Surface Treatment Technologies After CNC MachiningIn modern manufacturing, the widespread application of CNC machining technology has greatly improved the precision and shape complexity of parts. However, the surfaces of parts processed by CNC machining usually require further treatment to meet different performance and appearance requirements. Here are some common surface treatment technologies after CNC machining.

Spraying

Spraying is a common surface treatment method that uses a spray gun to evenly apply coating onto the surface of parts. Spraying offers a wide range of color options, while also protecting the part surface from corrosion and wear. Different types of coatings are suitable for different application scenarios. For example, anti-rust paint can prevent metal parts from rusting, whereas decorative coatings can enhance the aesthetic appearance of parts.

Before spraying, it is necessary to clean and pre-treat the part surface to ensure good adhesion of the coating. During the spraying process, the thickness and uniformity of the coating must be well controlled to avoid defects such as sagging and blistering.

Electroplating

Electroplating is a method that uses the principle of electrolysis to deposit a layer of metal or alloy on the surface of parts. Electroplating can improve the corrosion resistance, wear resistance, electrical conductivity and other properties of parts. Common types of electroplating include galvanizing, chromium plating and nickel plating.

The electroplating process requires strict control of various parameters, such as current density, electroplating time and solution temperature, to ensure the quality and uniform thickness of the plating layer. Meanwhile, electroplating will cause certain environmental pollution, so effective environmental protection measures need to be taken.

Oxidation

Oxidation treatment is mainly used for the surface treatment of metal parts such as aluminum and magnesium. A layer of oxide film is formed on the part surface through chemical reaction, which can improve the corrosion resistance and hardness of parts, while also enhancing their appearance.

Anodizing is a common oxidation treatment method. In a specific electrolyte, the part is used as the anode, and a dense oxide film is formed on the part surface by applying electric current. The thickness and performance of the oxide film can be controlled by adjusting parameters such as current density and oxidation time.

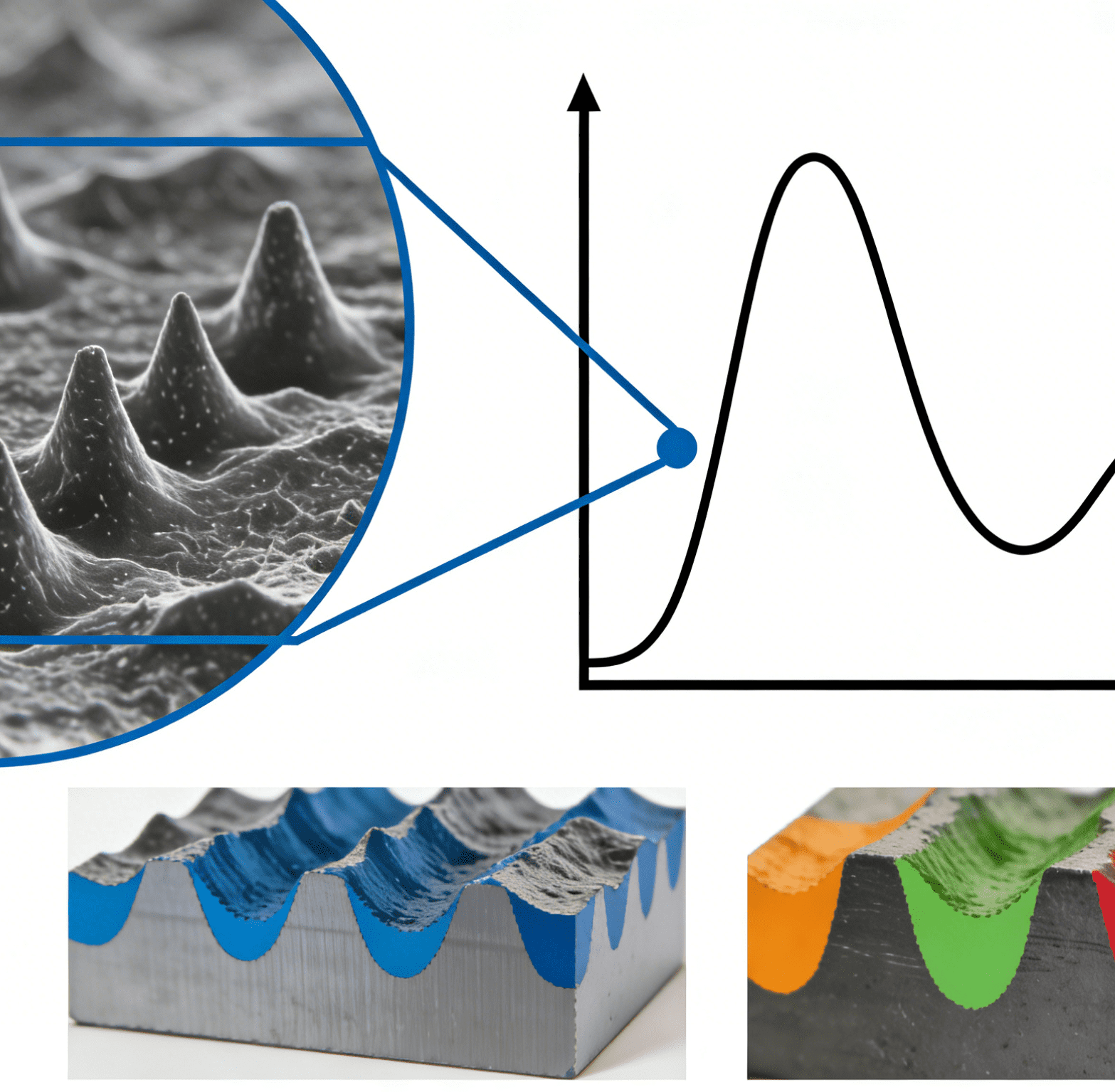

Polishing

Polishing is a treatment technology that removes micro-roughness on the part surface through mechanical, chemical or electrochemical methods to achieve a smooth surface. Polishing can improve the surface finish and appearance quality of parts, while also reducing surface roughness and friction coefficient.

Mechanical polishing is the most common polishing method, which uses tools such as sandpaper, grinding wheels and polishing wheels to grind and polish the part surface. Chemical polishing and electrochemical polishing use chemical solutions or electrochemical reactions to remove micro-roughness on the part surface.

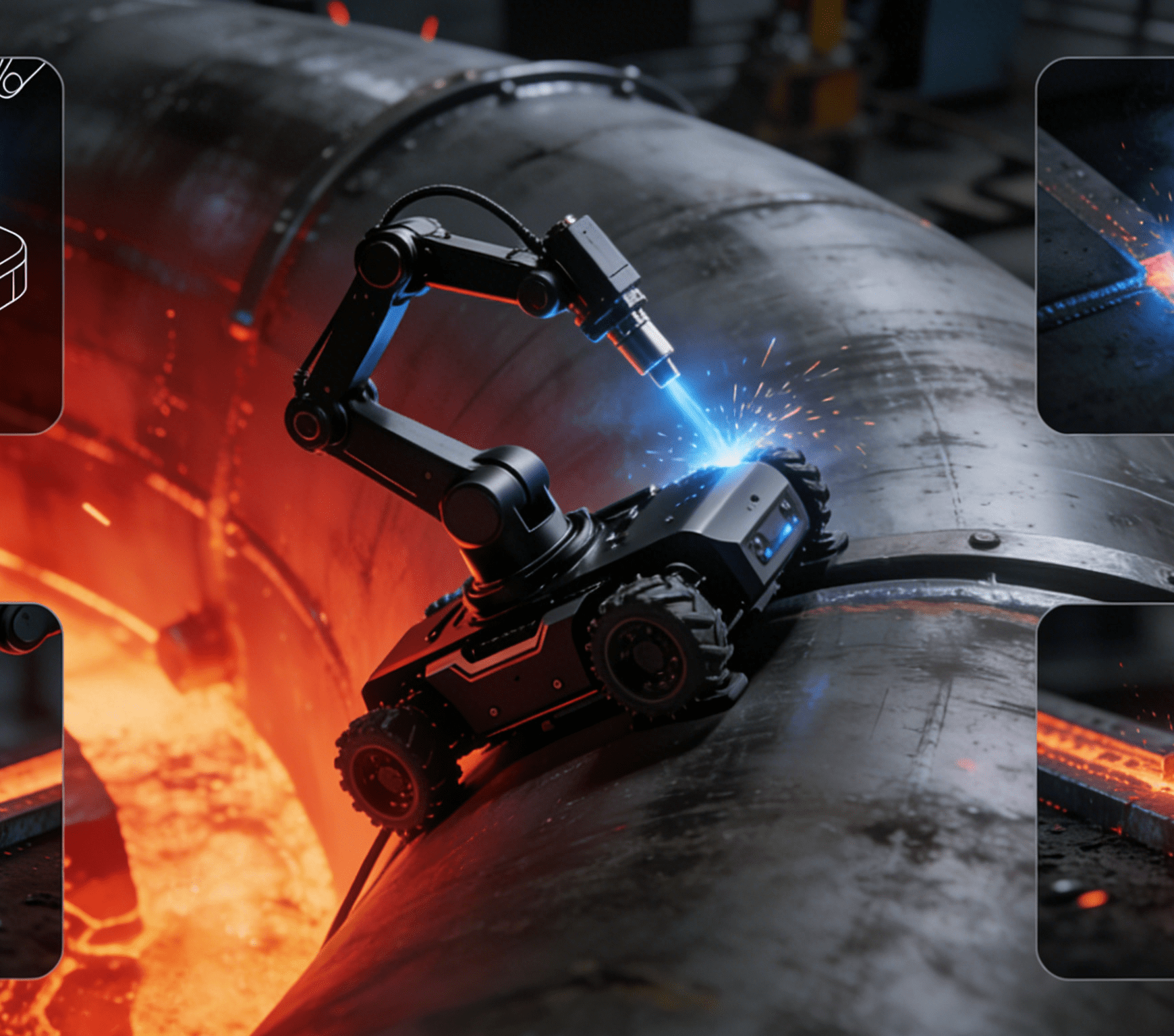

Sandblasting

Sandblasting uses high-speed sprayed sand particles to impact the part surface, removing impurities such as oxide scale, rust and oil stains, while also imparting a certain roughness to the part surface. Sandblasting can improve the adhesion of the part surface, providing a good foundation for subsequent treatments such as spraying and electroplating.

During the sandblasting process, it is necessary to select appropriate sand materials and particle sizes, and control the spraying pressure and angle to ensure the uniformity and consistency of the sandblasting effect. Besides, as sand particles are core auxiliary materials for sandblasting, their quality stability during storage and transportation is crucial—this is where the granule packaging machine comes into play. It can precisely package sand particles of different specifications in sealed bags according to preset weights, preventing moisture absorption, impurity mixing or particle size segregation that may affect sandblasting results, thus ensuring the batch consistency of surface treatment effects.

In conclusion, surface treatment technologies after CNC machining are crucial for improving the performance and appearance quality of parts. Different surface treatment technologies are suitable for different materials and application scenarios. When selecting a surface treatment method, it is necessary to comprehensively consider factors such as the service requirements, cost and environmental protection of parts to choose the most appropriate surface treatment technology.