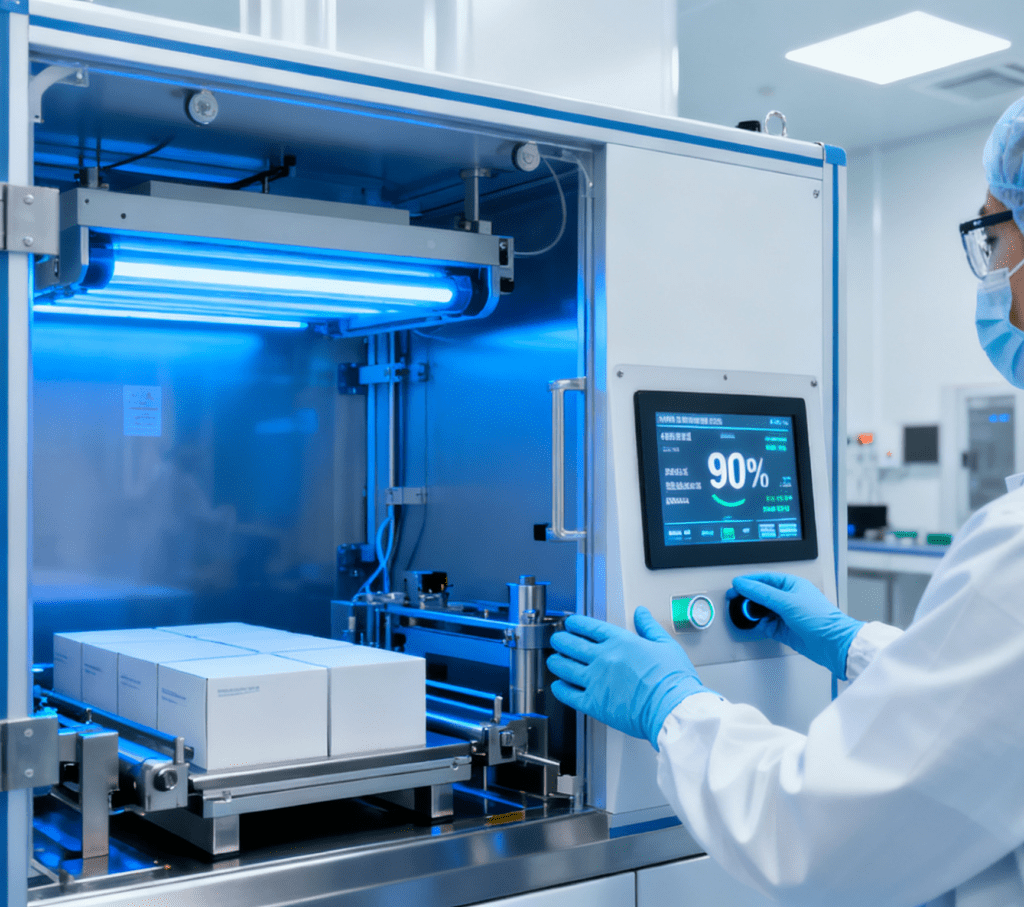

Box Opening, Filling and Sealing Machine

Case Erectors and Sealers: Indispensable Equipment in Automated Packaging Lines

Traditional packaging methods rely on manual labor to complete processes such as case erecting, flap folding, and bottom sealing. This approach not only suffers from low efficiency but also leads to issues like dimensional deviations and insecure seals. Modern case erectors and sealers, through the in-depth integration of PLC control systems and servo drive technology, have achieved full-process automation. As a key piece of equipment connecting production and logistics, case erectors and sealers are redefining efficiency standards in the packaging process with their high efficiency, precision, and flexibility. They are not only a powerful tool for reducing labor costs but also a core element in ensuring product transportation safety and […]

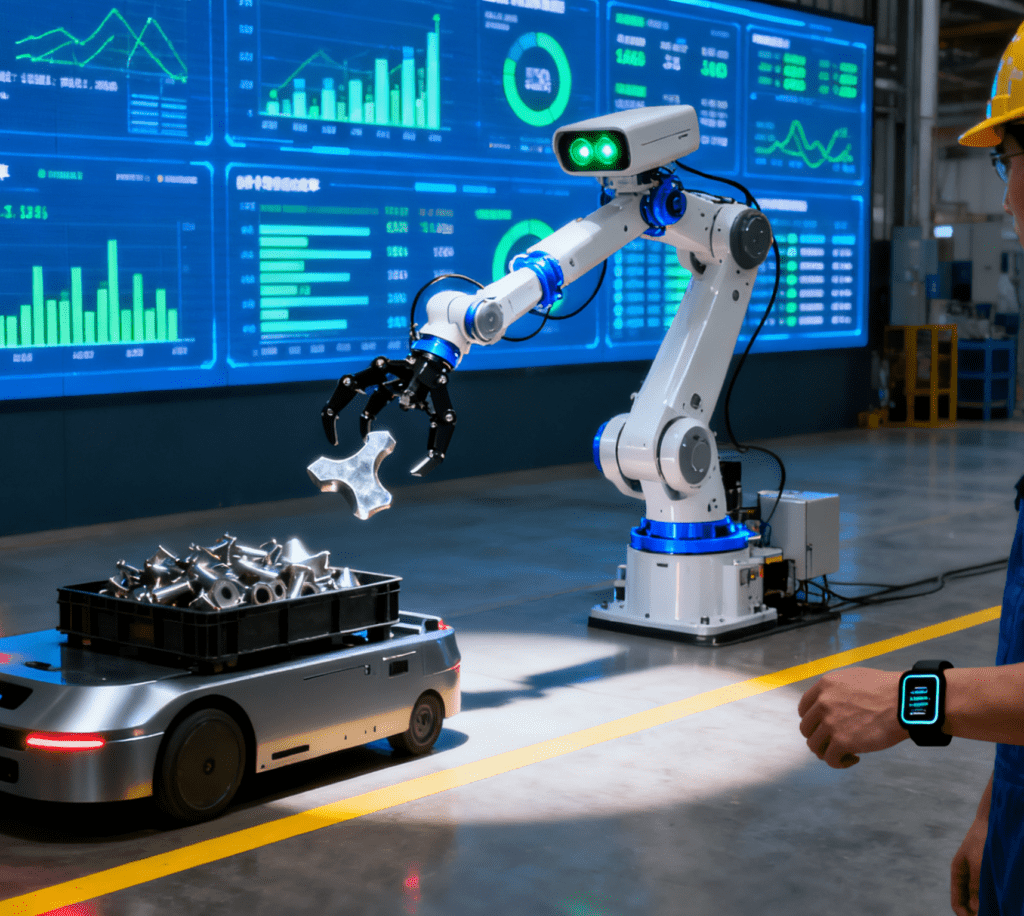

The New Wave of Artificial Intelligence in Manufacturing

With the continuous advancement of digitalization and intelligent transformation in manufacturing, artificial intelligence (AI) is gradually transitioning from early experimental applications to a core component of production and management systems. Currently, manufacturers face an increasingly complex business environment: rapid changes in customer demands, uncertainties in international trade policies, supply chain fluctuations, labor shortages, and escalating cybersecurity threats—all of which place higher demands on the resilience and efficiency of enterprises. Against this backdrop, AI and machine learning (ML) are emerging as key drivers of sustainable development in the manufacturing industry. The Popularization and Maturation Trend of Artificial Intelligence Survey data shows that 95% of manufacturing enterprises have invested in […]

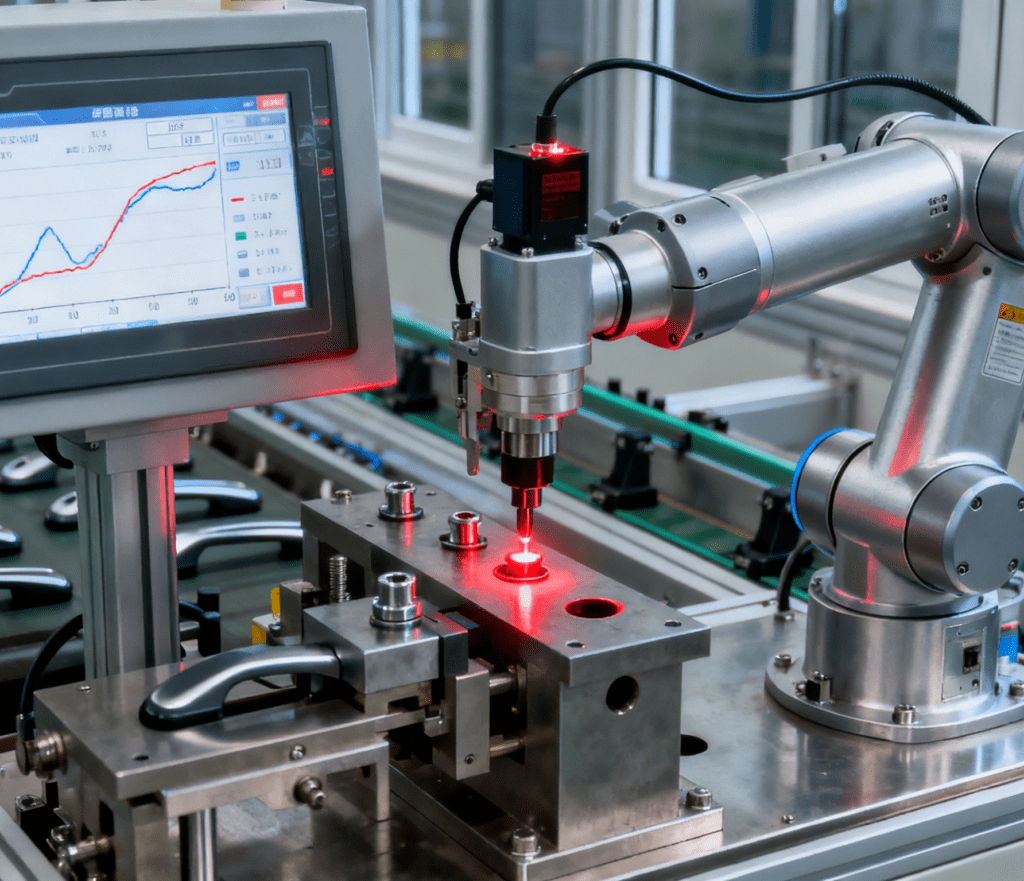

AutomaticTesting Assembly Machines

From automotive transmissions and transfer cases to fracking pumps, electronic controllers, hydraulic actuators, and refrigeration compressors, the modern world relies on highly complex electromechanical systems. These systems contain dozens, hundreds, or even thousands of precision components—all of which must fit and function perfectly to ensure product longevity, performance, and safety. Enter automatic testing assembly machines: the backbone of reliable electromechanical manufacturing. These integrated systems combine automated assembly (via robots, dedicated machinery, or hybrid setups) with in-process and end-of-line testing, ensuring every finished device meets design specifications and avoids unexpected failures long after leaving the factory. Why Automatic Testing Assembly Machines Are Non-Negotiable In today’s manufacturing landscape, “fit […]

Custom Automated Assembly Machinery

Industrial automation powers modern manufacturing, from massive stamping presses to precision small-scale machines. While automated equipment is designed for self-sufficiency, human interaction remains critical—for setup, monitoring, troubleshooting, and initiation. For decades, physical buttons, electromechanical dials, and manual controls handled this human-machine interface (HMI). Today, however, touchscreen HMIs—with their versatile input/output capabilities—have revolutionized how production facilities, original equipment manufacturers (OEMs), and systems integrators (SIs) interact with custom automated assembly machinery, unlocking new levels of efficiency and flexibility. The Evolution of HMIs in Custom Automated Assembly Machinery In custom automated assembly systems, the HMI is the bridge between operator and machine. Traditional physical controls worked for basic tasks but lacked […]

Automatic Testing Assembly Machines

From automotive transmissions and transfer cases to fracking pumps, electronic controllers, hydraulic actuators, and refrigeration compressors, the modern world relies on highly complex electromechanical systems. These systems contain dozens, hundreds, or even thousands of precision components—all of which must fit and function perfectly to ensure product longevity, performance, and safety. Enter automatic testing assembly machines: the backbone of reliable electromechanical manufacturing. These integrated systems combine automated assembly (via robots, dedicated machinery, or hybrid setups) with in-process and end-of-line testing, ensuring every finished device meets design specifications and avoids unexpected failures long after leaving the factory. Why Automatic Testing Assembly Machines Are Non-Negotiable In today’s manufacturing landscape, “fit […]

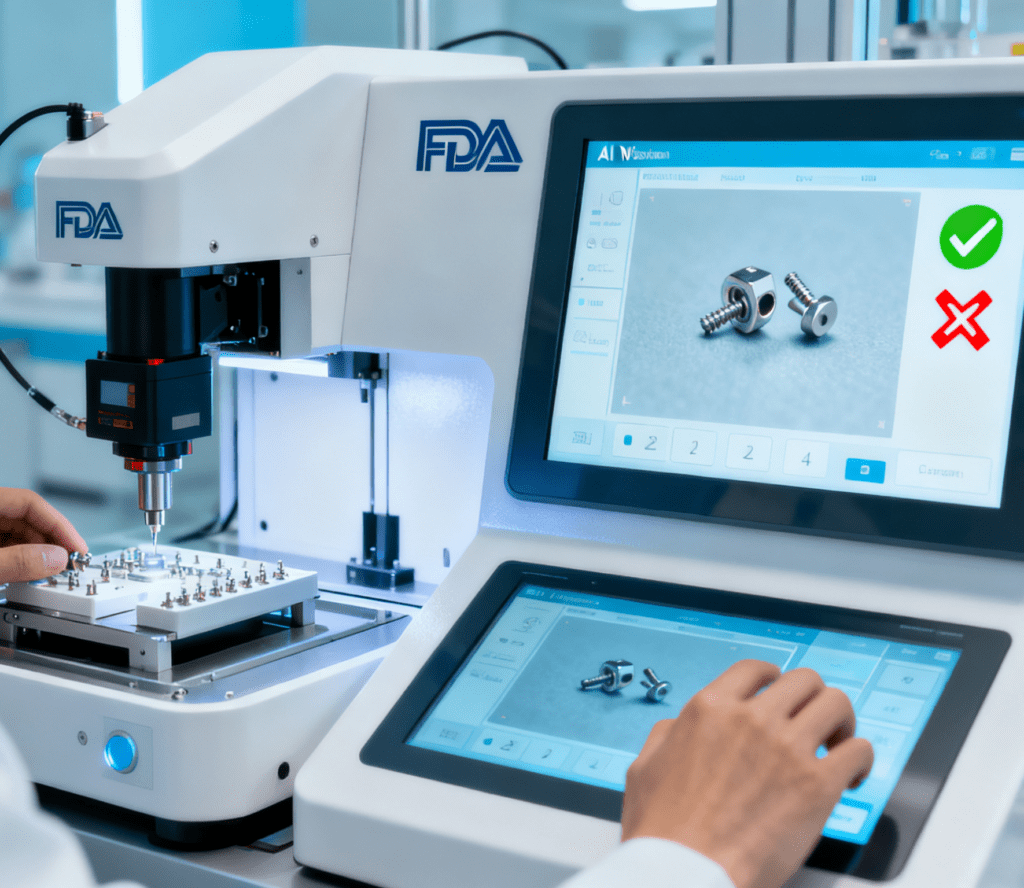

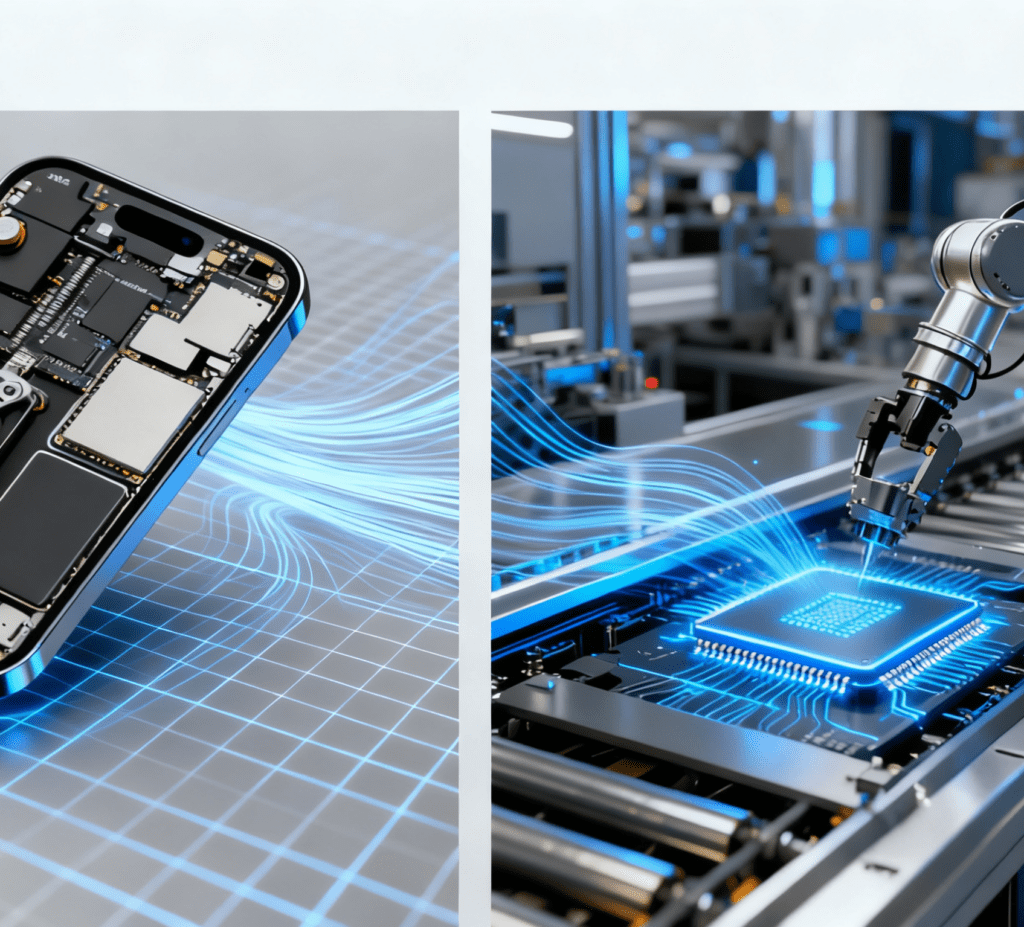

Automatic Assembly Machines for Electromechanical Components

Advanced technologies are rapidly transforming every corner of the electronics industry, and at the heart of this evolution lies a critical tool: automatic assembly machines for electromechanical components. From the earliest radio tubes to today’s nanoscale processors, these automated systems have enabled unprecedented precision, speed, and scalability in producing the electromechanical parts that power our smartphones, computers, and smart devices. Let’s explore how electromechanical component assembly automation has evolved, the role of industry leaders in advancing it, and the trends shaping its future. The Evolution of Electromechanical Component Assembly: From Manual to Automated The story of electromechanical component production began with manual labor. In the early 20th century, […]

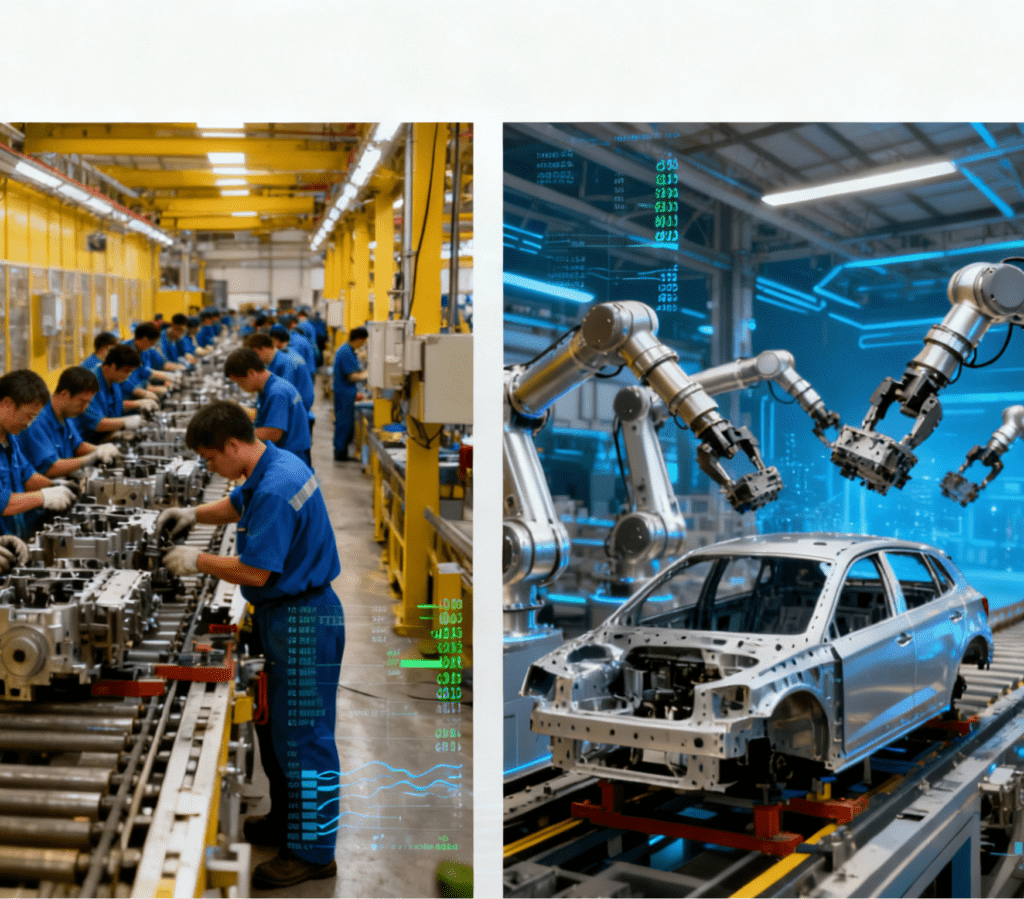

Automotive Assembly Machines for Automotive Applications

With the rise of smart manufacturing, exploring and applying automation has become an inevitable path for progress in the automotive industry. Enterprises often prioritize investing in advanced automated equipment, upgrading machinery to stay ahead of competitors in the era of transformation and innovation. However, due to the unique characteristics of automotive final assembly processes, the automation rate in final assembly across the industry remains around 12%—in stark contrast to stamping, welding, and painting processes, where automation rates exceed 80% thanks to declining robot costs and widespread adoption of vision systems in recent years. The key challenge now is: How to reasonably drive final assembly automation to reduce manufacturing costs, stabilize […]

What Can 5-Axis CNC Machining Do?

5-axis CNC machining technology has a significant impact in modern manufacturing. It can not only process components with complex shapes but also improve machining efficiency and precision. By controlling five axes simultaneously, the equipment can complete multiple cutting processes in a single step, thereby reducing the time spent on fixture replacement and lowering labor costs. Additionally, 5-axis CNC equipment has strong adaptability and can process metals, plastics, and composite materials, providing solutions for different production needs. This multi-material cutting capability enables manufacturers to flexibly respond to market changes and quickly meet the personalized needs of customers. For instance, 4 – Axis Robotic Injection Molding Part Removal Systems have become a […]

OpenAI Co-founder: It Will Take Another 10 Years for AI Agents to Truly Work

October 20 (News) – According to media reports, Andrej Karpathy, co-founder of OpenAI, recently stated publicly that current AI agents still have a long way to go before achieving “full functionality.” Core Assertion: A Decade to Realize Fully Functional AI Agents Karpathy pointed out: “The current agents are actually not easy to use. Their intelligence level is insufficient, their multimodal capabilities are limited, they cannot effectively operate computer systems, and they are even less capable of continuous learning. They cannot remember the information users tell them, and their cognitive abilities are far from meeting the standards – overall, they are not practical enough.” He estimated that it […]

AI News Anchor Debuts on U.K.’s Channel 4 in Stunt Proving Dangers of Artificial Intelligence

Program Core: A Special Investigating AI’s Impact on the Workplace A news special on Britain’s Channel 4 titled “Will AI Take My Job?” investigated how automation is reshaping the workplace and pitting humans against machines. From 4-axis robot automatic assembly equipment that has streamlined production lines in manufacturing plants by replacing manual assembly workers to AI-powered customer service systems handling daily inquiries, such technological advancements have already left tangible marks on various industries, laying the groundwork for the program’s exploration. At the end of the hour-long program, a major twist was revealed: the anchor, who narrates and appears throughout the telecast reporting from different locations, was entirely AI-generated. Key […]