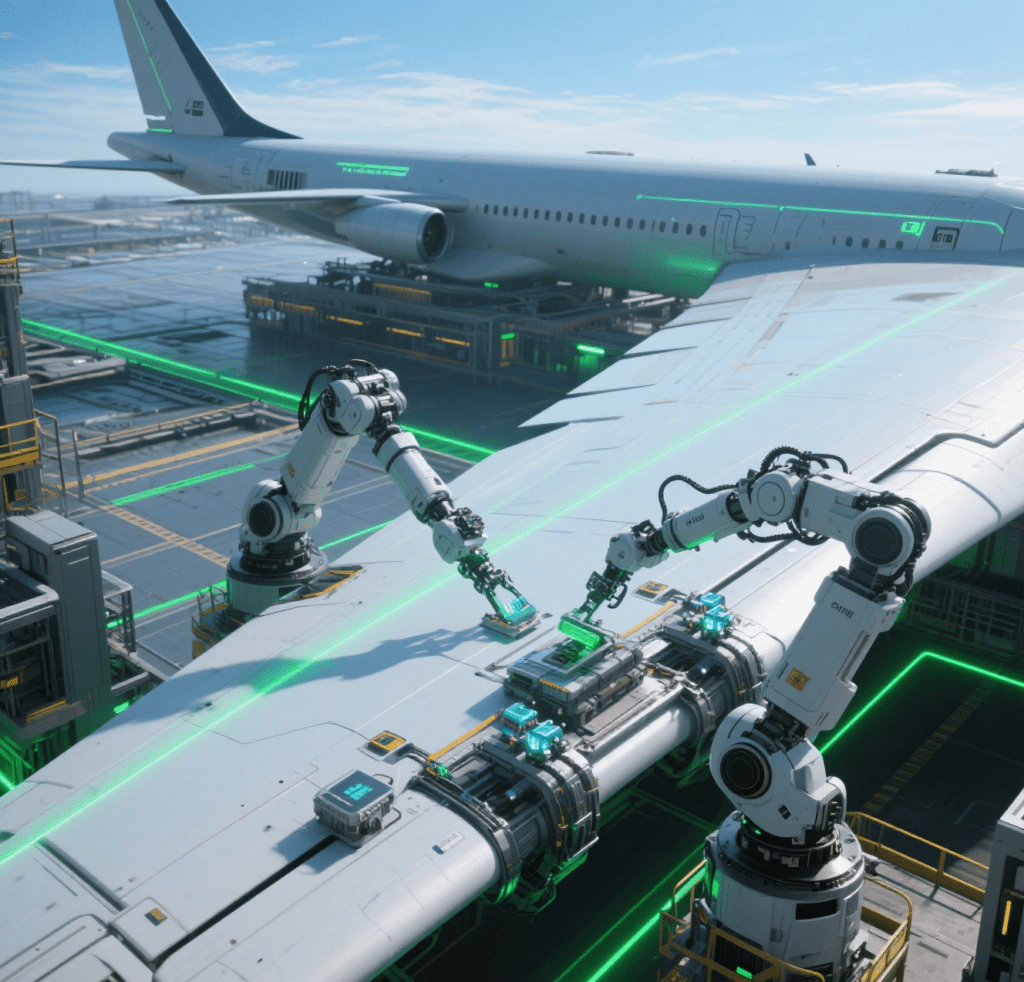

Universal Assembly System: The Future of Flexible, High-Precision Manufacturing

Universal Assembly System: The Future of Flexible, High-Precision Manufacturing In an era where consumer demands shift rapidly and product customization is king, traditional assembly lines—rigid, slow to reconfigure, and limited to single-product production—are no longer viable. Manufacturers face the challenge of assembling thousands of SKUs with varying complexities, from tiny smartphone components to large automotive sub-assemblies, while maintaining speed and precision. Enter the Universal Assembly System—a revolutionary solution designed to break free from these constraints. By integrating advanced robotics, adaptive tooling, and intelligent software, this system transforms assembly into a dynamic, scalable, and future-proof process. The Need for Universality: Why Traditional Systems Fall Short Traditional assembly lines excel at mass-producing identical […]

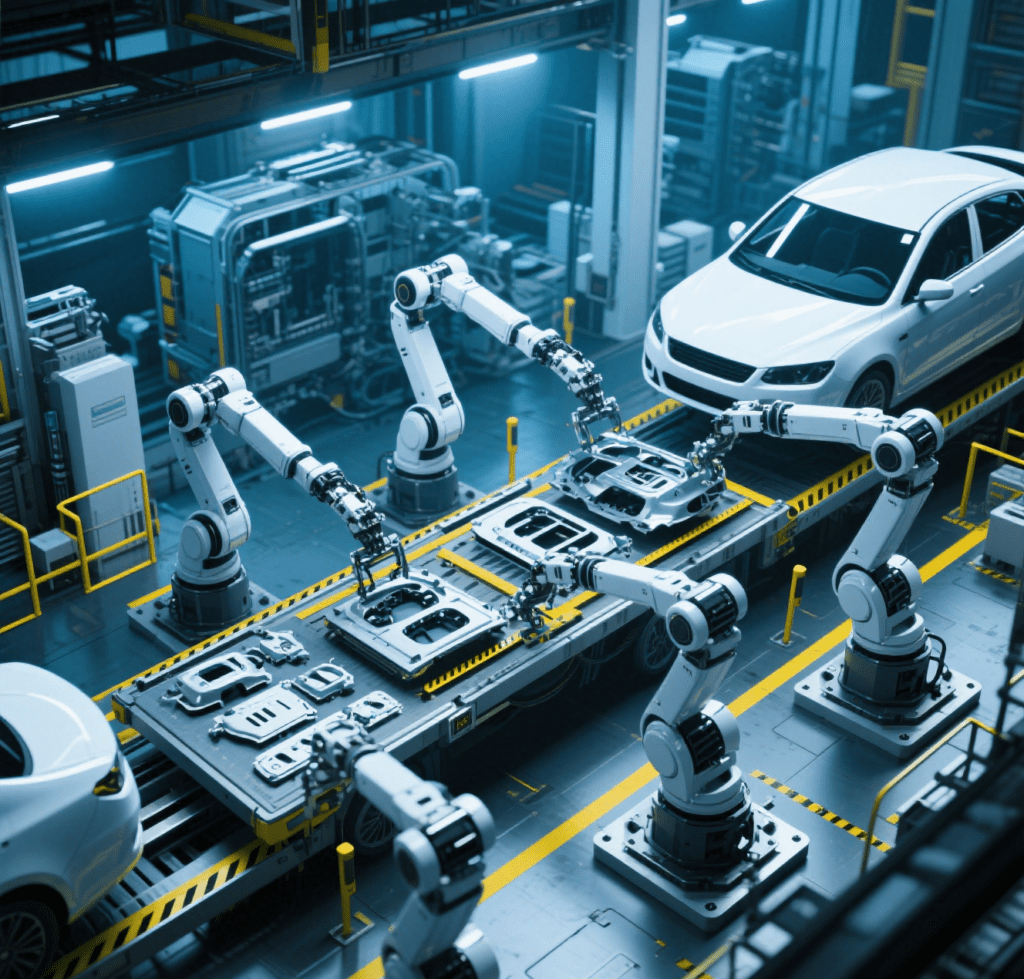

6-Axis Robotic Loading/Unloading System: Redefining Flexibility in Automated Material Handling

6-Axis Robotic Loading/Unloading System: Redefining Flexibility in Automated Material Handling In modern manufacturing, the ability to efficiently load and unload components into machines—from CNC lathes to injection molders—dictates production speed, quality, and cost. Manual handling is slow, error-prone, and unsafe, while 4-axis systems struggle with complex 3D geometries. Enter the 6-Axis Robotic Loading/Unloading System—a versatile solution engineered to tackle these challenges. By combining full 3D dexterity, precision positioning, and adaptive intelligence, this system transforms material handling into a streamlined, high-performance process for industries ranging from automotive to electronics. Why 6-Axis? The Power of Full 3D Mobility Six-axis robots offer 6 degrees of freedom (6DOF), enabling movement in all directions and rotations—a game-changer […]

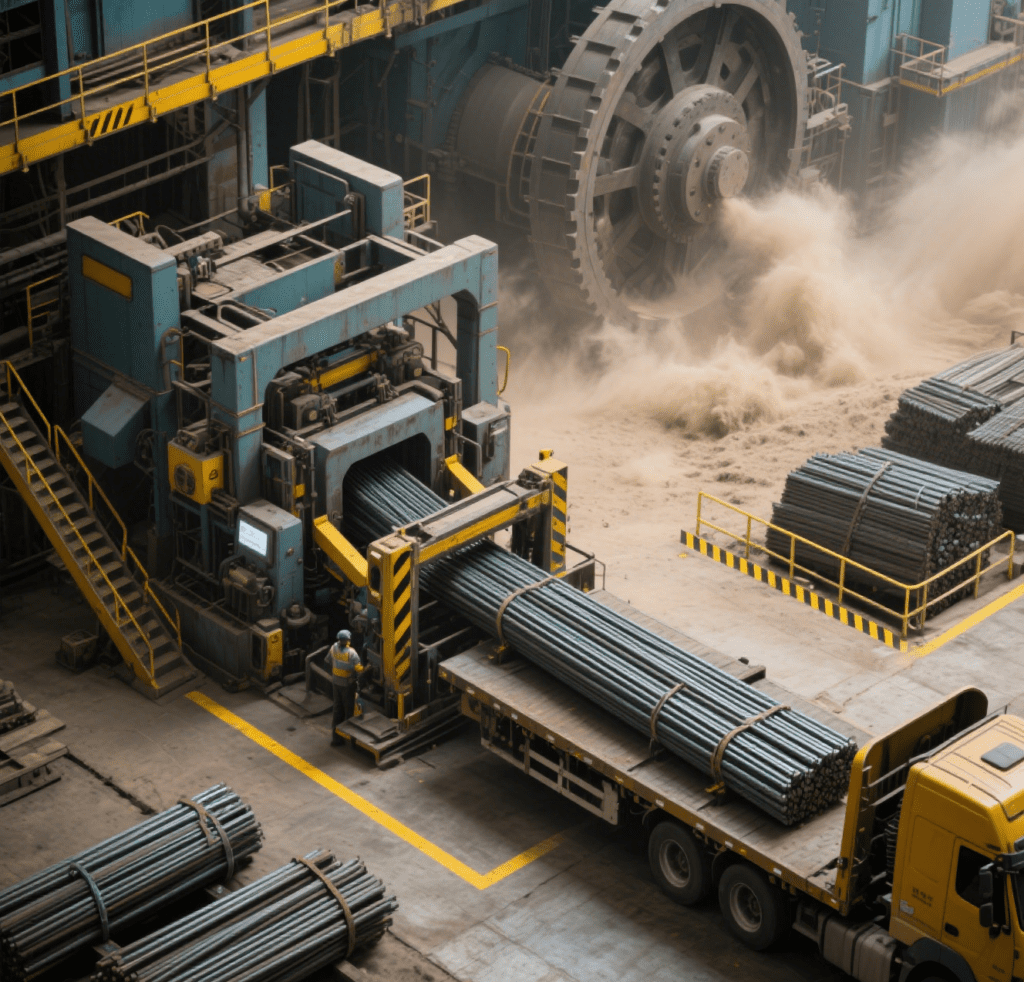

Automatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling Efficiency

Automatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling Efficiency In industries where iron rods serve as the backbone of production—from steel manufacturing to machinery 加工 and construction—manual loading/unloading is a relic of the past. Handling long, heavy iron rods (ranging from 6mm to 200mm in diameter and up to 12 meters in length) is labor-intensive, dangerous, and prone to inconsistencies. Misalignments during loading can damage CNC machines, while manual lifting leads to high rates of workplace injuries. Enter the Automatic Iron Rod Loading/Unloading System—a robust, intelligent solution engineered to streamline material flow, enhance safety, and boost productivity in high-volume, heavy-duty environments. The Imperative for Automation in Iron Rod Handling Iron […]

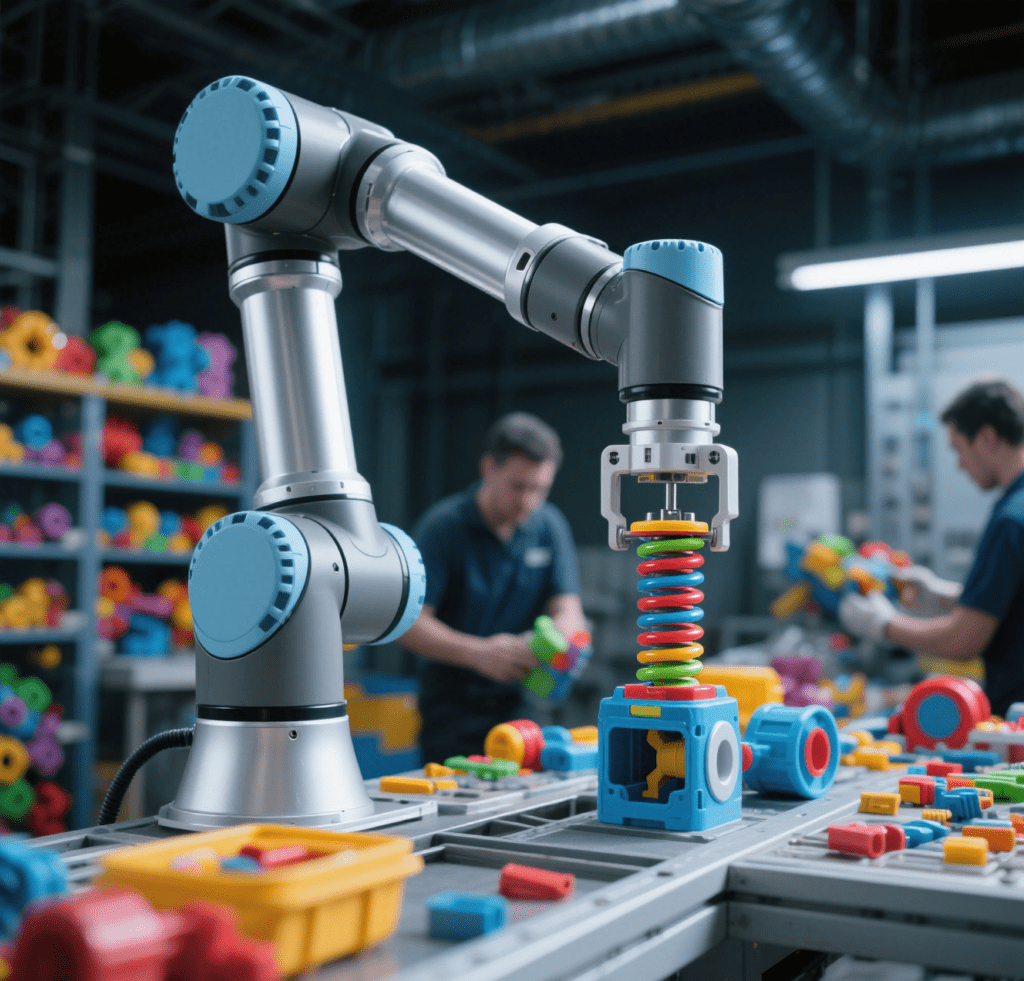

6-Axis Robotic Spring Pick-and-Place System: Mastering Precision in Elastic Component Handling

6-Axis Robotic Spring Pick-and-Place System: Mastering Precision in Elastic Component Handling In industries where tiny, elastic components dictate product performance—think automotive suspensions, electronic switches, or medical device actuators—handling springs is a delicate dance of force, precision, and adaptability. Manual pick-and-place operations struggle with inconsistent grip force (leading to deformation or slippage), while 4-axis robots falter with 3D orientation challenges. Enter the 6-Axis Robotic Spring Pick-and-Place System—a versatile solution engineered to tackle these complexities. By combining full 3D dexterity, intelligent force control, and adaptive vision, this system transforms spring handling from a high-risk bottleneck into a streamlined, error-free process. Why 6-Axis? The Imperative for Elastic Component Dexterity Springs are inherently complex: their […]

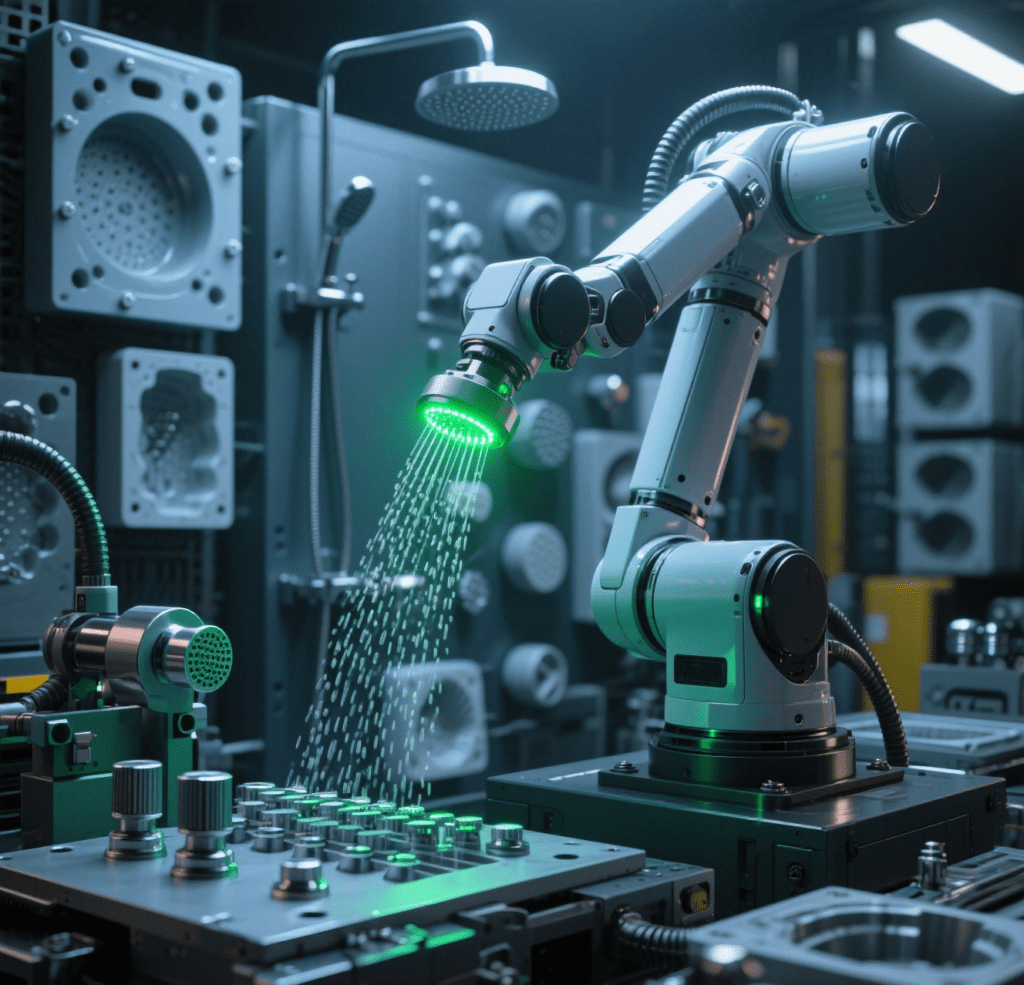

6-Axis Robotic Showerhead Loading/Unloading System: Mastering Complexity in Manufacturing

6-Axis Robotic Showerhead Loading/Unloading System: Mastering Complexity in Manufacturing In the intricate world of showerhead production—where curved surfaces, threaded connectors, and varied geometries demand precise handling—manual loading/unloading is a bottleneck riddled with inefficiencies. Human operators struggle with repetitive motions, inconsistent positioning, and the risk of ergonomic injuries, while traditional 4-axis systems fall short in managing the 3D complexity of showerhead designs. Enter the 6-Axis Robotic Showerhead Loading/Unloading System—a versatile solution engineered to tackle these challenges with unmatched dexterity, adaptability, and speed. Designed for 卫浴 factories, plumbing manufacturers, and assembly lines, this system transforms a once-laborious process into a streamlined, high-precision operation. Why 6-Axis? The Necessity of Full 3D Dexterity Showerheads are […]

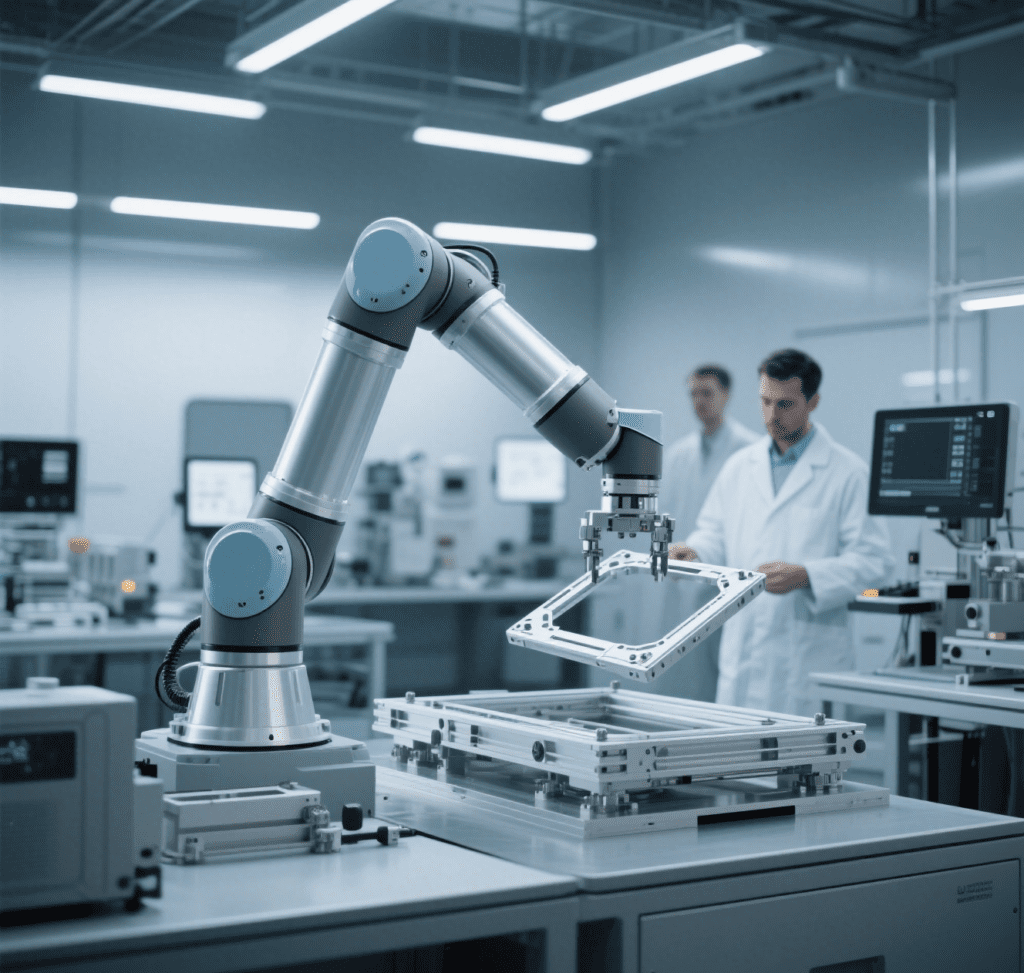

4-Axis Robotic Frame Pick-up System: Revolutionizing Precision Material Handling in Manufacturing

4-Axis Robotic Frame Pick-up System: Revolutionizing Precision Material Handling in Manufacturing In modern manufacturing, the efficient and precise handling of frames—whether for display panels, circuit boards, or industrial structures—is a make-or-break process. Manual frame picking is slow, error-prone, and risky for workers, while traditional automation often struggles with varying frame sizes, weights, and fragility. Enter the 4-Axis Robotic Frame Pick-up System, a SCARA-based solution engineered to address these challenges with unmatched speed, adaptability, and precision. Designed for industries ranging from consumer electronics to heavy machinery, this system transforms frame handling into a streamlined, reliable, and future-ready operation. Why 4-Axis for Frame Pick-up? The Perfect Balance of Speed and Control Four-axis SCARA […]

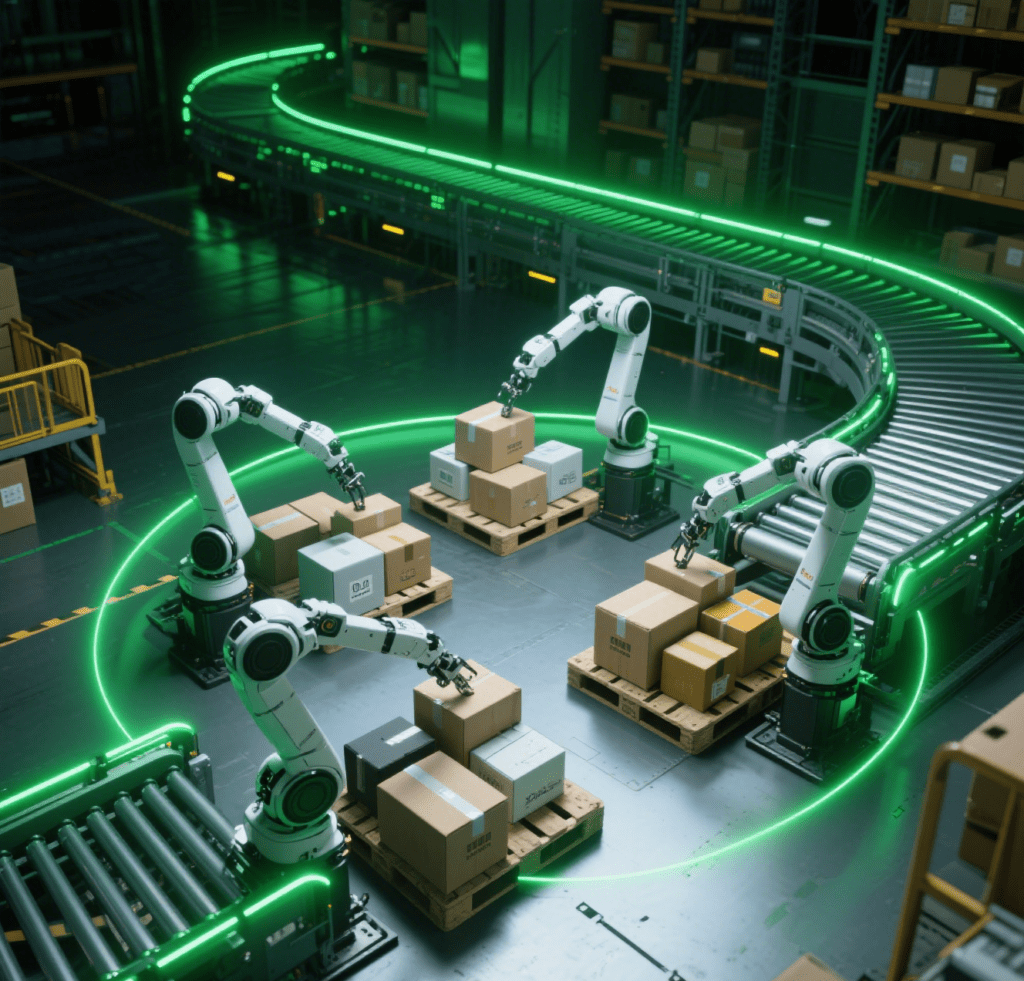

4-Axis Robotic Tray Loading System: Redefining Efficiency in Automated Material Handling

4-Axis Robotic Tray Loading System: Redefining Efficiency in Automated Material Handling In the fast-paced world of modern manufacturing, the seamless loading of components into trays is the unsung hero of streamlined production. Whether in electronics, automotive, or pharmaceuticals, manual tray loading is a bottleneck—prone to errors, slow, and labor-intensive. Enter the 4-Axis Robotic Tray Loading System, a SCARA-based solution designed to transform this critical process. By merging high-speed motion, precision positioning, and intelligent adaptability, this system eliminates inefficiencies, boosts quality, and future-proofs production lines for high-mix, high-volume environments. The 4-Axis Advantage: Engineered for Speed and Precision Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for planar material handling, making them […]

4-Axis Robotic Tray Loading System: Optimizing Precision and Speed in Material Handling

4-Axis Robotic Tray Loading System: Optimizing Precision and Speed in Material Handling In modern manufacturing and logistics, the efficient loading of components into trays is a critical bottleneck. Whether dealing with delicate electronic parts, automotive components, or pharmaceutical products, manual tray loading is slow, error-prone, and costly. Enter the 4-Axis Robotic Tray Loading System—a SCARA-based solution designed to streamline material handling with unmatched speed, precision, and adaptability. This system transforms tray loading from a labor-intensive task into a high-speed, automated process, addressing the demands of high-mix, high-volume production. Why 4-Axis for Tray Loading? The Geometry of Efficiency Four-axis SCARA robots excel in planar motion tasks, making them ideal for tray loading: Rigid […]

4-Axis Robotic TV Panel Screw-Fixing System: Redefining Precision in Large-Screen Assembly

4-Axis Robotic TV Panel Screw-Fixing System: Redefining Precision in Large-Screen Assembly In an era where TVs are racing toward larger sizes (up to 110”) and slimmer profiles (as thin as 6mm), the assembly process—especially screw-fixing panels to frames—has become a high-stakes balancing act. One misaligned screw can crack a panel, one loose screw can cause screen flickering, and one slow cycle can bottleneck an entire production line. Enter the 4-Axis Robotic TV Panel Screw-Fixing System—a SCARA-driven solution engineered to master these challenges with surgical precision, blistering speed, and unmatched adaptability. Why 4-Axis? The Perfect Match for Planar Screw-Fixing Four-axis SCARA robots are not just faster than their six-axis counterparts for flat-surface […]

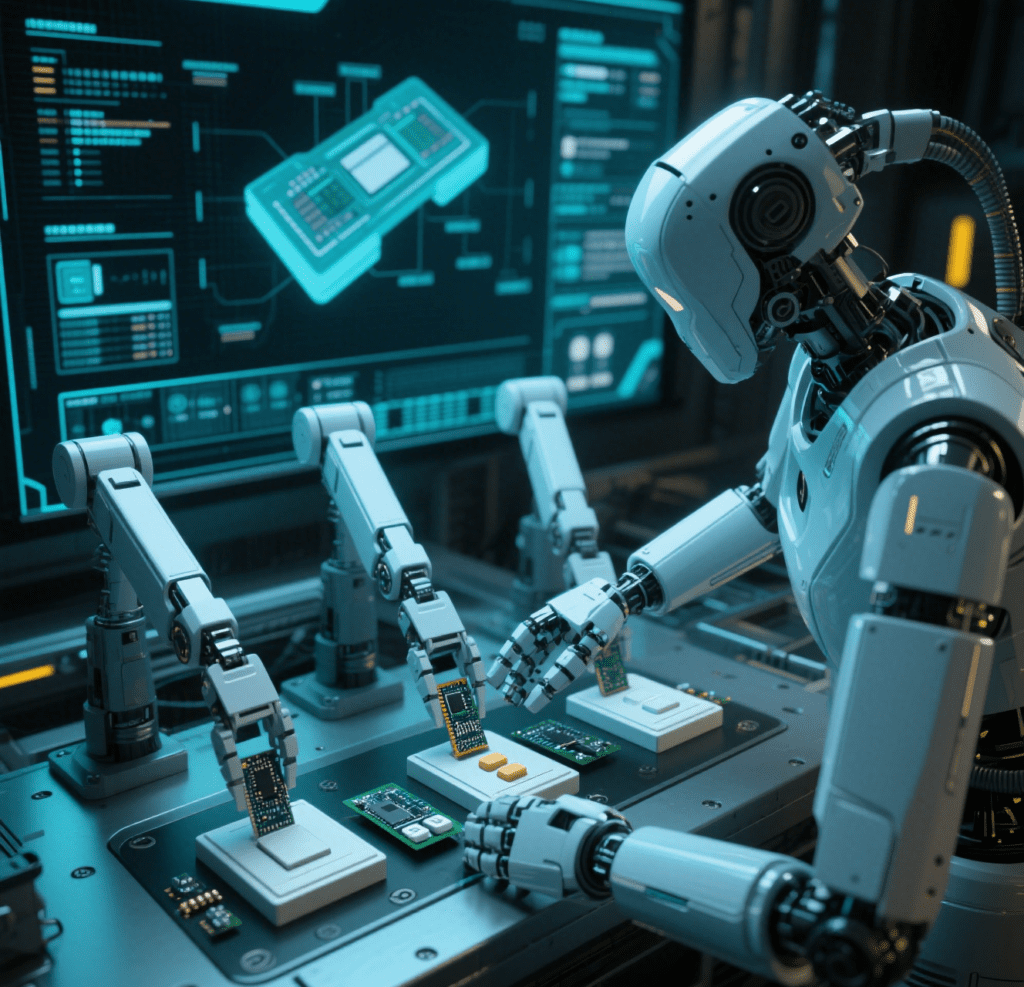

4-Axis Robotic Small Product Assembly System: Mastering Miniature Manufacturing Challenges

4-Axis Robotic Small Product Assembly System: Mastering Miniature Manufacturing Challenges In the intricate landscape of small-scale production—where components shrink to millimeters and assembly tolerances demand micron-level precision—traditional methods falter. Manual labor, prone to fatigue and inconsistency, struggles to meet the pace of high-volume, high-precision demands. Six-axis robots, while versatile, introduce unnecessary complexity and cost for planar tasks. Enter the 4-Axis Robotic Small Product Assembly System—a SCARA-driven solution engineered to conquer the unique hurdles of miniature assembly. The 4-Axis Edge: Engineered for Planar Excellence Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for fast, precise planar motion. Here’s why they outperform alternatives in small-part assembly: 1. Speed Redefined With a rigid […]