In the field of medical device manufacturing, the processing quality of precision parts directly determines the diagnostic accuracy and treatment safety of the equipment. For instance, the dimensional errors of miniature clamping components in surgical instruments or fluid channel accessories of laboratory analyzers must be controlled at the micrometer level to ensure the stable operation of the equipment. These parts are the core components of medical devices, and market demand for them continues to grow with the expansion of the global healthcare industry. However, traditional milling methods often face bottlenecks such as low efficiency, unstable precision, and fragmented processes when processing complex contours or high-precision requirements. How can we break through these common challenges and meet the stringent processing standards for medical device parts? The milling process is the key technology to resolve this predicament.

Basic Principles and Core Components of Milling Process

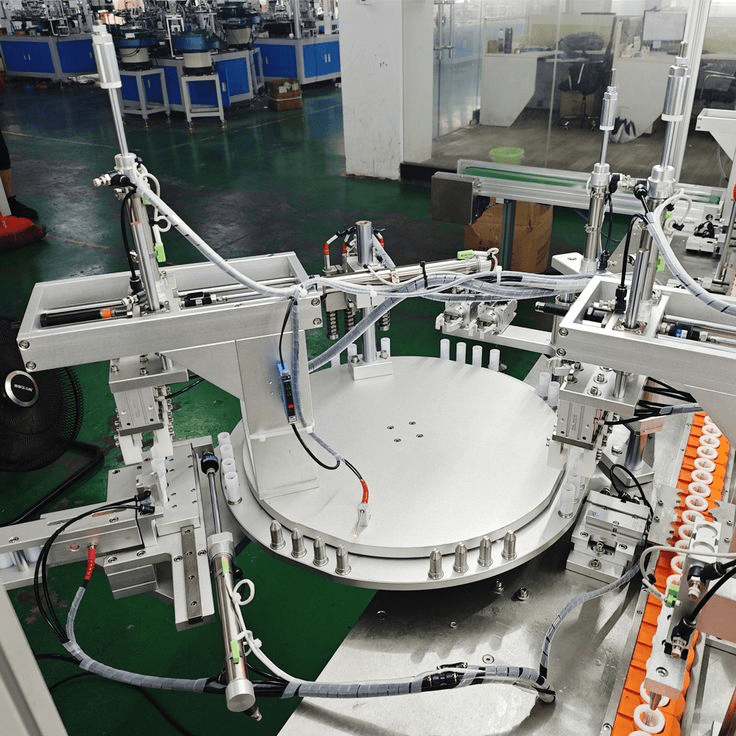

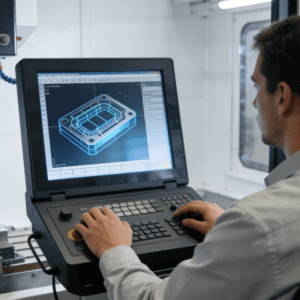

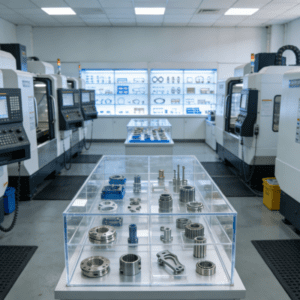

Milling process refers to the precise cutting of parts by controlling the movement of the spindle and worktable of the milling machine through a numerical control system (CNC). Its core components include the device, spindle system, feed system, worktable, and auxiliary parts. The device controls the rotational speed and direction of the spindle, as well as the feed movement of the worktable along the X, Y, and Z axes through pre-programmed instructions, thereby completing the milling process of the part. A machining center is an upgraded version of a milling machine, equipped with a tool magazine and an automatic tool changer (ATC) to enable automatic tool changes and reduce manual intervention. Some machining centers are also equipped with an automatic indexing rotary table, allowing multiple planes to be processed after a single workpiece clamping, reflecting the advantage of centralized processes.

Comparison Between Milling Process and Traditional Processing Methods

Traditional milling machines rely on manual operation, where precision is highly dependent on the operator’s skill level. Tool changes are also manually completed, resulting in low efficiency. For parts with complex contours, traditional processing requires multiple clamping, which is prone to error accumulation and fails to meet the high-precision requirements of medical device parts. In contrast, the milling process is controlled by programs, achieving a processing precision of ±0.005mm with stable and consistent results that are not affected by human factors. The automatic tool change function of machining centers enables continuous multi-process operations, reducing the number of clamps, minimizing errors, and shortening the production cycle. For example, a medical component requiring multiple processes may take 3 hours with traditional processing, but only 1 hour with a machining center.

Applications of Milling Process in Key Fields

Milling process is widely used in medical device parts, life science components, and high-end manufacturing. In medical device parts processing, it is commonly used to manufacture complex contour parts of surgical instruments (e.g., the clamping teeth of hemostats), sample processing modules of laboratory equipment (e.g., high-precision hole machining), and medical molds (e.g., syringe molds). In the field of life science, milling process can fabricate microfluidic chip molds, whose micron-level channel structures demand high-precision milling technology. Additionally, milling process is applied in aerospace, automotive manufacturing, and other fields, with its applications in the medical industry being particularly prominent due to the strict quality requirements.

Core Advantages and Processing Effects of Milling Process

The core advantages of the milling process include high precision, high efficiency, and high adaptability. High precision is reflected in its ability to stably control part dimensional errors, meeting the stringent standards of the medical industry. High efficiency stems from centralized processes and automatic tool changes, reducing production time. High adaptability enables the processing of parts with complex contours, such as three-dimensional surfaces or irregular shapes. In terms of processing effects, the milling process reduces waste rates, improves part consistency, and lowers labor costs. For instance, after adopting the milling process, a medical device manufacturer reduced the waste rate of its parts from 5% to 1% and improved production efficiency by 40%.

Technical Strengths and Customer Cases of Professional Milling Services

To meet the processing needs of medical device parts, professional milling service providers must be equipped with highly automated equipment. Their machining centers are equipped with advanced feed servo systems to achieve multi-axis linkage, minimizing manual intervention. Core components such as the spindle and guide rails are made of wear-resistant materials to ensure long-term stable operation and reduce maintenance costs. The R&D team continuously optimizes processing technologies, developing specialized cutting parameters for special materials in the medical industry (e.g., titanium alloy, stainless steel) to improve processing efficiency and part quality. For example, after using professional milling services, a medical device manufacturer saw a 20% improvement in the processing precision of surgical instrument parts and a 30% reduction in production cycles, effectively meeting the market demand for high-quality parts.

Market Prospects and Industry Trends of Milling Process

According to industry reports, the global medical device market is expected to reach $500 billion by 2025, driving the demand for high-precision parts processing. As a key processing technology, the market demand for milling process is projected to grow at an annual rate of over 10%. Meanwhile, with the advancement of intelligent manufacturing, milling equipment will evolve toward higher precision and intelligence, such as integrating AI technology to optimize processing parameters and further enhance processing efficiency and quality. In the future, milling process will play a more important role in the medical industry and become the core technology for high-end parts processing.

Key Considerations for Choosing Professional Milling Services

When selecting a professional milling service provider, key factors to consider include the automation level of their equipment, the durability of core components, R&D capabilities, and customer cases. High-automation equipment ensures processing stability; durable core components reduce maintenance costs; a strong R&D team can optimize processes for special requirements; and customer cases reflect the reliability of their services. For example, a professional service provider’s machining centers are equipped with imported spindles with a service life of over 10 years. Their R&D team has more than 10 years of experience in medical industry processing and has served many well-known medical device manufacturers.

In summary, the milling process has become the core technology for processing medical device parts due to its high precision and efficiency. Choosing a service provider with professional strength is crucial to ensuring part quality and improving production efficiency. As industry technology advances, milling process will play an increasingly important role in more high-end manufacturing fields in the future.