Precision CNC Machining: Do Environmental Requirements Hinder Industry Innovation and Development?

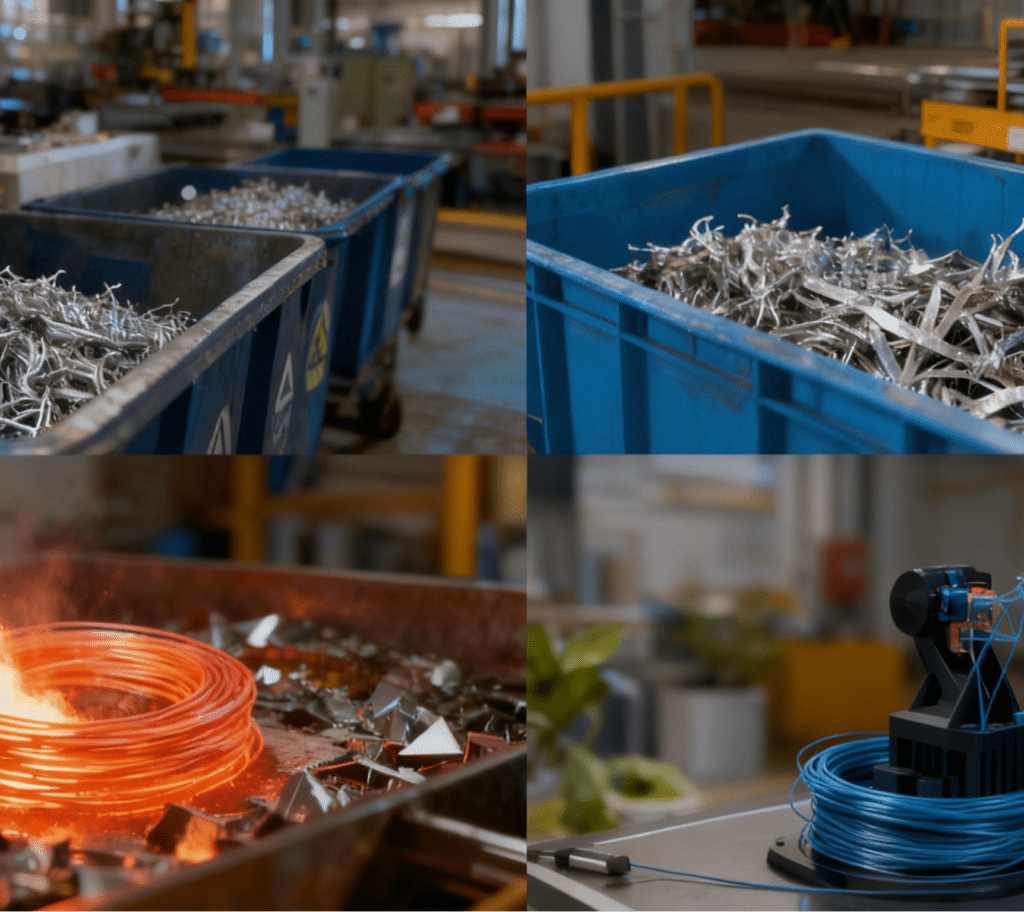

In an era of growing environmental awareness, the precision CNC machining industry is also facing increasingly stringent environmental requirements. This inevitably leads people to wonder: Will these environmental requirements become a stumbling block to the industry’s innovative development? In traditional perception, precision CNC machining is often regarded as a representative of high-precision and high-efficiency production, while environmental protection is not its primary concern. However, with the prominence of environmental issues, environmental concerns arising from the machining process—such as cutting fluid pollution, metal waste disposal, and energy consumption—have gradually gained attention. Environmental requirements force enterprises to properly handle these “by-products” of traditional machining models. For example, the use of cutting […]

Precision CNC Machining: Has Traditional Craftsmanship Been Completely Eliminated?

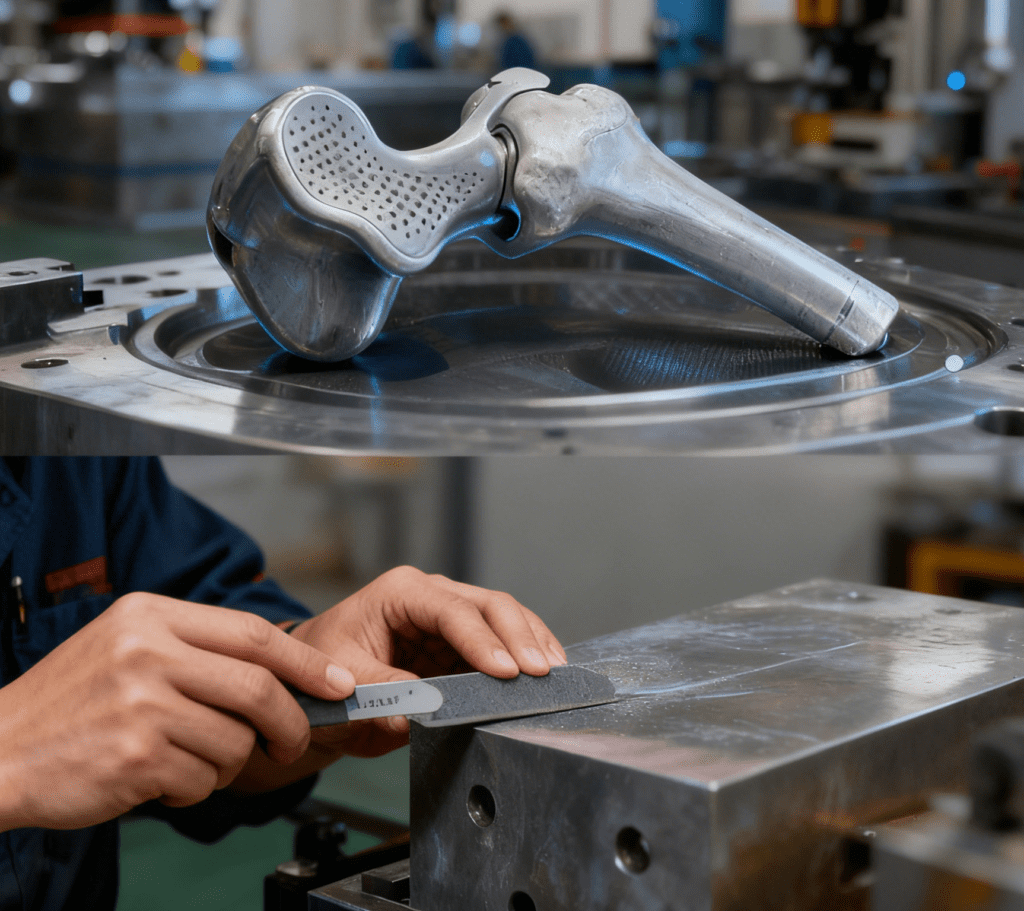

In modern manufacturing, precision CNC (Computer Numerical Control) machining undoubtedly occupies an extremely important position. Leveraging its advantages of high precision, high efficiency, and repeatability, CNC machining can accurately produce parts and components of various complex shapes, and is widely applied in numerous high-end fields such as aerospace, automobile manufacturing, and medical equipment. This inevitably leads people to wonder: amid the tide of the precision CNC machining era, has traditional craftsmanship been completely eliminated? CNC Machining’s Dominance: Unmatched Precision and Efficiency By controlling machine tool movements through computer programs, precision CNC machining can achieve machining precision at the micrometer or even nanometer level. It excels at rapid […]

High Precision in Precision CNC Machining: Overpursuit or Industry Necessity?

In the current landscape of manufacturing, precision CNC (Computer Numerical Control) machining stands out as a shining star due to its remarkable high precision. However, the question of whether this relentless pursuit of high precision is an act of overkill or a genuine necessity for industrial development is one that deserves in-depth exploration. High Precision as an Indispensable Foundation in Key Industries Across critical sectors, high precision is not a choice but a non-negotiable requirement for safety, performance, and technological progress: Aerospace: Turbine blades and aerospace components operate under extreme temperatures, pressures, and speeds. Even micro-scale dimensional deviations can cause uneven stress, fatigue cracks, and catastrophic accidents. […]

Precision CNC Machining Programming: How to Balance Simplicity and Functionality?

In the field of precision CNC (Computer Numerical Control) machining, programming is a crucial link that transforms design intentions into actual machining operations. How to balance simplicity and functionality in programming has become a significant challenge for CNC programmers. Functionality as the Core: Risks of Neglecting Simplicity Functionality is undoubtedly the primary consideration in programming. A fully functional CNC program can accurately instruct the machine tool to complete complex machining tasks, requiring precise definition of tool paths, cutting parameters, and machining sequences to ensure parts meet strict requirements for dimensional accuracy, shape accuracy, and surface quality. For example, machining high-precision aerospace engine components demands programs that precisely control […]

Why Is It Difficult to Achieve Both Speed and Precision in Precision CNC Machining?

In the world of precision CNC (Computer Numerical Control) machining, speed and precision are often like “fish and bear’s paw”—it is hard to have both at the same time. Behind this phenomenon lie many complex reasons. Mechanical Structure Constraints: Rigidity vs. Dynamic Responsiveness From the perspective of the machine tool’s own mechanical structure, high-precision machining relies on moving components with extreme rigidity and stability. For example, high-precision CNC machine tools typically adopt heavy-duty beds, high-precision guide rails, and ball screws. While these components guarantee machining precision, their large mass and inertia limit the machine tool’s acceleration and rapid response capabilities, directly restricting machining speed. When speeding up, two […]

CNC Boring Machining: Core Technical Composition and Precision Machining Advantages

CNC (Computer Numerical Control) boring machining is a precision mechanical processing technology based on digital program control. Its core lies in inputting instructions through computer programming to drive the boring machine to complete operations such as hole machining, end face machining, chamfering, and complex curved surface machining of workpieces. As a digital upgraded version of traditional boring machining, it inherits the core principle of boring machines—”taking the rotation of the boring tool as the main movement and the movement of the workpiece or boring tool as the feed movement”—while integrating the precise control advantages of the CNC system, realizing automation, high precision, and high efficiency in the machining process. […]

“Hangzhou Six Dragons” Enterprises Accelerate IPO Launches, with Technological Innovation Injecting Sustained Momentum

To seize the development opportunities in the capital market, a number of technology enterprises among the “Hangzhou Six Dragons” have recently accelerated their listing processes. The “Hangzhou Six Dragons” refer to Unitree Robotics, DeepSeek, Game Science, Shapr3D, BrainCo, and CloudMinds. As representative enterprises in the technology sector, they have provided crucial support for technological breakthroughs in relevant fields and the construction of industrial ecosystems in China through their core technologies and innovative practices, demonstrating the innovative strength of Chinese technology enterprises in the global technological competition and their responsibility for national technological development. Unitree Robotics Completes IPO Tutoring Recently, the IPO tutoring status of Unitree Robotics was updated […]

“Intelligent” Manufacturing Upgrade: Forging a New Path for Digital Transformation in Equipment Manufacturing

Looking back on the past five years, Dongfang Electric Corporation (DEC) has fully, accurately, and comprehensively implemented the new development philosophy, continuously strengthened its core functions, enhanced core competitiveness, strived to play the “three roles”, and endeavored to be the “three vanguards”. Centering on the industrial layout of “Six Power Sectors and Six Industries”, it has constantly opened up new prospects for development. As the 14th Five-Year Plan draws to a close and the 15th Five-Year Plan is being planned, we launch the special topic “DEC’s 14th Five-Year Report Card” to review the vivid stories of DEC employees carrying forward the “Dongqi Spirit”, vigorously developing high-end equipment, and accelerating the […]

Humanoid Robot Financing Frenzy Revives

Major Financing Rounds by Leading Enterprises Intensify Large-scale financing has reappeared in the humanoid robot sector! On November 20th, it was reported that Beijing Xingdong Jiyuan Technology Co., Ltd. (referred to as “Xingdong Jiyuan”), a company with the “Tsinghua background”, has completed a Series A+ financing round of nearly 1 billion yuan. This round of financing was led by Geely Capital, with strategic investment from BAIC Industry Investment, and co-investment from Beijing Artificial Intelligence Industry Investment Fund and Beijing Robot Industry Development Investment Fund. Notably, this is the second robot enterprise invested by Geely. The other one is Unitree Robotics, in which Geely, together with Tencent, Alibaba, Ant Group […]

Diverse Applications of Drones Behind a Single Event

On November 18, 2025, the 2025 FAI World Drone Soccer Championship—the world’s first International Category A drone soccer event hosted by the Fédération Aéronautique Internationale (FAI)—concluded at the Shanghai Indoor Stadium after a three-day run. A total of 46 elite teams from 18 countries and regions gathered in Shanghai to compete for the highest honor in “aerial soccer”. While preserving the team collaboration and goal-scoring mechanics of traditional soccer, this event ingeniously integrated drone technology. Competitors controlled drones equipped with spherical protective frames in enclosed low-altitude scenarios, competing in real-time 5v5 or 3v3 team matchups. Scores were earned by “shooting” the drone into the opponent’s goal. This not only […]