Automatic Hardware Part Feeding and Assembly: Revolutionizing Manufacturing Precision and Productivity

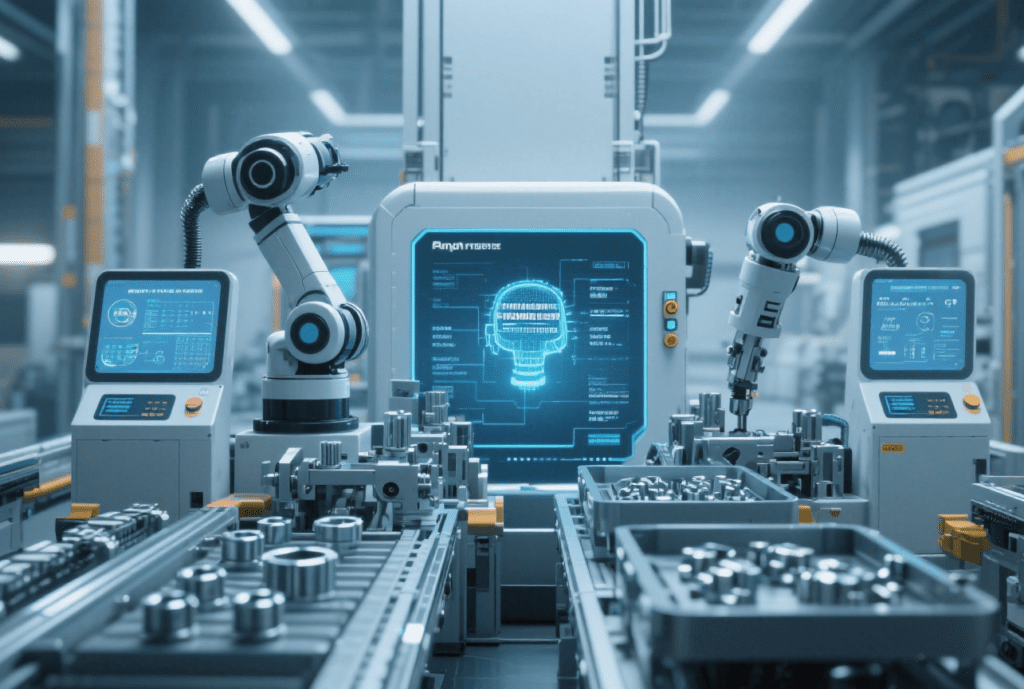

Automatic Hardware Part Feeding and Assembly: Revolutionizing Manufacturing Precision and Productivity Introduction In the industrial landscape, hardware components—ranging from screws and bolts to intricate metal fasteners and connectors—form the essential building blocks of countless products, from automotive engines to consumer appliances. Traditional manual and semi-automated methods for hardware part feeding and assembly are plagued by inefficiencies, including slow throughput (20–30 parts assembled per minute), high labor costs (accounting for 35% of production expenses), and inconsistent quality (defect rates up to 5%). Automatic hardware part feeding and assembly systems have emerged as a transformative solution, leveraging advanced robotics, intelligent control, and precision engineering to redefine manufacturing excellence. A leading automotive […]

Automated Loading Assembly Machine for Electronic Components: Revolutionizing the Future of Electronics Manufacturing

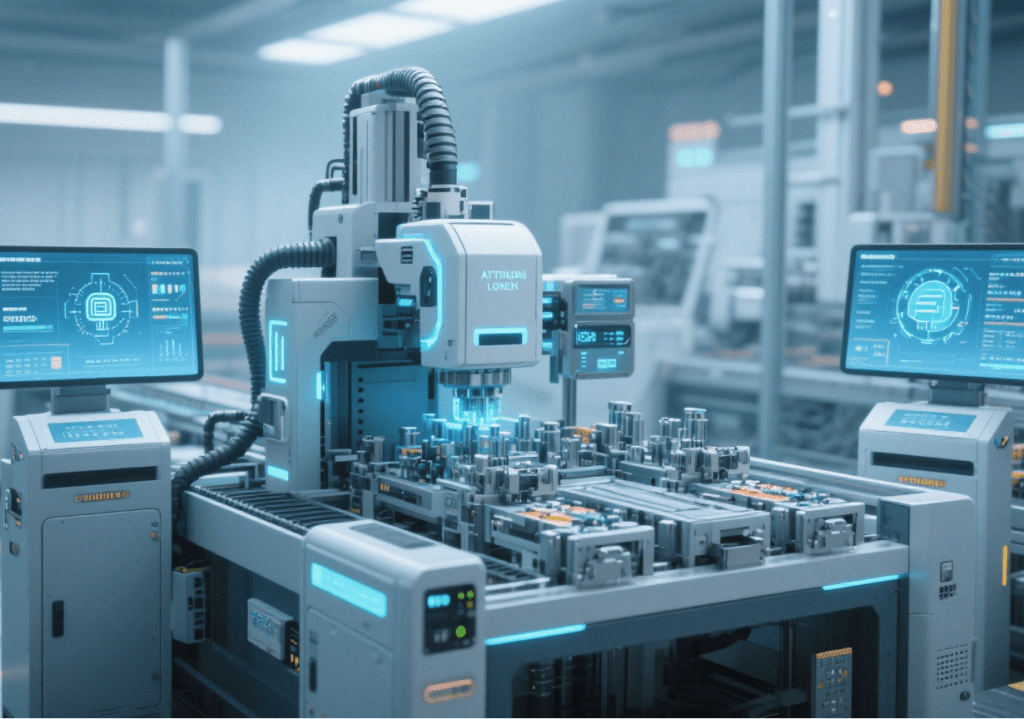

Automated Loading Assembly Machine for Electronic Components: Revolutionizing the Future of Electronics Manufacturing Introduction In the rapidly evolving electronics industry, where miniaturization, precision, and high-volume production are paramount, the assembly of electronic components has become a complex and critical process. Traditional manual and semi-automated assembly methods struggle to keep pace with the demands of modern devices, such as smartphones, laptops, and IoT gadgets. These methods suffer from limitations like low throughput (an average of 20–30 components assembled per minute), inconsistent quality (defect rates up to 2%), and high labor costs (accounting for 30–40% of production expenses). Automated Loading Assembly Machines (ALAMs) for electronic components have emerged as a game-changing solution, […]

Injection Molded Parts Automated Assembly System with Auto-Loading: Redefining Manufacturing Excellence

Injection Molded Parts Automated Assembly System with Auto-Loading: Redefining Manufacturing Excellence Introduction Injection molding is the backbone of modern manufacturing, producing billions of plastic parts annually for industries ranging from automotive and electronics to medical devices. However, the post-molding assembly process has long been a bottleneck. Traditional manual or semi-automated methods suffer from low throughput (average assembly time of 30–60 seconds per part), high labor costs (accounting for 25–40% of production expenses), and inconsistent quality (defect rates up to 3%). Injection Molded Parts Automated Assembly Systems with Auto-Loading have emerged as a transformative solution, integrating advanced robotics, intelligent control, and autonomous material handling to streamline production. A leading consumer […]

Automatic Injection-Molded Part Feeding and Assembly: Transforming Manufacturing Efficiency and Precision

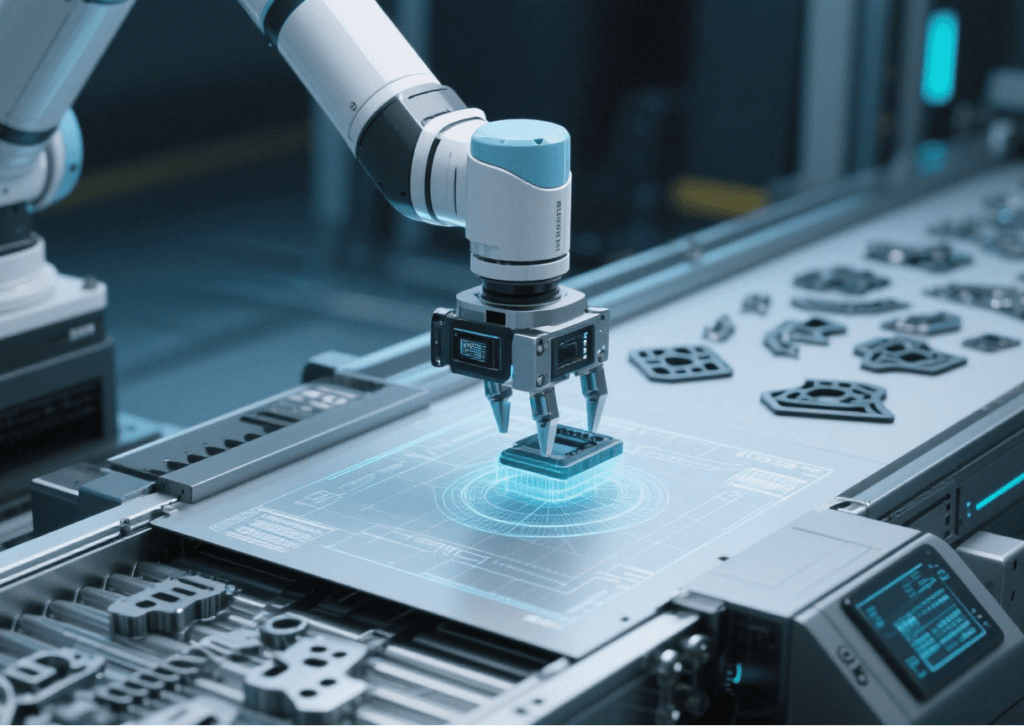

Automatic Injection-Molded Part Feeding and Assembly: Transforming Manufacturing Efficiency and Precision Introduction In the modern manufacturing landscape, the production of injection-molded parts is a cornerstone of countless industries, from automotive and consumer electronics to medical devices. The efficiency and precision of feeding and assembling these parts are critical to overall productivity, product quality, and cost – effectiveness. Traditional manual and semi – automated methods for handling injection – molded parts are often associated with limitations such as low throughput, inconsistent quality, and high labor costs. Automatic injection – molded part feeding and assembly systems have emerged as a revolutionary solution, leveraging advanced technologies to streamline the manufacturing process. Technical Components […]

カテーテル組立機:精度と自動化による低侵襲医療の革新

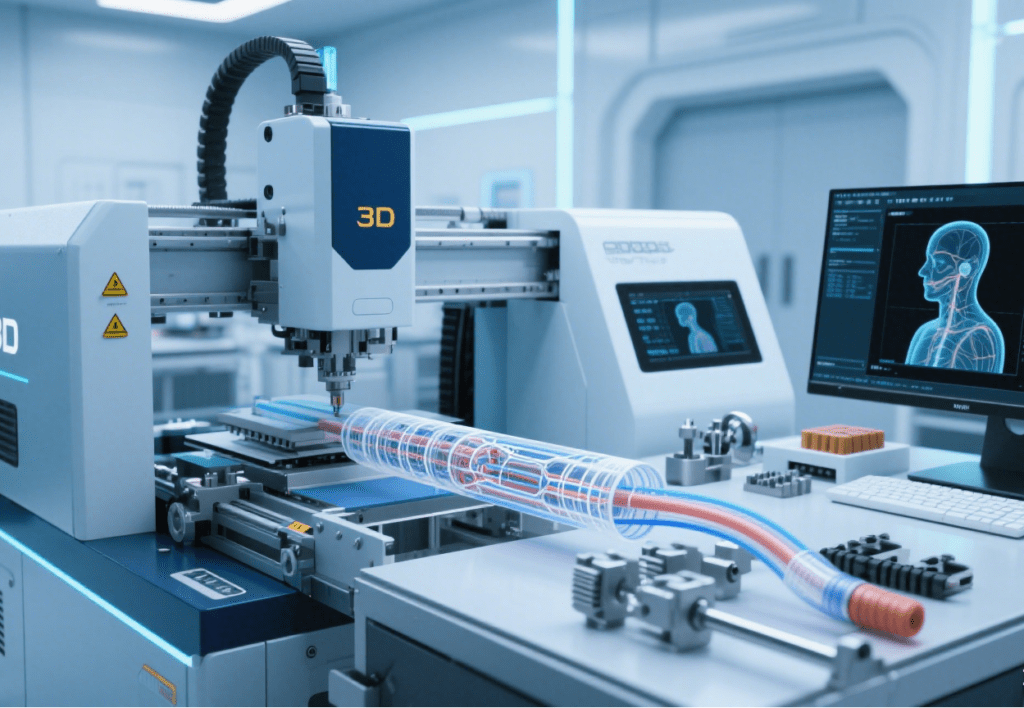

Catheter Assembly Machines: Revolutionizing Minimally Invasive Medicine through Precision and Automation Introduction In the realm of modern medical devices, catheters have emerged as indispensable tools for minimally invasive procedures, diagnostic imaging, and drug delivery. The precision and reliability of catheters directly impact patient outcomes, making their assembly a critical process. Traditional manual catheter assembly methods are fraught with challenges such as inconsistent quality, low production efficiency, and high labor costs. Catheter assembly machines have emerged as a game – changer, integrating advanced automation, precision engineering, and intelligent control systems to transform the manufacturing landscape. Technical Architecture of Catheter Assembly Machines 1. Precision Extrusion and Tubing Handling The foundation of catheter […]

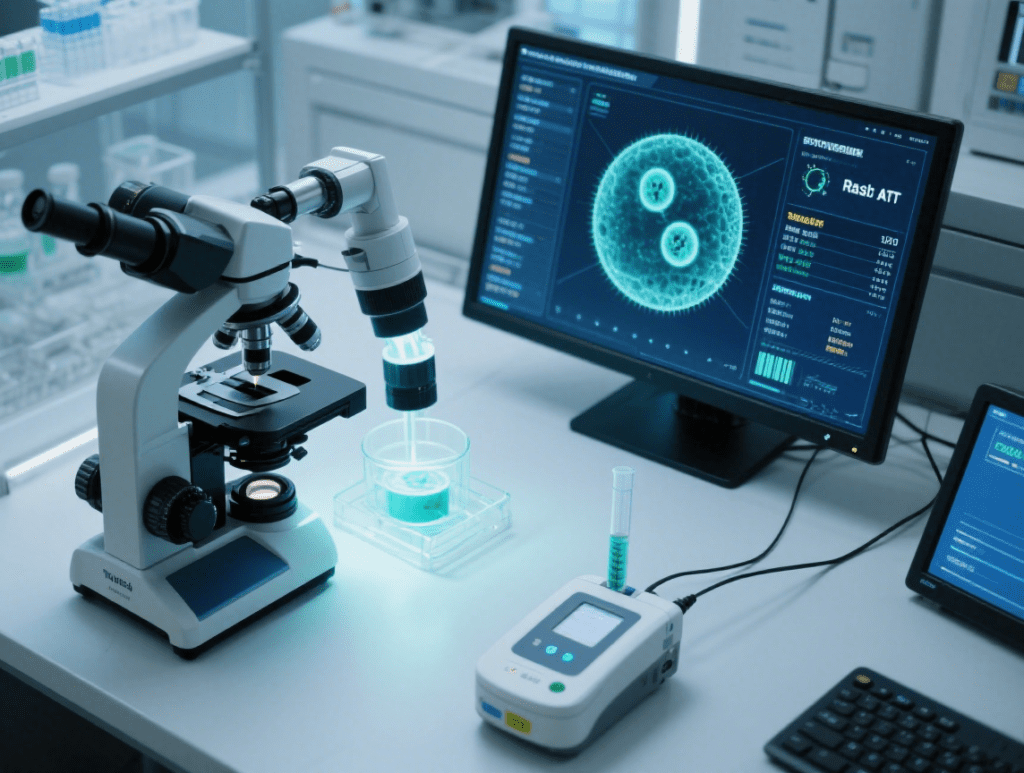

Precision and Compliance: The Evolution and Impact of Biological Indicator Assembly Machines

Precision and Compliance: The Evolution and Impact of Biological Indicator Assembly Machines I. The Critical Role of Biological Indicators in Sterilization Assurance In the highly regulated fields of pharmaceuticals, medical device manufacturing, and healthcare, biological indicators (BIs) serve as the gold standard for validating sterilization processes. These small, yet crucial devices contain live spores of highly resistant microorganisms—such as Geobacillus stearothermophilus for steam sterilization or Bacillus atrophaeus for ethylene oxide (EO) treatments—and confirm that sterilization procedures have achieved the required lethality (e.g., a 6-log reduction). Traditional manual assembly of BIs faced significant challenges: inconsistent spore loading (variance in spore counts exceeding ±10%), high contamination risks (human error leading to false positives), and limited production […]

A New Benchmark in Medical Manufacturing: Technological Breakthroughs and Industrial Innovation of Nebulizer Assembly Machines

A New Benchmark in Medical Manufacturing: Technological Breakthroughs and Industrial Innovation of Nebulizer Assembly Machines I. The Industrial Revolution of Nebulizer Assembly: From Manual Crafting to Intelligent Clean Production In the global wave of medical device intelligent transformation, nebulizers, as core instruments for respiratory disease treatment, rely on assembly precision to directly affect drug delivery efficiency and patient safety. Traditional manual assembly models suffer from critical pain points: low efficiency (50-80 seconds per piece), fluctuating precision (±0.1mm error in nozzle aperture), and cleanliness risks (manual operation contamination rate ~1.2%). Nebulizer assembly machines have achieved a leap from “handcrafted assembly” to “intelligent clean production” by integrating precision mechanical transmission, visual inspection, […]

he Intelligent Hub of Electrical Automation Manufacturing: Technological Evolution and Industrial Innovation of Contactor Assembly Machines - RUI ZHI

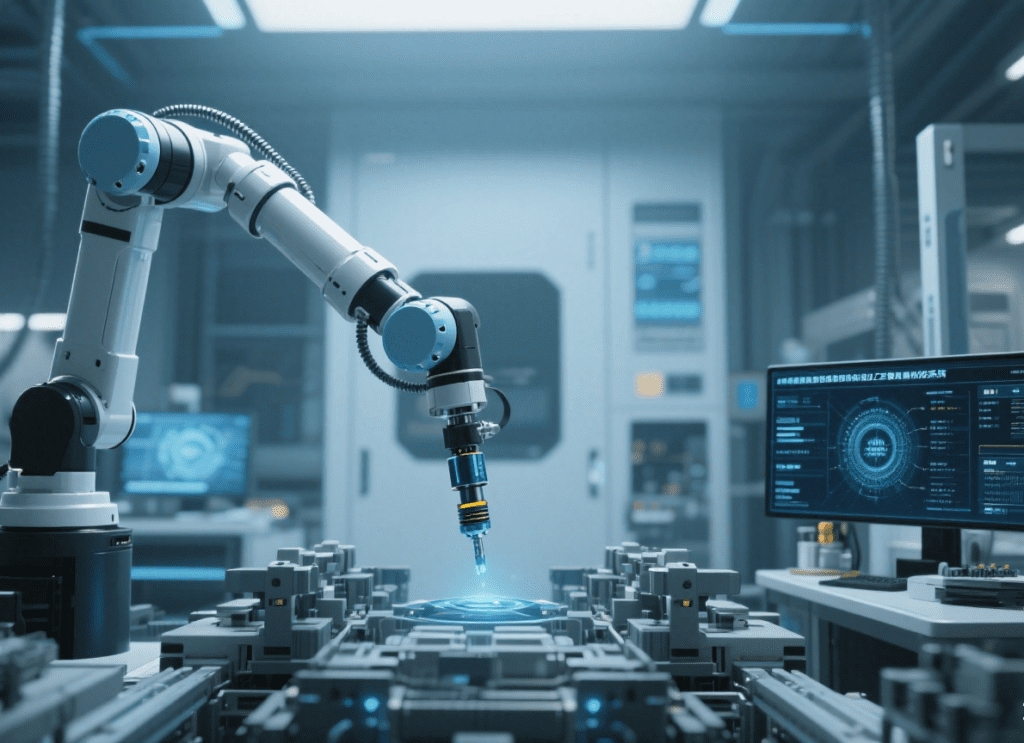

The Intelligent Hub of Electrical Automation Manufacturing: Technological Evolution and Industrial Innovation of Contactor Assembly Machines I. The Industrial Revolution of Contactor Assembly: From Manual Era to Intelligent Age In the field of industrial control and power electronics, contactors, as core components for circuit on-off control, have their assembly precision directly determining the reliability and safety of equipment. Traditional manual assembly models suffer from three core pain points: low efficiency (45-70 seconds per piece), fluctuating precision (±0.3mm alignment error of contacts), and high labor costs (accounting for 25%-35% of production costs). Contactor assembly machines have achieved a revolutionary leap from “manual assembly” to “full-process automation” by integrating multi-axis robotic arms, […]

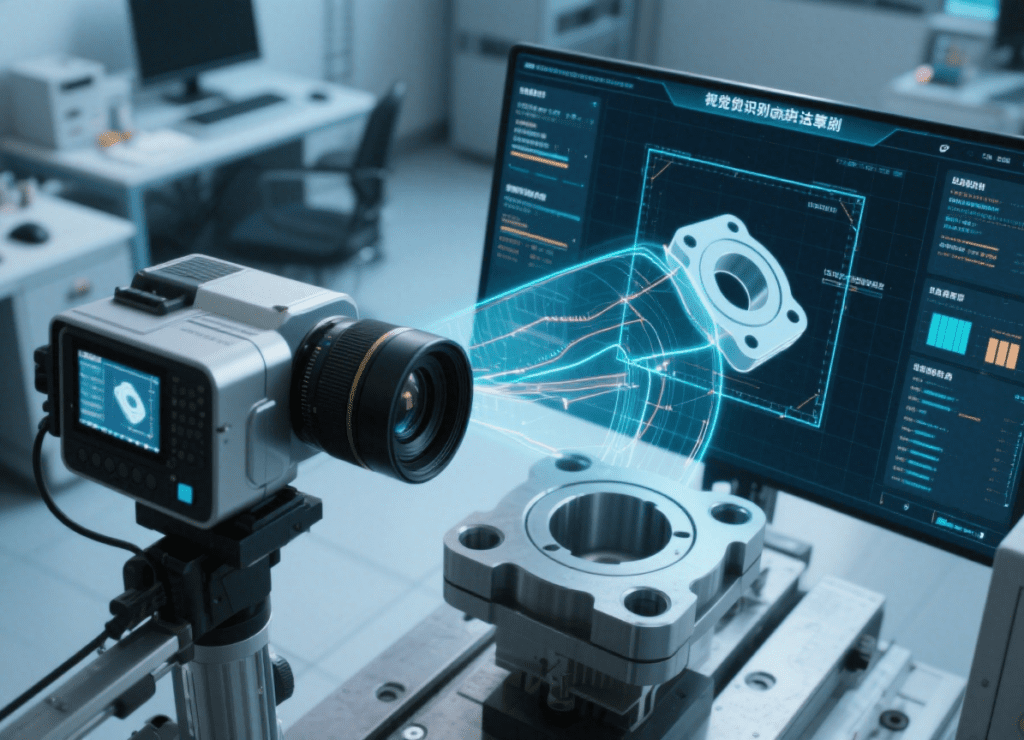

The New Engine of Smart Manufacturing: Technological Innovation and Industry Practices of CNC Lathe Automatic Loading/Unloading Systems

The New Engine of Smart Manufacturing: Technological Innovation and Industry Practices of CNC Lathe Automatic Loading/Unloading Systems I. Core Breakthroughs in Industrial Automation: The Paradigm Shift from Manual to Intelligent Operations In the wave of intelligent transformation in manufacturing, CNC lathes, as core equipment for precision machining, rely on the automation level of their loading/unloading processes to directly determine production line efficiency and cost control capabilities. Traditional manual loading/unloading models suffer from critical pain points: low efficiency (30-60 seconds per piece), fluctuating precision (±0.2mm-level errors), and high labor costs (accounting for 30%-40% of total processing costs). By integrating robotic arms, visual recognition, and intelligent control technologies, CNC lathe automatic loading/unloading […]

Automatic Hardware Part Feeding and Assembly: Unleashing Efficiency in Modern Manufacturing

Automatic Hardware Part Feeding and Assembly: Unleashing Efficiency in Modern Manufacturing Introduction In the realm of industrial production, hardware parts—ranging from tiny screws and nuts to complex metal brackets and connectors—are the fundamental building blocks across diverse sectors, including automotive, electronics, furniture, and aerospace. Traditional manual and semi-automated methods for hardware part feeding and assembly are fraught with limitations: slow cycle times (averaging 40–60 seconds per assembly), high labor costs (up to 40% of total production expenses), and inconsistent quality due to human error. Automatic hardware part feeding and assembly systems have emerged as a transformative solution, integrating advanced robotics, intelligent control, and precision engineering to revolutionize manufacturing processes. A […]