September 9 news: According to CATL’s official announcement, CATL’s new sodium-ion battery has recently passed the certification of GB 38031-2025 “Safety Requirements for Traction Batteries for Electric Vehicles” (hereinafter referred to as the “new national standard”), becoming the world’s first sodium-ion battery to pass the new national standard certification.

The new national standard will be officially implemented on July 1, 2026. It aims to eliminate the risk of spontaneous combustion of electric vehicles from the source and sets strict safety requirements for batteries in multiple dimensions such as thermal diffusion, bottom impact, and fast charging cycles.

Image source: CATL

In the third-party authoritative tests conducted by the China Automotive Technology and Research Center’s New Energy Testing Center, CATL’s new sodium-ion battery demonstrated excellent safety performance at both the cell and battery pack levels, successfully passing all tests.

The new sodium-ion battery not only effectively reduces reliance on lithium resources and builds a safer, lower-carbon new battery industry ecosystem but also addresses the low-temperature pain point in northern regions, promoting the popularization of new energy vehicles in northern China and other high-latitude areas.

This certification through the new national standard marks a crucial milestone for sodium-ion batteries to move towards large-scale applications and enter thousands of households.

Image source: CATL

It is reported that CATL’s sodium-ion power battery was officially announced at a press conference on April 21 this year. At that time, the official stated that mass production would start in December and that it could be applied to hybrid and pure electric models. To ensure mass production efficiency and product consistency, the introduced Automatic sorting, refining and tray loading equipment plays a key role in the production process — it can accurately complete electrode material sorting, electrolyte purification, and automated cell tray loading, improving production precision to the micrometer level. The capacity of a single production line has increased by 40% compared with traditional equipment, providing solid manufacturing support for the large-scale implementation of sodium-ion batteries.

CATL’s sodium-ion battery boasts an industry-leading energy density of 175Wh/kg. It offers a hybrid pure electric range of over 200 kilometers and a pure electric range of over 500 kilometers, supports 5C ultra-fast charging, and has a cycle life of 10,000 times.

Sodium-ion batteries are far safer than lithium batteries. They have undergone rigorous tests, including multi-faceted extrusion, needle penetration, electric drill penetration, and battery sawing, all without catching fire or exploding.

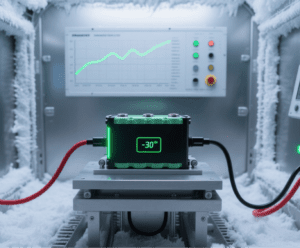

Most crucially, they are not afraid of low temperatures. In actual tests at -30°C, it only takes 30 minutes to charge from 30% to 80%, with 93% of the power available. Even in a 10% SOC (state of charge) low-power state, it can maintain a high speed of 120km/h.

Even in extremely cold environments of -40°C, the charging and discharging capabilities remain excellent, and it can still maintain a speed of 120km/h with 10% SOC, which is absolutely impressive.

What benefits does artificial intelligence bring to component assembly machines?