The Technological Revolution and Industrial Applications of Assembly Machines: The Evolution from Rigid Production to Intelligent Flexibility

The Technological Revolution and Industrial Applications of Assembly Machines: The Evolution from Rigid Production to Intelligent Flexibility Introduction: When Watch Movements Meet Assembly Robots — The Ultimate Game of Precision and Efficiency In the movement assembly workshop of a top Swiss watch factory, traditional craftsmen took 3 hours to assemble 68 parts of a complex movement with a yield rate of only 92%. However, the newly introduced micro-nano assembly robot, through force-controlled servo (±0.01N pressure control) and atomic force microscope vision, achieves 0.001mm-level precision assembly, reducing the time per movement to 45 minutes and increasing the yield rate to 99.8%. This is not just a leap in efficiency but a […]

Future Outlook for Non-Standard Automation Equipment: The Ultimate Evolution from “Customized Tools” to “Intelligent Ecosystems”

Future Outlook for Non-Standard Automation Equipment: The Ultimate Evolution from “Customized Tools” to “Intelligent Ecosystems” Introduction: When Equipment “Thinks, Collaborates, and Evolves”—The Ecosystem Revolution in a New Energy Factory A lithium battery production line at a CATL base is a scene that subverts tradition: Equipment Interconnection: The pole piece laminator detects abnormal diaphragm tension and automatically synchronizes data with the coating machine, which adjusts the slurry viscosity in real time. Autonomous Decision-making: The AI model on the inspection line identifies a trend of poor tab welding and proactively dispatches robots to fine-tune parameters, nipping defects in the bud. Self-Evolution: The production line runs virtual simulations at night, optimizing parameters based […]

Global Opportunities and Challenges of Non-Standard Automation Equipment: Key Points for Cross-Border Project Implementation and Localization Adaptation Strategies

Global Opportunities and Challenges of Non-Standard Automation Equipment: Key Points for Cross-Border Project Implementation and Localization Adaptation Strategies Introduction: From “Blocked Overseas Expansion” to “Localization Breakthrough”—The Pain and Rebirth of a Company’s EU Certification A new energy equipment manufacturer in Shenzhen first entered Europe by providing a “pole piece sorter” for a German battery factory. However, due to failing the CE-LVD low voltage directive certification (motor insulation class not meeting standards), the equipment was detained at the Port of Rotterdam for 30 days, resulting in not only a €150,000 port detention fee but also missing the customer’s production window. Learning from this, the company spent 18 months establishing a global […]

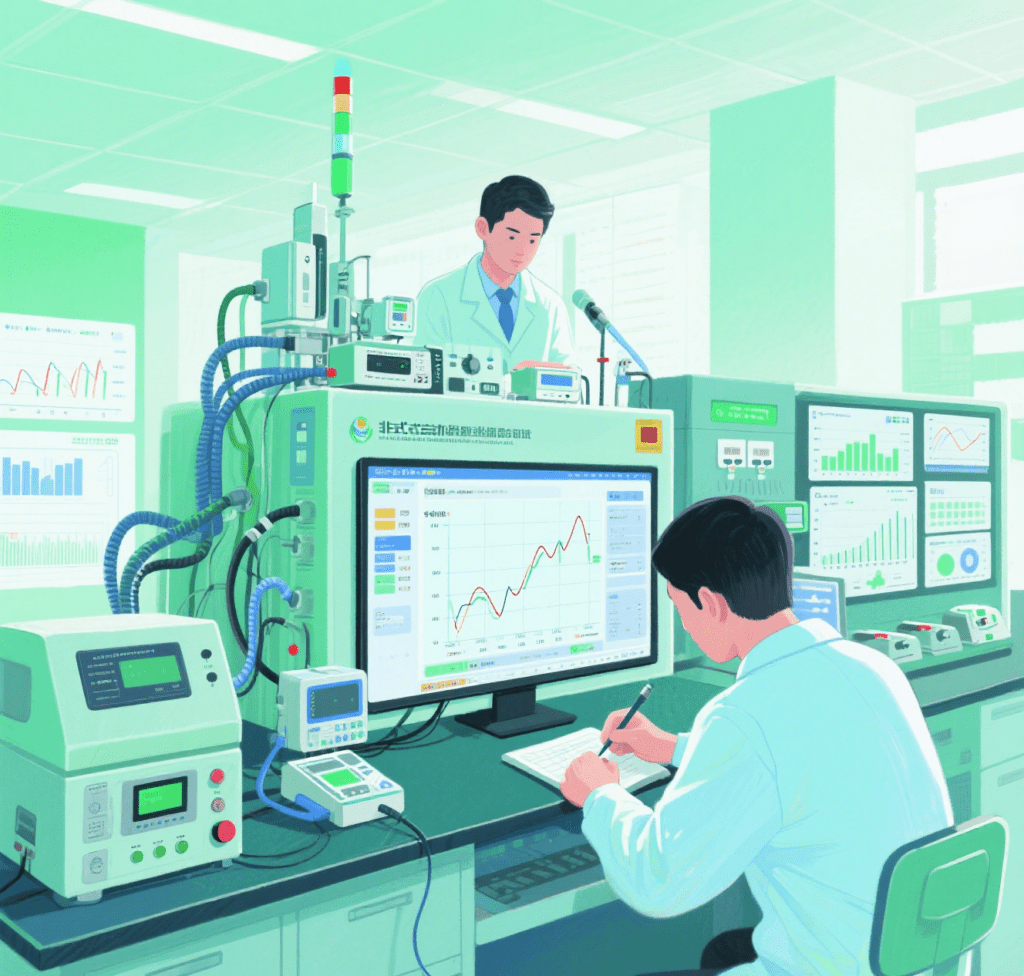

The Sustainable Development Path of Non-Standard Automation Equipment: Green Design, Energy Consumption Optimization, and Full Life Cycle Management

The Sustainable Development Path of Non-Standard Automation Equipment: Green Design, Energy Consumption Optimization, and Full Life Cycle Management Introduction: When “High Energy Consumption” Becomes an Elimination Criterion —— The Environmental Protection Transition Pain of an Auto Parts Factory The non-standard stamping line of an auto mold factory in Jiangsu has a single equipment power of 150kW·h, with annual power consumption exceeding 1.2 million kWh, and electricity expenses accounting for 18% of production costs. After the EU Carbon Border Adjustment Mechanism (CBAM) came into effect in 2024, its export products were subject to a 12% tax surcharge, causing profits to plummet. Learning from this pain, the enterprise invested 3 million RMB […]

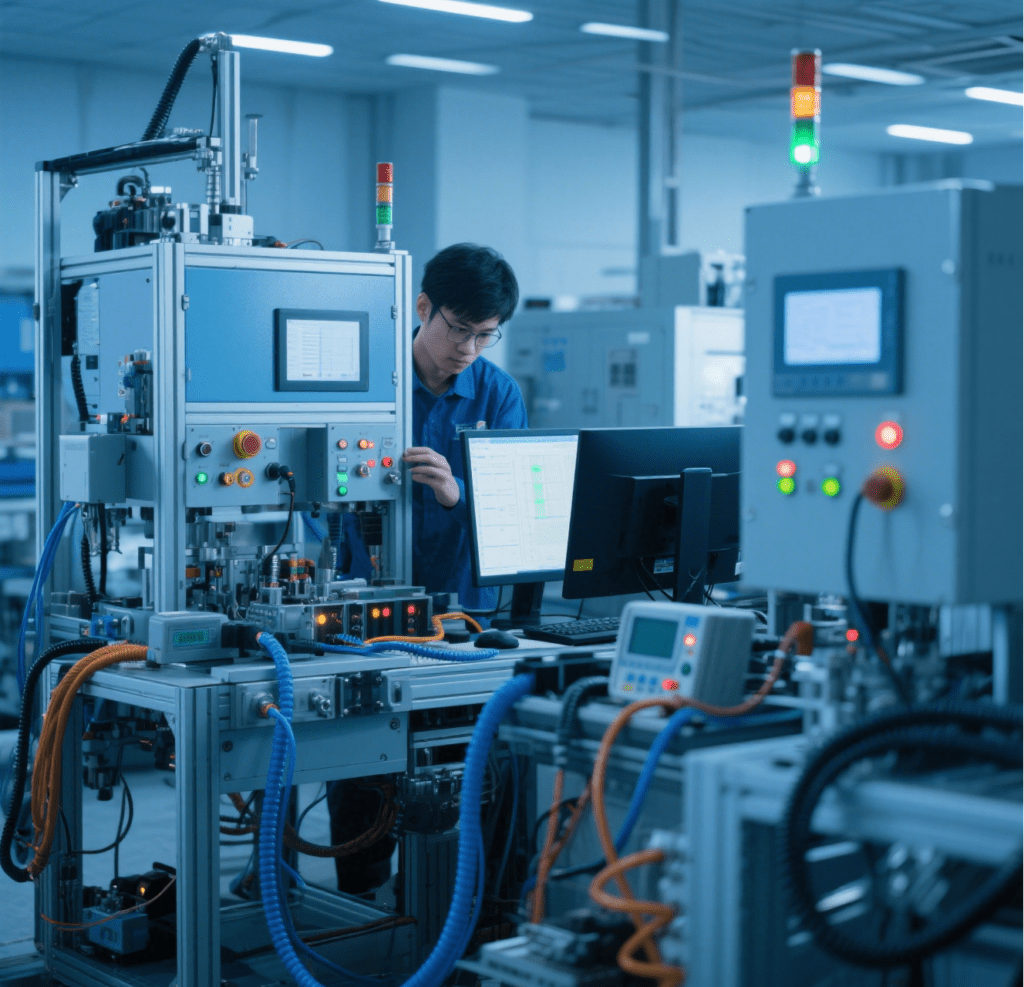

The New Paradigm of Human-Machine Collaboration in Non-Standard Automation Equipment: The Efficiency Revolution from “Machine Replacement” to “Human-Machine Integration”

The New Paradigm of Human-Machine Collaboration in Non-Standard Automation Equipment: The Efficiency Revolution from “Machine Replacement” to “Human-Machine Integration” Introduction: When a Robotic Arm “Crushes” Sponge —— The Collaboration Dilemma and Breakthrough of Traditional Automation In an automotive seat factory, a ¥2 million robotic arm attempted to grasp memory foam pads but caused indentation defects in 20% of pads due to rigid grippers unable to sense pressure. When manual intervention was needed for correction, 3 collision accidents occurred because the robotic arm lacked safety sensors. Eventually, a traditional automated production line with “human-machine isolation” required 8 workers to “guard” it, achieving only 30% efficiency improvement over pure manual labor. This […]

Selection Guide for Non-Standard Automation Equipment: 5 Dimensions and 30 Evaluation Indicators for Clients

Selection Guide for Non-Standard Automation Equipment: 5 Dimensions and 30 Evaluation Indicators for Clients Introduction: The Price of Choosing the Wrong Equipment —— Lessons from “800K Investment” to “Two Years of Idleness” A smart home enterprise in Zhejiang customized an “intelligent lock detection line”. Due to blindly choosing a low-cost supplier (ignoring core technical maturity), the equipment had issues such as “poor multi-model compatibility” (only adapting to 30% of products), “unstable detection accuracy” (15% missed detection rate), and “after-sales response exceeding 72 hours” after delivery. It was eventually forced out of use, with the 800K investment wasted. Selecting non-standard equipment is a multi-dimensional game of “technology + business + risk”. This article constructs 5 […]

Technical Breakthroughs of Non-Standard Automation Equipment: 5 Core Technologies and Future Evolution Directions

Technical Breakthroughs of Non-Standard Automation Equipment: 5 Core Technologies and Future Evolution Directions Introduction: When Precision Demands Break Through the “Human Eye Limit”—How Technology Reshapes the Boundaries of Non-Standard Equipment In new energy battery production, the alignment precision of pole piece lamination needs to be controlled within ±0.02mm (about 1/3 of a human hair), a physical limit for traditional mechanical positioning. A leading battery enterprise introduced “binocular vision guidance + force-controlled servo” technology, using algorithms to rectify lamination deviations in real-time, increasing the yield rate from 92% to 99.8%. This confirms a fact: the core competitiveness of non-standard automation essentially lies in the “dimensionality reduction strike” of technological breakthroughs. This article […]

The Cost Black Hole of Non-Standard Automation Equipment: 6 Out-of-Control Links and 12 Cost-Reduction Strategies

The Cost Black Hole of Non-Standard Automation Equipment: 6 Out-of-Control Links and 12 Cost-Reduction Strategies Introduction: Non-Standard Projects Devoured by Costs —— A Warning from “Budget 800K” to “Final Accounts 1.5M” A new energy enterprise in Suzhou customized a “lithium battery pole piece sorter” with an original budget of 800,000 RMB, but the final accounts reached 1.5 million RMB—requirement changes caused mechanical structure rework (+250K), customized sensor premiums (+180K), supply chain delays increasing labor costs (+120K), and debugging overruns (+150K)… The “cost black hole” of non-standard equipment is devouring enterprises’ return on investment. This article decomposes 6 out-of-control links and presents 12 implementable cost-reduction strategies, making non-standard equipment truly “valuable […]

The Complete R&D Process of Non-standard Automation Equipment: 18 Key Nodes from Requirement Decomposition to Delivery Acceptance

The Complete R&D Process of Non-standard Automation Equipment: 18 Key Nodes from Requirement Decomposition to Delivery Acceptance Introduction: The “Out-of-Control Dilemma” and Breakthrough Logic in Non-standard R&D In a “pole ear laser welding machine” project of a new energy enterprise in Dongguan, misunderstandings in requirements (failing to clarify the “oxygen-free welding chamber” requirement), supply chain delays (custom welding head procurement cycle exceeding 60 days), and debugging loss (on-site debugging taking 45 days, accounting for 40% of the total cycle) extended the R&D period from 12 months to 15 months, with costs exceeding the budget by 40%. This case exposes the core pain point of non-standard R&D: the uncertainties brought by […]

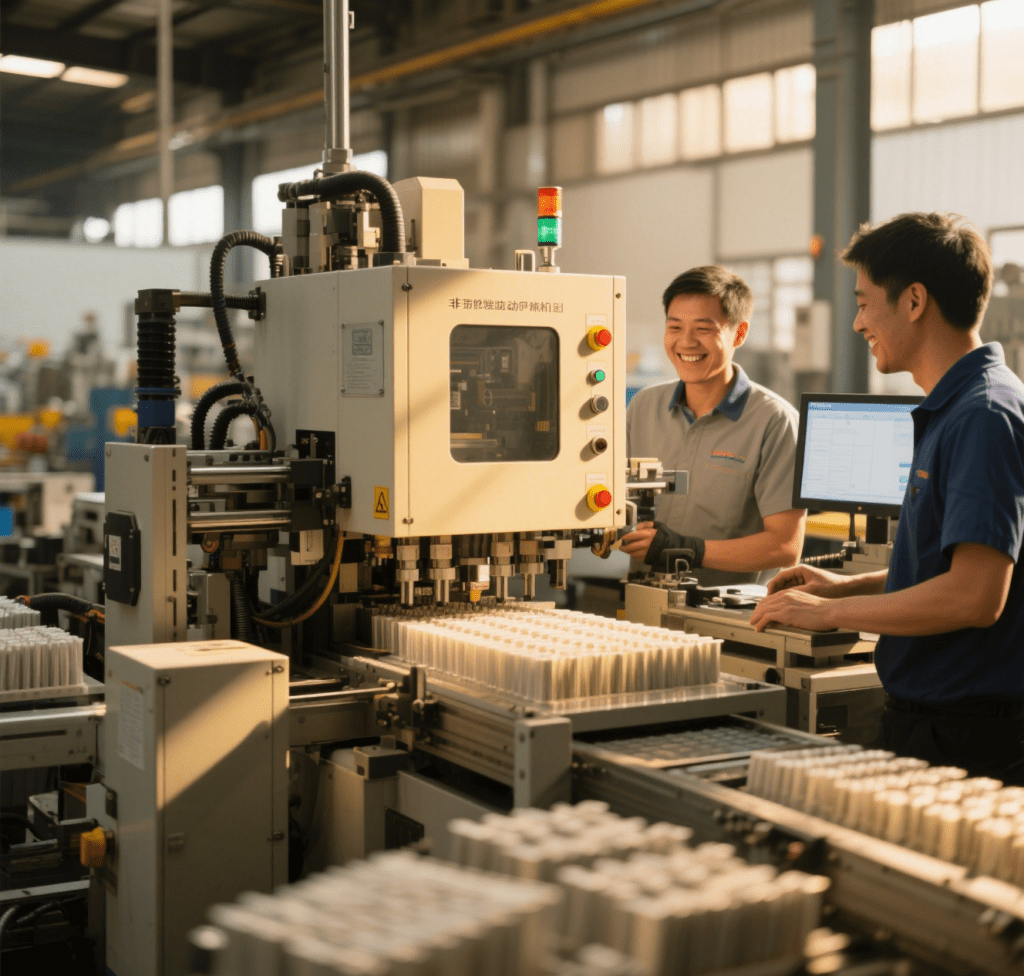

Non-standard Automation Equipment: The Breakthrough Code for Customized Production —— In-depth Deconstruction from Requirement to Value

Non-standard Automation Equipment: The Breakthrough Code for Customized Production —— In-depth Deconstruction from Requirement to Value Introduction: When Standard Equipment Fails, How Does Non-standard Equipment Rescue the Situation? In the workshop of a 3C OEM factory in Shenzhen, the production of a new folding-screen phone frame hit a deadlock: the surface contour tolerance was only ±0.03mm. Traditional standard punching machines couldn’t adapt to the complex curvature due to fixed molds, causing the yield rate to plummet to 78% and extending the order delivery cycle by 15 days. Eventually, a set of non-standard automatic punching lines broke the dilemma—through “flexible molds + visual guidance + servo pressure control”, the yield rate […]