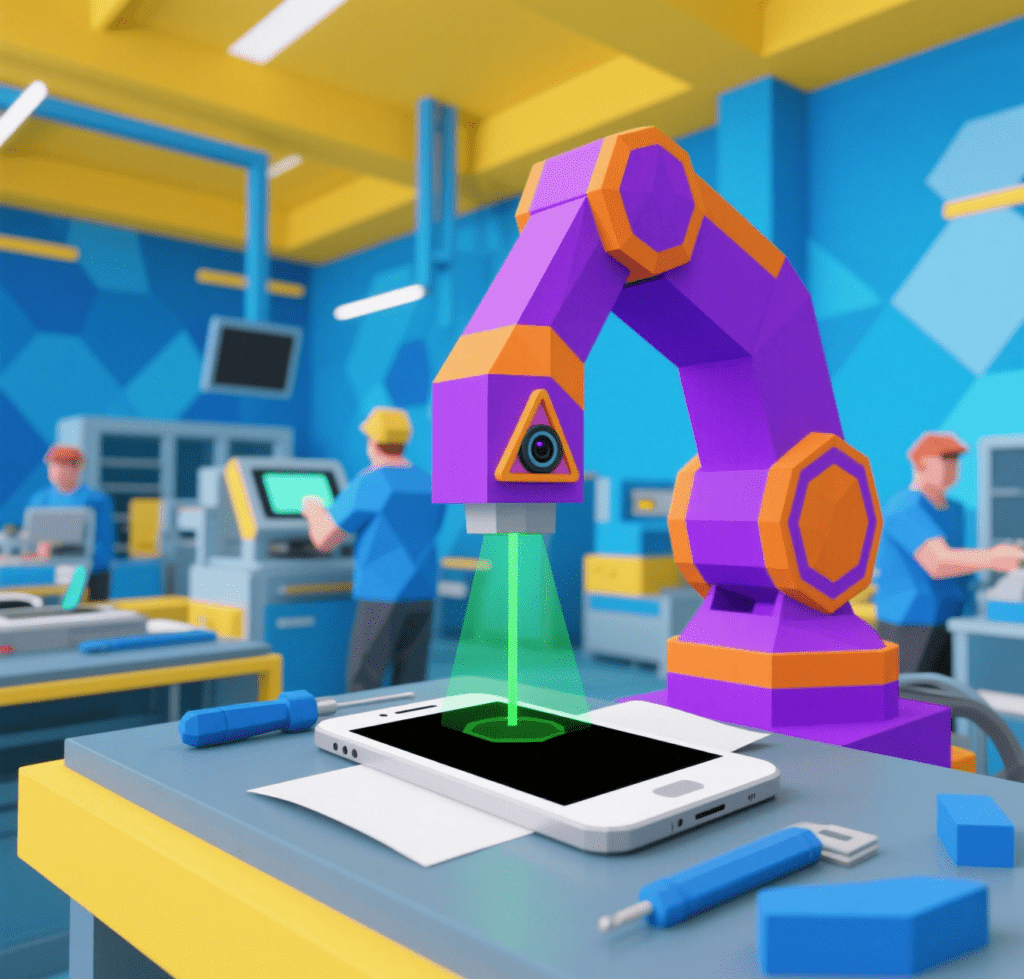

4-Axis Robotic Automatic Film Laminating System: Elevating Precision and Efficiency in Surface Protection

4-Axis Robotic Automatic Film Laminating System: Elevating Precision and Efficiency in Surface Protection In an era where product aesthetics, durability, and functionality rely on flawless surface treatments, traditional film laminating methods—manual alignment, fixed fixtures, and slow changeovers—fall short of modern manufacturing demands. The 4-Axis Robotic Automatic Film Laminating System emerges as a transformative solution, integrating the dexterity of 4-axis robotics with intelligent automation to achieve unparalleled precision in applying films to flat, curved, and complex surfaces. Designed for industries ranging from consumer electronics to automotive and aerospace, this system eliminates human error, accelerates production, and ensures consistent quality across millions of units, redefining the standard for surface protection. The Core Architecture: Where […]

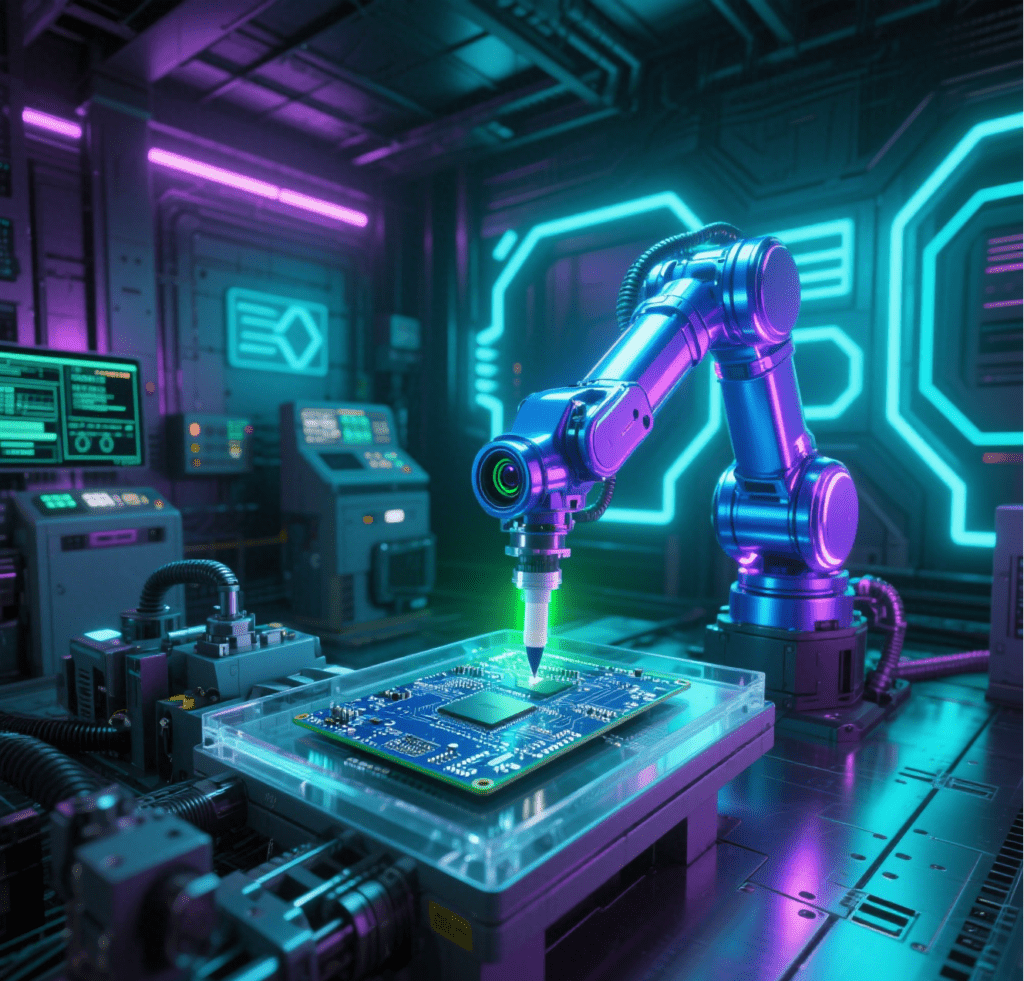

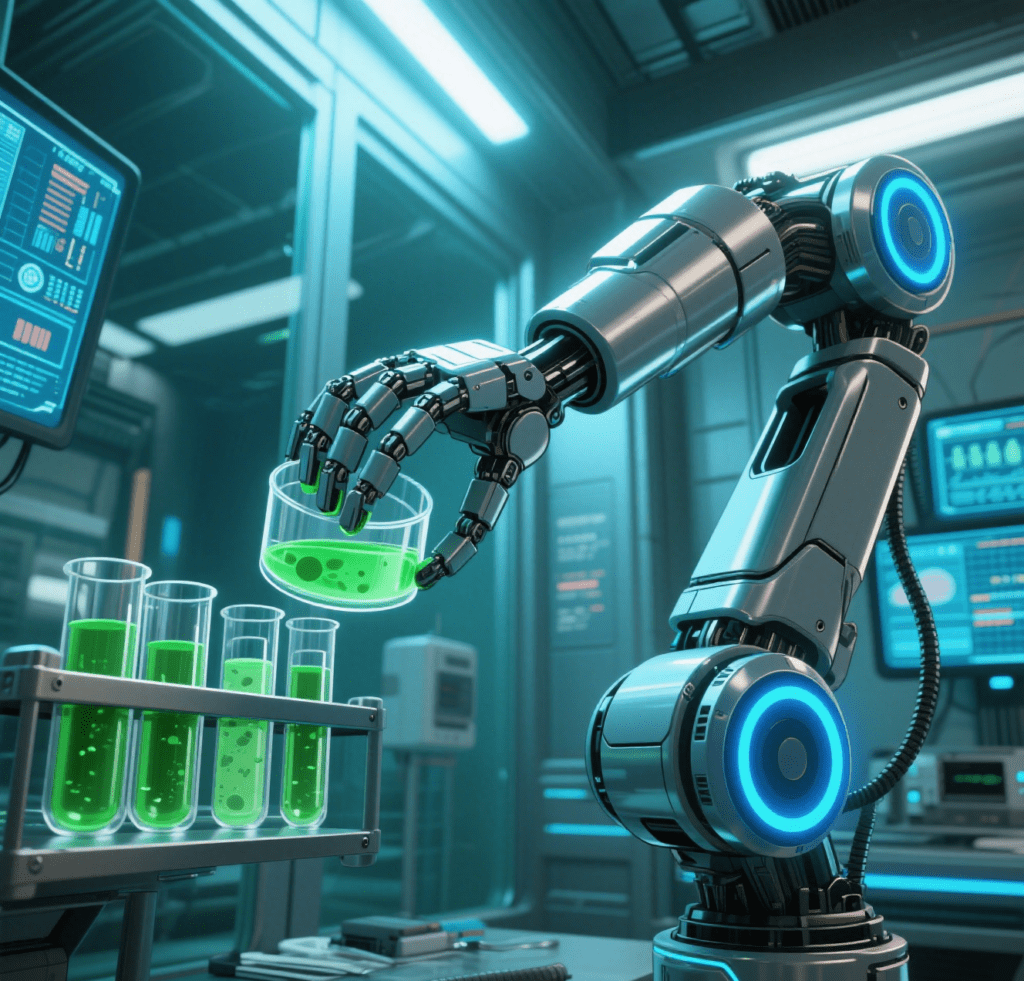

4-Axis Robotic Vision-Guided Dispensing System: Redefining Precision in Industrial Adhesive Applicati

4-Axis Robotic Vision-Guided Dispensing System: Redefining Precision in Industrial Adhesive Applications In industrial manufacturing, precise dispensing of adhesives, sealants, and coatings is critical for product integrity—from bonding tiny microchips to sealing automotive windshields. Traditional dispensing systems, reliant on fixed fixtures, manual programming, and 2D positioning, struggle with complex geometries, part variations, and rapid changeovers, leading to inconsistent quality and costly rework. The 4-Axis Robotic Vision-Guided Dispensing System emerges as a game-changing solution, integrating the speed of 4-axis robotics with the intelligence of 3D vision to automate fluid application with unmatched accuracy and flexibility. Designed for industries ranging from electronics to automotive, this system transforms dispensing from a manual, error-prone process into a […]

Automatic Sorting and Packaging System: Revolutionizing Efficiency in Global Supply Chains

Automatic Sorting and Packaging System: Revolutionizing Efficiency in Global Supply Chains In an era defined by e-commerce dominance, personalized consumer demands, and the need for rapid order fulfillment, traditional sorting and packaging methods—reliant on manual labor, static conveyors, and rule-based systems—are struggling to keep pace. The Automatic Sorting and Packaging System (ASPS) emerges as a transformative solution, integrating advanced robotics, AI-driven vision, and adaptive automation to streamline the entire process: from sorting mixed SKUs at high speeds to packaging products with precision and care. Designed to handle everything from tiny electronics components to bulky consumer goods, this system eliminates bottlenecks, reduces errors, and enables businesses to thrive in the age of mass […]

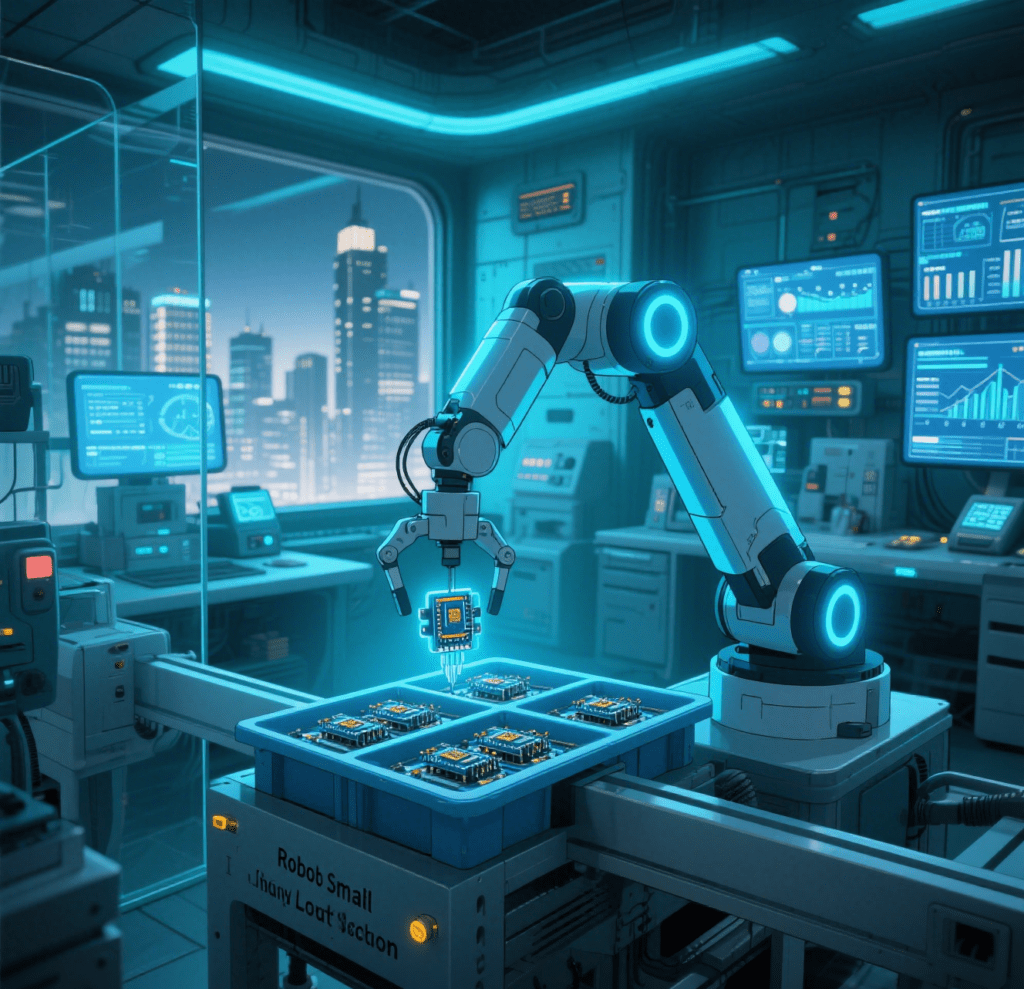

Robotic Small Product Tray Loading System: Mastering Precision and Speed in Micro-Manufacturing

Robotic Small Product Tray Loading System: Mastering Precision and Speed in Micro-Manufacturing In an era where miniaturization defines innovation—from wearable electronics to medical micro-devices—the challenge of efficiently loading small products (1mm to 100mm) into trays has become a critical bottleneck. Traditional manual or semi-automated methods are plagued by slow speeds (20–50 parts/min), high error rates (10–15% misalignments), and reliance on skilled labor, limiting scalability for industries demanding precision at scale. The Robotic Small Product Tray Loading System emerges as a transformative solution, combining high-speed robotics, AI-driven vision, and adaptive software to automate the delicate process of arranging tiny components into trays with unmatched accuracy and speed. Designed for industries ranging from electronics […]

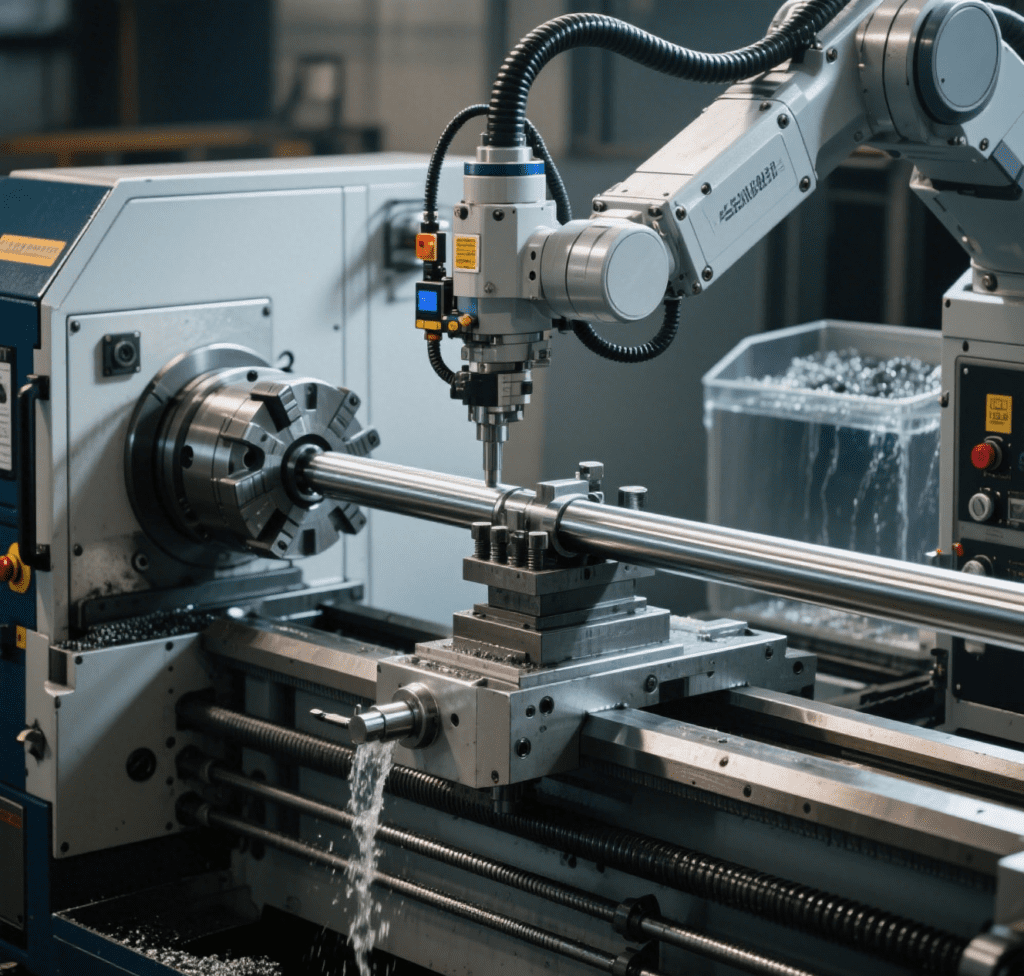

CNC Lathe Automatic Loading/Unloading System: Elevating Productivity and Precision in Machining

CNC Lathe Automatic Loading/Unloading System: Elevating Productivity and Precision in Machining In the realm of precision machining, CNC lathes are the backbone of producing cylindrical components—from automotive axles to medical implants. However, traditional manual loading/unloading processes introduce bottlenecks: inconsistent cycle times, operator fatigue leading to errors, and safety risks from heavy part handling. The CNC Lathe Automatic Loading/Unloading System emerges as a game-changing solution, integrating robotics, intelligent sensing, and seamless automation to transform standalone lathes into fully optimized, lights-out manufacturing cells. By eliminating human intervention in repetitive tasks, this system delivers unmatched productivity, accuracy, and flexibility, making it indispensable for modern machining operations. The Core Components: How Automatic Systems Redefine Machining Efficiency […]

Automatic Showerhead Assembly System: Streamlining Precision and Efficiency in Plumbing Manufacturing

Automatic Showerhead Assembly System: Streamlining Precision and Efficiency in Plumbing Manufacturing In the competitive landscape of plumbing fixture production, assembling showerheads—with their intricate mix of plastic, metal, and rubber components—has long relied on labor-intensive manual processes. Misalignments, inconsistent torque, and time-consuming quality checks plague traditional lines, driving up costs and limiting scalability. The Automatic Showerhead Assembly System emerges as a transformative solution, integrating advanced robotics, intelligent sensing, and adaptive software to automate every step—from component feeding to final testing. Designed to handle diverse showerhead types (handheld, rainfall, dual-function) with precision, this system eliminates human error, accelerates production, and enables manufacturers to meet global demand for high-quality, affordable fixtures. The Anatomy of an […]

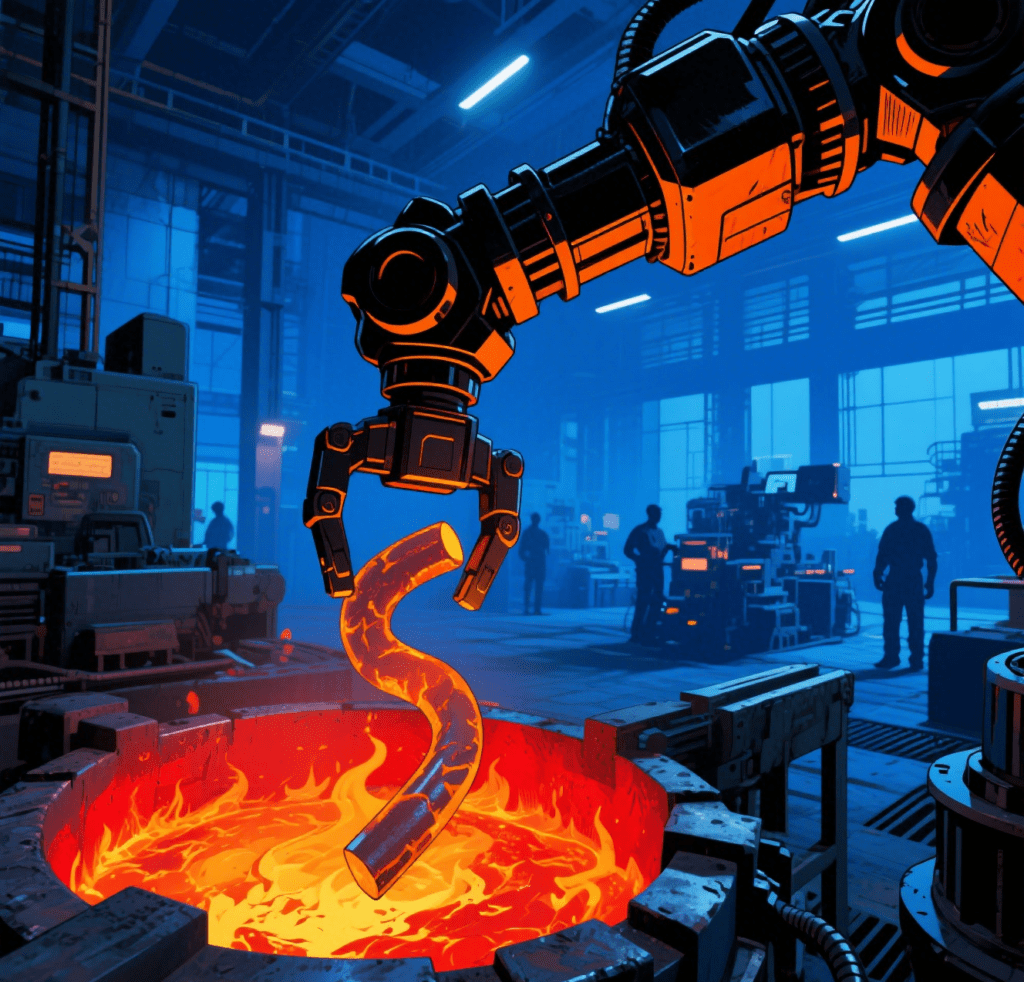

Robotic Irregular-Shaped Metal Part Removal System: Conquering Complexity in Industrial Handling

Robotic Irregular-Shaped Metal Part Removal System: Conquering Complexity in Industrial Handling In industrial manufacturing, the handling of irregular-shaped metal parts—castings, forgings, die-cast components, and custom-machined pieces—has long been a challenge. Traditional methods, relying on manual labor or rigid automation, struggle with inconsistent geometries, heavy weights, and safety risks, leading to inefficiencies, quality issues, and costly downtime. The Robotic Irregular-Shaped Metal Part Removal System emerges as a groundbreaking solution, combining advanced robotics, 3D vision, and adaptive control to transform how factories handle complex components. Designed to tackle parts with asymmetrical forms, sharp edges, or varying surface textures, this system delivers unmatched precision, speed, and safety, revolutionizing processes in automotive, aerospace, and metal fabrication […]

Automatic Small Metal Part Feeding System: Revolutionizing Precision and Efficiency in Micro-Manufacturing

Automatic Small Metal Part Feeding System: Revolutionizing Precision and Efficiency in Micro-Manufacturing In the realm of modern manufacturing, where components are shrinking to micrometers and production volumes demand unprecedented speed, the challenge of handling small metal parts—screws, pins, connectors, and gears—has become a critical bottleneck. Traditional manual or semi-automated feeding methods are plagued by inefficiencies: misaligned parts, downtime for jams, and reliance on skilled operators. Enter the Automatic Small Metal Part Feeding System, a technological marvel designed to overcome these hurdles. By integrating vibration control, intelligent sorting, and seamless automation, this system ensures that even the tiniest components (0.5mm to 50mm) are delivered precisely, consistently, and at scale, powering industries from […]

Universal Assembly System: Redefining Flexibility and Precision in Modern Manufacturing

Universal Assembly System: Redefining Flexibility and Precision in Modern Manufacturing In an age where consumer demands for customized products clash with the need for mass production efficiency, traditional assembly lines—rigid, slow to reconfigure, and reliant on specialized fixtures—are reaching their limits. The Universal Assembly System (UAS) emerges as a transformative solution, blending advanced robotics, adaptive software, and modular design to create a single platform capable of assembling everything from tiny electronic components to large industrial machinery. By eliminating the constraints of legacy systems, UAS enables manufacturers to achieve unprecedented levels of flexibility, precision, and speed, making it the cornerstone of the future factory. The Core Architecture: What Makes a Universal Assembly System […]

6-Axis Robotic Loading/Unloading System: Redefining Flexibility in Automated Material Handling

6-Axis Robotic Loading/Unloading System: Redefining Flexibility in Automated Material Handling In an era where manufacturing demands shift toward customization, speed, and precision, the limitations of traditional material handling systems—rigid workflows, manual intervention, and limited adaptability—have become critical bottlenecks. Enter the 6-Axis Robotic Loading/Unloading System, a game-changing solution designed to overcome these challenges. By leveraging the full range of motion offered by six degrees of freedom (6DOF), advanced sensors, and intelligent software, this system transforms repetitive, complex material handling tasks into streamlined, error-free processes. Whether transferring delicate electronic components or heavy industrial parts, it delivers unmatched flexibility, accuracy, and efficiency, making it the cornerstone of modern smart factories. The Power of Six […]