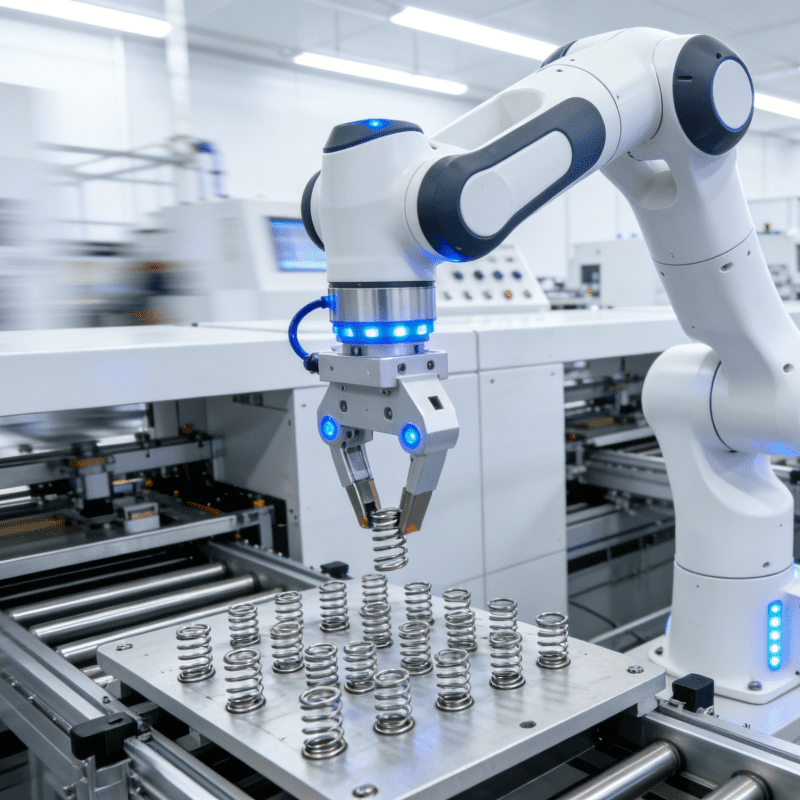

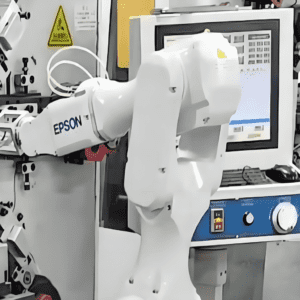

For enterprises engaged in spring manufacturing and assembly, rising labor costs and low production efficiency have long been core pain points. Manual spring handling is not only slow and error-prone but also increases rework costs due to workpiece damage. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has launched a 6-Axis Robotic Spring Pick-and-Place System, which takes cost reduction and output improvement as the core goals, integrating flexibility, stability and efficiency to help global customers break through production bottlenecks and achieve profitable development.

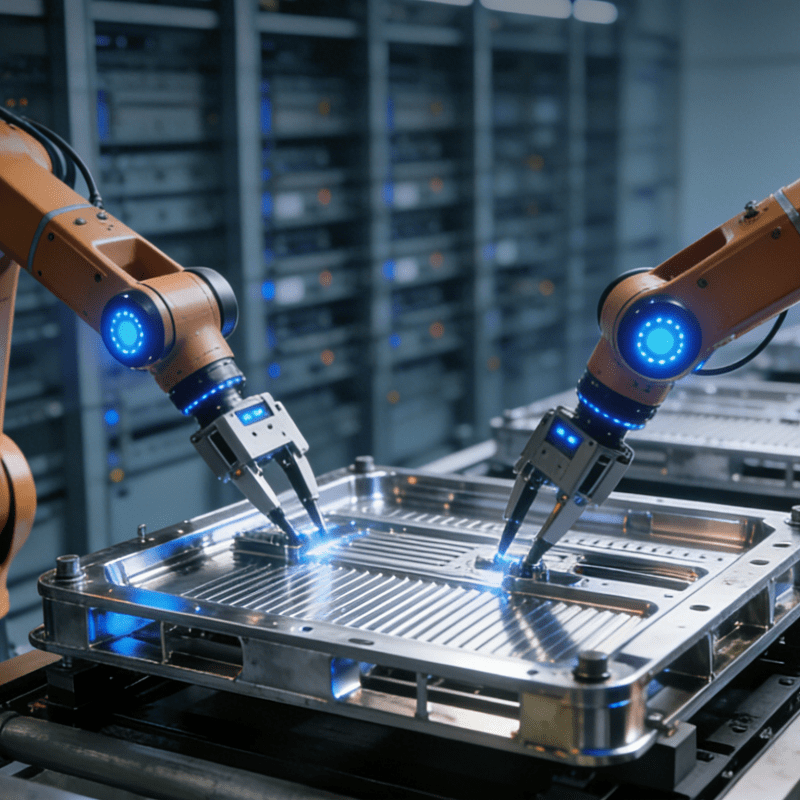

Significantly Reduce Labor Costs

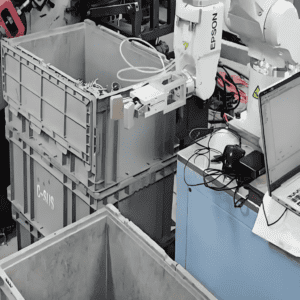

Traditional spring handling requires 3-5 manual workers per shift to complete picking, placing and transferring tasks, which not only incurs high labor costs but also faces risks such as staff turnover and operational errors. Ruizhi’s 6-Axis Robotic Spring Pick-and-Place System can completely replace manual operations, realizing 24-hour uninterrupted work without rest. One set of equipment can replace 4-6 manual workers, reducing annual labor costs by more than 40%. It also avoids workpiece damage and rework caused by manual fatigue, further reducing additional production costs for enterprises.

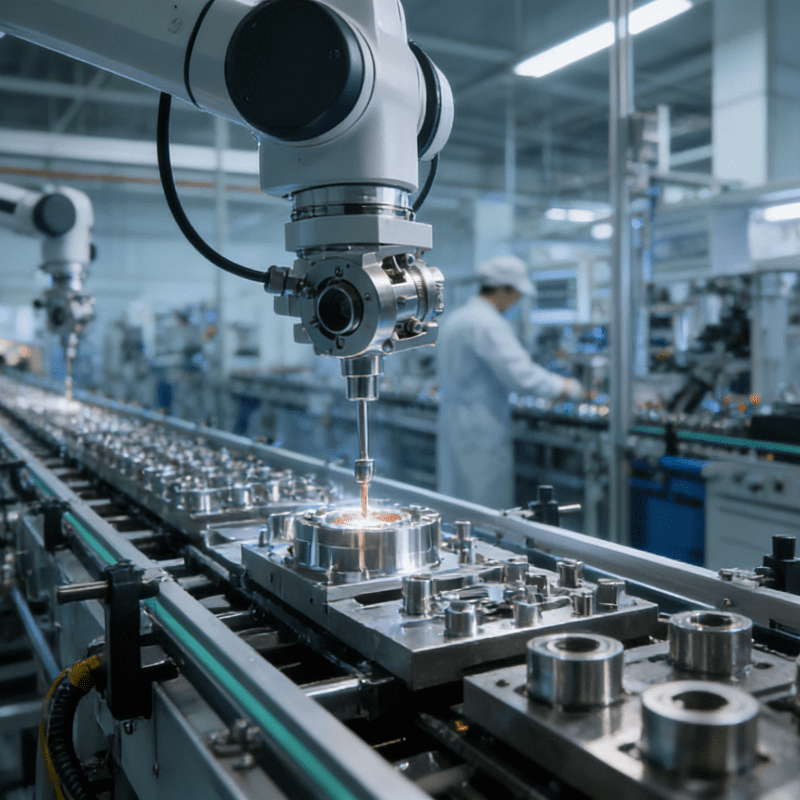

Boost Production Output Steadily

Efficiency improvement is the key to increasing output. The system adopts high-performance servo drive and optimized motion control algorithm, with a single handling cycle as short as 0.3 seconds, which is 5-7 times faster than manual handling. It can seamlessly integrate with assembly lines, stamping machines and testing equipment, eliminating the waiting time between processes and realizing continuous automatic production. After adopting this system, customers’ spring production output can be increased by more than 50%, effectively meeting the growing market demand and shortening the delivery cycle.

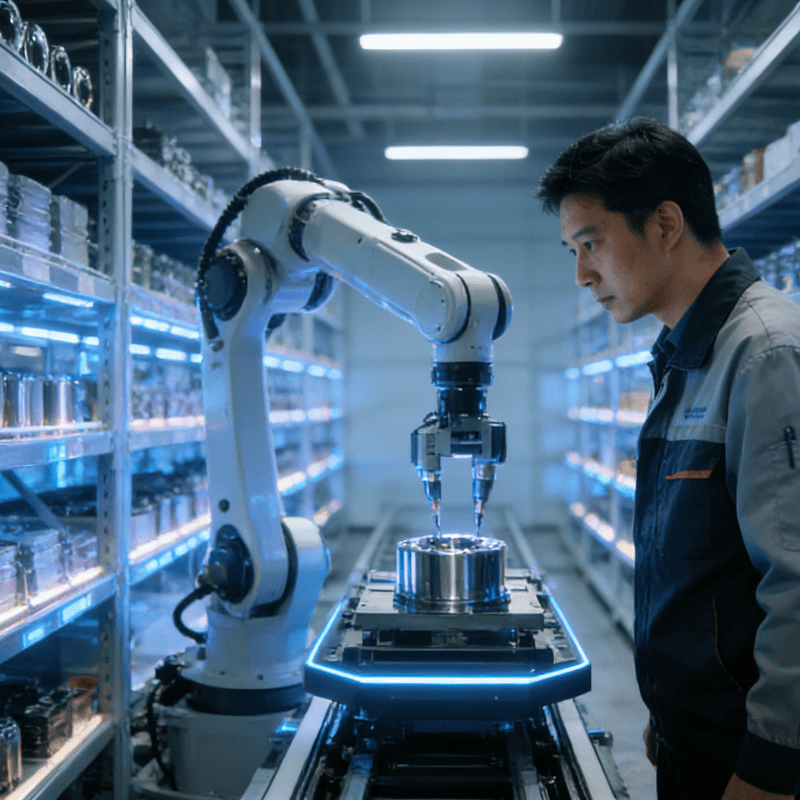

Maximize Production Efficiency

As an expert in non-standard automation, Ruizhi Intelligent Manufacturing fully adapts to the diverse needs of different industries. The 6-Axis Robotic Spring Pick-and-Place System supports customized design according to spring specifications, production layout and output requirements. We customize end effectors, handling paths and control systems to ensure the equipment fits perfectly with the on-site production process, avoiding the inefficiency caused by mismatched standard equipment. The system is easy to operate and maintain, reducing the training cost of operators and further helping enterprises control overall costs.

Ruizhi Intelligent Manufacturing is committed to providing cost-effective automation solutions for global manufacturing enterprises. Our 6-Axis Robotic Spring Pick-and-Place System perfectly interprets the core demands of “cutting costs and improving output”, solving the key pain points of spring production. Choose Ruizhi, and let non-standard automation empower your enterprise to achieve higher efficiency, lower costs and stronger market competitiveness.