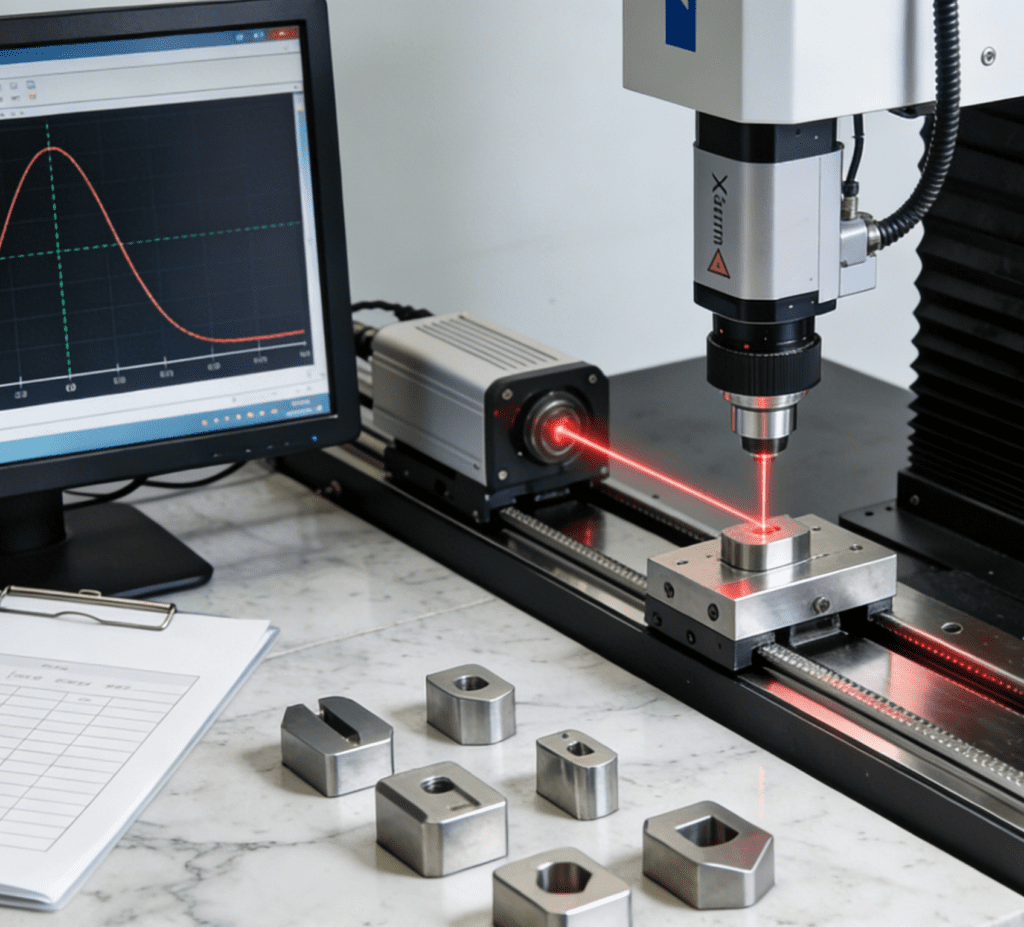

Optimization Study on Process Parameters of Precision Grinding

In fields such as precision machining, CNC precision machining and medical component manufacturing, precision grinding is an extremely crucial process, which is directly related to product accuracy and surface quality. To achieve ideal grinding results, optimizing process parameters is the key. Below is an in-depth exploration of knowledge in this regard. Grinding Wheel Speed: Balancing Speed and Precision Grinding wheel speed is one of the critical parameters in precision grinding. In intelligent machining, an appropriate grinding wheel speed can effectively improve grinding efficiency and surface quality. When the speed is too low, the material removal rate decreases significantly, leading to prolonged processing time and reduced production efficiency. Conversely, […]

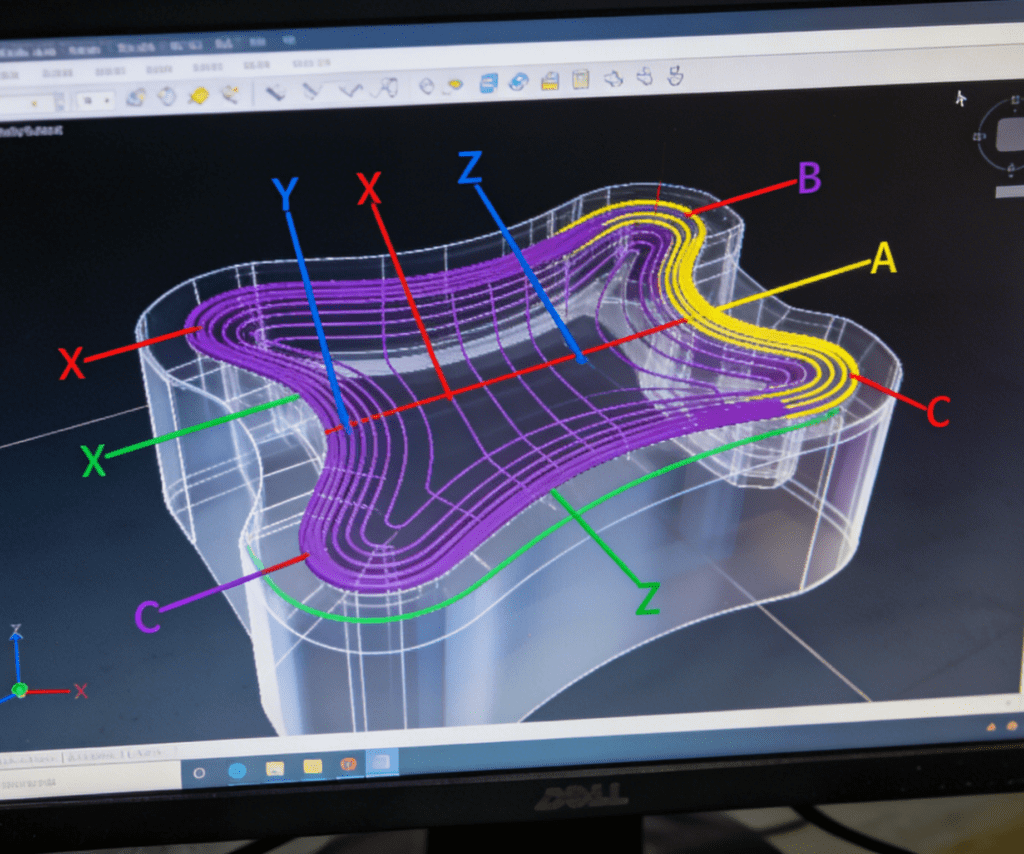

Multi-Axis Simultaneous Intelligent Machining Technology for 5-Axis CNC Machine Tools: Precision Enhancement of Aerospace Components

Multi-axis simultaneous intelligent machining technology for 5-axis CNC machine tools is a pivotal innovation in modern manufacturing. It enables simultaneous control over the movements of multiple axes to achieve highly efficient and precision machining of complex curved surfaces. This article will systematically analyze the core principles of this technology, including how multi-axis synchronization enhances machining accuracy and efficiency. Subsequently, it will explore its applications in the machining of aerospace components, facilitating the production of lighter yet more robust parts. Finally, it will focus on the mold manufacturing sector, demonstrating how to break through precision limits and optimize component quality. Through these discussions, readers can gain a comprehensive understanding of how […]

High-Speed Milling Technology: How Intelligent Machining Achieves Precision Machining with Higher Spindle Speed and Smaller Cutting Depth

High-speed milling technology represents an innovation in modern manufacturing. It enables high-efficiency machining through the intelligent control strategies of intelligent machining systems. This article focuses on how intelligent systems optimize parameters such as spindle speed and cutting depth to enhance the precision and efficiency of precision machining under the conditions of higher rotational speed and micron-level cutting depth. The core content includes the optimal design of cutting tools, such as material selection and geometric adjustment, as well as process monitoring technologies to ensure machining stability and quality control. The article will analyze these elements step by step, laying a foundation for the subsequent discussion on intelligent control mechanisms. Core […]

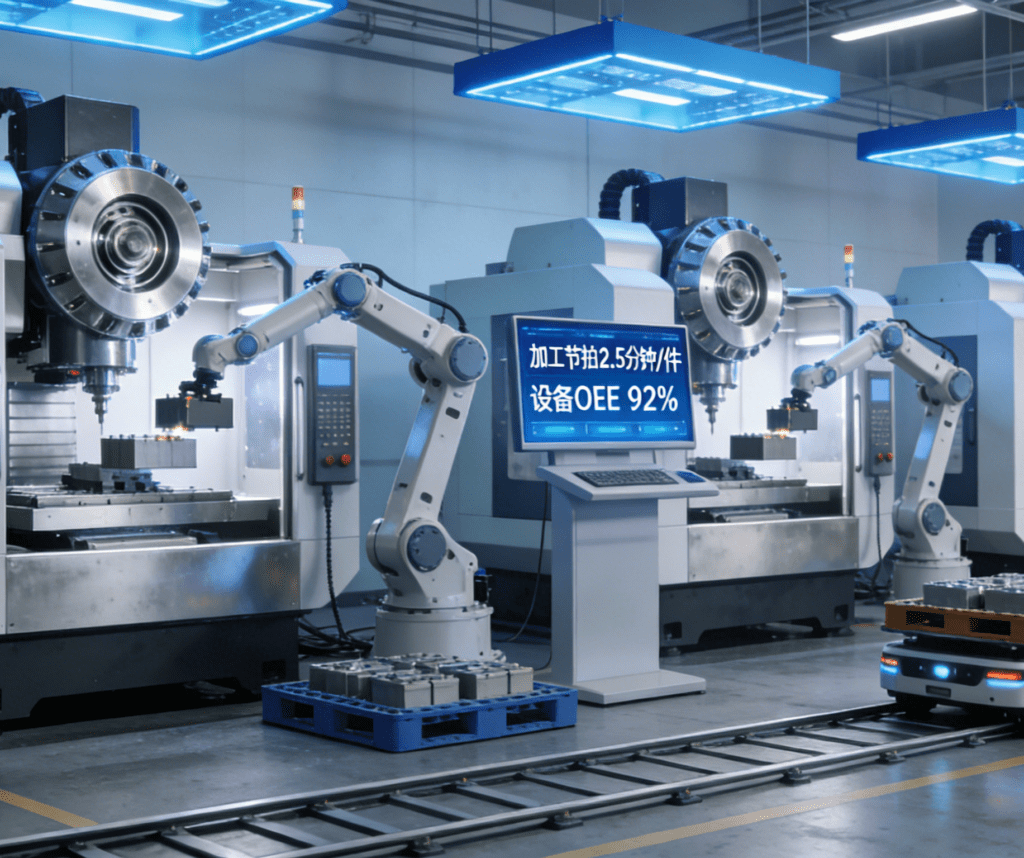

Multi-Axis Machining Breaks Five-Axis Linkage Limits! Collaborative Cutting Drives Skyrocketing Production Capacity of Aero Turbines and Automotive Cylinder Blocks

The modern manufacturing industry has an increasingly urgent demand for the efficient and precision machining of complex components. While traditional five-axis machining technology is already mature, there is still room for improvement in breaking through its efficiency bottlenecks. This article focuses on how multi-axis machining systems overcome the linkage constraints of conventional five-axis machine tools through innovative collaborative cutting strategies. We will delve into the technical principles of multi-spindle synchronous operation and analyze its remarkable speed advantages in machining complex curved surfaces. Through practical application cases such as key automotive components and precision aerospace structural parts, we will specifically demonstrate the contribution of multi-axis configurations to overall production capacity improvement. […]

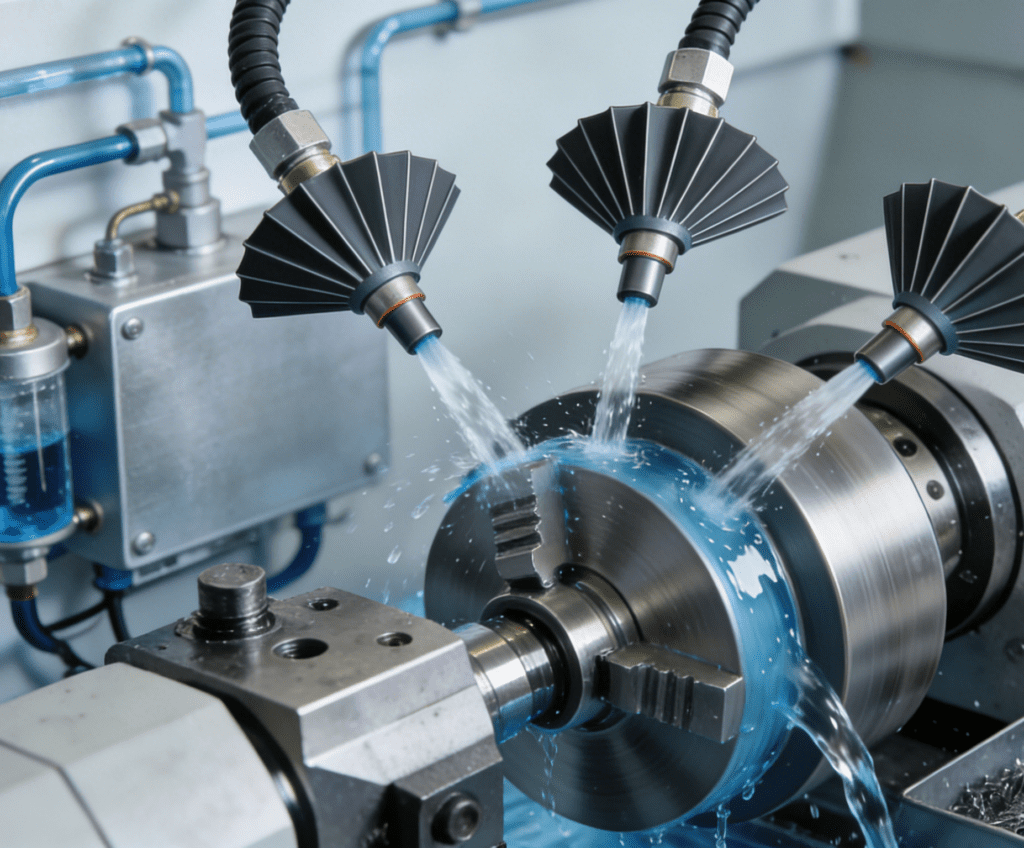

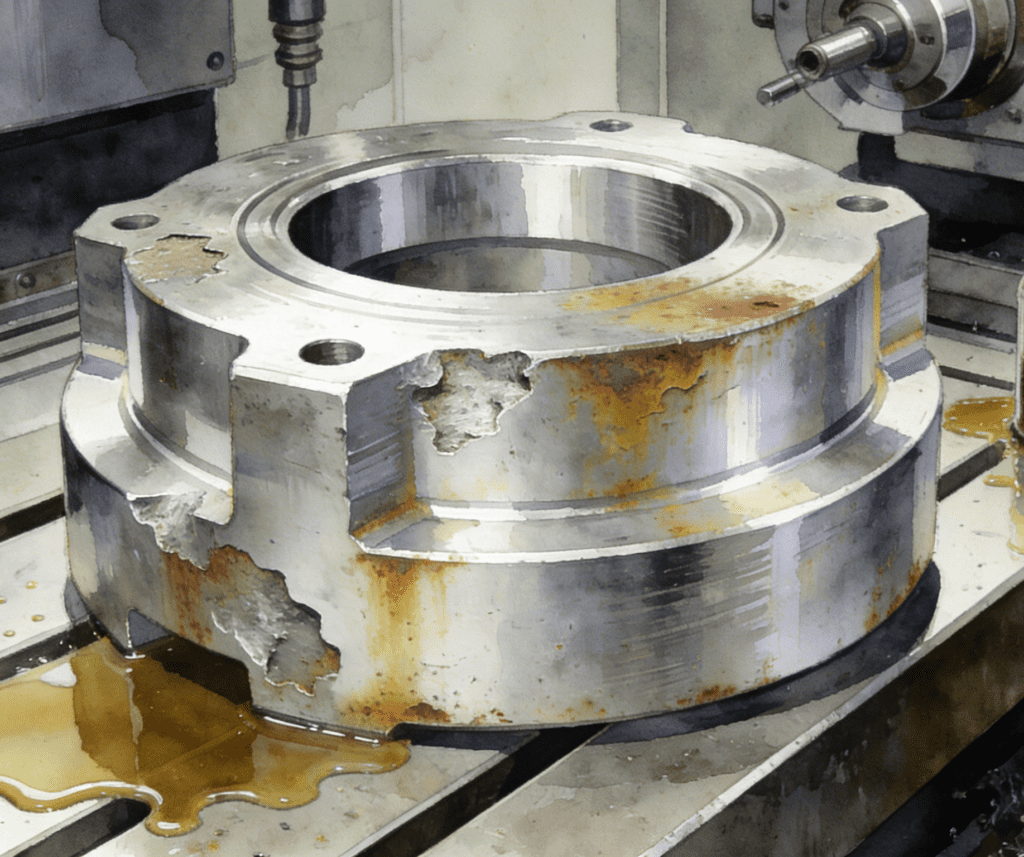

Problems Caused by Improper Selection of Cutting Fluid in CNC Machining and Optimization Solutions

In the process of CNC machining, improper selection of cutting fluid often leads to serious problems such as abnormal tool wear, workpiece corrosion and equipment failure, which directly affect machining accuracy and production efficiency. This article will conduct an in-depth analysis of the causes of these hazards, including how errors in viscosity and additive ratio exacerbate machining defects. Meanwhile, we will explore scientific selection methods based on material characteristics and process parameters to help operators avoid common mistakes. In addition, the article will share practical optimization solutions for cutting fluid maintenance to ensure the stable operation of the machining system. Three Major Hazards of Improper Cutting Fluid Selection […]

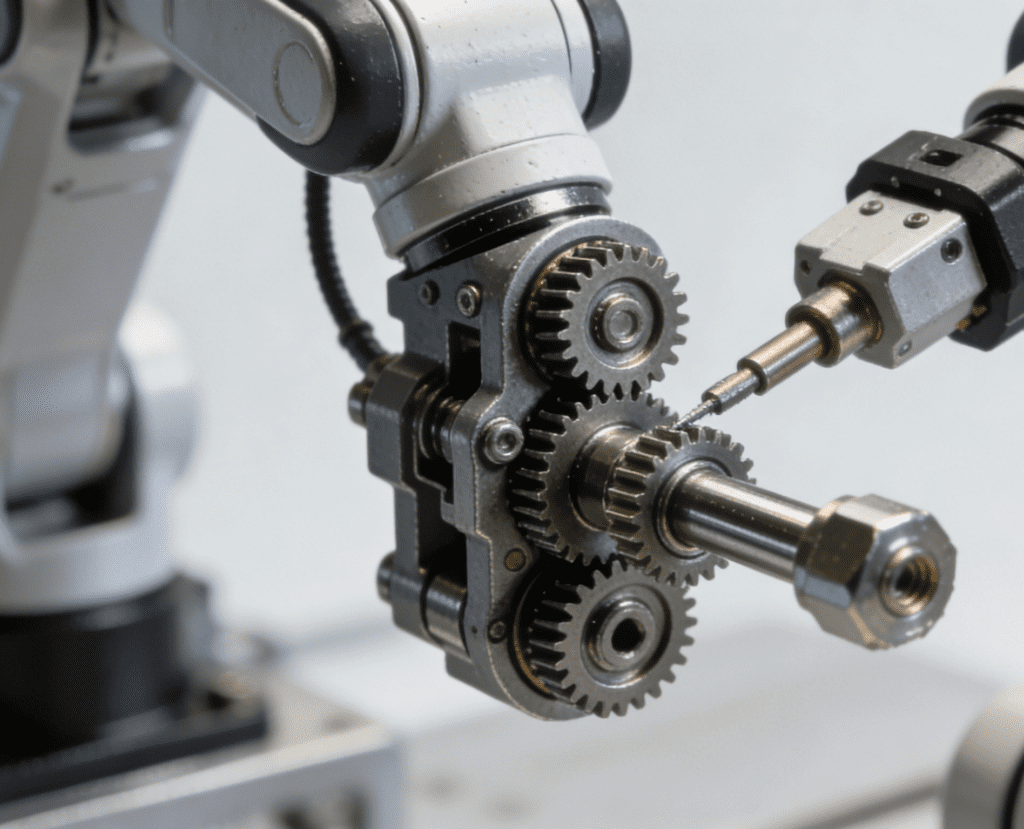

CNC Gear Machining: A Core Technical Pillar in Precision Manufacturing

As a core component of mechanical transmission systems, the machining accuracy of gears directly affects the operational efficiency, stability, and service life of equipment. With the transformation of the manufacturing industry towards precision and intelligence, CNC gear machining technology has gradually become the mainstream method for gear production, thanks to its unique technical advantages. This article will objectively analyze the core value of CNC gear machining from three dimensions: technical definition, application scenarios, and process advantages. CNC gear machining refers to a technical method that uses a computer numerical control (CNC) system to achieve precise programming and automatic control of gear processing equipment, so as to machine key gear […]

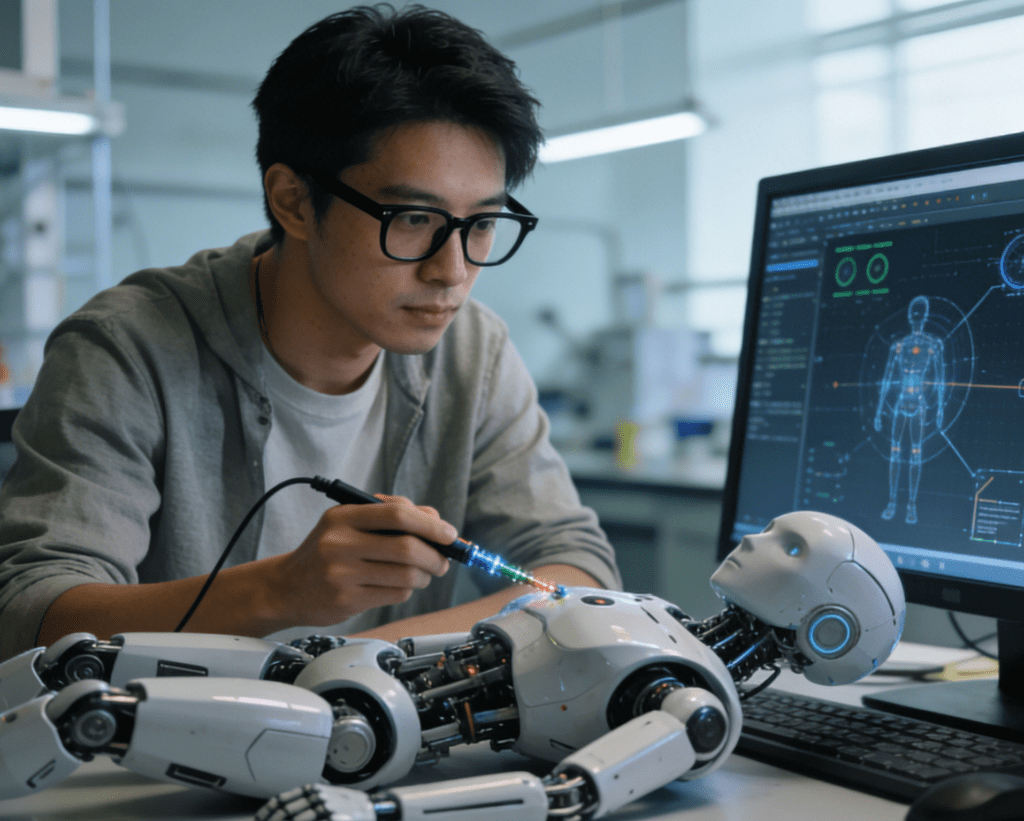

29-Year-Old HUST PhD Founds Startup, Grabs 86% Market Share

Capital Surge in Humanoid Robotics: Langyi Secures Two Rounds of Financing In the second half of this year, the humanoid robot sector has continued to see surging capital interest. Not only have humanoid robot manufacturers secured financing worth hundreds of millions of yuan, but core upstream technology suppliers in the industrial chain have also emerged as key targets in the capital market, thanks to their irreplicable underlying value. Among them, Langyi Robotics has successively attracted investments from renowned institutions including Inno Angel Fund, Jiadao Capital, Optics Valley Financial Holdings and MiraclePlus. It secured two rounds of financing worth tens of millions of yuan in just half a year. […]

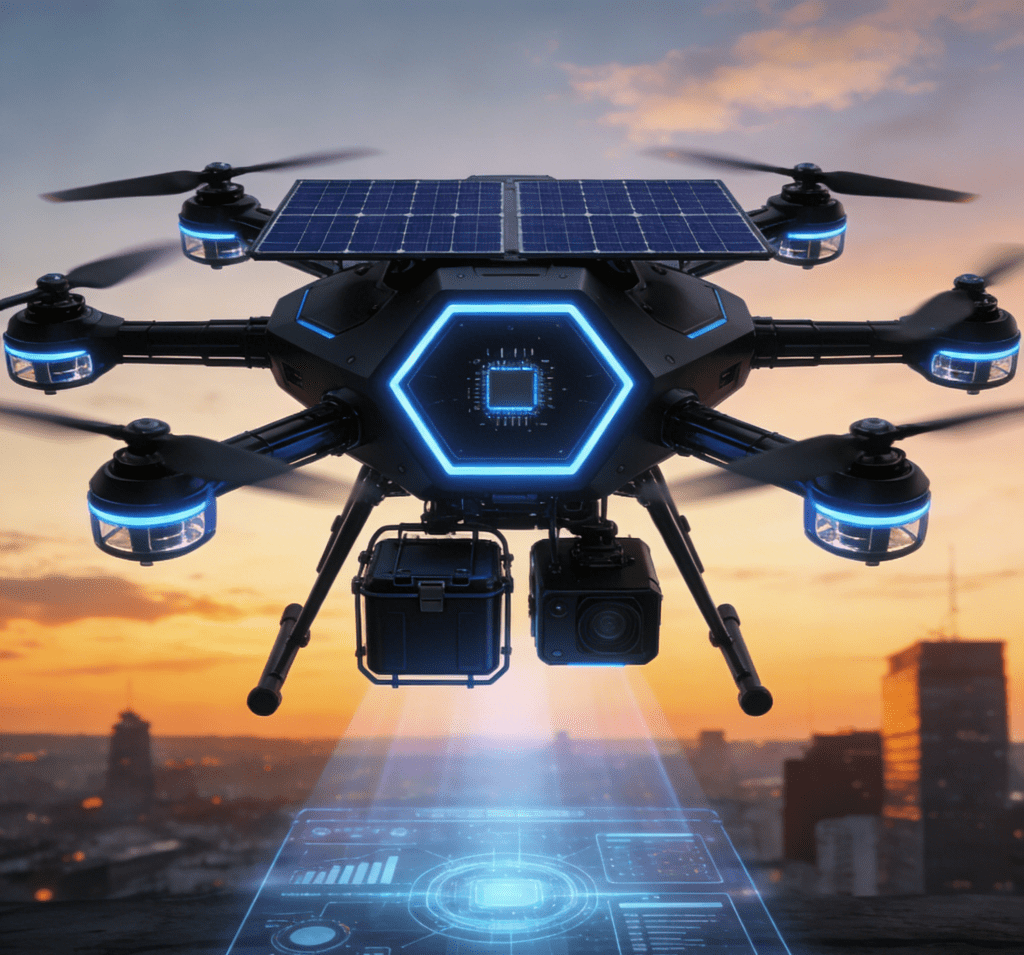

“The First Share of Civilian Drone Motors” to Undergo Listing Review Soon

IPO Sprint: Sunrui Intelligent Nears ChiNext Listing Recently, the Shenzhen Stock Exchange (SZSE) issued an announcement stating that Nanchang Sunrui Intelligent Technology Co., Ltd. (hereinafter referred to as “Sunrui Intelligent”) will hold its initial public offering (IPO) review meeting on December 26, launching the final sprint for ChiNext listing. As early as September 2023, Sunrui Intelligent completed the listing counseling filing with the Jiangxi Securities Regulatory Bureau. After four phases of counseling, the company officially submitted its IPO application for ChiNext at the end of May 2025, and soon obtained the acceptance notice from the SZSE. In June of the same year, the SZSE’s first-round inquiry letter covered […]

Here Comes the Remote-Control-Free Intelligent Robot Dog – Bobo the Big Head!

On December 23, Vitas Dynamics officially launched and opened pre-sales for its first intelligent companion robot, Bobo the Big Head, with the first batch of products expected to be delivered sequentially starting from March 2026. Unlike the mainstream quadruped robot dogs currently on the market, Bobo the Big Head’s biggest highlight is that it truly achieves autonomous movement and intelligent interaction through body intelligence, spatial intelligence and Agent intelligence – without the need for remote control operations. From “Controlled Machine” to “Autonomous Companion”: Bobo’s Three-Fold Intelligent Breakthroughs Vitas Dynamics’ definition of the “next-generation robot” lies in a three-layer architecture of “body intelligence, spatial intelligence and Agent intelligence”. […]