Against the backdrop of the manufacturing industry’s transformation towards high precision, high efficiency and high flexibility, precision machining has become a key indicator for measuring the core competitiveness of enterprises. As the core equipment in this field, machining centers, by virtue of their integrated machining capabilities, superior precision control and stable production performance, are gradually replacing traditional machining equipment and emerging as the cornerstone of intelligent manufacturing that underpins the development of high-end sectors such as aerospace, automotive manufacturing and medical devices.

Machining Centers: The Core Carrier of Precision Machining

The core demands of precision machining are controllable precision, stable efficiency and manufacturability of complex components. By integrating multi-process machining functions and intelligent control systems, machining centers perfectly meet such demands and become an irreplaceable core equipment in this field.

Integrated machining with reduced precision loss: Traditional precision machining requires multiple pieces of equipment for different processes, and repeated clamping of workpieces is prone to positioning errors. A machining center can complete multiple processes such as milling, drilling, boring and tapping in one operation, reducing the number of clamping times by more than 80%. It effectively controls machining errors within the range of 0.01-0.05mm, meeting the machining requirements of high-precision components.

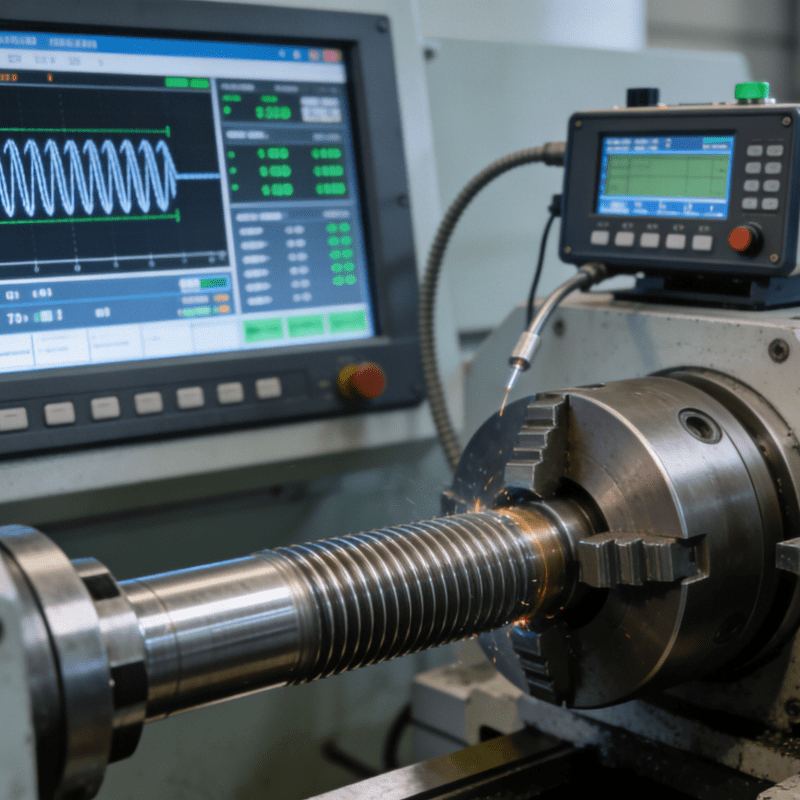

Intelligent control to ensure machining stability: The systems equipped on the equipment (e.g., FANUC, SIEMENS) can monitor cutting parameters and tool wear status in real time, and correct machining deviations through automatic compensation functions. Combined with high-precision servo motors and ball screws, it achieves precise control of feed speed and position, ensuring the precision consistency of each product in batch production.

Flexible production adaptable to complex demands: Faced with the order characteristics of multi-variety and small-batch production in precision machining, machining centers can complete the switching of machining scenarios within 10-30 minutes by quickly changing tool magazines (usually with a capacity of 24-60 tools) and editing program parameters, without large-scale equipment adjustment, thus greatly improving production flexibility.

Technological Breakthroughs in Precision Machining: Centered on Machining Centers

Relying on the technological advantages of machining centers, precision machining has achieved breakthroughs in three core dimensions: precision, efficiency and complex component machining, providing critical technical support for the high-end manufacturing sector.

Precision breakthrough: From Micron Level to Submicron Level With the high-speed spindles of machining centers (maximum speed up to 20,000r/min), constant temperature workshop environmental control and online inspection systems, the dimensional accuracy of components can reach ±0.02mm with a surface roughness of Ra≤0.4μm. This meets the ultra-precision machining requirements for core components such as engine blades and precision bearings in the aerospace field.

Efficiency improvement: Doubled productivity per unit time Compared with traditional milling machines, the automatic tool change time of machining centers is shortened to 0.5-2 seconds, and they support 24-hour continuous unmanned machining. Taking the machining of automobile gearbox housings as an example, the output of traditional equipment per shift is about 50 pieces, while machining centers can increase the output to more than 120 pieces, representing a 140% increase in productivity per unit time.

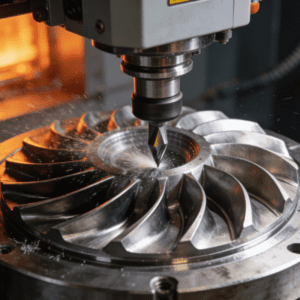

Complex component machining: Breaking the shape limitations Multi-axis machining centers (e.g., 5-axis machining centers) enable multi-angle and multi-directional machining of workpieces, easily meeting the machining demands of components with complex curved surfaces and special-shaped structures. For instance, in the medical device field, the machining of curved contours of artificial joints needs to meet both precision and biocompatibility requirements simultaneously. A 5-axis machining center can complete the forming in one operation, raising the machining qualification rate from 75% of traditional processes to 99%.

Application Fields of Machining Centers and Precision Machining: Covering the Core Demands of Multiple Industries

With their outstanding machining capabilities, machining centers and precision machining have deeply penetrated into various high-end manufacturing fields, becoming a key driving force for the technological upgrading of industries.

Aerospace field: The core components such as aircraft engine turbine blades and fuselage structural parts to be machined need to withstand high-temperature and high-pressure environments, imposing extremely high requirements on the dimensional accuracy and material strength of components. By virtue of high-strength spindles and cemented carbide cutting tools, machining centers can achieve precision cutting of difficult-to-machine materials such as titanium alloys and superalloys, ensuring the stable performance of components.

Automotive manufacturing field: For precision components such as motor housings and battery trays of new energy vehicles, machining centers can realize batch and high-efficiency machining. Meanwhile, unqualified products are eliminated in real time through online inspection systems, ensuring the assembly accuracy and safety of automotive components.

Medical device field: Products such as artificial joints and surgical instruments must comply with medical-grade precision standards with burr-free and scratch-free surfaces. Through the integrated process of low-speed high-precision cutting and polishing, machining centers can achieve both surface smoothness and precision of components, meeting the stringent requirements of medical applications. For thermometers, a typical medical device, after precision machining of core components by machining centers, the Thermometer visual labeling machine can perform high-precision visual positioning and labeling, ensuring the clarity and accuracy of product information such as measurement scales and safety warnings, which is an important guarantee for the compliance and reliability of thermometer products.

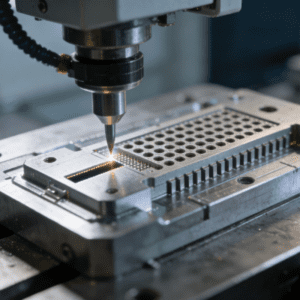

Electronic component field: The machining precision of precision components such as 5G base station filters and semiconductor packaging molds directly affects product performance. By virtue of micro-milling technology, machining centers can achieve precise machining of micro-holes (0.1-0.5mm in diameter) and narrow slots (0.05-0.1mm in width), supporting the miniaturization and high-precision development demands of the electronic industry.

Choosing Professional Machining Center Services to Empower Enterprises’ Precision Manufacturing Upgrade

For enterprises, selecting suitable machining centers and professional precision machining services is the key to enhancing product competitiveness, reducing costs and improving efficiency. Three core factors should be prioritized when selecting cooperation partners:

Equipment configuration and technical strength: Priority should be given to service providers equipped with mainstream control systems and high-precision testing equipment (e.g., coordinate measuring machines) to ensure machining precision and stability. Attention should also be paid to whether the service provider’s technical team has the capabilities of complex component programming and process optimization.

Quality management system: A sound quality management system is the guarantee of precision machining. It is necessary to confirm whether the service provider has obtained quality management system certifications such as ISO9001 and IATF16949, and whether a full-process control mechanism from raw material inspection, machining process monitoring to finished product testing has been established.

Customized service capability: Machining demands vary across different industries. Service providers need to have the ability to optimize machining processes and adjust equipment parameters according to the characteristics of enterprises’ products, such as providing customized fixture design for special-shaped components and formulating flexible production plans for batch orders.

In the tide of the rapid development of the high-end manufacturing industry, machining centers are no longer merely machining equipment, but the core engine that drives technological innovation in precision machining and helps enterprises achieve the upgrade of intelligent manufacturing. In the future, with the in-depth integration of 5G, artificial intelligence technology and machining, machining centers will evolve towards the direction of higher precision, greater intelligence and greener production, continuously injecting new momentum into the high-quality development of the manufacturing industry.