Advantages and Application Exploration of 4-Axis Simultaneous CNC Machine Tools in Precision Manufacturing

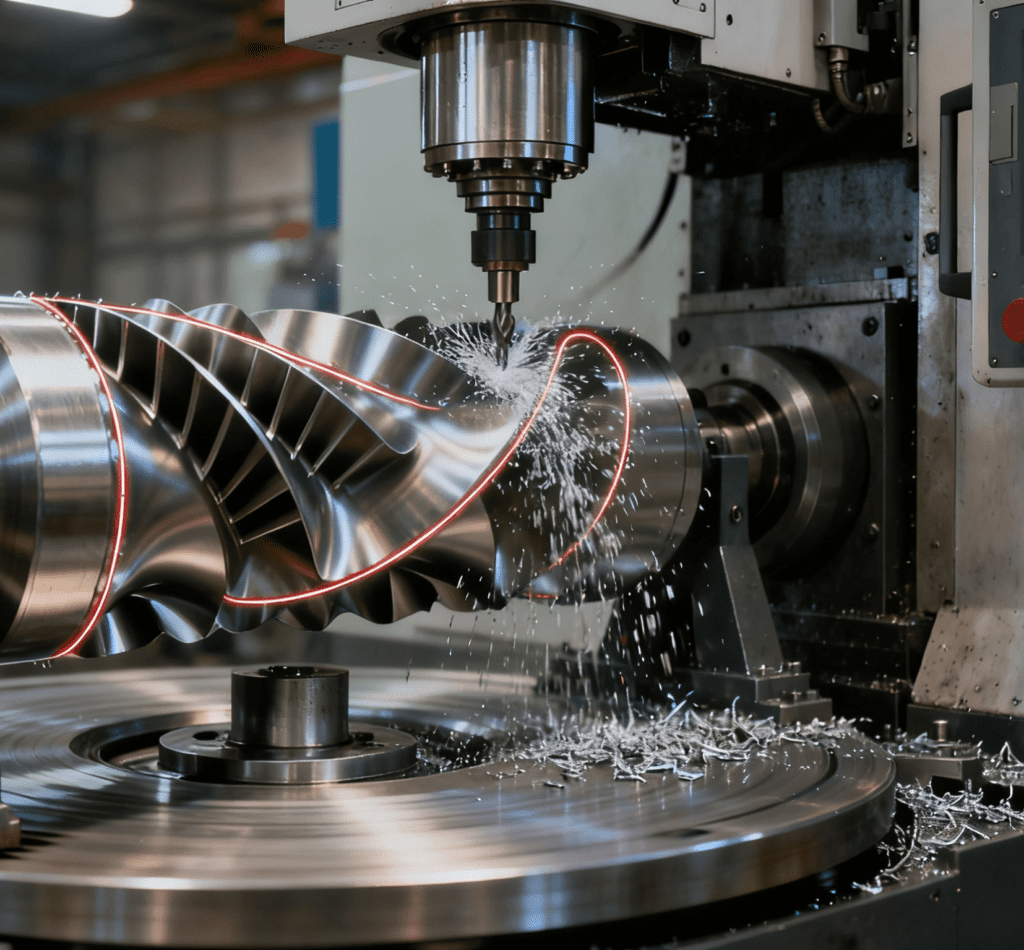

As important equipment in the field of modern precision manufacturing, 4-axis simultaneous CNC machine tools possess unique advantages and application potential. When we gain an in-depth understanding of CNC machine tools, the definition of 4-axis simultaneous machining is that a fourth axis, namely the rotary axis, is added on the basis of traditional 3-axis machining. This enables not only planar cutting during the machining process but also three-dimensional processing of complex parts, thus greatly improving machining flexibility. In addition, 4-axis machine tools can achieve multi-angle and multi-directional machining on a fixed workpiece, thereby enhancing production efficiency and part precision. Notably, for batch production of small precision parts, 4-axis simultaneous CNC […]

CNC Precision Machining: How to Achieve High-Quality and High-Efficiency Part Manufacturing?

In modern manufacturing, precision machining is a core link to improve product quality and production efficiency. We understand that precision machining is not merely repetitive operation, but also involves complex processes and technologies. Its basic concept is to remove materials in accordance with strict dimensional standards through high-precision equipment and process parameters, thereby obtaining high-precision and high-complexity components. In this process, we need to fully consider every link of raw materials, processing equipment and production flow. This importance is reflected in multiple aspects: first, precision machining can effectively reduce the defective product rate of products and improve overall production efficiency. Second, its high-precision requirements provide important support for many high-end […]

Unveiling CNC Machining Technology: Practical Applications and Advantages of 4-Axis and 5-Axis Machine Tools

A 4-axis machine tool is a type of numerical control (NC) equipment developed based on traditional 3-axis machine tools, capable of providing an additional rotational axis during machining, which typically rotates around a fixed point of the workpiece. The design of this machine tool enables multi-angle machining of workpieces, thereby improving machining flexibility and efficiency. A 4-axis machine tool generally consists of three linear motion axes (X, Y, Z) and one rotational axis, the latter commonly referred to as a rotary table or dividing head. This structure allows for the machining of complex-shaped parts such as molds and aerospace components—many of which require subsequent nut assembly, and the machining precision […]

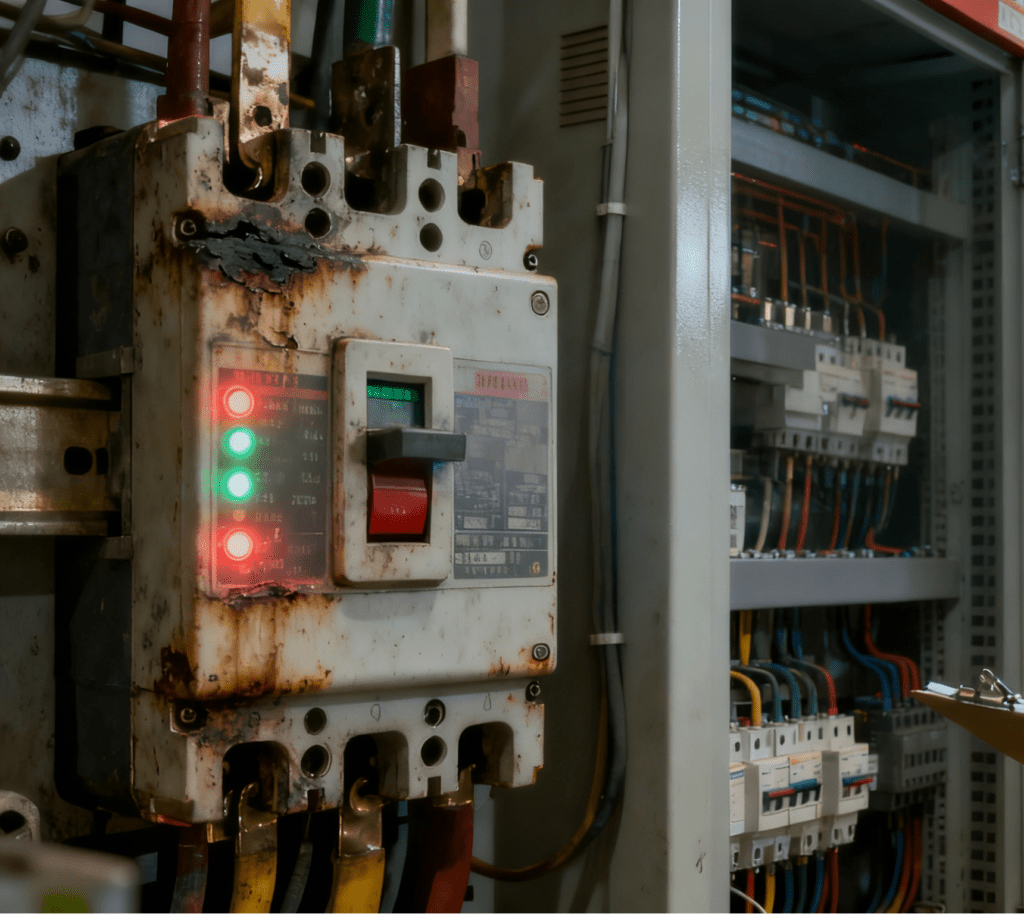

ABB Low-Voltage Digital & Intelligent Upgrade Services: Empowering Enterprises to Achieve Worry-Free Operation and Maintenance

As the service life extends, component aging and performance degradation of traditional low-voltage distribution equipment are inevitable, leading to a decline in operation and maintenance (O&M) efficiency. Aging core components pose persistent risks; abnormal heating at connection points, blind spots in operation and maintenance, and insufficient precision of motor protection devices frequently result in equipment damage. Especially in production workshops equipped with Sheet automatic loading robot and other automated equipment, the instability of low-voltage distribution systems is more likely to cause abnormal startup/shutdown of robots, deviation in loading precision, and even interrupt the entire production line, amplifying the losses caused by faults. At the O&M management level, the traditional […]

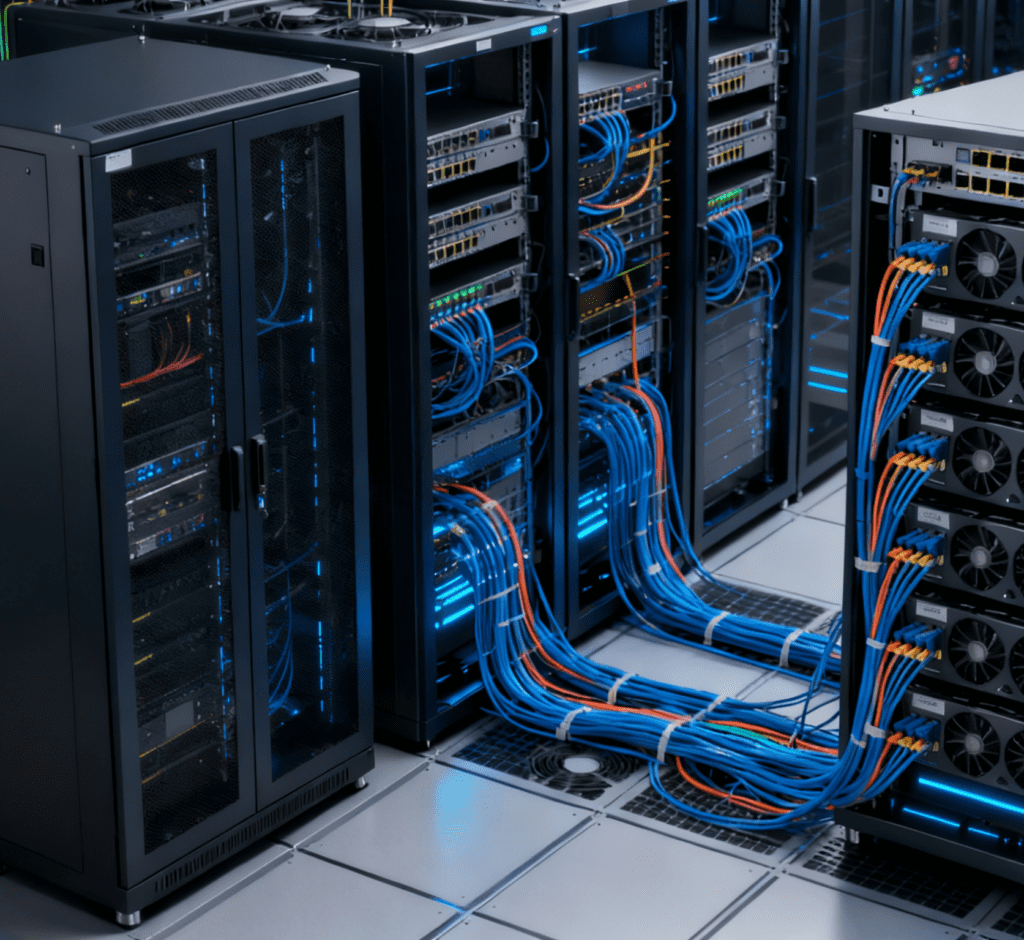

How Modular Cabling Addresses Key Challenges in AI Data Center Networks

With the rapid development of artificial intelligence (AI) technology, the network architectures of data centers are facing unprecedented challenges. The high demands of AI workloads on computing power, storage, and networks make traditional data center network architectures unable to meet the needs of modern AI applications. As an innovative solution, modular cabling is emerging as a key technology to tackle these challenges. This article explores how modular cabling addresses the critical challenges of AI data center networks and provides practical deployment recommendations—with insights into how such network upgrades also empower high-precision manufacturing scenarios like Catheter Assembly Machine operations. Key Challenges of AI Data Center Networks High-Density Cabling Requirements AI […]

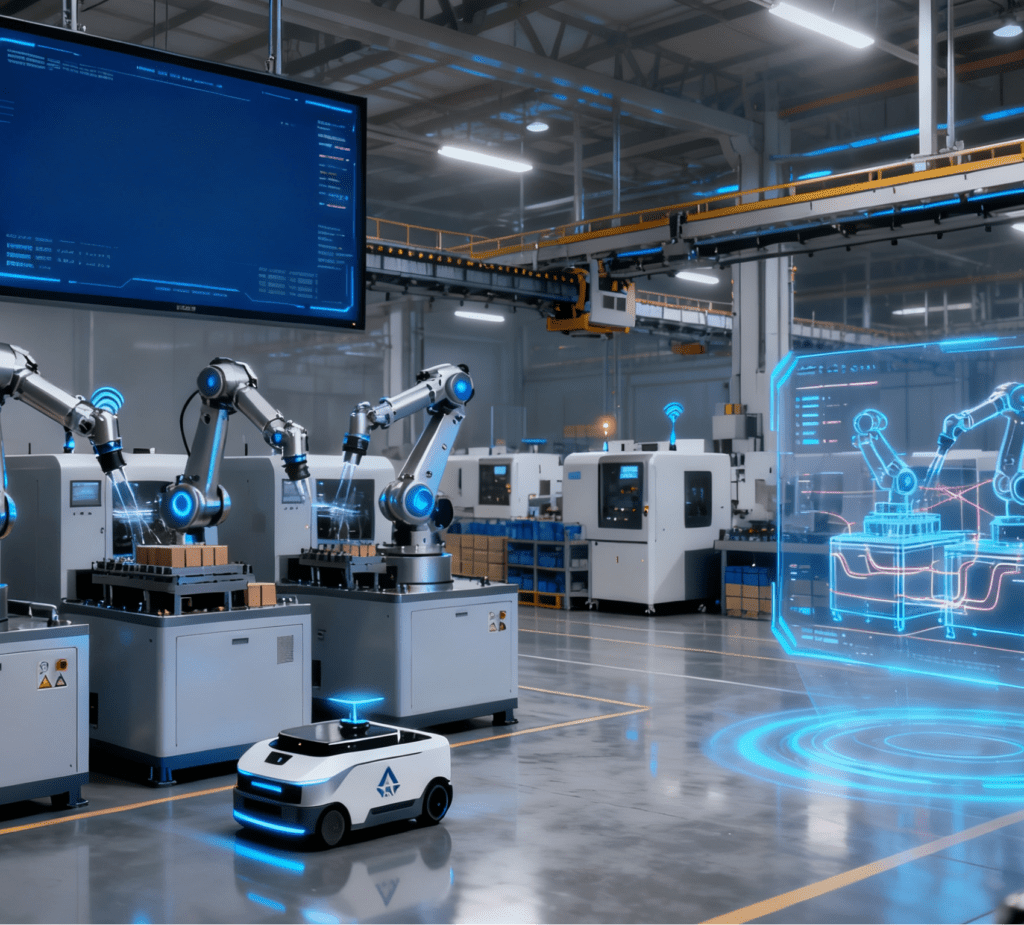

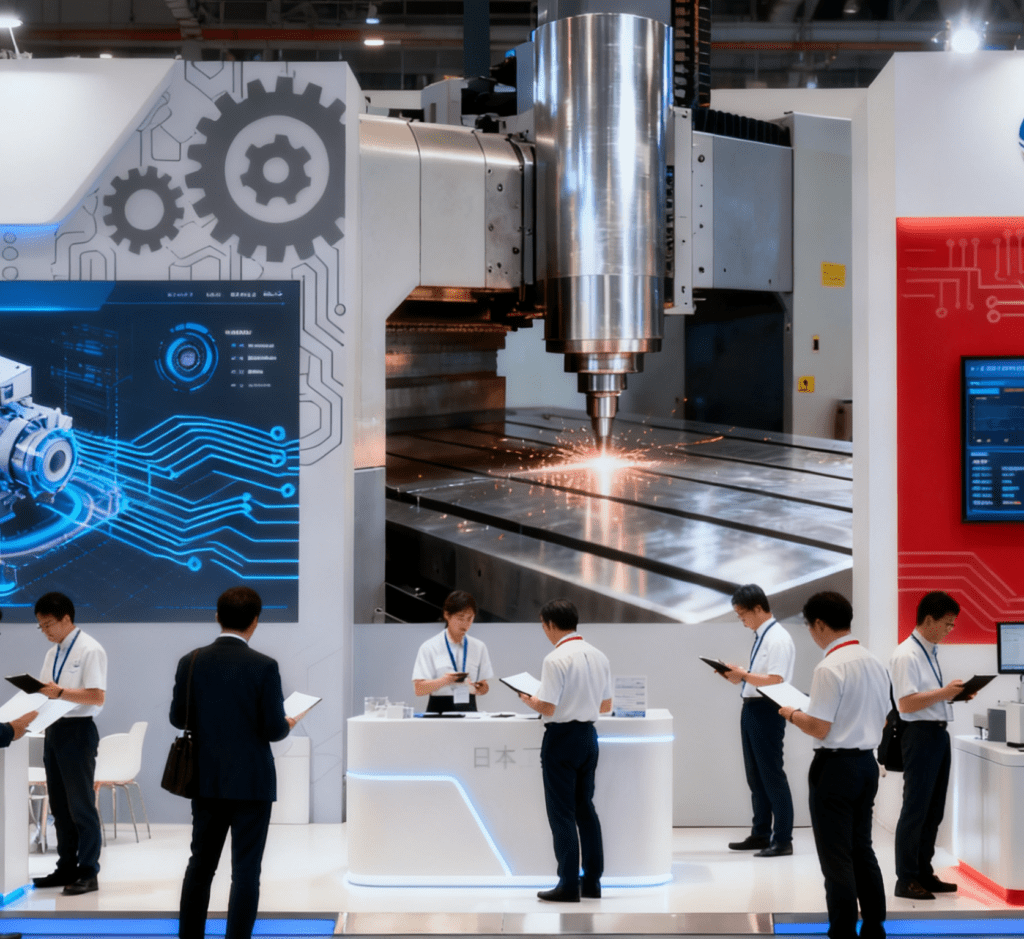

Cutting-Edge Technology Draws Closer to the Public, Global Smart Manufacturing Ignites Jinling: The 2025 World Smart Manufacturing Expo Concludes Splendidly

In a boxing ring, tiny “boxers” throw punches to compete and defend their glory; a female humanoid intelligent robot with chestnut shoulder-length hair and exquisite makeup mimics human expressions with a “wink”; a humanoid robot dressed in a traffic police uniform can not only stand on a sentry platform to direct traffic, but also twist its waist and deliver a spinning high kick… In recent days, Nanjing International Expo Center has been bustling with activity, where a variety of new technologies and achievements in smart manufacturing have attracted the attention of numerous visitors. Among the diverse exhibits, advanced intelligent manufacturing equipment for the medical field also made a striking appearance, […]

Special Event for Supply and Demand Matching of the Artificial Intelligence Terminal Industry Chain Held in Xiamen

Event Overview: Gather Multiple Stakeholders for Industry Synergy On November 25, 2025, to promote the integrated innovation of the artificial intelligence (AI) terminal industry chain and accelerate the formation of an open, collaborative, and complementary industrial ecosystem, the 2025 “100 Events for 10,000 Enterprises” matchmaking event for the integration of large, medium and small enterprises – a special session focusing on the AI terminal industry chain – was held in Xiamen City, Fujian Province. The event was hosted by the Xiamen Municipal Bureau of Industry and Information Technology and the Artificial Intelligence Industry Working Committee of the China Computer Industry Association, and undertaken by the AI Terminal Working Group. […]

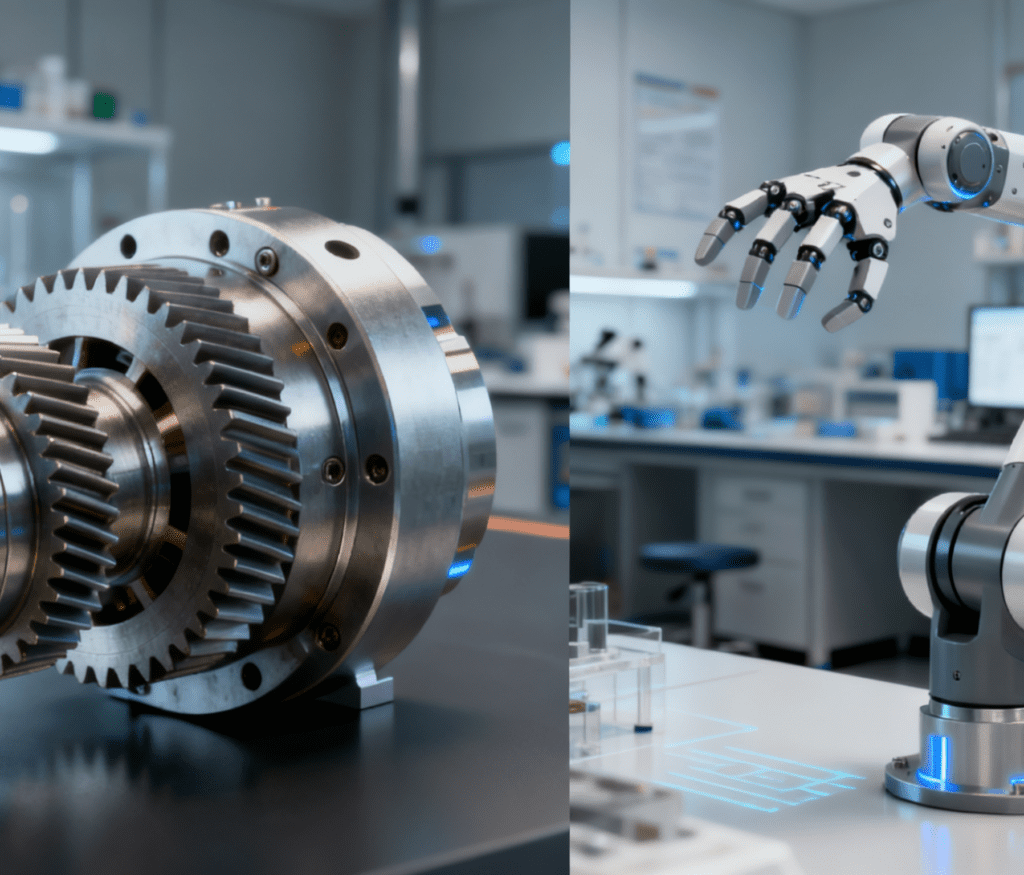

The Core Battlefield in the Robot Boom: It’s the Right Time for Domestic Reducers to Achieve Breakthroughs

As a core precision component in the robotics field, reducers are known as the “joints” of robots. Their market scale and industrial value are witnessing rapid growth with the continuous advancement of industrial automation and smart manufacturing. Notably, reducers also play a pivotal role in driving the upgrading of specialized automation equipment—for instance, the high-precision harmonic reducers are widely applied in Syringe Automatic Assembly Equipment, ensuring the equipment’s stable operation and ultra-high assembly accuracy required for medical device production. Enterprise Dynamics: Domestic Players Accelerate Layout and Cooperation On November 26th, Wanliyang, Lingyi Zhizao, and Haozhi Electromechanical respectively disclosed their latest progress in reducers through interactive platforms, attracting widespread […]

Smart Space: When the Physical World is Endowed with a “Digital Brain and Senses”

Amid the tide of technology, we are witnessing the rise of an entirely new paradigm: smart space. No longer confined to scenes in science fiction movies, it is rapidly evolving into a reality integrated into our work, daily lives, and the fabric of cities. Today, let us step into the world of smart space and explore its development together. Smart Space: The Leap from “Automation” to “Intelligence” In essence, a smart space is a physical environment that can actively perceive, analyze, make decisions, and interact with humans through the in-depth integration of technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data, and edge computing. […]

Operational Skills for Screen Changing of Granulator Die Head: Key Points to Reduce Waste and Extend Service Life

In plastic granulation production, the operating status of hydraulic screen changers (including single-plate double-station, double-plate double-station, double-column double-station, etc.) directly affects production efficiency and costs. Mastering the correct screen changing operation and maintenance methods can effectively reduce waste generation and significantly extend the service life of equipment. Notably, similar to how precise operation is critical for granulator die heads, equipment like the Fuse Assembly Machine also relies on standardized operational procedures and regular maintenance to ensure assembly accuracy and stable long-term operation, highlighting the universal importance of professional operational skills in industrial production. Precise Operation: The Key to Reducing Waste Grasp the Optimal Screen Changing Timing Core Basis: Die […]