Automatic Circlip Feeding System: Revolutionizing Precision Component Handling in Industrial Assembly

Automatic Circlip Feeding System: Revolutionizing Precision Component Handling in Industrial Assembly In the realm of precision mechanical assembly, circlips (retaining rings) play a critical role in securing components such as bearings, gears, and shafts. Traditional manual or semi-automated feeding methods for these small, elastic components—ranging from 2mm to 100mm in diameter—suffer from inherent limitations: inconsistent orientation (error rate ≥5%), slow cycle times (15–30 seconds per clip), and high labor intensity. The Automatic Circlip Feeding System emerges as a transformative solution, integrating vibratory bowl technology, intelligent vision guidance, and adaptive control to streamline high-precision circlip handling in automotive, electronics, and medical device manufacturing. Core Technical Architecture: Precision Meets Efficiency The system synergizes […]

6-Axis Robotic Spring Pick-and-Place System: Redefining Precision in Complex Spring Manipulation

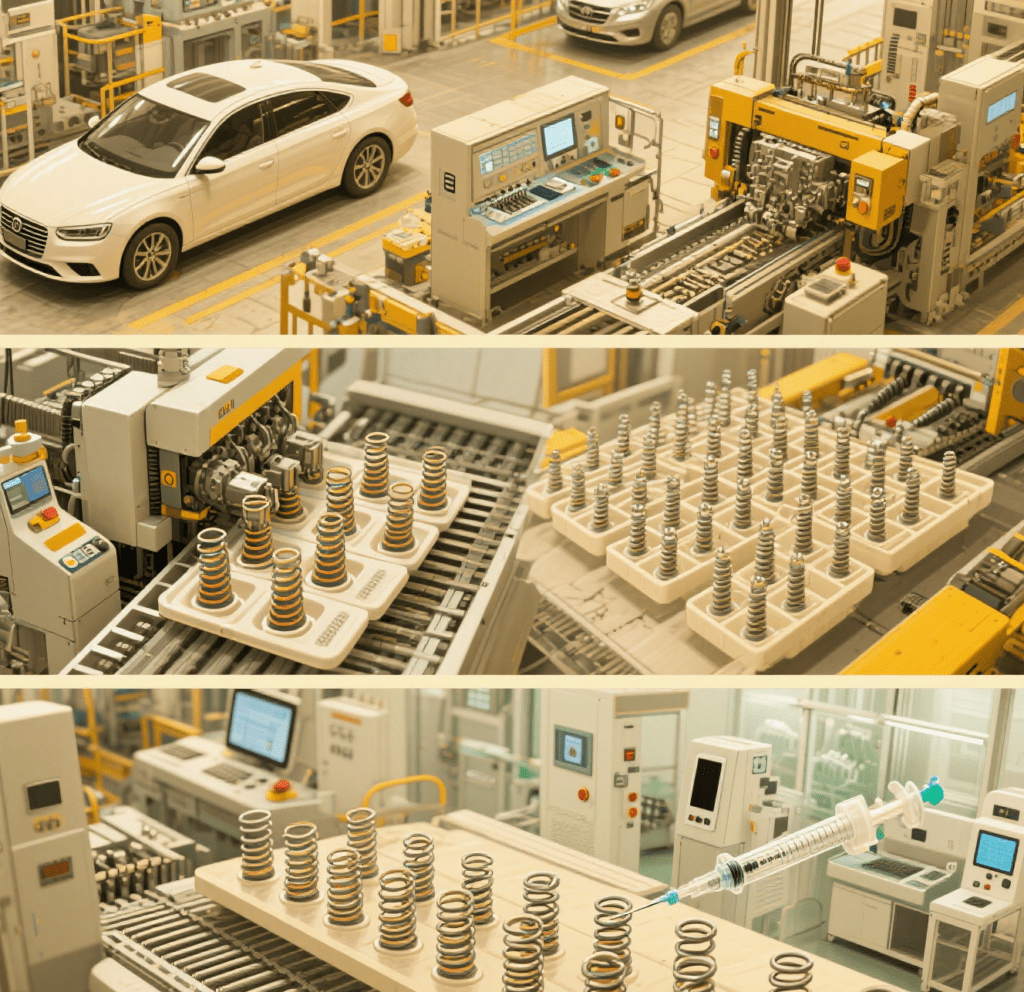

6-Axis Robotic Spring Pick-and-Place System: Redefining Precision in Complex Spring Manipulation In the realm of precision manufacturing, spring assembly presents unique challenges due to diverse geometries (compression, torsion, extension springs), delicate materials (titanium alloys, music wire), and tight tolerances (±0.05mm). Traditional pick-and-place systems—limited by 4-axis planar motion—struggle with 3D spring orientations, complex trajectories, and fragile component handling. The 6-Axis Robotic Spring Pick-and-Place System emerges as a transformative solution, combining full 3D mobility with AI-driven vision and force control to address these challenges in high-precision industries like automotive, medical devices, and aerospace. Core Technical Architecture: 3D Mobility Meets Intelligent Control The system integrates 6-axis industrial robots, high-resolution vision systems, and adaptive […]

4-Axis Robotic Frame Pick-up System: Revolutionizing High-Speed Material Handling in Smart Manufacturing

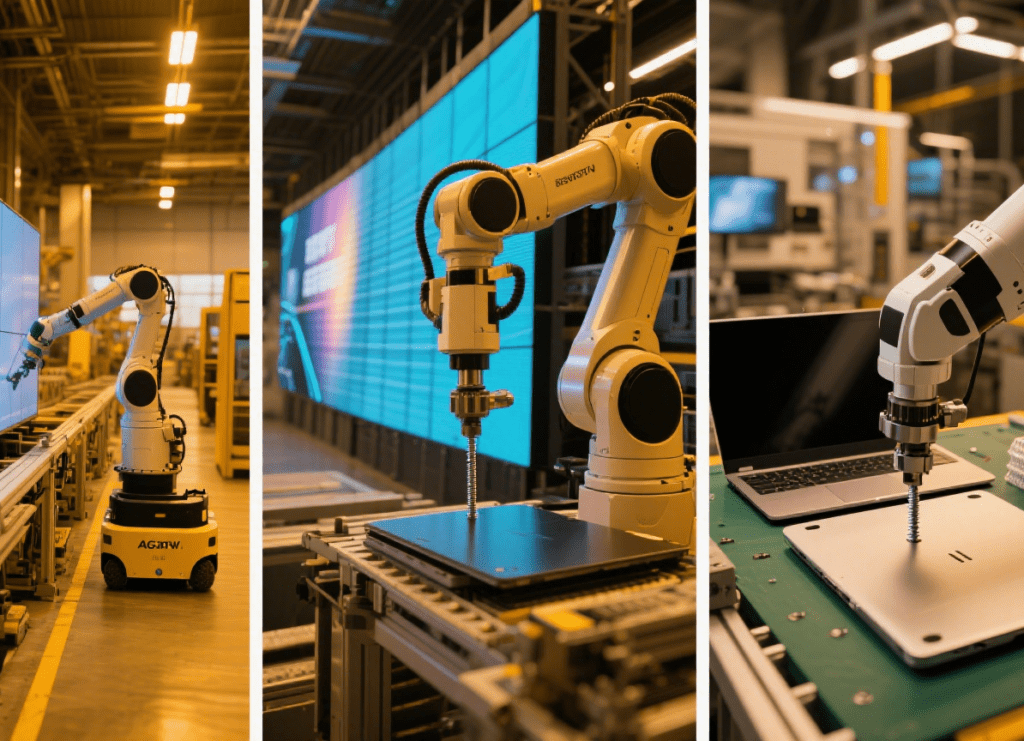

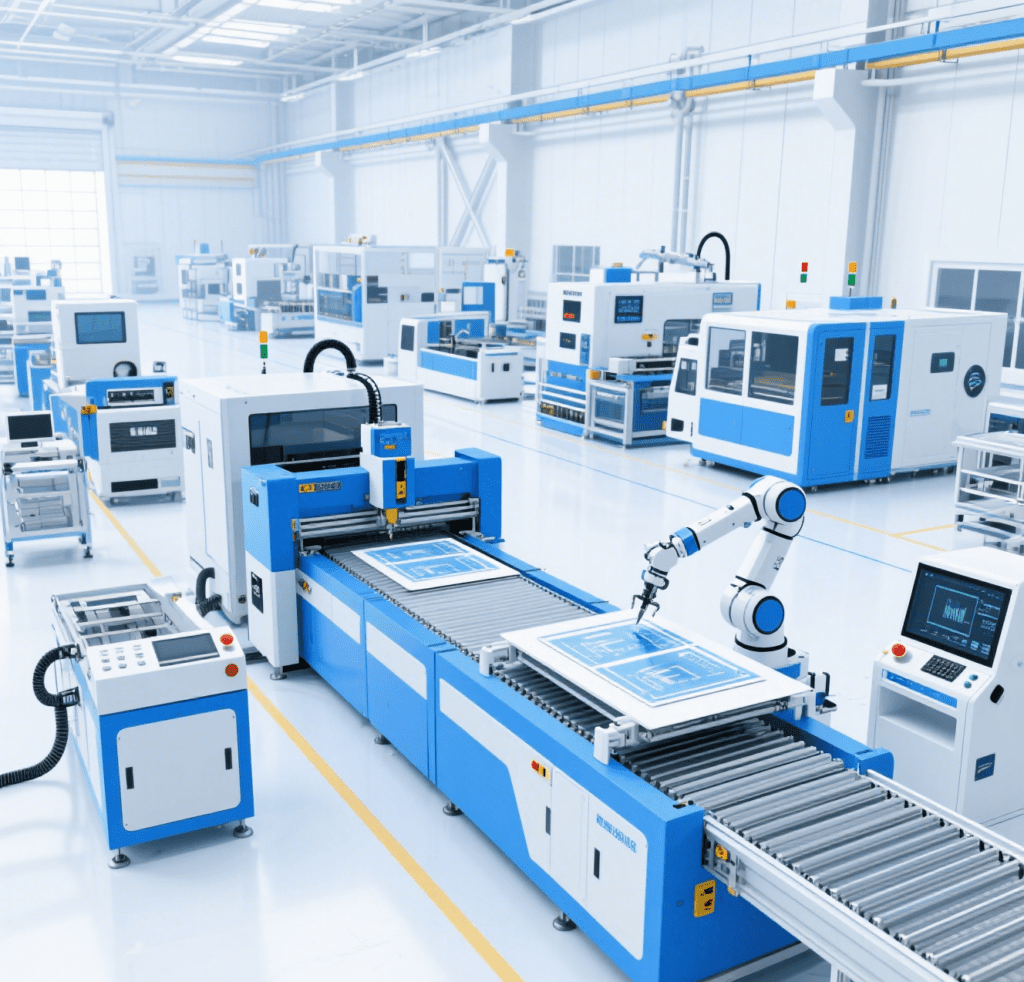

4-Axis Robotic Frame Pick-up System: Revolutionizing High-Speed Material Handling in Smart Manufacturing In the fast-paced landscape of modern manufacturing, efficiently handling large and complex frames—such as PCB panels, automotive body frames, or display modules—poses significant challenges for traditional material handling systems. Manual or semi-automated solutions suffer from slow cycle times (20–40 seconds per frame), inconsistent positioning (±1mm errors), and limited adaptability to diverse frame sizes and weights. The 4-Axis Robotic Frame Pick-up System emerges as a transformative solution, integrating high-speed SCARA robotics, intelligent vision guidance, and adaptive gripping technologies to streamline frame handling in high-volume production environments. This article explores its technical architecture, industrial applications, and role in driving next-generation manufacturing […]

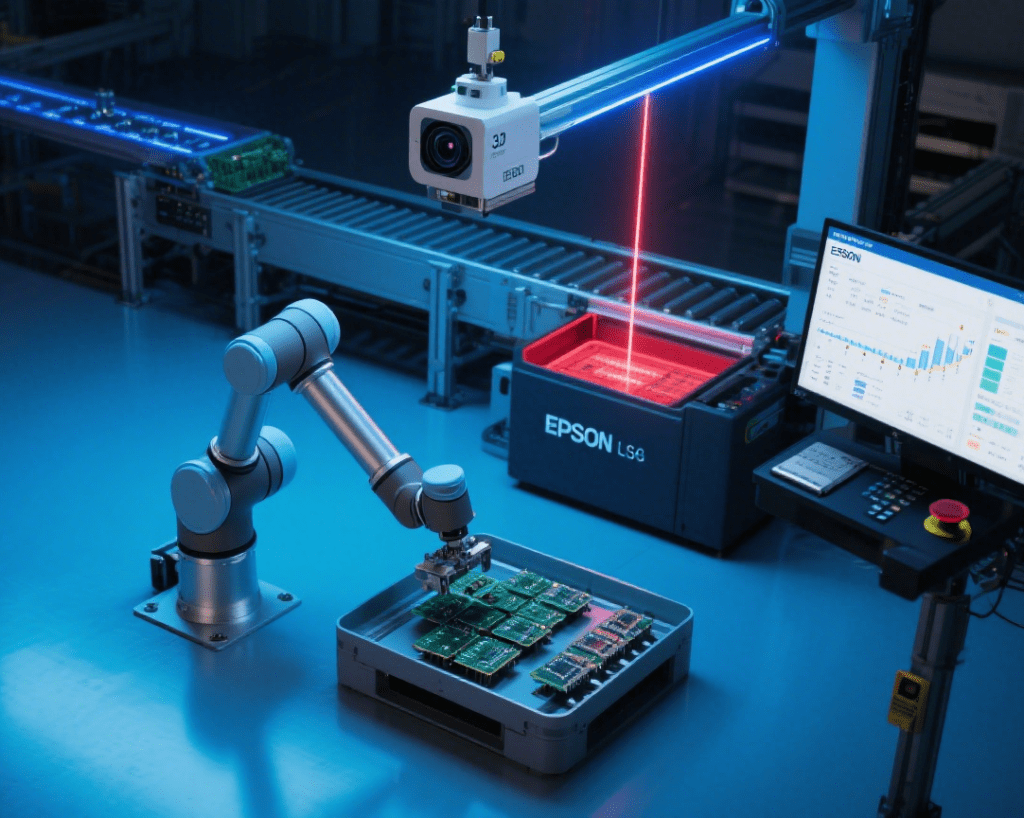

4-Axis Robotic Tray Loading System: Revolutionizing Automated Material Handling in Smart Factories

4-Axis Robotic Tray Loading System: Revolutionizing Automated Material Handling in Smart Factories In the era of Industry 4.0, efficient material handling is the backbone of agile manufacturing. Traditional tray loading systems for components—ranging from electronic parts to automotive components—face critical limitations: slow cycle times (10–20 seconds per tray), inconsistent positioning (±0.5mm errors), and limited adaptability to diverse part types. The 4-Axis Robotic Tray Loading System emerges as a transformative solution, integrating high-speed SCARA robotics, intelligent vision guidance, and adaptive control to streamline automated material loading in high-mix, high-volume production environments. This article explores its technical architecture, industrial applications, and role in driving next-generation factory automation. Core Technical Architecture: Precision Meets Velocity […]

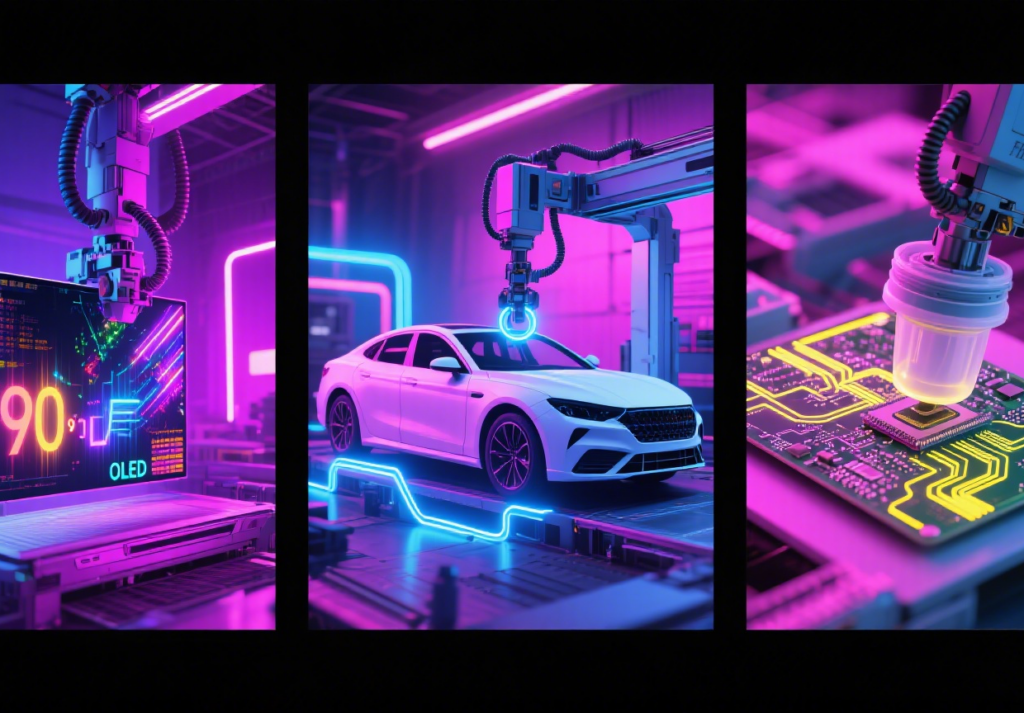

4-Axis Robotic TV Panel Screw-Fixing System: Revolutionizing Display Assembly with Speed and Precision

4-Axis Robotic TV Panel Screw-Fixing System: Revolutionizing Display Assembly with Speed and Precision In the fast-paced world of consumer electronics manufacturing, assembling large TV panels (ranging from 55″ to 100″+) with consistent precision is critical to meet market demands for sleek, defect-free displays. Traditional manual or semi-automated screw-fixing methods suffer from inherent limitations: slow cycle times (30–60 seconds per panel), positional errors (±0.5mm or worse), and high labor costs due to repetitive heavy lifting. The 4-Axis Robotic TV Panel Screw-Fixing System emerges as a game-changing solution, combining the agility of 4-axis SCARA robots with intelligent vision guidance to streamline panel assembly in high-volume production lines. This article explores its technical architecture, […]

4-Axis Robotic Vision-Guided Spring Placement System: Elevating Precision and Efficiency in Automated Assembly

4-Axis Robotic Vision-Guided Spring Placement System: Elevating Precision and Efficiency in Automated Assembly In modern manufacturing, springs serve as critical mechanical components in industries ranging from automotive to medical devices, requiring precise placement to ensure functional reliability. Traditional spring placement methods— —suffer from limitations like inconsistent accuracy (±0.5mm or worse), slow cycle times (5–10 seconds per spring), and poor adaptability to diverse spring types (e.g., compression, torsion, or micro springs). The 4-Axis Robotic Vision-Guided Spring Placement System emerges as a transformative solution, combining the speed of 4-axis robotics with the precision of machine vision to automate spring handling in high-mix, high-precision assembly lines. This article explores its technical architecture, industrial applications, […]

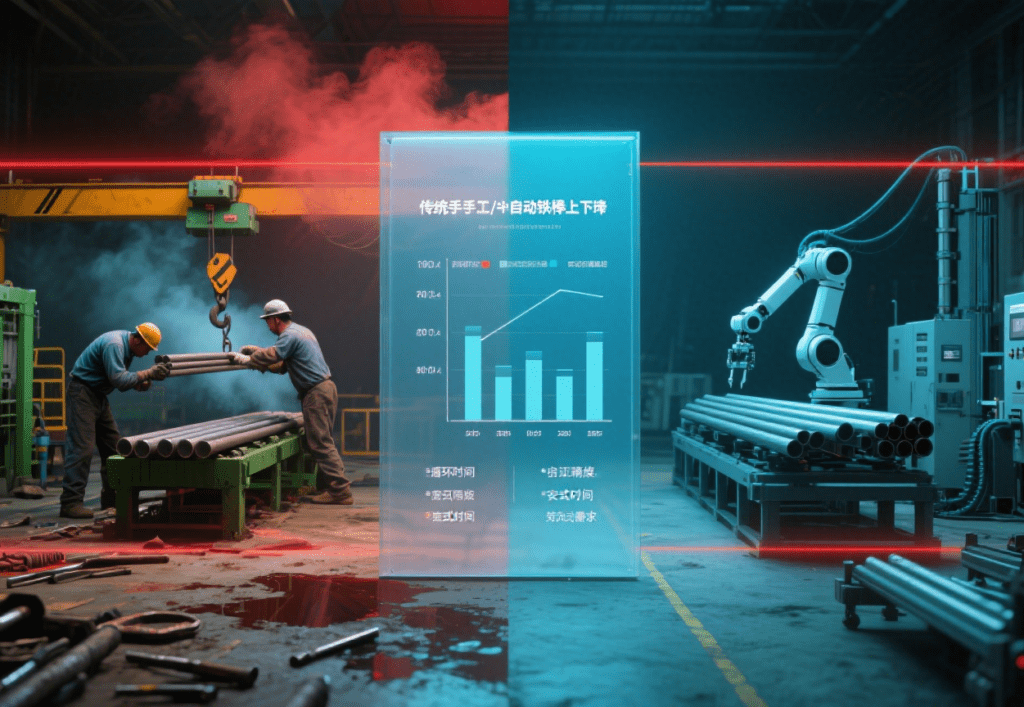

Automatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling in Industrial Manufacturing

Automatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling in Industrial Manufacturing In the realm of industrial manufacturing—especially in steel processing, forging, and mechanical machining—handling iron rods efficiently and safely is critical to maintaining production flow. Traditional manual or semi-automated systems for loading and unloading iron rods (ranging from 6mm to 200mm in diameter and up to 12 meters in length) suffer from inherent flaws: high labor intensity, slow cycle times (5–10 minutes per batch), inconsistent positioning accuracy (±5mm or worse), and significant safety risks from heavy lifting. The Automatic Iron Rod Loading/Unloading System emerges as a transformative solution, integrating robotic automation, intelligent sensing, and adaptive control to streamline material […]

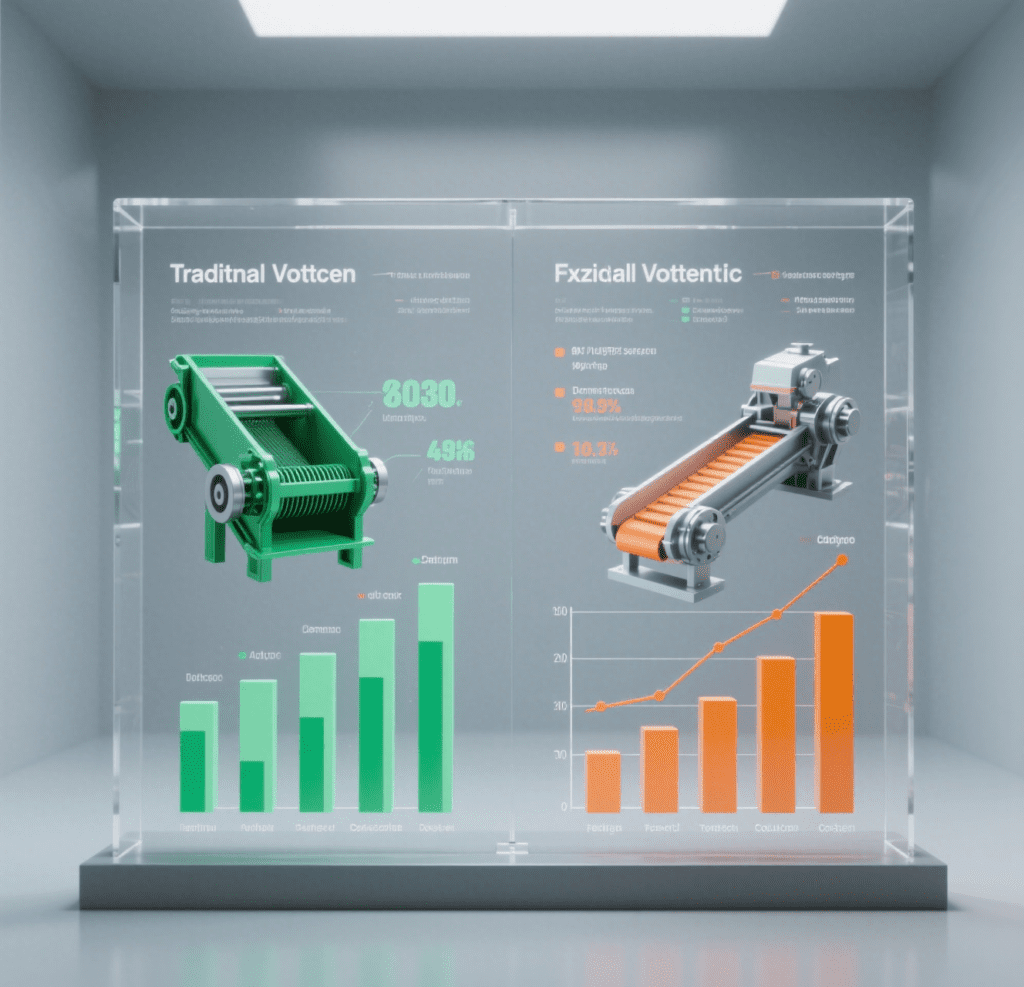

Flexible Vibratory Feeder: Revolutionizing Precision Parts Handling in Smart Manufacturing

Flexible Vibratory Feeder: Revolutionizing Precision Parts Handling in Smart Manufacturing In the era of Industry 4.0, where manufacturing demands shift toward multi-variety, small-batch production and high-precision assembly, traditional vibratory feeders—once reliable workhorses for parts orientation—face significant limitations. Their rigid design struggles with irregularly shaped, delicate, or fragile components, often causing surface damage, orientation errors, or lengthy changeover times. Enter the flexible vibratory feeder—a cutting-edge solution integrating adaptive vibration control, intelligent vision systems, and modular design to address the pain points of modern precision manufacturing. This article explores its technical architecture, industrial applications, and role in enabling agile production lines. Core Technology: Redefining Parts Orientation through Flexibility A flexible vibratory feeder […]

Robot Vision Positioning Automatic Film Applicator Machine: Reshaping the Intelligent Production Paradigm of Precision Lamination

Robot Vision Positioning Automatic Film Applicator Machine: Reshaping the Intelligent Production Paradigm of Precision Lamination In high-end manufacturing sectors such as consumer electronics, automotive manufacturing, and medical devices, film lamination is a critical process determining product appearance quality and functional stability. From optical protective films for mobile phone screens to anti-glare coatings for automotive dashboards, and from sterile isolation films for medical devices to insulating films for new energy vehicle batteries, the precision and efficiency of film lamination directly impact the yield rate and market competitiveness of end products. Traditional manual lamination relies on operational experience, suffering from issues like large precision fluctuations, low efficiency, and severe material waste, which […]

Automatic Spring Tray Arrangement Equipment: Reshaping the Automation Paradigm of Precision Manufacturing

Automatic Spring Tray Arrangement Equipment: Reshaping the Automation Paradigm of Precision Manufacturing In the field of modern industrial manufacturing, springs serve as indispensable basic components, widely applied in automotive, electronics, machinery, aerospace, and numerous other industries. From valve springs in automobile engines to tiny contact springs in electronic products, their quality and assembly efficiency directly impact the performance and reliability of end products. With the acceleration of industrial automation, traditional manual spring tray arrangement methods have struggled to meet the growing demands for high-precision, high-efficiency, and large-batch production. As a result, automatic spring tray arrangement equipment has emerged, becoming a key force driving the upgrading of precision manufacturing industries. I. […]