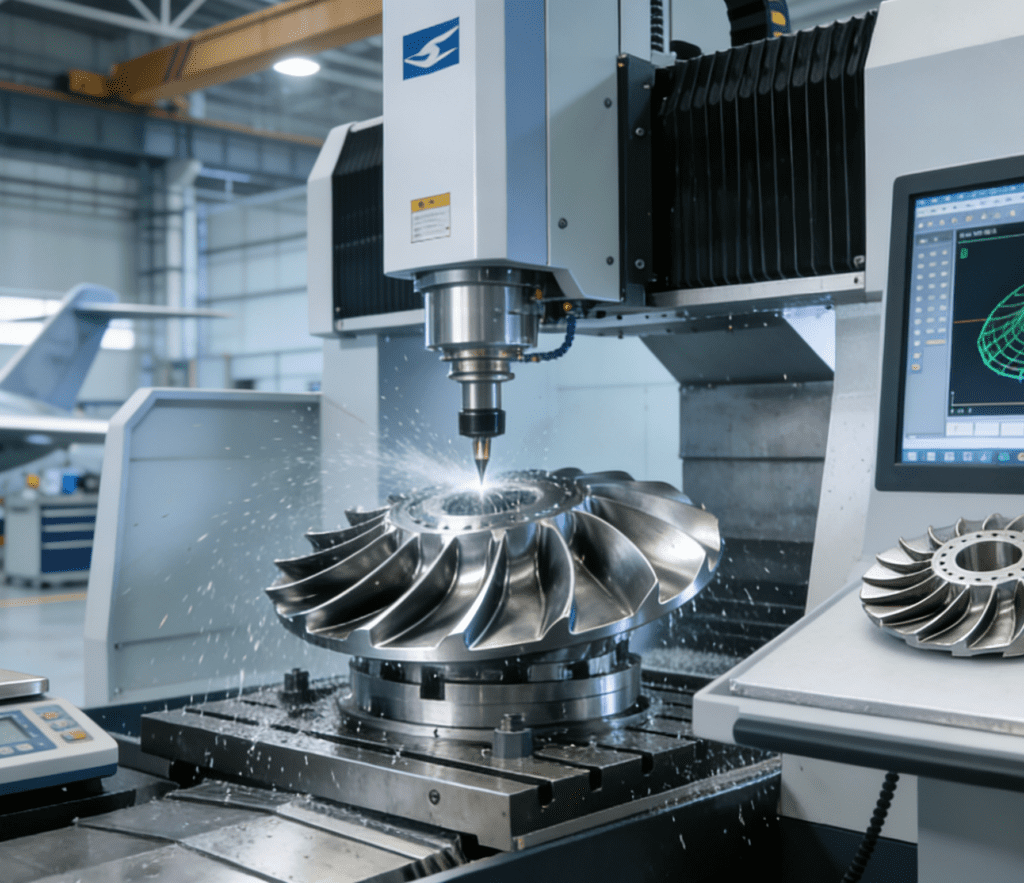

CNC 4-Axis Machining — Intelligent Cutting Reshaping a New Era of Industrial Manufacturing

With the rapid development of science and technology, traditional machining methods are increasingly unable to meet the ever-growing complex production demands, while CNC 4-axis machining stands out with its outstanding advantages. It is not merely a machining technology, but also a powerful driving force propelling the continuous advancement of various industries. So, what are the remarkable advantages of CNC 4-axis machining? The advantages of CNC 4-axis machining are mainly reflected in the following five aspects: High-Precision Machining CNC 4-axis machining is capable of achieving extremely high machining precision. In traditional 3-axis machining, due to the constraints of workpiece shape and machining requirements, multiple clamping and adjustment procedures may be required, […]

CNC 4-Axis Machining — Intelligent Cutting Reshaping a New Era of Industrial Manufacturing

With the rapid development of science and technology, traditional machining methods are gradually unable to meet increasingly complex production demands, while CNC 4-axis machining stands out with its outstanding advantages. It is not only a machining technology, but also a powerful driving force for the continuous advancement of various industries. So, what are the remarkable advantages of CNC 4-axis machining? The advantages of CNC 4-axis machining are mainly reflected in the following five aspects: High-Precision Machining CNC 4-axis machining can achieve extremely high machining precision. In traditional 3-axis machining, due to the limitations of workpiece shape and machining requirements, multiple clamping and adjustment operations may be required, which are prone […]

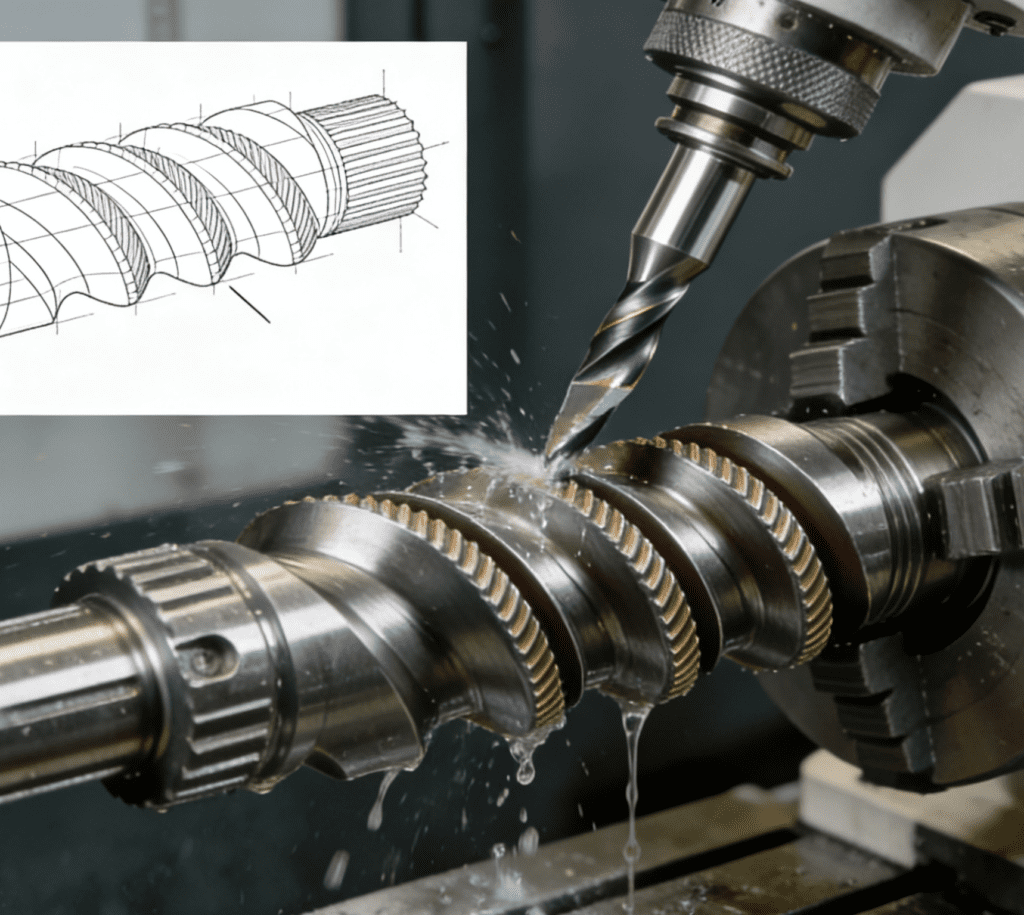

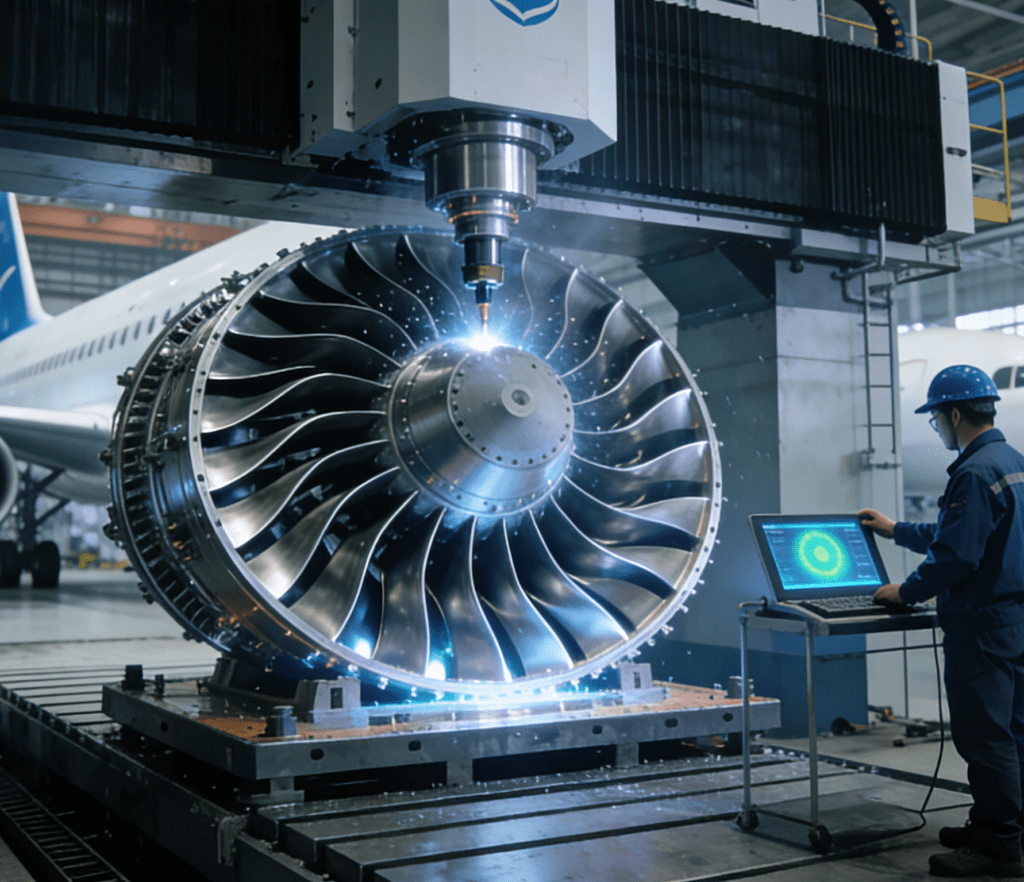

What is CNC 5-Axis Machining?

CNC, short for Computer Numerical Control, is a technology that uses computer programs to precisely control the movement of machine tools. 5-axis machining, on the other hand, adds two rotary axes—usually two out of the A, B, and C axes—to the traditional three linear axes (X, Y, Z). These two rotary axes enable the workpiece to rotate at different angles, allowing the cutting tool to machine the workpiece from more orientations. The principle of 5-axis machining may seem complex, but it actually embodies sophisticated engineering design. First, programming and design are carried out using professional CAD/CAM software. Based on the workpiece’s shape, dimensions, and machining requirements, designers precisely plan the […]

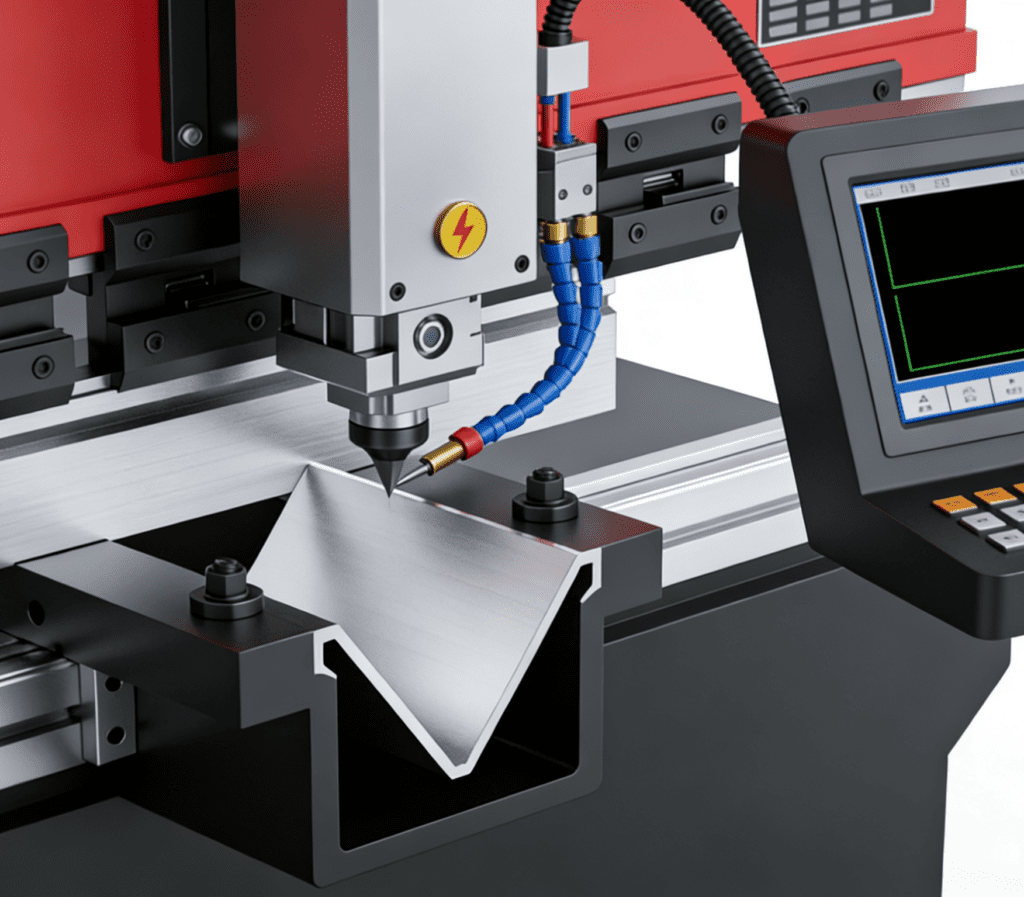

CNC Bending Process

CNC bending technology is mainly realized by CNC bending machines. A CNC bending machine consists of two major components: the mechanical structure and the CNC system. The mechanical structure includes parts such as the worktable, slider, and mold. Its working principle is that the CNC system precisely controls the movement trajectory and pressure of the slider, causing the metal sheet placed on the worktable to undergo plastic deformation under the action of the mold, thereby achieving the bending operation. The CNC system is the core of CNC bending technology. First, the operator inputs relevant bending parameters, such as bending angle, bending length, and bending speed, into the CNC system. Based […]

CNC Wire Cut EDM Technology

CNC Wire Cut EDM TechnologyCNC wire cut Electrical Discharge Machining (EDM) technology uses a continuously moving thin metal wire (referred to as the electrode wire) as the tool electrode. It removes metal from the workpiece through pulsed electrical discharge, thereby achieving cutting and machining of the workpiece.During the machining process, a certain discharge gap is always maintained between the electrode wire and the workpiece. When the pulse voltage generated by the pulse power supply is applied between the electrode wire and the workpiece, spark discharge occurs in an extremely short time. This causes the local metal on the workpiece surface to melt and vaporize instantly and be eroded away. By […]

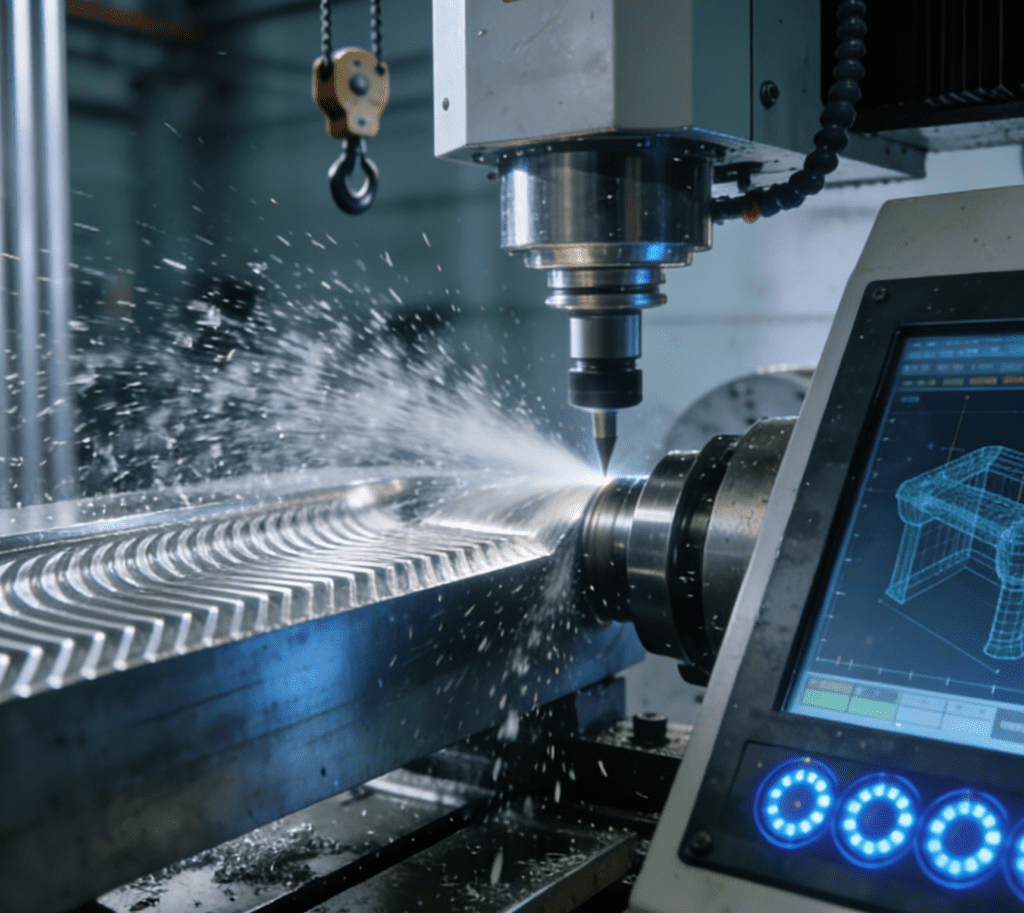

A New Leap in CNC Machining! High-Speed Cutting Technology Leads a New Revolution in Manufacturing Speed

High-speed cutting refers to a machining technology that adopts a cutting speed much higher than the conventional one. Generally speaking, it can be called high-speed cutting when the cutting speed exceeds 5 to 10 times that of traditional cutting. High-speed cutting usually employs high-speed spindles, advanced cutting tools and optimized machining parameters to achieve efficient and high-precision machining. The Principle of High-Speed Cutting The principle of high-speed cutting is mainly based on the following aspects: Reduced Cutting Force During the high-speed cutting process, the cutting force decreases significantly as the cutting speed increases. This is because the temperature of the cutting deformation zone rises in high-speed cutting, which reduces the […]

Surface Treatment Technologies After CNC Machining

Surface Treatment Technologies After CNC MachiningIn modern manufacturing, the widespread application of CNC machining technology has greatly improved the precision and shape complexity of parts. However, the surfaces of parts processed by CNC machining usually require further treatment to meet different performance and appearance requirements. Here are some common surface treatment technologies after CNC machining. Spraying Spraying is a common surface treatment method that uses a spray gun to evenly apply coating onto the surface of parts. Spraying offers a wide range of color options, while also protecting the part surface from corrosion and wear. Different types of coatings are suitable for different application scenarios. For example, anti-rust […]

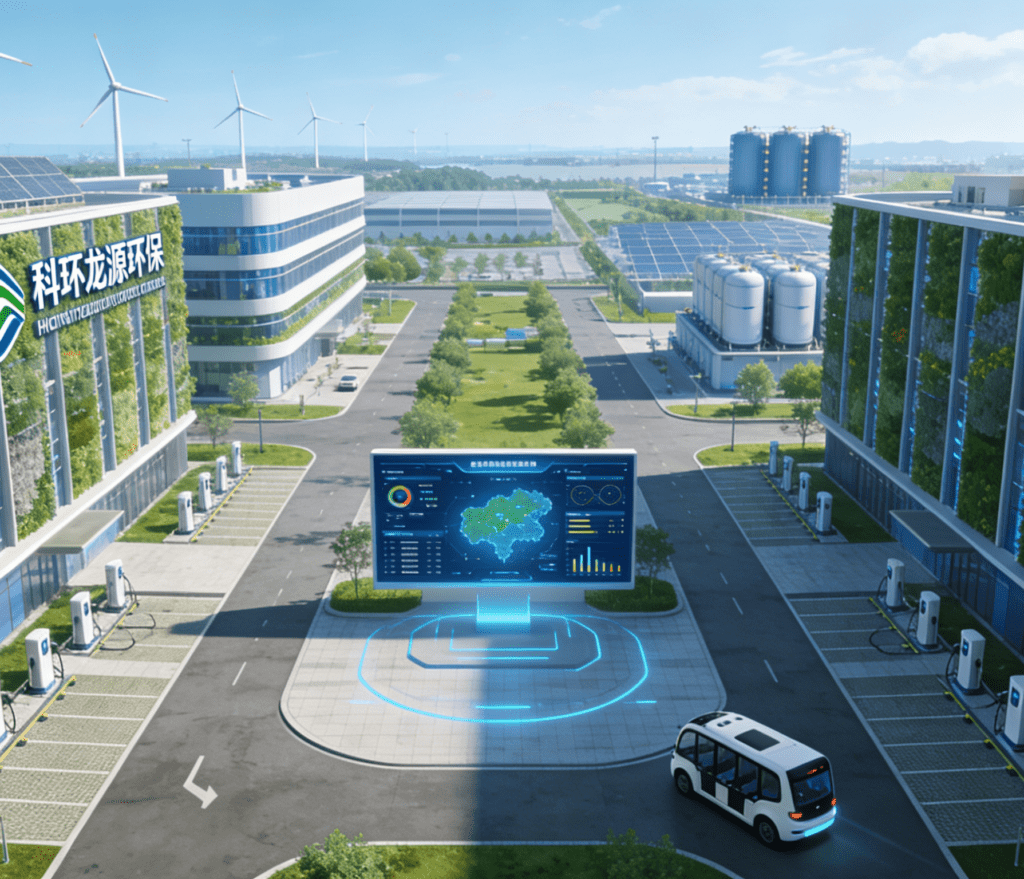

Kehuan Longyuan Environmental Protection Helps Build a Green Benchmark for Smart Zero-Carbon Parks

In response to the national strategy of pollution reduction, carbon emission reduction and green expansion, Kehuan Longyuan Environmental Protection has actively laid out the construction of zero-carbon parks. By deeply integrating the advantages of green power with park carriers, the company has participated in two projects: the Boao Dongyu Island Zero-Carbon Demonstration Zone in Hainan and the Ganquanpu Source-Grid-Load-Storage Integrated Park in Xinjiang. Covering multiple application scenarios such as low-carbon buildings, low-carbon parks, green transportation and incremental distribution networks, these projects have provided highly valuable model cases for the group company to promote the construction of zero-carbon parks. Boao Zero-Carbon Demonstration Zone in Hainan The smart energy project […]

China-Denmark Green Ship Repair and Conversion Seminar Held in Shanghai

Release of Typical Cases on Supporting and Upgrading Jiangsu’s Food Industry ChainRecently, the Food Safety Special Committee of Jiangsu Provincial Food and Drug Safety Commission released the 2025 typical cases on supporting and upgrading the province’s food industry chain. The initiative aims to summarize and promote effective models and experiences in providing targeted services for industrial development, generate a batch of replicable and scalable practical outcomes, and further drive the high-quality development of Jiangsu’s food industry. Government-Enterprise Collaboration: Enabling Nanjing Duck Blood Vermicelli Soup to “Go Global” Taking the export of Nanjing duck blood vermicelli soup as a breakthrough, the Special Committee launched an innovative support project for […]

China-Denmark Green Ship Repair and Conversion Seminar Held in Shanghai

Overview of the Seminar: Chinese and Danish Maritime Sectors Gather in Shanghai to Discuss Green Development On the afternoon of December 4, the China-Denmark Green Ship Repair and Conversion Seminar was successfully held during the Shanghai Maritime Exhibition. More than 30 representatives from relevant maritime enterprises and institutions of China and Denmark attended the seminar. COSCO Shipping Heavy Industry Co., Ltd., the chairman unit of the Ship Repair Branch of China Association of the National Shipbuilding Industry, hosted the event. Speeches by Both Sides: Anchoring the Core Value of Green Conversion and Looking Forward to Cooperation Prospects Li Yanqing, Vice President of the China Association of the […]