- Cooking Robots: A Delicious Innovation from Concept to Reality

In the era of rapid technological development, cooking robots are gradually moving from concept to reality, becoming a new favorite in the catering industry and home kitchens. So, how exactly do cooking robots stir-fry ingredients to serve people delicious dishes?

- Focus on Industry Trends: Continuous Expansion of Application Scenarios for Cooking Robots

Recently, there have been constant news about cooking robots, and their applications in various scenarios have become increasingly widespread, attracting much attention. In the era of rapid technological development, cooking robots are gradually moving from concept to reality, becoming a new favorite in the catering industry and home kitchens. So, how exactly do cooking robots stir-fry ingredients to serve people delicious dishes?

- Take “Xiongmao Dashi” as an Example: The Rigorous Logic of Standardized Operating Procedures

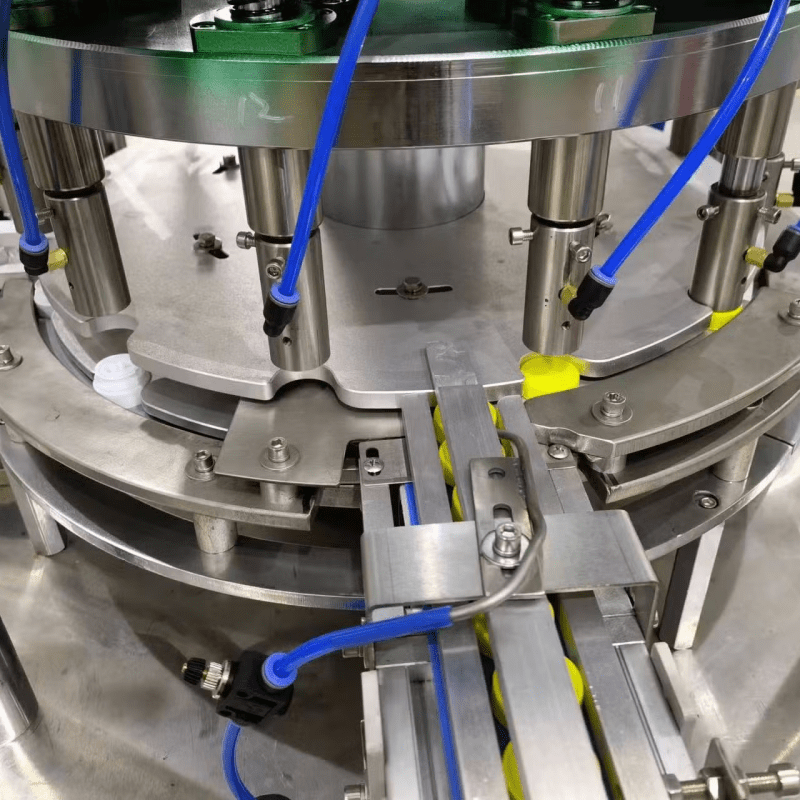

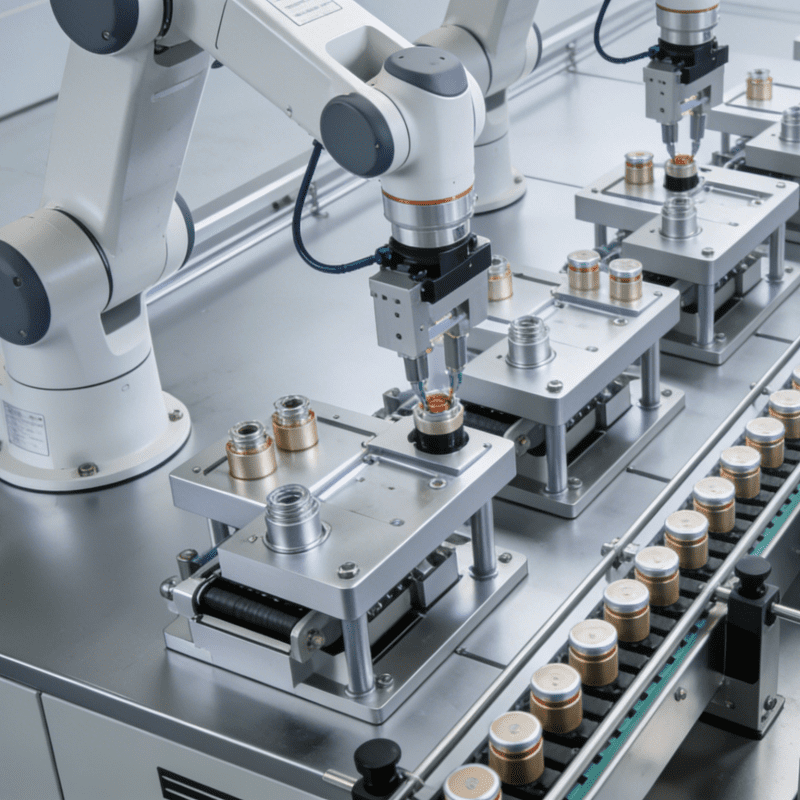

Take the Xiongmao Dashi intelligent cooking machine, which has made its mark in many restaurants, for example. Its operating procedures have strict steps. When the kitchen operator receives an order, they first skillfully prepare ingredients according to the recipe, placing the chopped ingredients and corresponding seasonings into the special ingredient boxes equipped with the cooking machine. Then, the operator only needs to tap the screen of the cooking machine and accurately select the program for the corresponding dish, and the machine immediately “takes over” the subsequent cooking process. Behind this, from the triggering of screen instructions to the execution of mechanical actions, it is just like a button-controlled assembly machine scheduling robotic arms to complete component docking through precise button commands. Every step relies on the seamless collaboration between preset programs and hardware execution.

- Start of Stir-Frying: The Initial Stage of Precise Temperature Control and Standardized Feeding

At the beginning of the stir-frying process, the heating device of the cooking machine starts quickly, preheating the pot rapidly according to the preset program to create a suitable initial temperature environment for the ingredients to be stir-fried. When the predetermined temperature is reached, the cooking oil in a specific container flows into the pot through an automated pipeline or mechanical device under precise control. In this process, the amount of oil is completely according to the standardized requirements of the dish, eliminating the possible oil quantity deviation in manual operation.

- Ingredients into the Pot: An Orderly Feeding Design Following Cooking Logic

Immediately after, the ingredient boxes open in sequence, and the ingredients slide into the pot in a predetermined order. The feeding order of ingredients required for different dishes is determined by the R&D team after in-depth research on traditional cooking techniques and combining a large amount of experimental data. This ensures that each dish can achieve ingredient integration at the optimal time, fully stimulating the flavor of the ingredients. Take Yu-Shiang Shredded Pork as an example: the shredded pork is first stir-fried in the pot until it changes color to lock in the meat’s aroma and moisture, then shredded green bamboo shoots, shredded fungus and other ingredients are added in sequence to allow all ingredients to fully mix in the pot.

- Core Stir-Frying: Heat Control through Collaboration of Intelligent Algorithms and Sensors

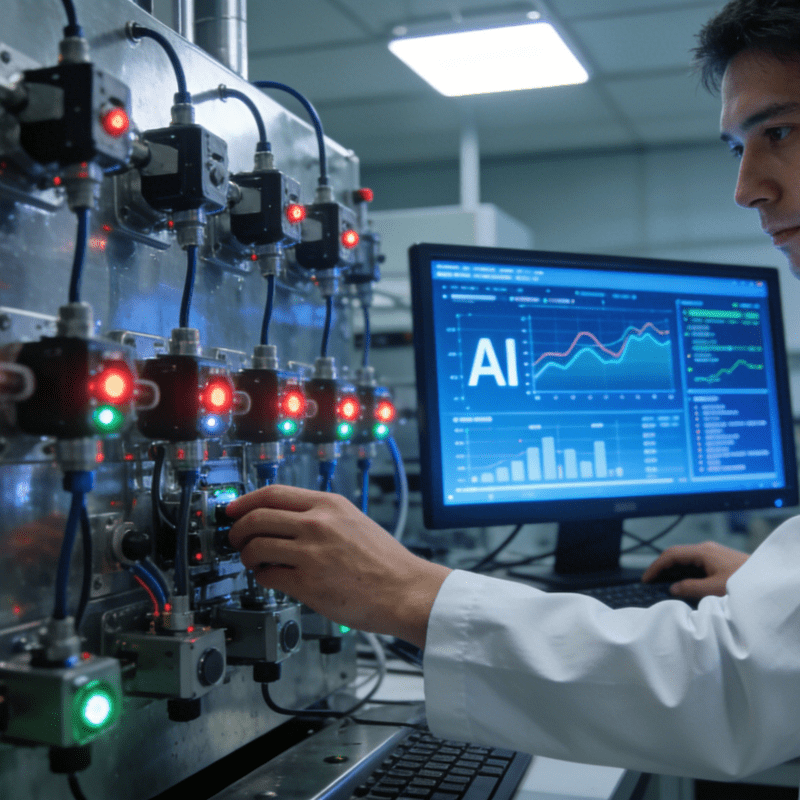

After the ingredients are put into the pot, the key stir-frying begins. The robotic arm of the cooking robot is exquisitely designed, simulating manual stir-frying techniques through unique algorithms to achieve diverse stir-frying actions. It can flexibly adjust the strength, speed and angle of stir-frying according to the characteristics of different ingredients and dish requirements. For example, when stir-frying leafy vegetables, the robotic arm stir-fries gently and quickly to avoid damaging the leaves; when stir-frying harder ingredients such as meat, it increases the strength to ensure that the ingredients are evenly heated, fully cooked and flavorful. During the stir-frying process, the sensors built into the cooking machine monitor key data such as the temperature in the pot and the state of the ingredients in real time, and feed this data back to the control system. The control system dynamically adjusts the stir-frying actions and heating power accordingly, precisely controlling the heat to cook the ingredients within the optimal temperature range, maximizing the retention of the ingredients’ nutrients and texture, while ensuring that each dish has a rich “wok hei” (the unique flavor and aroma from high-temperature stir-frying).

- Seasoning Stage: Precise Measurement Achieves Stable and Uniform Taste

When the ingredients are stir-fried to a certain stage and need to be seasoned, the cooking robot can also operate precisely. Various seasonings, such as salt, sugar, light soy sauce, dark soy sauce, etc., are pre-loaded into special seasoning boxes, each equipped with a precise metering device. According to the program settings, the cooking machine adds the accurate amount of seasonings into the pot at the appropriate time, realizing the standardization and precision of seasoning. Whether it is a home-cooked stir-fry or a complex classic famous dish, it can ensure the consistency and stability of the taste.

- Software Empowerment: Cloud Data Drives Continuous Evolution of “Cooking Skills”

Throughout the stir-frying process, it is not only the hardware that plays a role; the software system is also crucial. Many cooking robots are connected to the cloud in real time, and they can record and analyze massive amounts of data such as each meal’s serving situation, cooking time, and ingredient usage. This data is fed back to the cloud, and R&D personnel use professional algorithms to conduct in-depth mining and analysis, thereby continuously optimizing dish programs and adjusting stir-frying parameters, so that the “cooking skills” of cooking robots continue to improve, and the taste and quality of dishes are continuously enhanced.

- Case Witness: Yaogun Intelligent Cooking Machine’s Debut on the International Stage

At the New York City Mayor’s reception held in May this year, the Yaogun YG-B01 intelligent cooking machine from Wuhan Smart Chef Internet of Things Technology Co., Ltd. shined, cooking 5 Chinese dishes for nearly a thousand guests and winning praise from everyone. Its operating principle is similar to the above process. The R&D team, after 8 years of effort and in collaboration with more than a dozen Chinese chefs at home and abroad, carried out “digital deconstruction” on a large number of dishes, converting key elements and operating skills such as the ratio of ingredients, seasonings, heat, stir-frying strength and speed of each dish into algorithm parameters, which are stored in the cloud. This enables the cooking machine to replicate more than 2,300 dishes, accurately presenting the fresh aroma of braised prawns and the spiciness of Gele Mountain spicy chicken.

- Technical Strength: Efficient Cooking Demonstration at the World Robot Expo

There is also a cooking robot that attracted much attention at the World Robot Expo, which can cook a plate of candied sweet potatoes, sweet and sour pork ribs and other dishes in 3-5 minutes. It also relies on advanced technology to achieve precise control over the ingredient stir-frying process. From the pre-processing of ingredients to the final serving and plating, every step is carried out in an orderly manner under the scheduling of the intelligent system.

- Scenario Implementation: Multi-Field Applications Bring Changes to Dietary Life

Today, cooking robots have been widely used in catering stores, community canteens, and even begun to enter home kitchens. In catering stores, they effectively reduce labor costs, improve meal serving efficiency, and solve the problems of insufficient chefs and unstable dish tastes. In community canteens, cooking robots can provide residents with meals with stable taste and affordable prices, and can set cooking modes with less oil, salt and sugar according to the dietary needs of the elderly. For family users, cooking robots allow people who can’t cook to easily make delicious dishes, saving time for busy office workers.

- Future Outlook: Technological Iteration Promotes Functional Upgrades of Cooking Robots

With the continuous progress and innovation of science and technology, cooking robots will also continue to iterate and upgrade in ingredient stir-frying technology. In the future, we are expected to see cooking robots with more diversified functions, more intelligent operations and richer dishes, bringing more convenience and surprises to people’s dietary life.

Assembly line for mass production by artificial intelligence