Toothbrush Case Packing Machine

A Comprehensive Analysis of CNC Machining Types: Opening the Door to Precision Manufacturing

In today’s manufacturing industry, CNC (Computer Numerical Control) machining technology provides strong support for the realization of precision manufacturing. CNC machining encompasses a variety of types, each with unique characteristics and application scopes, jointly driving the manufacturing industry toward higher precision and efficiency. CNC Milling CNC milling is a common type of CNC machining. It mainly cuts workpieces using rotating cutting tools and is capable of machining various complex planar and curved shapes. It is widely used in fields such as mold manufacturing and aerospace component machining. For example, when manufacturing a complex plastic mold, CNC milling can precisely machine the mold cavity and core, ensuring the mold’s […]

An Introduction to CNC Machining: Opening the Door to Precision Manufacturing

In the vast landscape of modern manufacturing, CNC (Computer Numerical Control) machining acts like a key, unlocking the door to the world of precision manufacturing. This technology, which integrates advanced computer technology with the essence of traditional mechanical machining, is spearheading the transformation and development of the manufacturing industry with its unique features and extensive application scope. CNC Machining: Definition and Working Principle CNC machining, or Computer Numerical Control machining in full, is a technology that utilizes pre-written computer programs to control machine tools for automated machining operations. Its fundamental principle is that pre-compiled numerical control programs guide the cutting tools on machine tools to perform machining operations […]

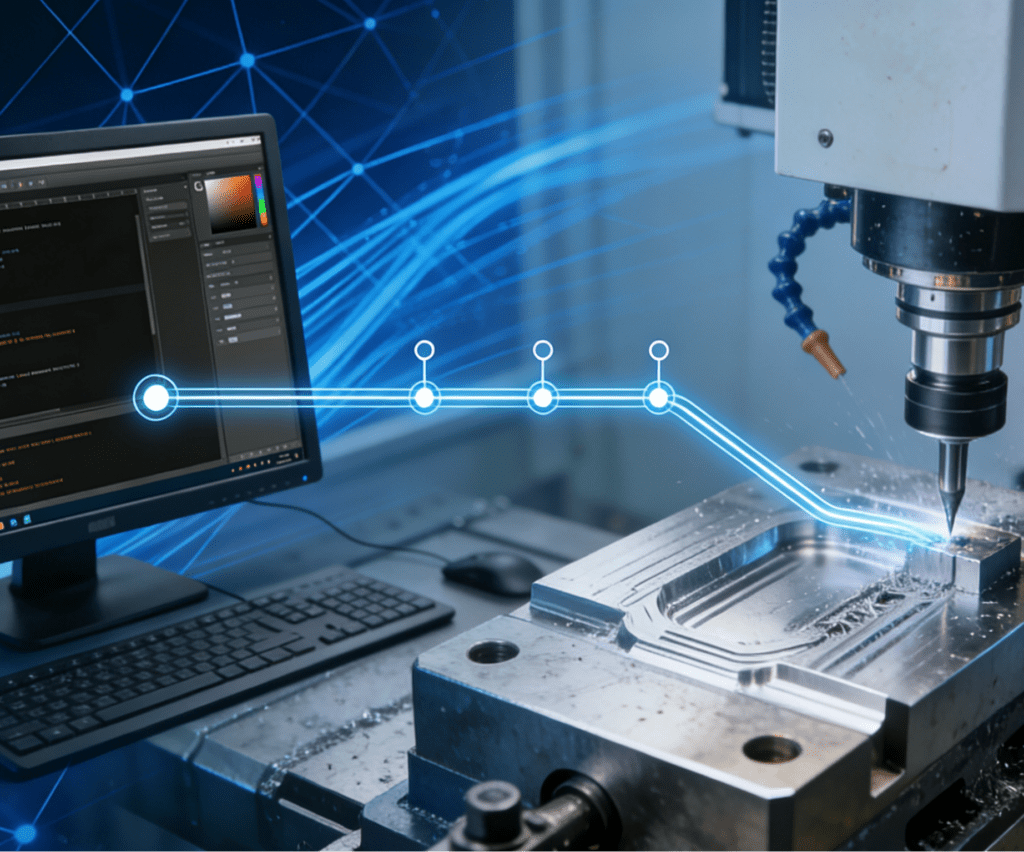

Programming Skills for CNC Machining: Enabling the Machining of Complex Parts

CNC machining is a process that uses pre-written programs to control machine tools for automated machining. The programs contain information such as the machine tool’s motion trajectory, cutting parameters, and tool selection. Before programming, it is necessary to have an in-depth understanding of the machine tool’s structure, working principle, and various machining processes. Only in this way can efficient and accurate programs be written. Rational Selection of Programming Software There are many CNC programming software options available on the market currently, such as MasterCAM, UG, and PowerMILL. Different software programs have distinct features and advantages, and the appropriate one should be selected based on specific machining requirements. For […]

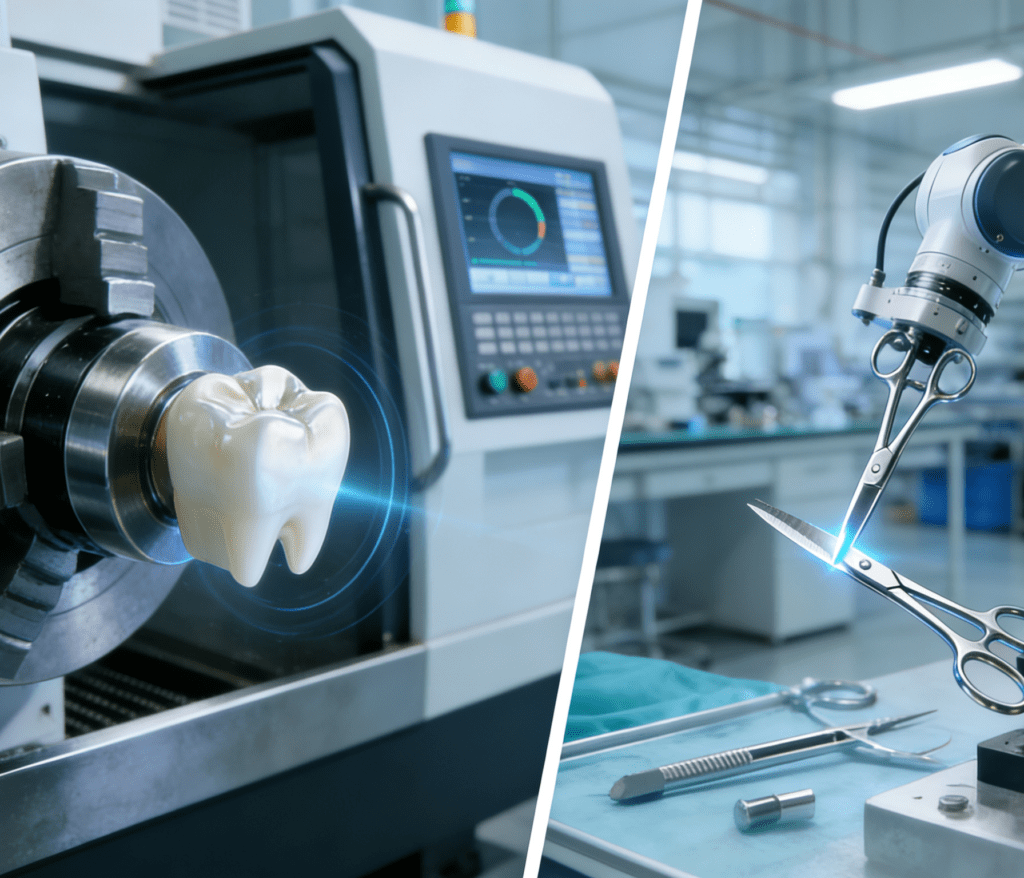

Precision Machining with Digital Control: Integration of Technology and Accuracy

Core Technologies: Algorithms and Control Principles Precision machining with digital control is a method that uses digital technology to achieve precise control over the mechanical machining process. By virtue of advanced algorithms and control systems, it enables accurate positioning of machining tools, precise control of motion trajectories, and real-time adjustment of machining parameters, thereby ensuring that the processed parts possess extremely high precision and quality. The underlying algorithms are the core of precision machining with digital control. These algorithms mainly include path planning algorithms, interpolation algorithms, and error compensation algorithms. Path planning algorithms are responsible for determining the motion trajectory of machining tools on the workpiece to achieve […]

Exploring Precision Digital Manufacturing: How Programming Enables Accurate Machining

Core Enablers: Programming, Algorithms and Control Principles The core of precision digital manufacturing lies in the precise control of the machining process through programming. By virtue of complex algorithms and advanced control principles, it achieves a seamless connection from design to finished products, laying a solid foundation for the production of high-precision products. Programming plays a vital role in precision digital manufacturing. First of all, programmers need to convert design drawings into machine-understandable instructions using specific programming languages and software according to product design requirements. These instructions include the movement trajectory of machining tools, cutting parameters, feed rate and so on. Accurate control of these parameters ensures the […]

“Zero-Carbon Power Bank” Debuts at Jiading Hydrogen Energy Port

On November 27, the off-grid demonstration project of integrated source-grid-load-storage zero-carbon hydrogen storage at Jiading Hydrogen Energy Port in Shanghai was broadcast live on China Central Television (CCTV). As China’s first zero-carbon energy system to achieve a full “electricity-hydrogen-electricity” closed loop, it has attracted widespread attention for its innovative technologies and remarkable benefits. It is understood that this demonstration project is Shanghai’s first full-closed-loop zero-carbon hydrogen storage project integrating source, grid, load and storage, with a core logic analogous to a “zero-carbon power bank”. Based on a 1.4-megawatt photovoltaic power generation system, the project captures solar energy through rooftop photovoltaic panels and converts it into electricity. To address the […]

Zoomlion’s Flagship Paddy Field Agricultural

Event Overview: On-site Highlights and Flagship Harvester Debut Recently, Zoomlion’s new paddy field agricultural machinery product appreciation event was successfully held in Changde, Hunan Province. A customer group consisting of over 500 large grain growers and professional operators from Hubei and Hunan provinces participated on site. A number of flagship products including the 2026 model crawler harvesters, power-shift tractors and intelligent assisted driving transplanters made their upgraded debut, receiving high praise and positive feedback from the customer group, with over 200 units ordered on the spot. The Zoomlion PL80-S crawler harvester, which has undergone 102 targeted enhancements and 16 optimization upgrades, became the absolute highlight of the event. […]

Restructuring the Knowledge and Competence System to Cultivate π-shaped Talents for Intelligent Manufacturing

In recent years, the rapid development of artificial intelligence technologies such as ChatGPT-5, o4-mini, Grok, Gemini and China’s DeepSeek is profoundly reshaping the field of intelligent manufacturing. From intelligent production lines to collaborative operations of embodied intelligent robots, driven by the wave of AI-enabled digital transformation and intelligent upgrading, the demand for traditional manufacturing positions has undergone drastic changes, while emerging occupations such as AI engineers, intelligent manufacturing engineers and additive manufacturing engineers have been created. This transformation not only tests enterprises’ capability in implementing intelligent upgrading, but also calls for interdisciplinary talents who possess both in-depth AI technology expertise and manufacturing know-how, injecting new impetus into the intelligent manufacturing […]

Another Major Green Hydrogen Project in Inner Mongolia Publicized

Project Overview: Scale and StrategAic Significance On December 2, 2025, the People’s Government of Aohan Banner, Chifeng City, officially released the Public Notice on the Social Stability Risk Assessment of the Ar Horqin-Ningcheng Green Hydrogen Pipeline Project. According to the public notice document, this large-scale pipeline network project has a total length of 808.8 kilometers and a total investment of 5.5 billion yuan, marking that the largest dedicated green hydrogen transmission network in northern China has entered a substantive advancement stage.The Ar Horqin-Ningcheng Green Hydrogen Pipeline Project publicized this time is not a single pipeline, but a systematic hydrogen transmission network composed of five interconnected pipelines. The entire network […]