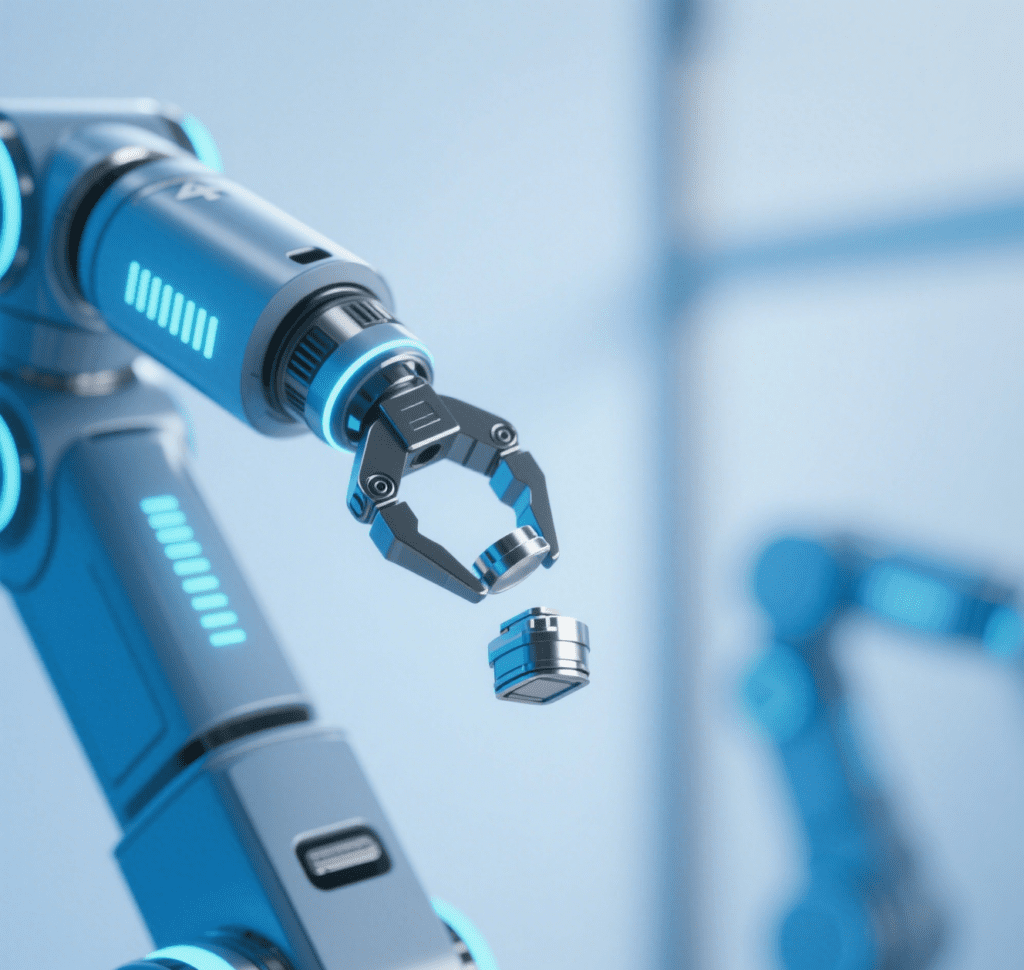

4-Axis Robotic Assembly System: Revolutionizing Efficiency in Smart Manufacturing Automation

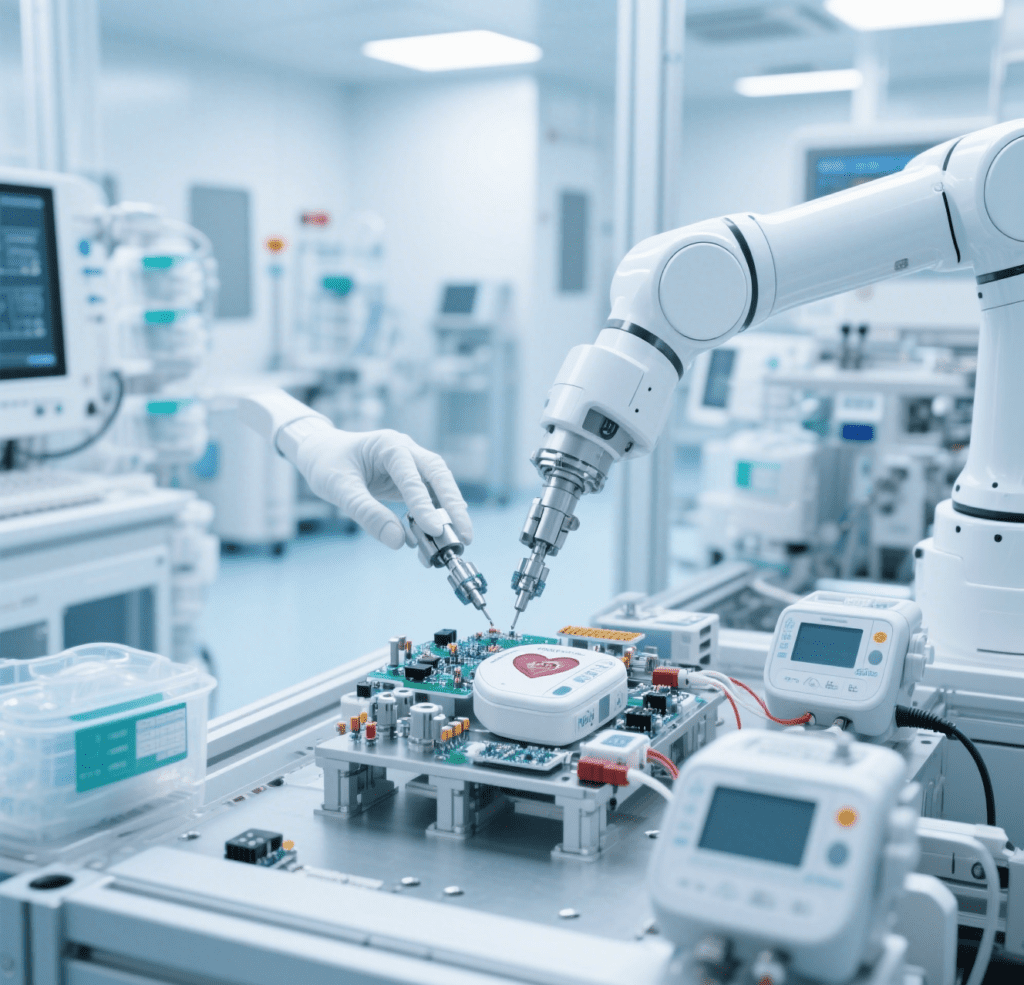

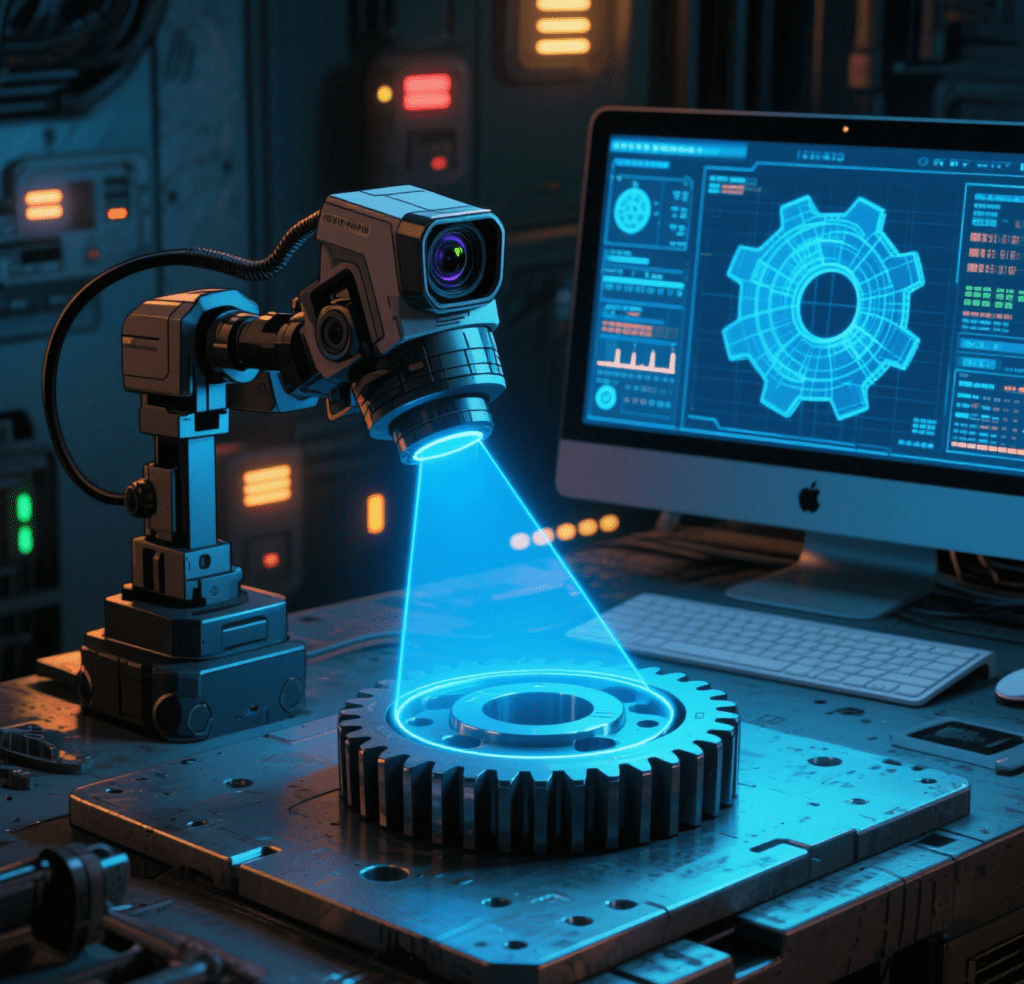

4-Axis Robotic Assembly System: Revolutionizing Efficiency in Smart Manufacturing Automation In the era of Industry 4.0, traditional assembly systems struggle to keep pace with the demands of high-mix, low-volume production. Characterized by slow cycle times (15–30 seconds per part), limited flexibility, and high labor costs, these systems fail to address the agility required in modern manufacturing. The 4-Axis Robotic Assembly System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and modular tooling to enable seamless automation across electronics, automotive, and medical device industries. I. Core Technical Architecture: Speed Meets Precision The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis […]

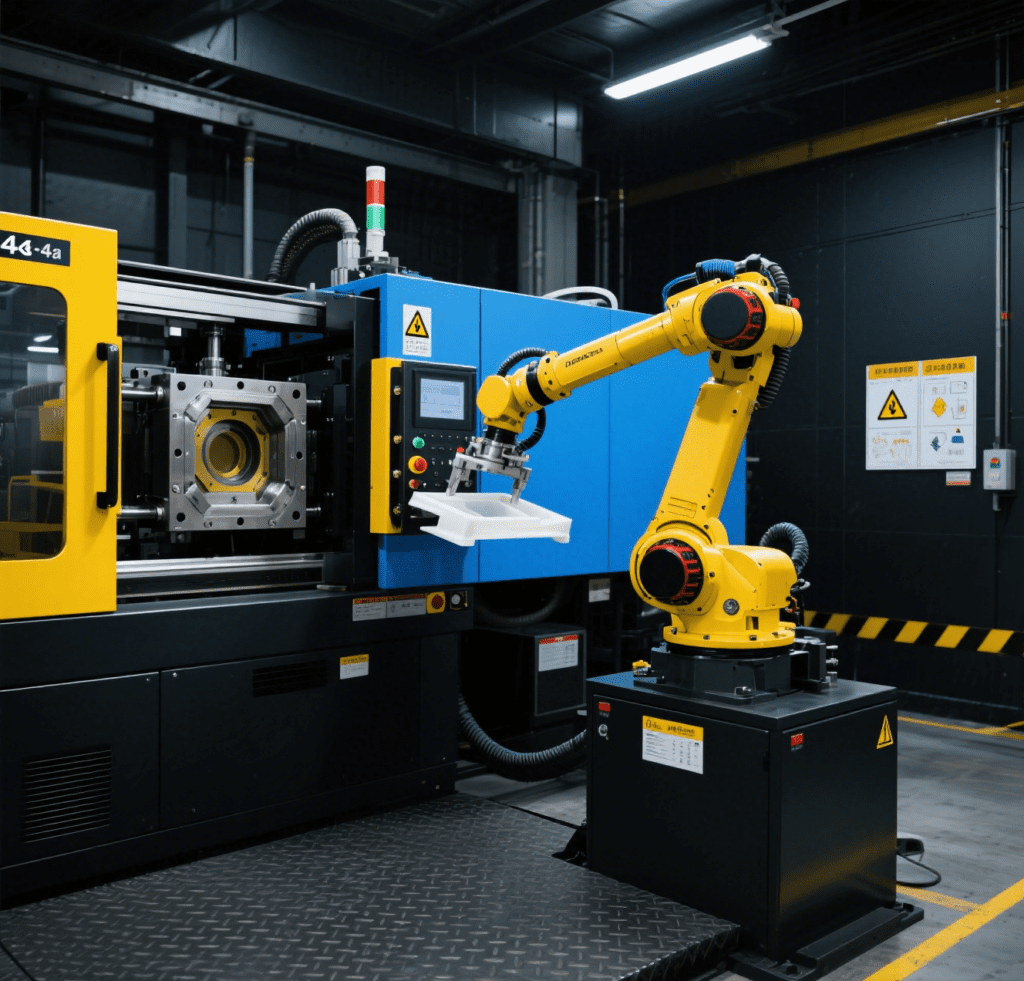

4-Axis Robotic Injection Molding Part Removal System: Revolutionizing Post-Molding Automation

4-Axis Robotic Injection Molding Part Removal System: Revolutionizing Post-Molding Automation In the high-volume landscape of injection molding, traditional part removal methods—ranging from manual extraction to basic mechanical arms—face critical limitations: slow cycle times (15–30 seconds per part), inconsistent handling (±0.5mm positioning errors), and high risk of part damage. The 4-Axis Robotic Injection Molding Part Removal System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive gripping to streamline post-molding operations in automotive, electronics, and medical device manufacturing. I. Core Technical Architecture: Speed Meets Precision The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis Robotic Manipulation Powered by SCARA […]

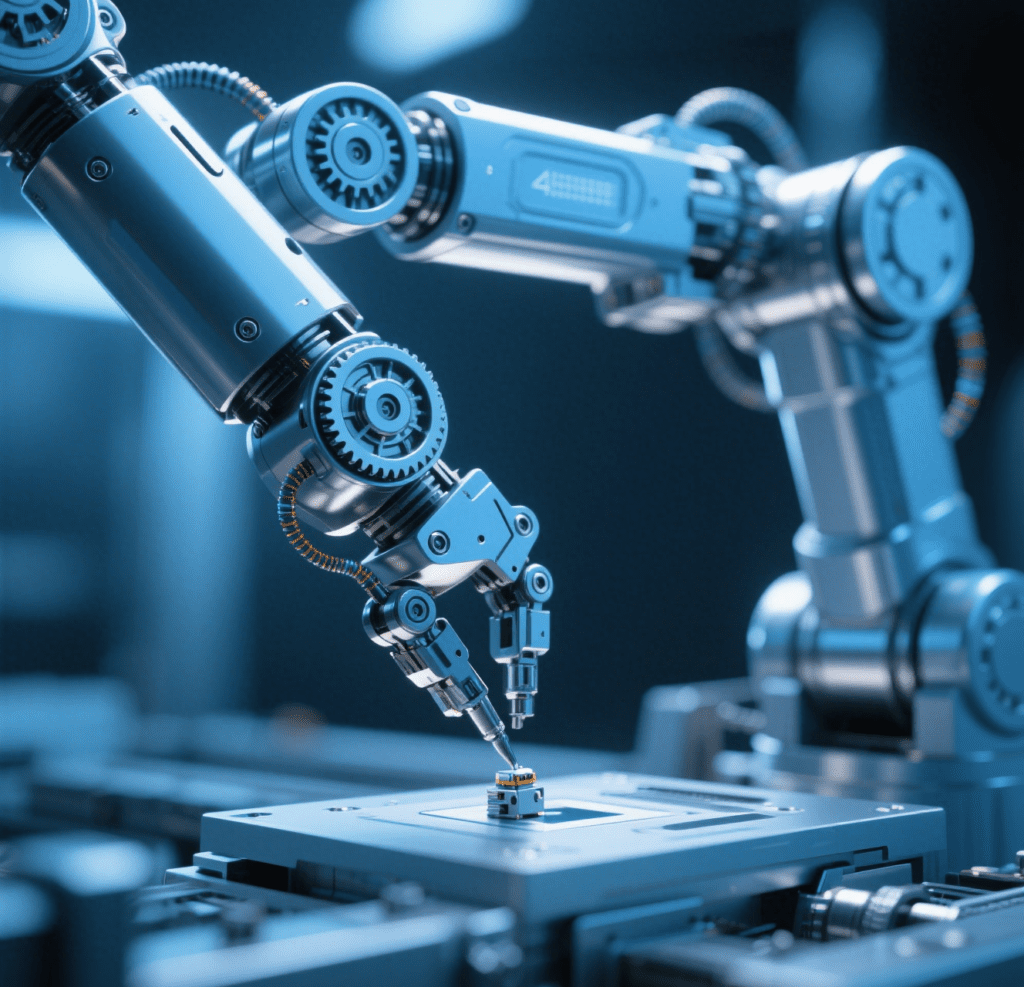

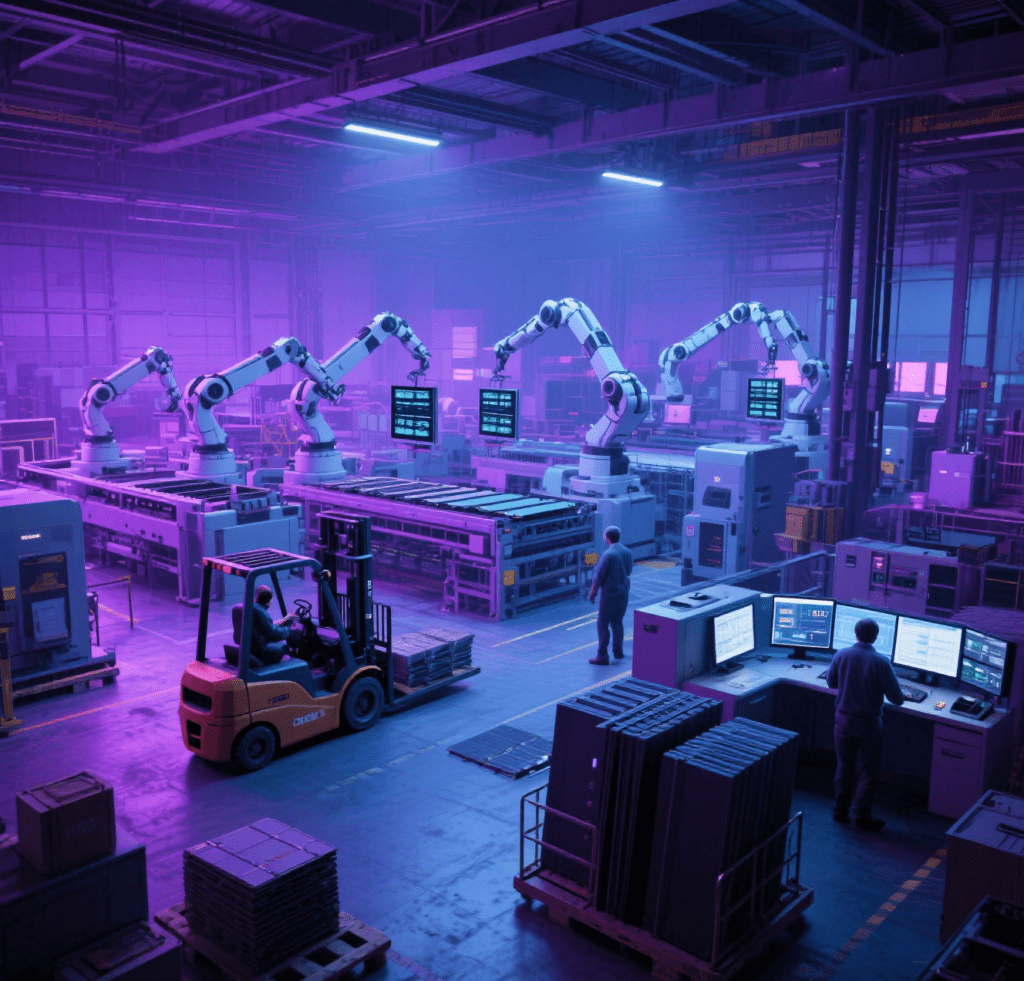

4-Axis Robotic Automated Assembly Line: Redefining Efficiency in Smart Manufacturing

4-Axis Robotic Automated Assembly Line: Redefining Efficiency in Smart Manufacturing In the era of Industry 4.0, traditional assembly lines struggle to keep pace with the demands of high-mix, low-volume production. Characterized by slow cycle times (15–30 seconds per part), limited flexibility, and high labor costs, these systems fail to address the agility required in modern manufacturing. The 4-Axis Robotic Automated Assembly Line emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and modular tooling to enable seamless automation across diverse industries—from electronics to automotive. I. Core Technical Architecture: Speed Meets Flexibility The system’s modular design synergizes robotic precision with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis […]

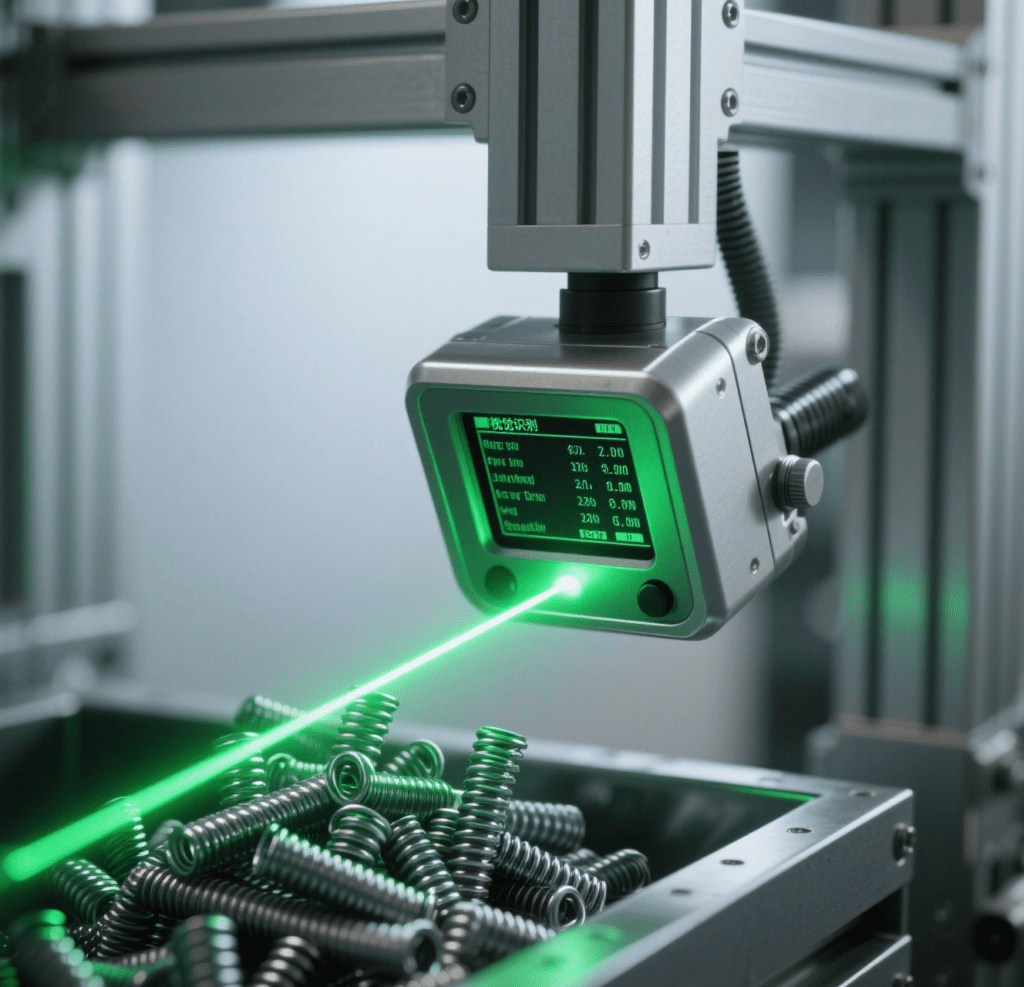

4-Axis Robotic Vision-Guided Spring Placement System: Redefining Precision in Elastic Component Assembly

4-Axis Robotic Vision-Guided Spring Placement System: Redefining Precision in Elastic Component Assembly In the realm of precision manufacturing, spring placement for complex assemblies—ranging from automotive suspensions to microelectronics—demands unparalleled accuracy and repeatability. Traditional manual or semi-automated systems struggle with slow cycle times (10–20 seconds per spring), inconsistent positioning (±0.5mm errors), and limited adaptability to diverse spring geometries. The 4-Axis Robotic Vision-Guided Spring Placement System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive force control to enable micron-level precision in high-mix, high-volume production. I. Core Technical Architecture: Speed Meets Surgical Precision The system’s modular design synergizes robotic agility with intelligent perception, comprising three interdependent subsystems: 1. […]

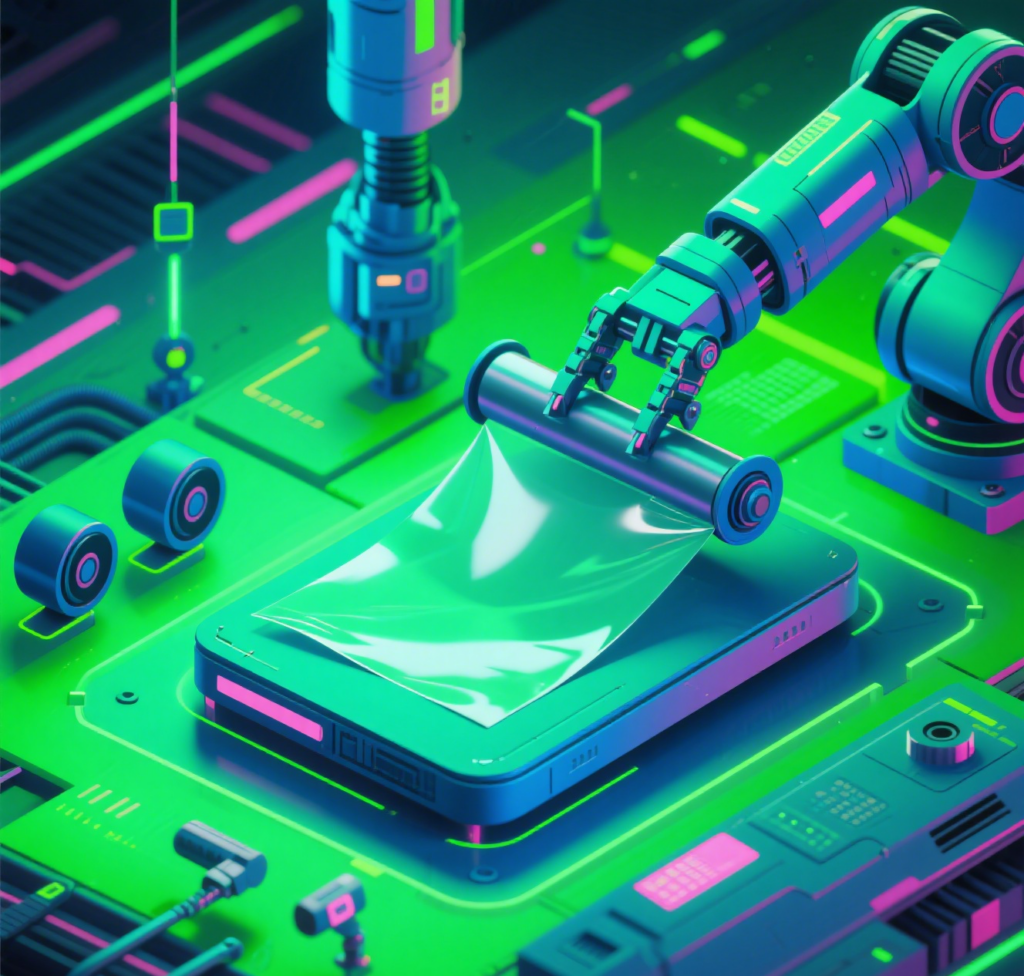

4-Axis Robotic Automatic Film Laminating System: Revolutionizing Precision Surface Treatment in Manufacturing

4-Axis Robotic Automatic Film Laminating System: Revolutionizing Precision Surface Treatment in Manufacturing In the era of high-precision manufacturing, film lamination for delicate components—ranging from smartphone displays to solar panels—demands unparalleled accuracy and consistency. Traditional manual or semi-automated laminating systems suffer from critical limitations: slow cycle times (20–40 seconds per part), inconsistent alignment (±0.5mm errors), and high risk of film wrinkles or bubbles. The 4-Axis Robotic Automatic Film Laminating System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive pressure control to enable micron-level precision in high-volume production across electronics, renewable energy, and medical device sectors. I. Core Technical Architecture: Speed Meets Micro-Precision The system’s modular design […]

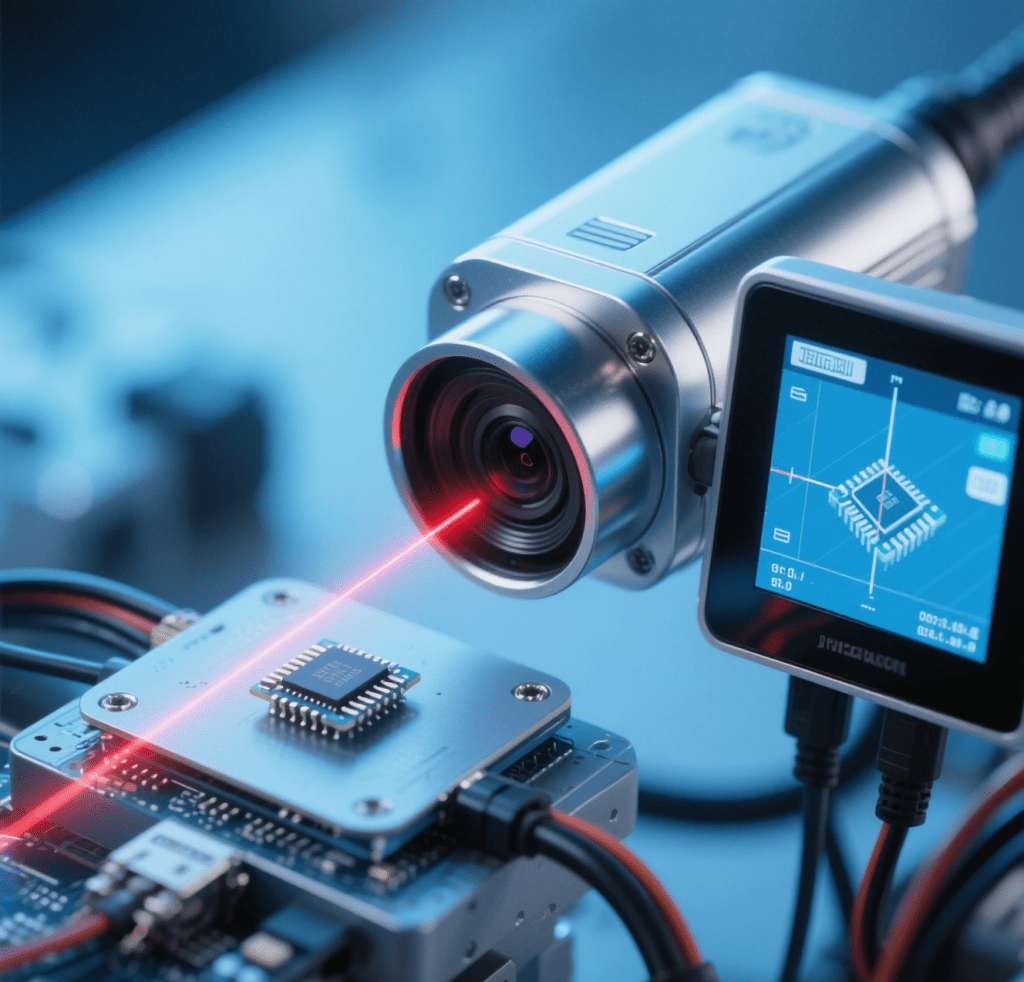

4-Axis Robotic Vision-Guided Dispensing System: Redefining Precision in Adhesive Application

4-Axis Robotic Vision-Guided Dispensing System: Redefining Precision in Adhesive Application In the landscape of precision manufacturing, adhesive dispensing for complex components—ranging from microelectronics to medical devices—requires unparalleled accuracy and consistency. Traditional manual or 2-axis dispensing systems struggle with slow cycle times (10–20 seconds per part), inconsistent bead profiles (±0.3mm errors), and limited adaptability to 3D surfaces. The 4-Axis Robotic Vision-Guided Dispensing System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive fluid control to enable micron-level precision in high-mix, high-volume production. I. Core Technical Architecture: Speed Meets Micro-Precision The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems: 1. High-Speed 4-Axis Robotic […]

Robotized Display Pick-and-Place System: Revolutionizing Precision Handling in Display Manufacturing

Robotized Display Pick-and-Place System: Revolutionizing Precision Handling in Display Manufacturing In the high-stakes world of display manufacturing, handling delicate panels (ranging from 10″ smartphone screens to 100″+ TV displays) with absolute precision is non-negotiable. Traditional manual or semi-automated pick-and-place methods suffer from critical flaws: slow cycle times (20–40 seconds per panel), positional errors (±0.5mm), and high risk of panel damage (defect rates ≥1%). The Robotized Display Pick-and-Place System emerges as a transformative solution, integrating high-precision robotics, AI-driven vision, and adaptive gripping to enable seamless handling of OLED, LCD, and micro-LED panels in high-volume production. I. Core Technical Architecture: Precision Meets Delicacy The system’s modular design balances robotic agility with display-specific […]

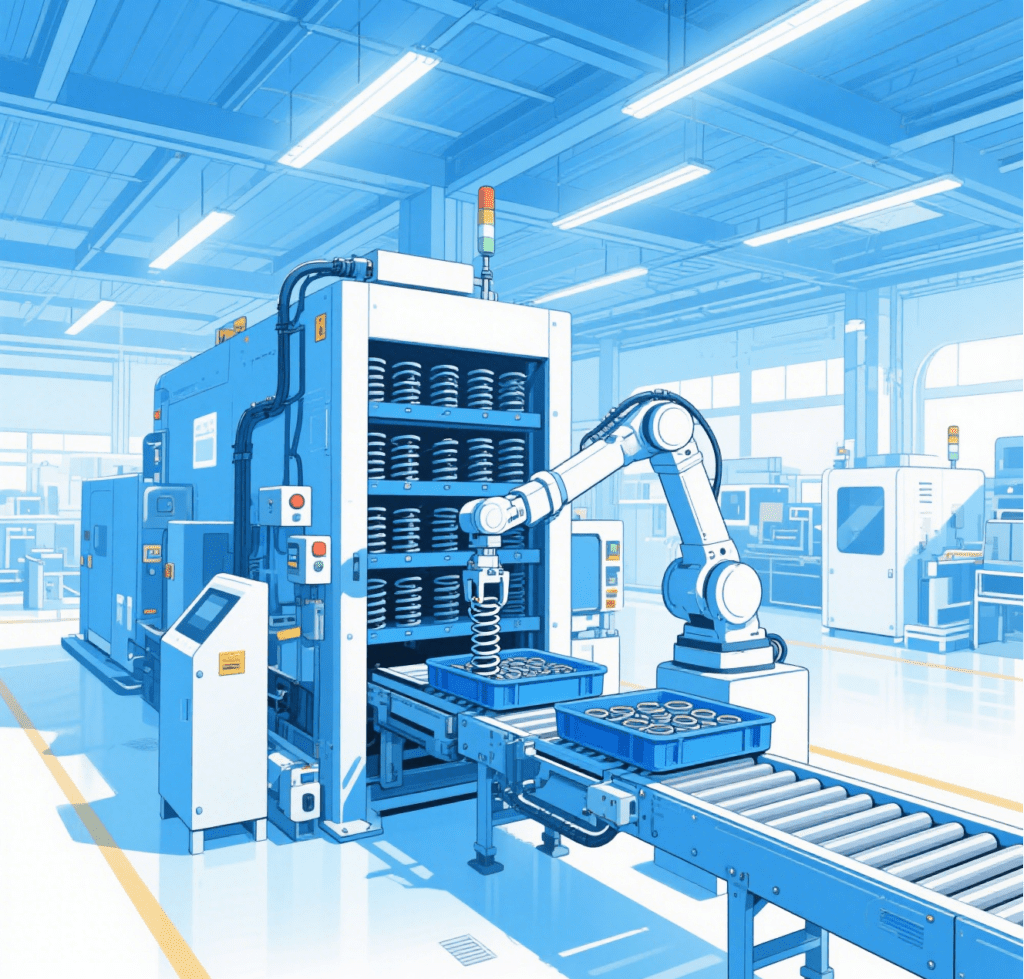

Automatic Spring Tray Loading System: Revolutionizing Precision Material Handling in Manufacturing

Automatic Spring Tray Loading System: Revolutionizing Precision Material Handling in Manufacturing In the realm of precision manufacturing, spring tray loading presents unique challenges due to diverse spring geometries (compression, torsion, extension), delicate materials (titanium, music wire), and tight tolerances (±0.05mm). Traditional manual or semi-automated systems struggle with slow cycle times (10–20 seconds per tray), inconsistent positioning (±0.5mm errors), and limited adaptability to varying spring types. The Automatic Spring Tray Loading System emerges as a transformative solution, integrating high-speed robotics, AI-driven vision, and adaptive tooling to streamline spring handling in automotive, electronics, and medical device production. I. Core Technical Architecture: Speed Meets Precision The system’s modular design synergizes robotic agility with […]

CUniversal Assembly System: Redefining Flexibility in Smart Manufacturing Automation

CUniversal Assembly System: Redefining Flexibility in Smart Manufacturing Automation In the era of mass customization, traditional assembly systems struggle to keep pace with rapidly evolving product demands. Characterized by rigid workflows and lengthy retooling times (20–40 hours per product change), these systems fail to address the needs of high-mix, low-volume production. The CUniversal Assembly System emerges as a transformative solution, integrating modular robotics, AI-driven vision, and adaptive control to enable seamless reconfiguration across diverse industries—from automotive to electronics. This article explores its technical architecture, industrial applications, and role in shaping the future of agile manufacturing. I. Core Technical Architecture: Modularity Meets Intelligence The system’s design prioritizes flexibility through four interdependent […]

NC Lathe Automatic Loading/Unloading System: Revolutionizing Precision Machining Through Intelligent Automation

NC Lathe Automatic Loading/Unloading System: Revolutionizing Precision Machining Through Intelligent Automation In the era of Industry 4.0, CNC lathes serve as the backbone of precision metal machining, but traditional manual loading/unloading methods have become bottlenecks in modern manufacturing. Struggling with slow cycle times (5–10 minutes per part), inconsistent positioning (±0.5mm errors), and high labor costs, these outdated systems fail to meet the demands of high-mix, low-volume production. The CNC lathe automatic loading/unloading system emerges as a transformative solution, integrating industrial robotics, vision guidance, and smart control to enable lights-out machining and redefine productivity in precision manufacturing. I. Core Technical Architecture: Where Mechanics Meets Intelligence The system’s modular design synergizes mechanical […]