The Embryonic Form of Future Factories: How Flexible Automatic Assembly Equipment Defines the Next-Generation Manufacturing Paradigm

The Embryonic Form of Future Factories: How Flexible Automatic Assembly Equipment Defines the Next-Generation Manufacturing Paradigm Introduction As Tesla’s Giga Press die-casts 70 parts into a single vehicle body component, and Siemens’ AMAPOLA project achieves “zero-drawing” autonomous production, flexible automatic assembly equipment is breaking through its positioning as an “efficient execution tool” and evolving into the core engine defining the next-generation manufacturing paradigm. This article delves into the frontiers of technological testbeds, analyzes three disruptive directions—”autonomous decision-making systems,” “bio-manufacturing integration,” and “resilient manufacturing networks”—and combines cases such as Airbus’ “Future Factory” and Boston Dynamics’ robot clusters to reveal the manufacturing revolution from “flexible production” to “intelligent evolution”—the future factory is […]

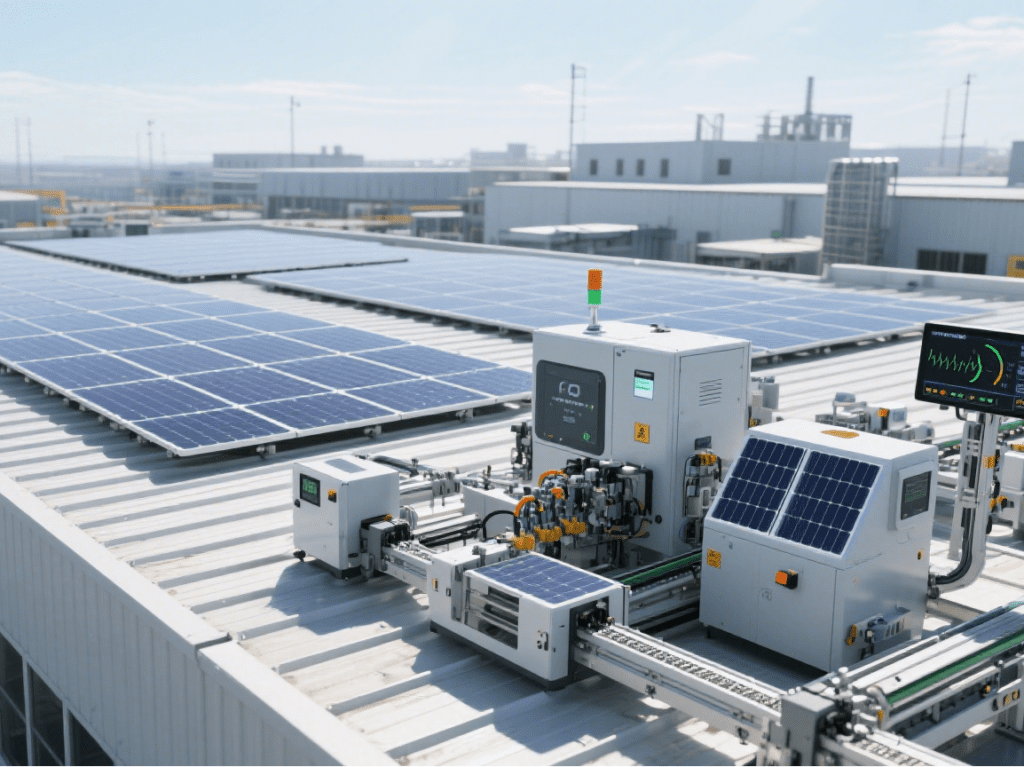

The New Dimension of Sustainable Manufacturing: How Flexible Automatic Assembly Equipment Empowers Green Production

The New Dimension of Sustainable Manufacturing: How Flexible Automatic Assembly Equipment Empowers Green Production Introduction Against the backdrop of the “Double Carbon” goals and the rise of ESG (Environmental, Social, Governance) investment, manufacturing is shifting from “efficiency-first” to “dual-drive of green and efficiency.” With core advantages of “precise control, rapid model switching, and resource reuse,” flexible automatic assembly equipment has become a key solution to address traditional manufacturing pain points of “high energy consumption, excessive waste, and difficult recycling.” This article explores three dimensions—energy optimization, material saving, and circular production—combined with industry practices in photovoltaics, lithium batteries, and electronic recycling, revealing how flexible equipment transforms “green manufacturing” from a concept […]

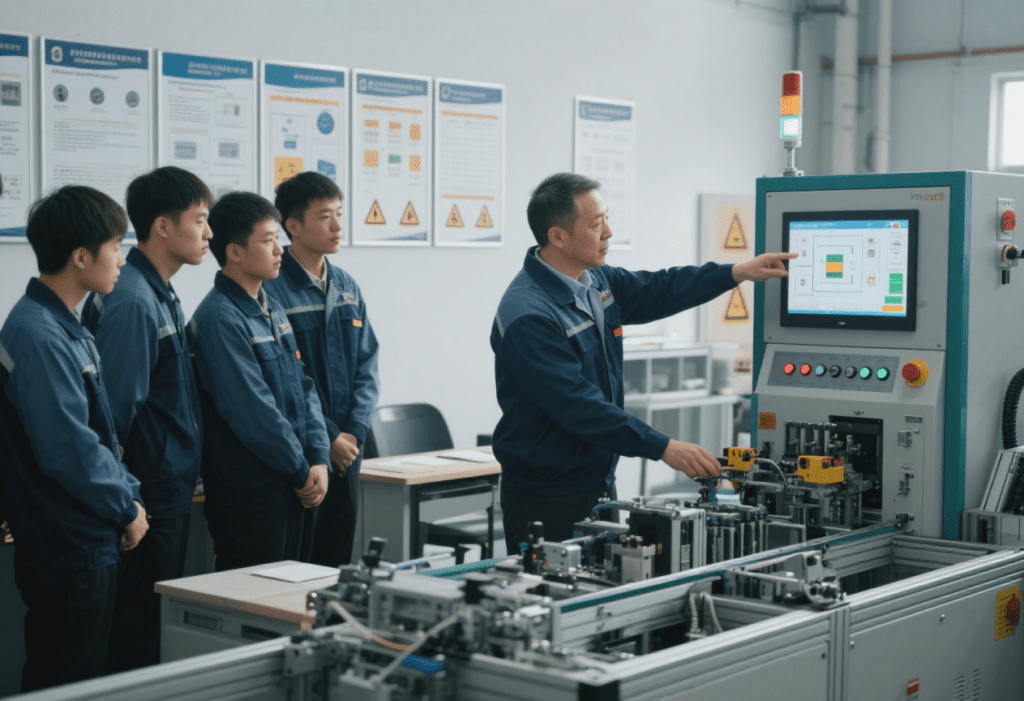

The New Path of Human-Machine Skill Transfer: How Flexible Automatic Assembly Equipment Cultivates “Intelligent Industrial Workers”

The New Path of Human-Machine Skill Transfer: How Flexible Automatic Assembly Equipment Cultivates “Intelligent Industrial Workers” Introduction In the process of flexible automatic assembly equipment accelerating the substitution of traditional workstations, “machine replacement” triggers not a labor crisis but a “skill reconstruction revolution”—industrial workers are transforming from “repetitive executors” to “human-machine collaborators.” This article analyzes three core mechanisms: AR immersive training, digital twin practical training, and skill data precipitation. Combining the upgrading of Germany’s dual-system education and China’s industry-education integration practices, it reveals how flexible equipment becomes a “bridge for skill transfer,” enabling workers to evolve from “afraid of machines” to “proficient in intelligence,” and ultimately constructing a new labor […]

The New Ecosystem of Supply Chain Collaboration: How Flexible Automatic Assembly Equipment Reconstructs Manufacturing Networks

The New Ecosystem of Supply Chain Collaboration: How Flexible Automatic Assembly Equipment Reconstructs Manufacturing Networks Introduction Under the dual pressures of “fragmented consumer demand” and “escalating supply chain uncertainties,” traditional “chain-type supply chains” are accelerating their evolution into “networked manufacturing ecosystems.” Flexible automatic assembly equipment is no longer confined to improving efficiency within enterprises; instead, it integrates into the industrial internet as an “intelligent node,” driving the manufacturing network’s shift from “plan-driven” to “demand-pull.” This article analyzes three models—distributed manufacturing, capacity sharing, and real-time collaboration—combined with platform practices like Haier COSMOPlat and Siemens MindSphere, revealing how flexible equipment reshapes the collaborative logic of industrial chains and makes “global collaborative production […]

Software-Defined Flexibility: How Industrial Software Reshapes the “Brain” of Automatic Assembly Equipment

Software-Defined Flexibility: How Industrial Software Reshapes the “Brain” of Automatic Assembly Equipment Introduction As robotic arms break through micron-level precision and hardware modular design enables minute-level model switching, the ultimate bottleneck of flexible automatic assembly equipment has shifted from “hardware capability” to “software intelligence”—industrial software, as the “nerve center” of equipment, is evolving from a traditional “programming control tool” to an “autonomous decision-making system.” This article deeply analyzes core software technologies such as PLCopen motion control, digital twin debugging, and AI process optimization, revealing how software architectures from vendors like Siemens, Beckhoff, and Inovance upgrade equipment from “executing instructions” to “understanding requirements,” ultimately achieving the manufacturing revolution of “software-defined flexibility.” […]

The New Cost-Benefit Formula: ROI Calculation and Implementation Path of Flexible Automatic Assembly Equipment

The New Cost-Benefit Formula: ROI Calculation and Implementation Path of Flexible Automatic Assembly Equipment Introduction Facing market pressures of “multi-variety, small-batch” production, SMEs commonly encounter three puzzles when introducing flexible automatic assembly equipment: “Can equipment investment be recouped within 3 years?” “How to quantify the implicit value of flexible production?” “How to avoid resource waste from blind investment?” This article constructs an ROI calculation model with 12 core indicators. Combining practical cases from automotive parts, 3C electronics, and medical device industries, it provides a full-process implementation guide from investment evaluation to continuous optimization, helping enterprises clarify the economic accounts of “flexible transformation.” I. Core ROI Calculation Model: Full-Dimensional Evaluation from […]

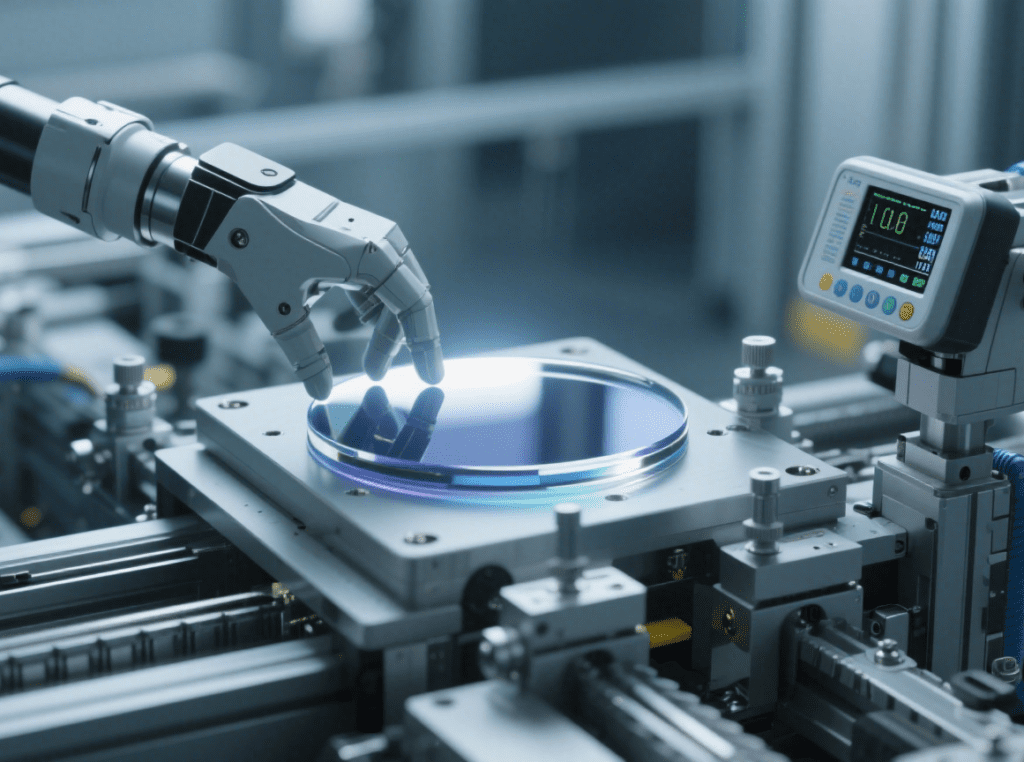

The New Frontier of Precision Manufacturing: How Flexible Automatic Assembly Equipment Breaks Through the Limits of Micro-Dimensional Assembly

The New Frontier of Precision Manufacturing: How Flexible Automatic Assembly Equipment Breaks Through the Limits of Micro-Dimensional Assembly Introduction In precision fields such as watch movements, medical catheters, and MEMS sensors, assembly accuracy requirements have entered the “micron era” — the fit tolerance of watch gear shafts and holes ≤5μm (0.005mm), and the bonding offset of MEMS chips must be controlled within ±2μm. Traditional manual operations or rigid automated equipment can hardly meet such standards. Through the deep integration of vision technology, force control systems, and environmental control, flexible automatic assembly equipment is breaking through the precision limits of micro-dimensional assembly, making it possible for “millimeter-scale equipment to complete micron-scale […]

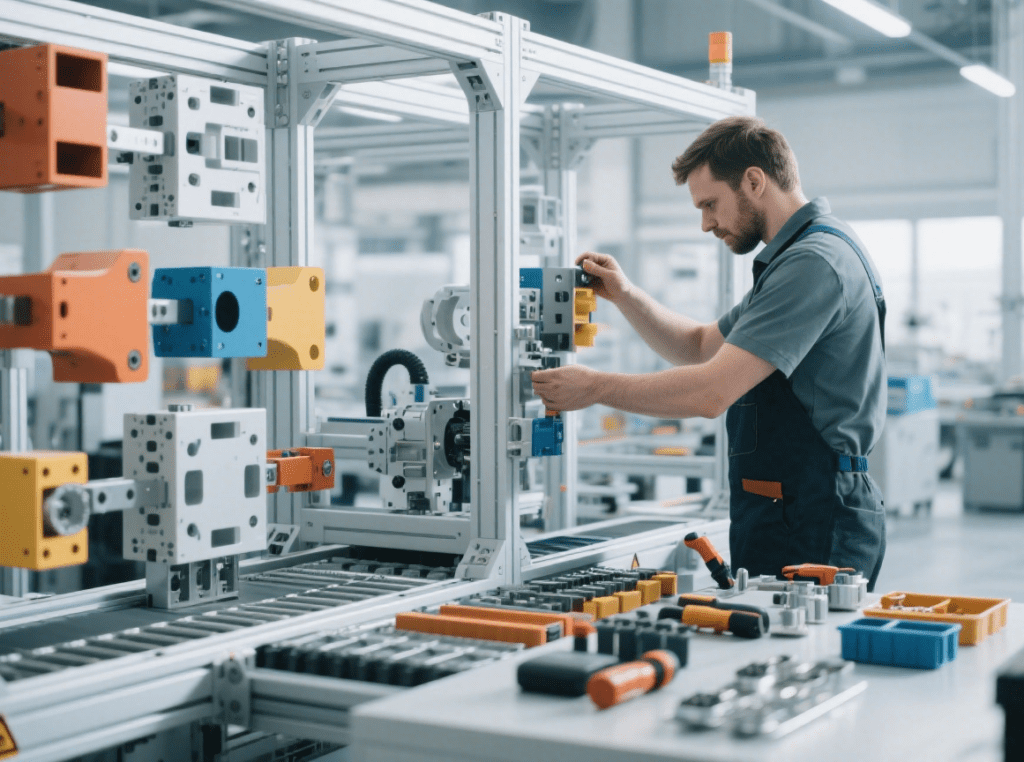

The New Paradigm of Human-Machine Collaboration: How Flexible Automatic Assembly Equipment Reconstructs Factory Human-Machine Relationships

The New Paradigm of Human-Machine Collaboration: How Flexible Automatic Assembly Equipment Reconstructs Factory Human-Machine Relationships Introduction Under the wave of Industry 4.0, the single logic of “machines replacing humans” is evolving toward “human-machine integration”. Through breakthroughs in safety technologies, innovations in interaction interfaces, and reconstruction of task allocation, flexible automatic assembly equipment not only improves efficiency but also redefines the collaboration boundaries between humans and machines in factories. This article analyzes this ongoing human-machine relationship revolution from three dimensions: technical principles, application scenarios, and ecological changes. I. Iteration of Safety Technologies: From “Physical Isolation” to “Dynamic Integration” Traditional automated production lines rely on physical isolation means such as guardrails and […]

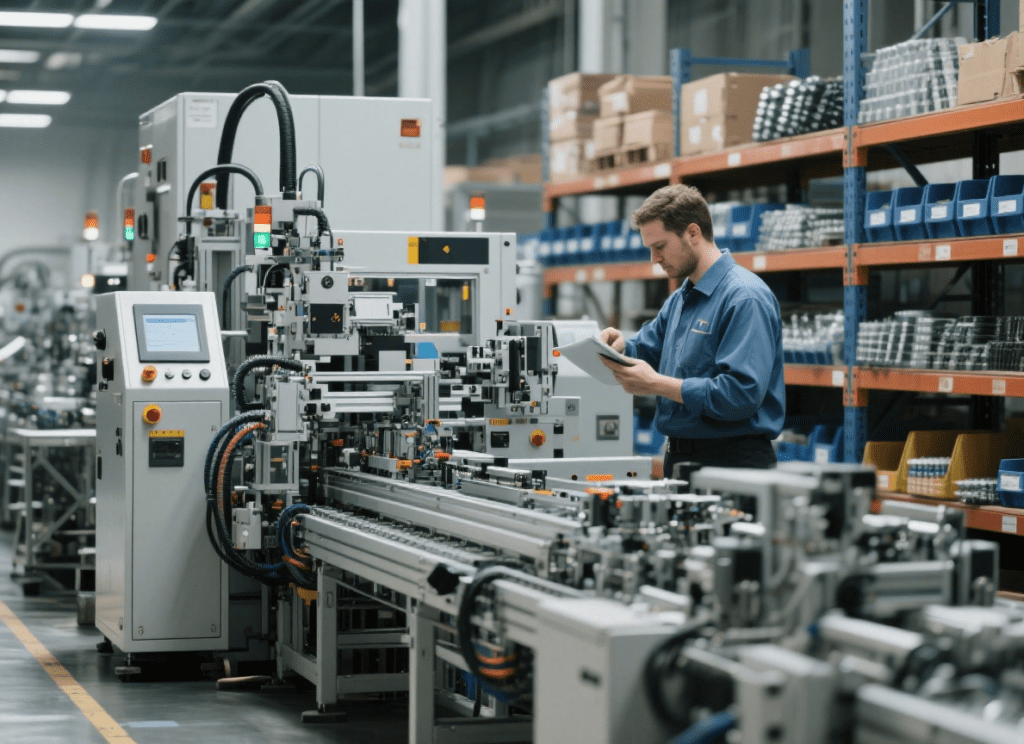

Cracking the Dilemma of Small-Batch Multi-Variety Production: Three Breakthrough Points of Flexible Automatic Assembly Equipment

Cracking the Dilemma of Small-Batch Multi-Variety Production: Three Breakthrough Points of Flexible Automatic Assembly Equipment Introduction As “personalized customization” becomes the new normal in manufacturing, the “economies of scale” advantage of traditional assembly lines fails in the face of market demands for “minimum order quantities of 500 pieces”. Small and medium-sized enterprises generally face three pain points: high model switching costs (accounting for 35% of production costs), low capacity utilization (average below 60%), and large quality fluctuations (defect rate exceeding 5%). Flexible automatic assembly equipment reconstructs production logic through technological innovation, transforming “multi-variety small-batch” production from “losing money for market share” to “profitable business”. Combining practical experience in automotive parts, medical […]

Analysis of Core Technologies of Flexible Automatic Assembly Equipment: How Modular Design Reshapes Manufacturing Flexibility

Analysis of Core Technologies of Flexible Automatic Assembly Equipment: How Modular Design Reshapes Manufacturing Flexibility Introduction In the new manufacturing ecosystem featuring “multiple varieties, small batches, and rapid iteration,” flexible automatic assembly equipment is breaking through the “rigid shackles” of traditional production lines through modular design. This technical architecture centered on “decoupling and reconstruction” not only enables rapid replacement of hardware modules but also endows production lines with intelligent flexibility for “versatile adaptation” through software-defined logical recombination. From the three dimensions of mechanical engineering, control algorithms, and industrial software, this article analyzes how modular design evolves manufacturing systems from “customized special machines” to “universal transformers,” combined with in-depth practices in […]