Fully Automatic Tissue Packaging Machin

Seiko Intelligent Manufacturing: Full-Process Precision Machining Solutions Empower High-End Manufacturing in Multiple Fields

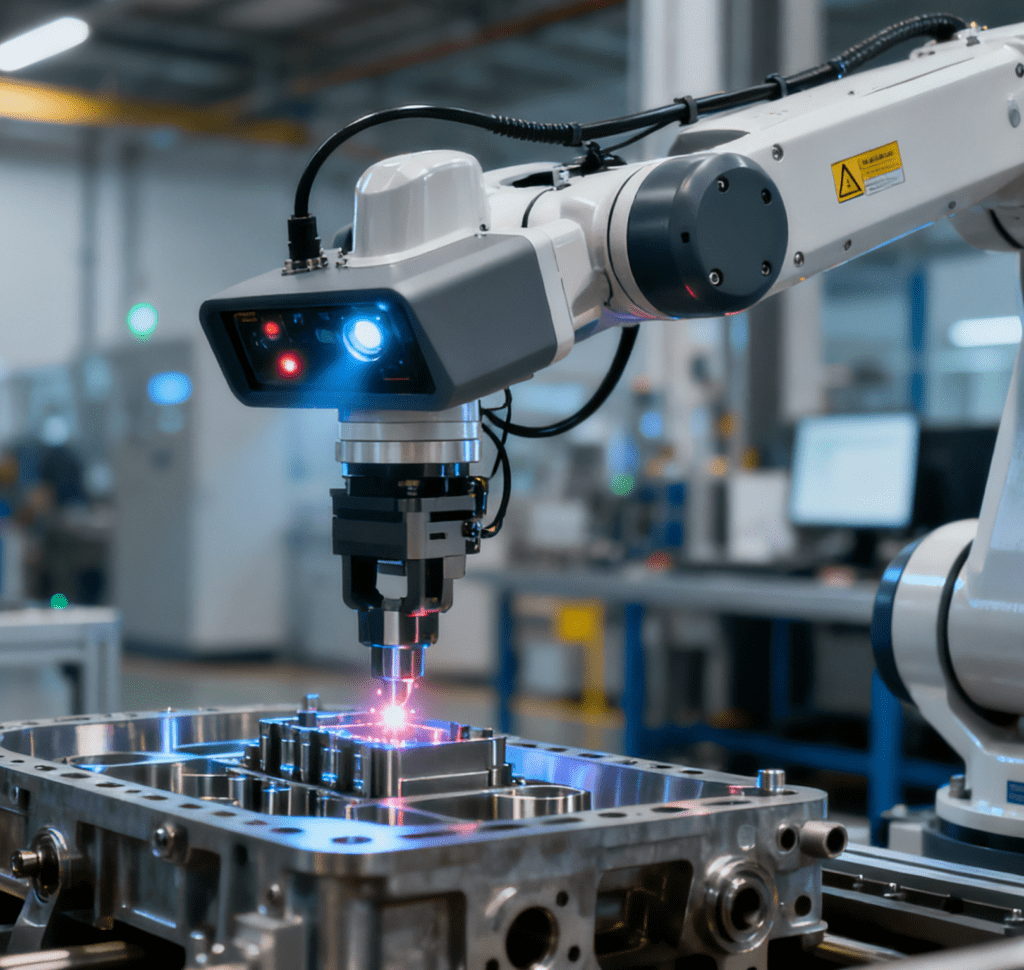

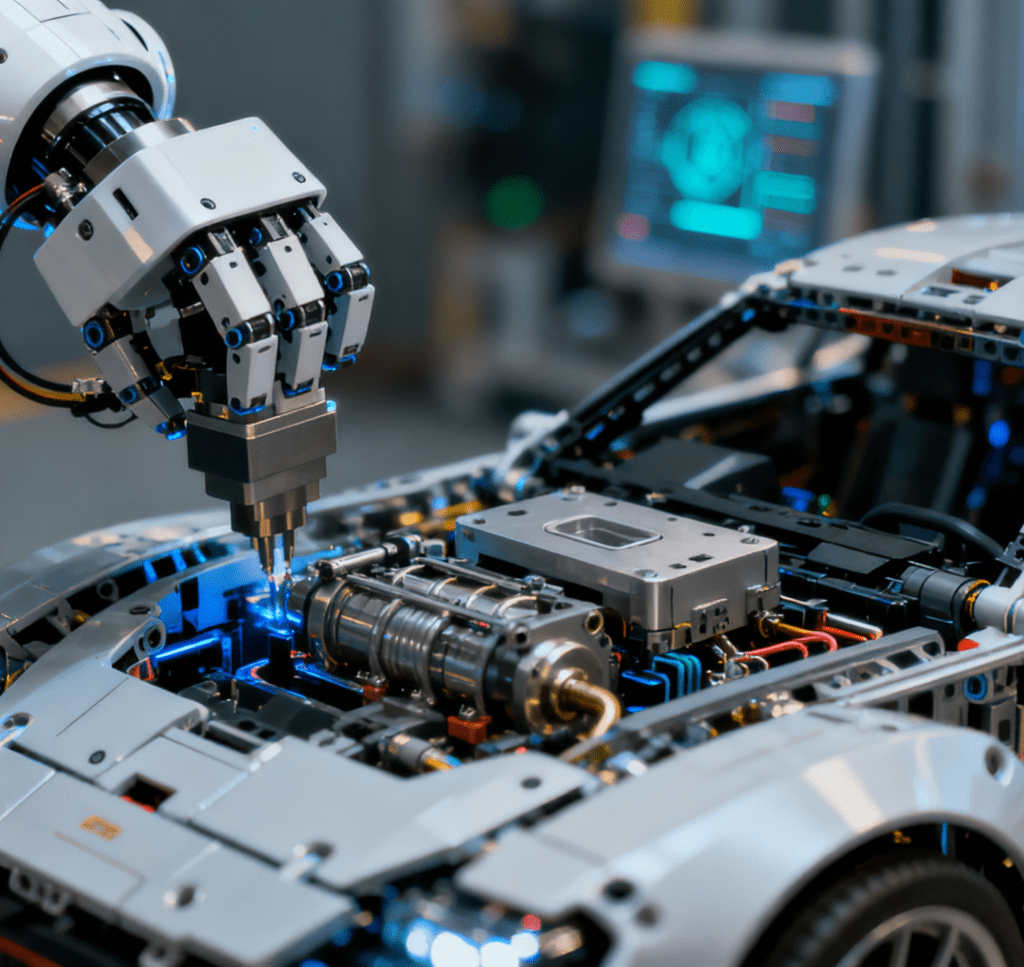

As industrial manufacturing moves towards intelligence and high-endization, the performance of precision components directly determines the reliability and competitiveness of products. As a core technology in modern manufacturing, CNC precision machining is characterized by high precision, high efficiency, and high consistency, and is providing solid technical support for fields such as automotive, aerospace, electronic equipment, and industrial machinery. We specialize in the field of CNC precision machining, with advanced equipment, mature processes, and strict quality control as the core, providing customers with full-process solutions from design to mass production, helping products achieve stable performance in complex application scenarios. Anchoring on Technology, Defining New Standards for Precision The core […]

CNC Wire Electrical Discharge Machining: An Efficient EDM Forming Solution in Precision Component Manufacturing

In the field of precision mold and complex component manufacturing, CNC wire electrical discharge machining (CNC WEDM) has become one of the core processes to solve the machining challenges of high-hardness and complex-contour components, thanks to its unique advantage of “non-contact EDM forming”. Based on the principle of material erosion by electrical discharge, it uses a CNC system to control the trajectory of the electrode wire, enabling precise machining of special-shaped, thin-walled, and high-hardness workpieces that are difficult to process with traditional cutting techniques. Currently, it is widely applied in high-precision manufacturing fields such as mold making, aerospace, automotive, and electronics. Technical Principles and Core Characteristics of CNC Wire […]

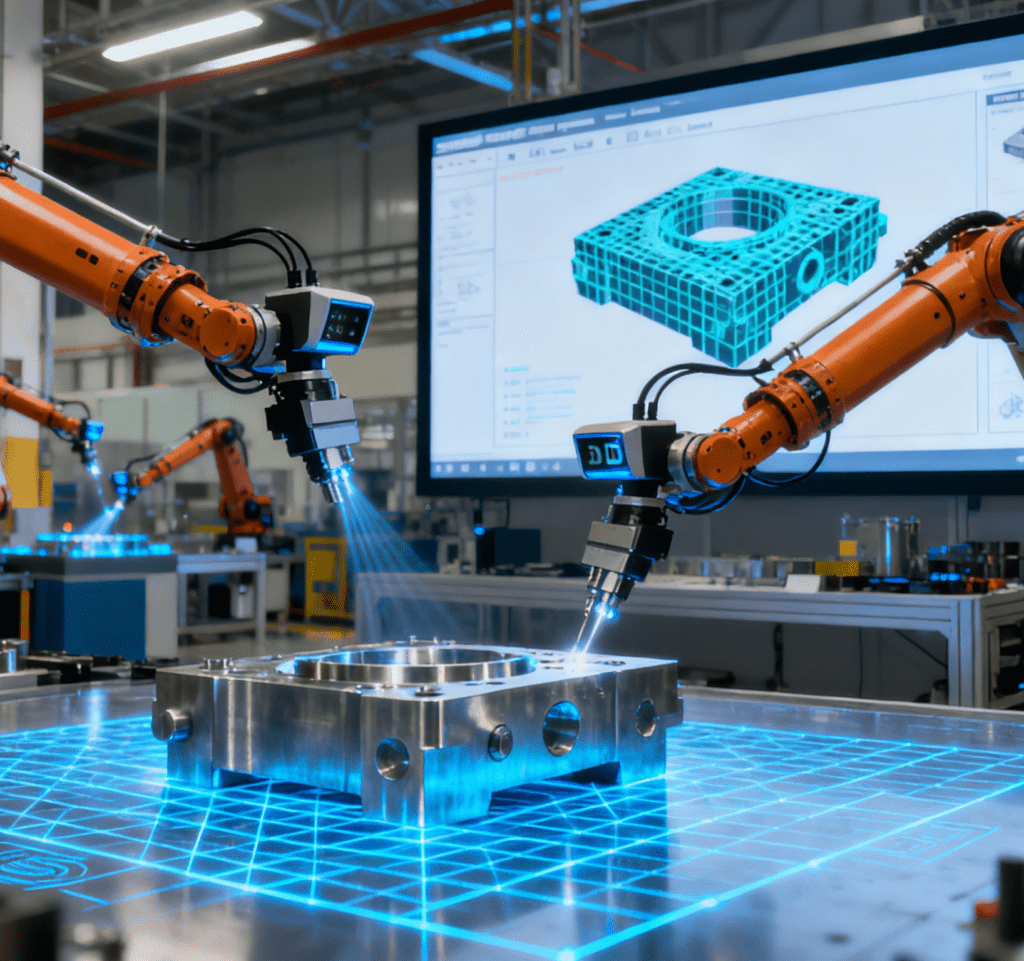

Why Does AI in Manufacturing Need Spatial Intelligence?

Amid the global wave of digital transformation in manufacturing, technologies such as Artificial Intelligence (AI), Machine Learning (ML), and Digital Twin are widely applied in production optimization, quality inspection, and equipment maintenance. However, despite enterprises’ increasing investment in technology, many AI projects still fail to achieve expected results in practical deployment. The fundamental reason lies in the fact that current AI systems lack an understanding of spatial structures and physical contexts. Traditional AI excels at processing numerical and image information but struggles to capture the geometric relationships and environmental dependencies of physical objects in real space. This limitation makes such systems vulnerable when facing complex and variable manufacturing environments. […]