In an era where artificial intelligence technology dominates headlines, production lines are undergoing another profound revolution. The essence of this transformation lies in “data defining manufacturing” — ing the physical world with digital models through intelligent machine vision systems, and driving the industrial chain to shift from cost orientation to value innovation. The evolution history of machine vision is a microcosm of industrial automation evolving from “mechanical arms” to “smart eyes”. Around 2000, machine vision technology began to enter the Chinese market. In the first decade, its development was relatively slow. However, after 2012, driven by the booming development of domestic 3C, lithium battery, photovoltaic and other industries, as well as the wave of domestic substitution, the machine vision industry ushered in a period of rapid growth. The industry scale has increased 4-5 times in the past decade, and the number of industrial cameras has grown from 500,000-600,000 in 2014 to more than 2.5 million in 2024, with the localization rate rising from less than 20% to more than 75% at present.

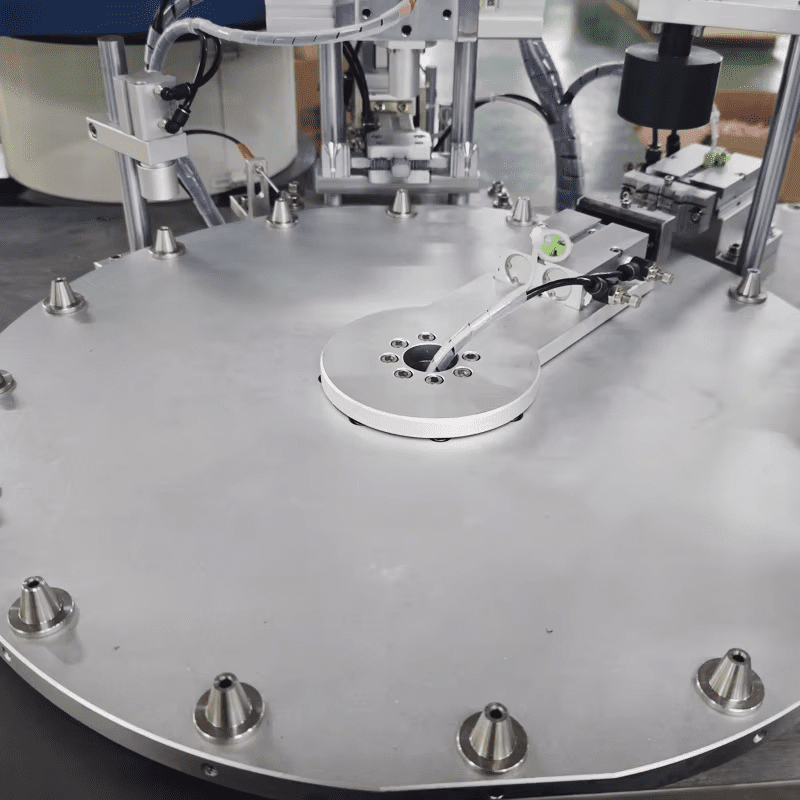

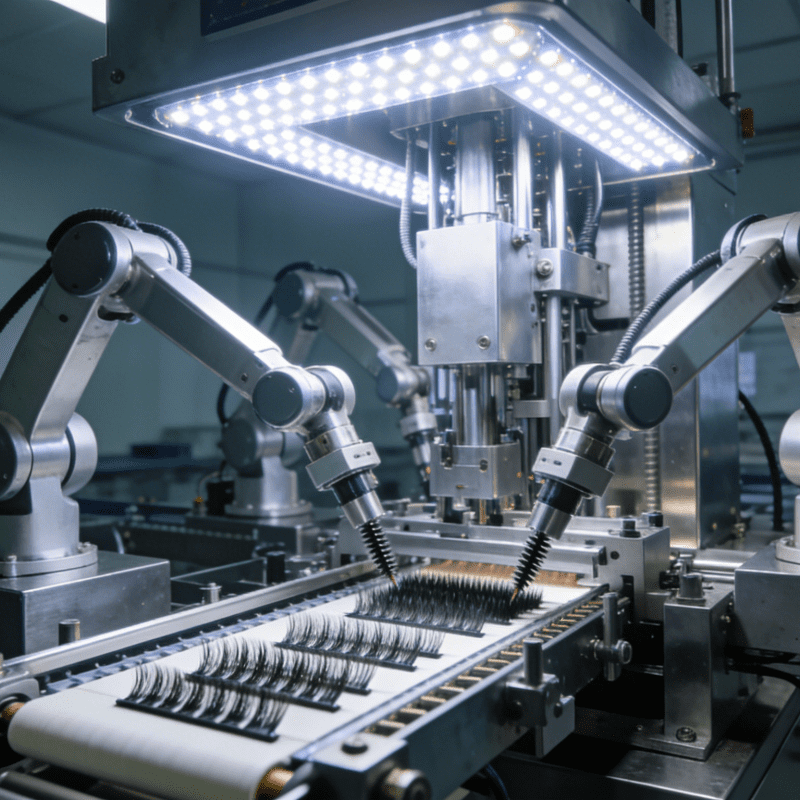

In traditional production lines, manual operations account for a large proportion. Workers need to place product materials into various manufacturing machines for the next process. This method is not only inefficient but also prone to human errors, resulting in uneven product quality. The emergence of intelligent industrial control machine vision systems has completely changed this situation. It enables machines to have “eyes” and “brains”, which can automatically identify product features and defects, and achieve precise grasping and placing. For example, in the field of mobile and wearable device assembly, where production needs rapid upgrading and product quick conversion, intelligent machine vision can be used for insertion inspection before assembly, verification after assembly, precise robot guidance, and serial number and barcode reading, greatly improving the quality and efficiency of production and assembly.

The DLIA industrial defect detection system, as an embodiment of the large-scale application of intelligent industrial control machine vision systems, has broken the boundary of “human-machine collaboration” in industrial scenarios in the past, enabling production lines to adapt to changes in market demand — shifting from mass standardized production to small-batch customized manufacturing. In the past, the hierarchy of the industrial chain was dominated by labor costs and economies of scale; now, the penetration rate of intelligent industrial control systems has become a new yardstick to measure a country’s manufacturing competitiveness. Relying on the explosive demand of 3C, lithium battery, and photovoltaic industries, China has become the main battlefield for technology implementation. Moreover, by virtue of automation upgrading in the automotive, electronics and other fields, it leads the global machine vision market with a compound annual growth rate of 24.5%. When an automobile welding line automatically identifies welding spot parameters of different vehicle models through a vision system and adjusts the robot trajectory in real-time, the ideal of flexible manufacturing finally comes into reality.

Standing at the critical point of technological revolution, the ceiling of machine vision is constantly being broken. Curved surface inspection, precision assembly and other tasks no longer rely on experienced craftsmen; foreign object detection in the food industry has changed from a “probability game” to a “deterministic science”. And as distributed vision networks realize collaborative intelligent control across factories and regions, this will completely release the potential of the industrial Internet. This revolution led by intelligent industrial control and machine vision will eventually bring humanity into a new era of “everything measurable, all machines interconnected”. When every piece of equipment has “insightful eyes” and every process is filled with “wisdom”, the global industrial chain is no longer a cold and rigid interlocking of gears. This is not only a subversion of production methods but also the prelude to the leap of human civilization to a higher dimension — here, the boundaries of manufacturing are redefined, and the spark of innovation will never be extinguished.