Localization Rate Exceeds 55%: China’s Industrial Robots Reshape the Global Smart Manufacturing Landscape

The breakthrough in localization rate from 32% to 55% is not only the result of past efforts but also the starting point for future competition. In the reconstruction of the global industrial robot landscape, Chinese enterprises are using technological innovation as a spear and industrial collaboration as a shield to carve out their own path in the fierce market game. At the mid-2025 milestone, a historic turning point is quietly taking shape in China’s industrial landscape. According to MIR DATABANK data, the localization rate of China’s industrial robots has exceeded 55% for the first time. Behind this figure lies a landmark breakthrough after more than a decade of technological […]

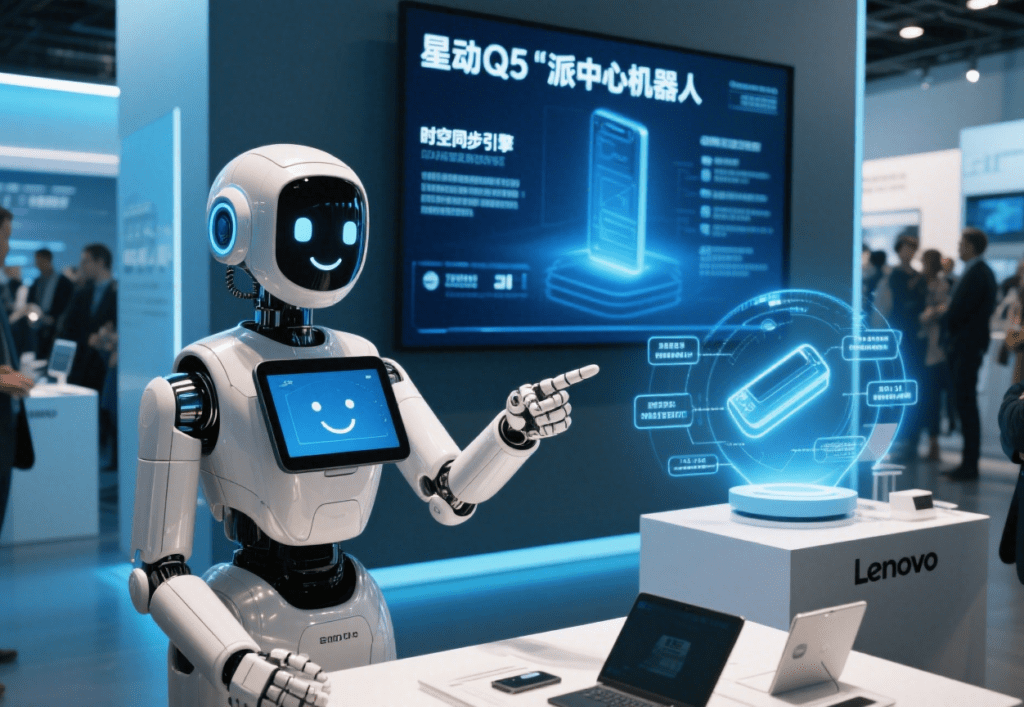

Following Haier, Xingdong Era and Lenovo have reached a strategic cooperation to jointly promote the intelligent exhibition hall solution for humanoid service robots

The cooperation between Xingdong Era and Lenovo aims to create a dedicated service robot for intelligent exhibition hall scenarios – “Pai Center Robot” based on Xingdong Era’s humanoid service robot Xingdong Q5, as well as the corresponding intelligent exhibition hall solution for humanoid service robots. On August 20, 2025, Lenovo New Vision Technology (Beijing) Co., Ltd., a subsidiary of Lenovo Group, and Beijing Xingdong Era Technology Co., Ltd. held a strategic signing ceremony at Lenovo Group’s global headquarters (Beijing) to jointly launch the intelligent exhibition hall solution for humanoid service robots. Bai Yuli, Vice President of Lenovo Group and General Manager of Lenovo New Vision, Chen Jianyu, Founder of […]

The Driving Force Behind Seamless Docking: Decoding the Efficiency Revolution of Automatic Quick-Connect Assembly

In modern factories where assembly lines operate at full speed, the precise docking of parts is often the key node that determines the production rhythm. From the snap fixation of automotive pipelines to the plug-in combination of electronic device interfaces, those seemingly simple “connection” actions hide the core code for improving manufacturing efficiency — automatic quick-connect part assembly machines are redefining the meaning of “connection” in industrial production with millisecond-level response speeds. From “Jamming” to “Smoothing”: Breaking the Efficiency Bottleneck in Connection Links Traditional part connection processes have long been constrained by two major problems: fatigue-induced errors in manual operations and lag in mechanical positioning. In the old […]