Automatic Bag-feeding Packaging Machine

What to Do About Overcut in CNC Machining? A 4-Step Solution from Tool Selection to Parameter Adjustment

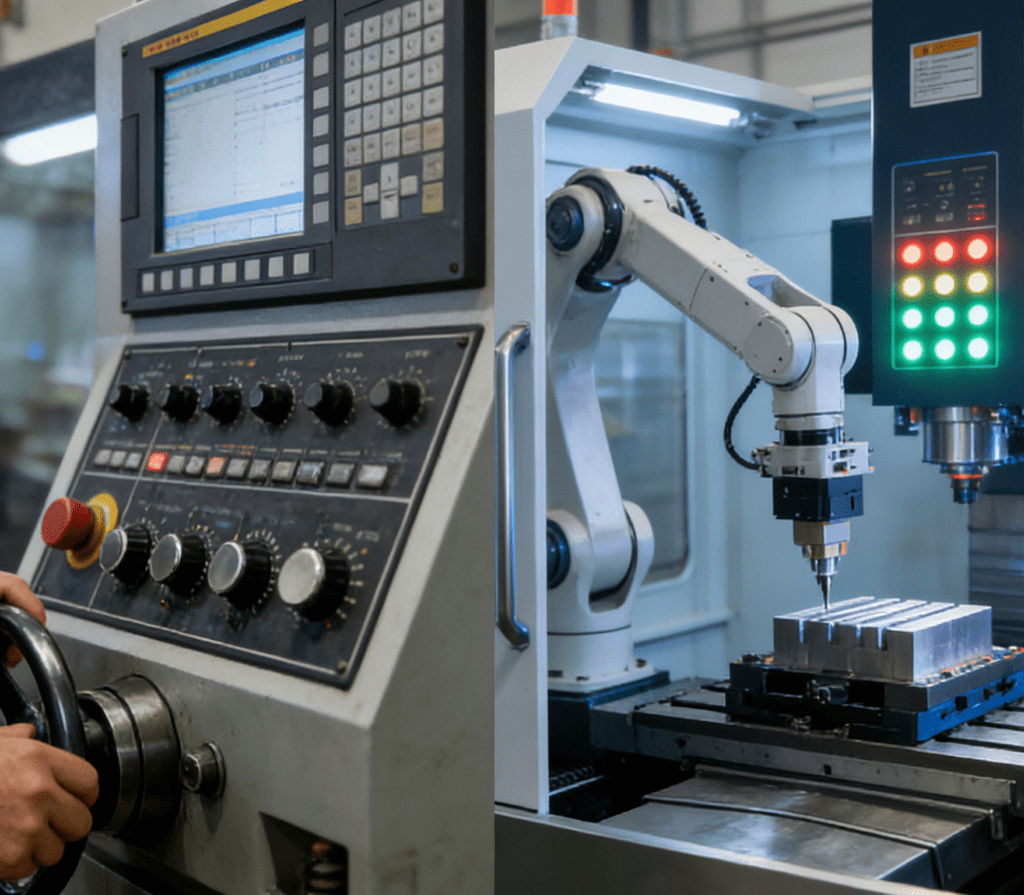

In CNC machining, issues like overcut and tool deflection frequently occur, leading to reduced workpiece precision and tool damage. To address these challenges, this article systematically introduces a 4-step solution. First, we will explore precise tool selection strategies to help you choose suitable tools and apply compensation methods. Second, we will elaborate on key parameter optimization techniques, including adjusting settings such as rotational speed, feed rate, and depth of cut. Then, we will discuss measures to enhance clamping stability, ensuring a more reliable machining process. Next, we will provide practical improvement strategies that you can immediately apply in real work. By following these steps, you can gradually reduce vibration and […]

Differences Between CNC Precision Machining and Conventional Machining: A Dialogue Between Precision and Efficiency

In the arena of manufacturing, machining technologies are like dancers of different schools, each showcasing unique charm. CNC precision machining and conventional machining are two such performers with distinct styles—though both fall under the machining category, they exhibit striking differences in precision, efficiency, application scenarios, and other aspects. Many manufacturing enterprises often face confusion when choosing a machining method: what exactly sets them apart, and where do their respective advantages lie? Next, we will adopt an anthropomorphic perspective to take you deep into the core differences between these two machining technologies, providing a reference for your production decision-making. CNC precision machining and conventional machining are like the “precision artists” […]

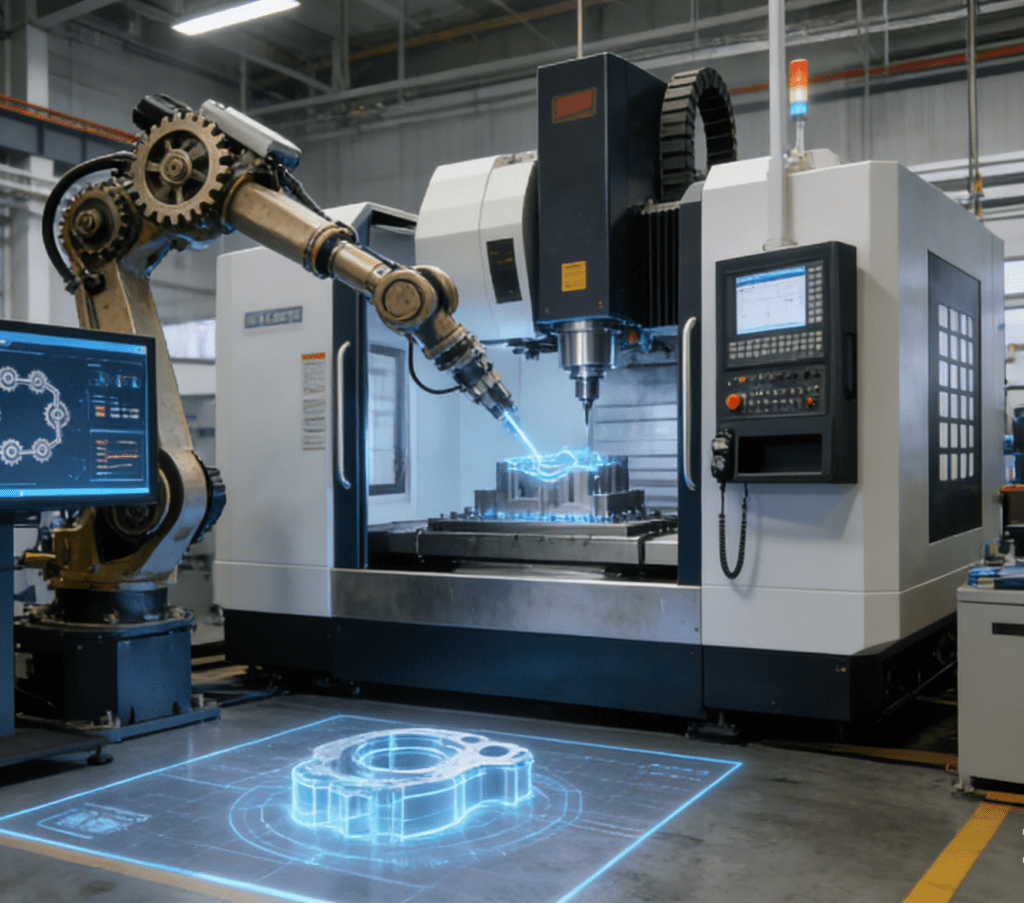

CNC Machining Process Route Planning: Follow Tradition or Embrace Bold Innovation?

In the field of CNC machining, process route planning is a key link to ensure machining quality and efficiency. The question of whether to adhere to traditional methods or boldly attempt innovations in CNC machining process route planning has long been a hotly debated topic in the industry. CNC machining (Computer Numerical Control machining), especially CNC precision machining and precision part machining, imposes extremely high requirements on the scientificity and rationality of process routes. Traditional Process Routes: Maturity, Stability, and Proven Reliability Traditional CNC machining process route planning has been verified by long-term practices and is characterized by maturity and stability. Based on existing machining experience and fixed […]

Chip Removal in CNC Precision Machining: Simple Solutions or In-depth Transformation?

In the field of CNC machining, especially CNC precision machining, the issue of chip removal has long been a key factor affecting machining quality and efficiency. As the precision requirements for precision part machining continue to rise, the choice of chip removal methods is facing a dilemma: simple solutions or in-depth transformation. Traditional Simple Solutions: Application Scenarios and Limitations Traditionally, many enterprises have adopted a simple coping strategy for chip removal in CNC precision machining. A common method is to flush the machining area with coolant to wash away chips. This approach can clear chips to a certain extent and ensure machining continuity. For CNC machining scenarios with […]

CNC Machining Process Route Planning: Follow Tradition or Embrace Bold Innovation?

In the field of CNC machining, process route planning is a key link to ensure machining quality and efficiency. The question of whether to adhere to traditional methods or boldly attempt innovations in CNC machining process route planning has long been a hotly debated topic in the industry. CNC machining (Computer Numerical Control machining), especially CNC precision machining and precision part machining, imposes extremely high requirements on the scientificity and rationality of process routes. Traditional Process Route Planning: Mature and Stable with Proven Value Traditional CNC machining process route planning has been verified by long-term practices and is characterized by maturity and stability. Based on existing machining experience […]

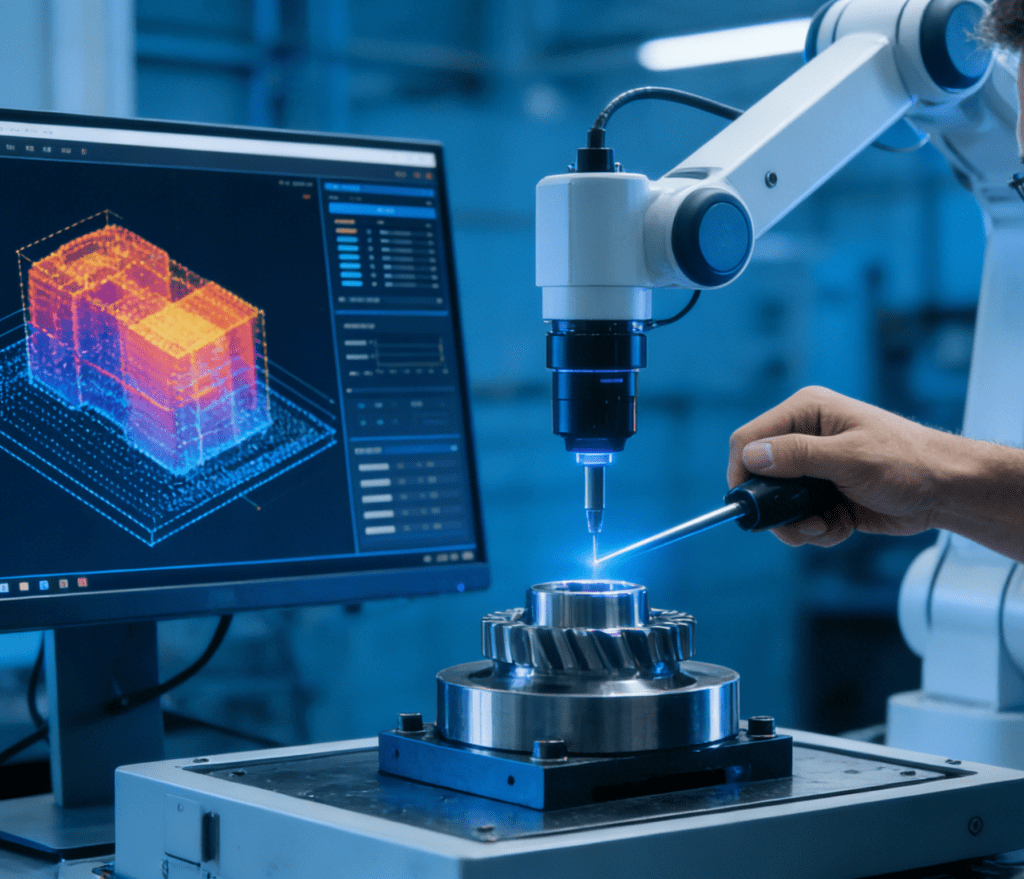

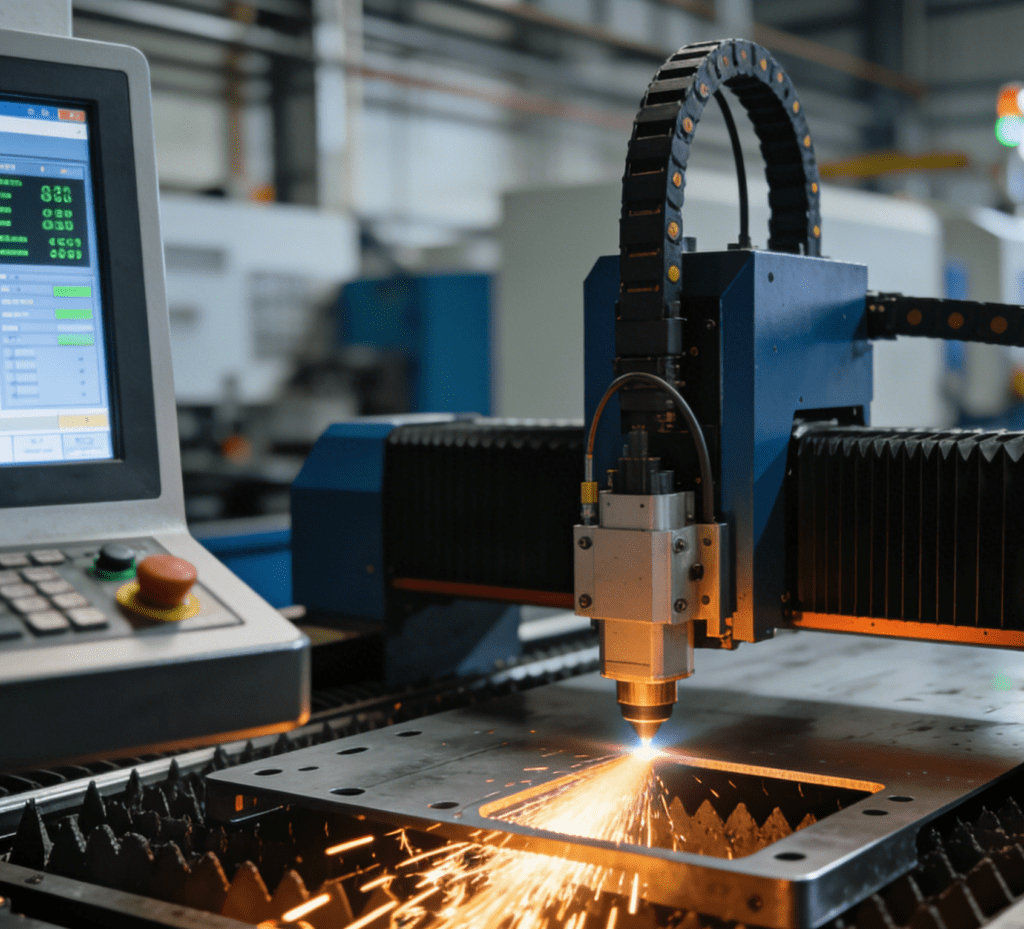

Dimensional Accuracy Control Strategies in Precision Part Machining

In modern manufacturing, the dimensional accuracy of precision part machining directly determines product performance and quality. From precision electronic components to core components of large-scale equipment, high-precision parts are the key to ensuring the normal operation of products. Especially in fields such as laser sheet metal processing and sheet metal chassis manufacturing, the requirements for dimensional accuracy are extremely stringent. Below, let’s explore the crucial dimensional accuracy control strategies in precision part machining. Application of Advanced Machining Equipment High-precision machining equipment is the foundation of ensuring dimensional accuracy. In laser sheet metal processing, advanced laser cutting machines are equipped with high-precision CNC systems, which can accurately control the […]

Precision CNC Machining Requirements for Raw Materials: Reasonable Constraints or Resource Waste?

In modern manufacturing, precision CNC machining technology has become a key link in the production of numerous high-end products due to its high precision and efficiency. However, its specific requirements for raw materials have sparked extensive discussions: are these requirements reasonable constraints or a waste of resources? The Rationality of Strict Requirements: Guaranteed Quality and Technological Progress Precision CNC machining usually requires raw materials to have good dimensional stability, uniform material structure, as well as specific physical and chemical properties. For instance, in the aerospace field, strict standards are imposed on the purity, grain size, and internal defects of metal materials used for manufacturing key components. From a […]

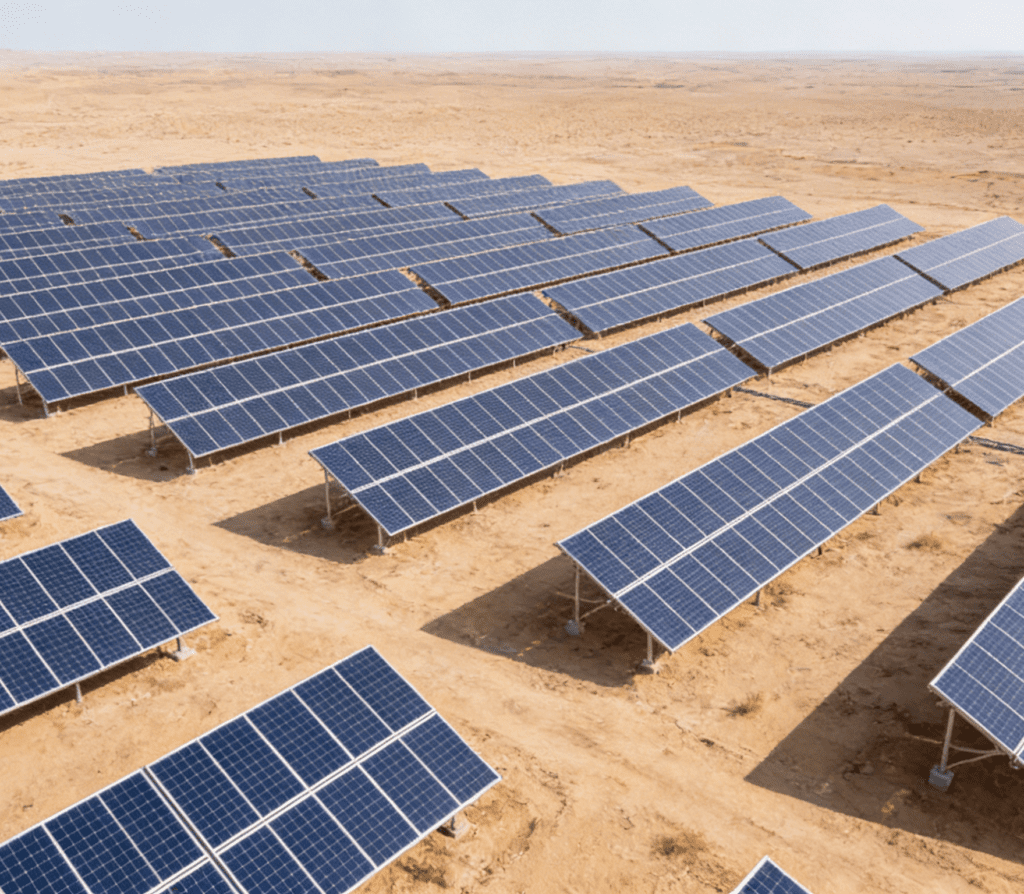

LONGi Green Energy’s BC Modules Win Bid for 696MW PV Project in Ningxia

Recently, LONGi Green Energy successfully won the bid for the 696MW photovoltaic (PV) project of Ningxia Zhongying Zhengyuan Power Generation Co., Ltd., relying on its second-generation BC technology product, the Hi-MO 9 module, once again setting a new record for the largest bid-winning scale of BC modules in China. The project consists of two sub-projects: a 380MW project in Tongxin County, Wuzhong City, Ningxia, and a 200MW project in Yongning County, Yinchuan City, with an AC-side installed capacity of 580MW and a DC-side installed capacity of 696MW. Economic & Technical Advantages: BC Modules Outperform in Comprehensive Feasibility Study During the feasibility study phase of the project, the design […]

UBTECH Officially Included in the “HKEX Tech 100 Index”

As a new benchmark emerges in the tech landscape of Hong Kong stocks, the strength of Chinese technology is gaining global capital attention. On December 9, the Hong Kong Exchanges and Clearing Limited (HKEX) made a major announcement of the first batch of constituent stocks for the “HKEX Tech 100 Index”. UBTECH Robotics (Stock Code: 09880.HK), hailed as the “first stock of humanoid robots”, was successfully selected. The “Entry Ticket” to the Index The “Passport” to Hard Tech Strength The “Tech 100” Index launched by HKEX is by no means an ordinary list. It adopts R&D intensity, innovation capability and industry representativeness as its core screening criteria. Constituent […]

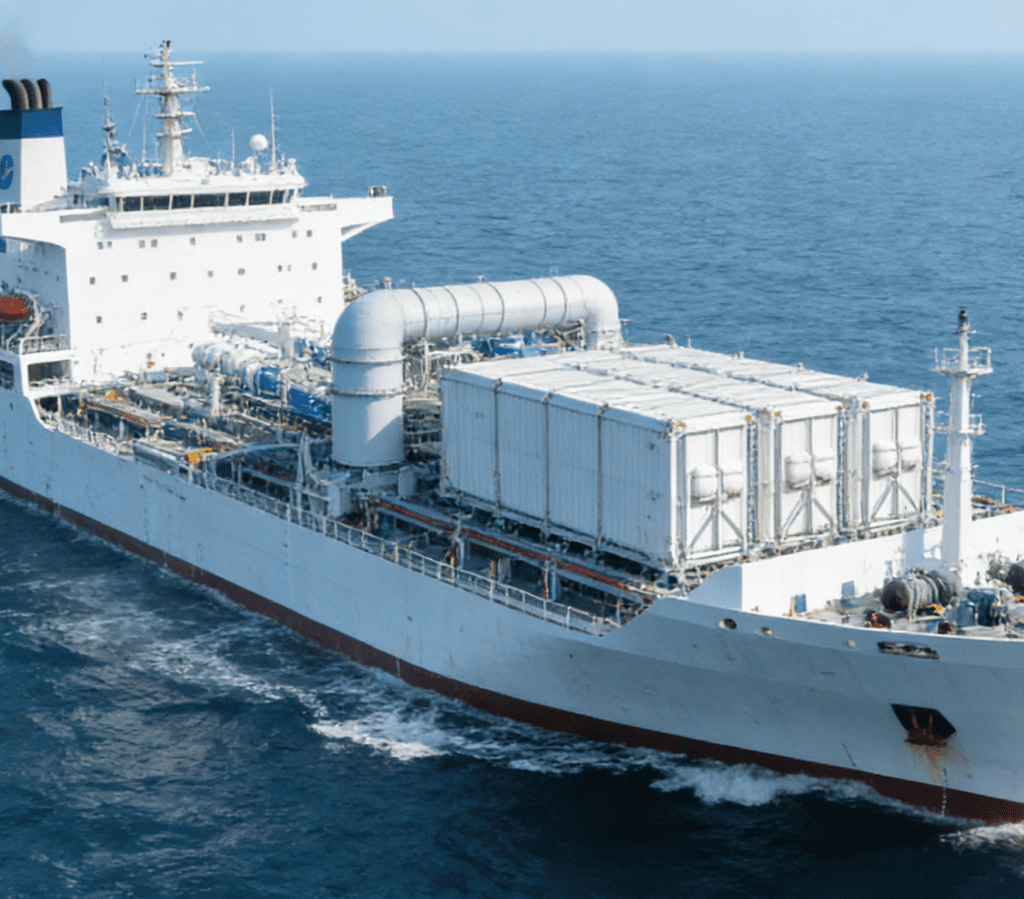

Key Milestones Achieved in the First-of-Class New Vessel Projects of Multiple Shipyards

Recently, several Chinese shipbuilding enterprises have successfully hit key milestones in their first-of-class new vessel projects. This not only demonstrates the spirit of bold breakthroughs and forging ahead of China’s shipbuilding enterprises, but also reflects the depth and breadth of technological accumulation of China’s shipbuilding industry across various vessel types. Xiamen Shipbuilding Industry Commences Construction of the First 80,000 DWT Universal Bulk Carrier A groundbreaking ceremony for the first vessel in the series of 80,000 DWT universal bulk carriers built by Xiamen Shipbuilding Industry for CITIC Financial Leasing was recently held successfully. The start of construction of this vessel not only marks the phased progress of the series […]