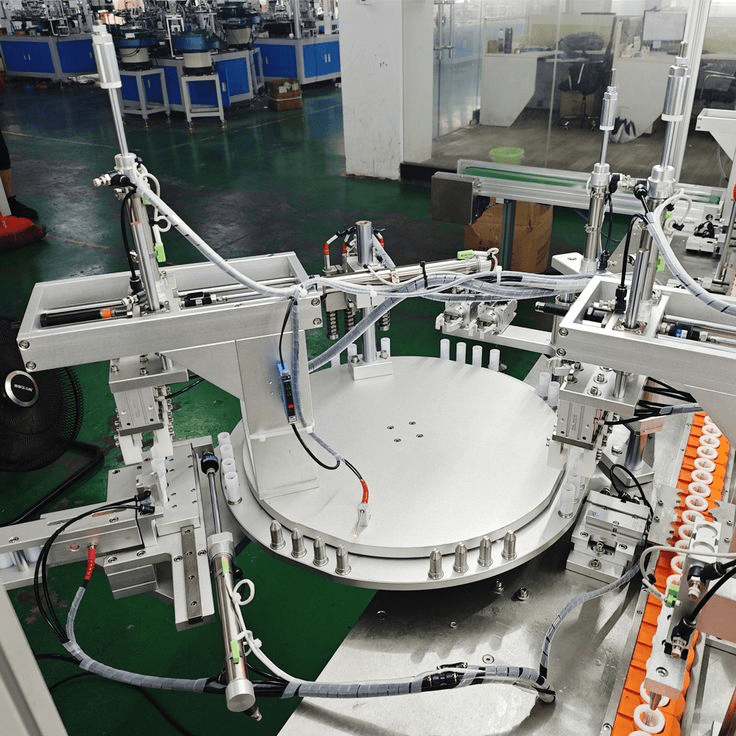

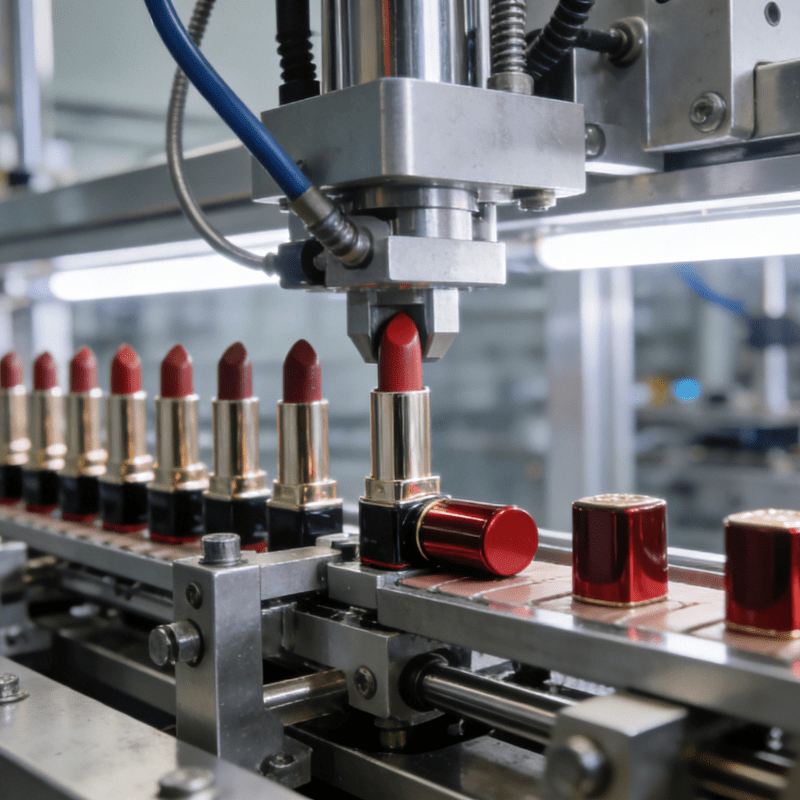

In the dynamic cosmetic packaging industry, cream jars vary greatly in shape, size, and material—from round plastic jars to square glass jars, and from small sample jars to large-capacity storage jars. This diversity poses huge challenges to traditional assembly equipment, which often fails to adapt to multiple specifications, resulting in low efficiency and high labor costs. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing launches the Flexible Cream Jar Assembly Machine, which breaks the limitations of standard equipment and becomes a core helper for cosmetic factories to achieve flexible production.

Break Specification Limitations for Diverse Production

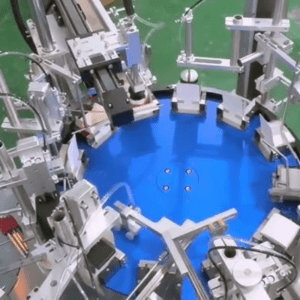

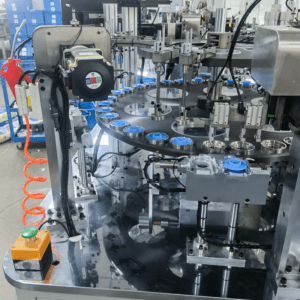

The core advantage of Ruizhi’s Flexible Cream Jar Assembly Machine is its strong compatibility, covering all mainstream cream jar styles and specifications on the market. Unlike standard machines that can only assemble one fixed type of jar, our machine can flexibly switch between different diameters, heights, and shapes with simple parameter adjustments, without replacing core components. It is suitable for both plastic and glass jars, and can easily handle assembly tasks of sample jars (5-10ml) and large-capacity jars (50-200ml), solving the pain point of low efficiency caused by frequent equipment replacement in factories.

Tailor-Made Solutions for Special Production Needs

Ruizhi Intelligent Manufacturing focuses on non-standard automation, deeply understanding the personalized needs of cosmetic factories. For factories with special assembly requirements—such as unique jar mouth structures, special cap assembly processes, or integration of filling and capping functions—our R&D team will tailor exclusive flexible solutions. We adjust the machine’s structure, control system, and assembly steps according to your specific needs, ensuring that the equipment perfectly matches your production line and realizes efficient and precise assembly of personalized cream jars.

Balance Flexibility and Productivity

Flexibility does not mean sacrificing efficiency. Ruizhi’s Flexible Cream Jar Assembly Machine achieves a perfect balance between diverse adaptation and high productivity. Equipped with an intelligent PLC control system, it can complete automatic feeding, jar positioning, cap assembly, and quality inspection in one stop, with a production speed of 50-70 pieces per minute. The machine adopts high-quality stainless steel components, ensuring stable operation, low failure rate, and easy maintenance, while replacing 5-8 manual workers, reducing labor costs by

30%-50% annually.

In conclusion, Ruizhi Intelligent Manufacturing’s Flexible Cream Jar Assembly Machine plays a key role in promoting the automation of cosmetic packaging. It not only solves the core pain point of diverse cream jar assembly for factories but also helps improve production flexibility and market competitiveness. Choose Ruizhi, and let professional non-standard automation technology empower your cream jar production business.