Table of Contents

ToggleRevolutionizing Fuse Assembly: Ruizhi Intelligence’s Fuse Assembly Machine Redefines Precision Manufacturing

Di era manufaktur elektronik global yang terus-menerus mengejar miniaturisasi dan kecerdasan, perakitan sekering—yang krusial untuk perlindungan sirkuit pada elektronik konsumen, sistem otomotif, dan peralatan industri—telah memasuki fase otomatisasi baru. Ruizhi Intelligence baru-baru ini meluncurkan Mesin Perakitan Sekering mutakhirnya, sebuah solusi revolusioner yang dirancang untuk mengatasi kompleksitas perakitan sekering mikro, sekering otomotif, dan sekering tegangan tinggi dengan presisi tingkat nanometer dan fleksibilitas adaptif. Sistem ini menandai pergeseran paradigma dari perakitan manual tradisional menuju produksi cerdas yang sepenuhnya otomatis, menetapkan standar baru untuk keandalan dan efisiensi dalam manufaktur sekering.

Terobosan Teknologi Inti: Rekayasa Presisi Bertemu dengan Kontrol Cerdas

Sistem Perakitan Multi-Sumbu Tingkat Nanometer

Peralatan ini mengintegrasikan lengan robotik piezoelektrik enam sumbu dengan motor servo frekuensi tinggi, menciptakan sistem kontrol loop tertutup untuk “posisi-pengelasan-deteksi”:

- Kontrol Torsi Ultra-HalusUntuk sekring mikro yang membutuhkan torsi 0,5-1,2 N·m dan sekring otomotif yang membutuhkan torsi 3-5 N·m, sistem ini secara otomatis menyesuaikan 16 mode pengencangan dengan akurasi ±0,01 N·m. Sebuah produsen elektronik terkemuka melaporkan penurunan kelonggaran terminal sekring sebesar 98% setelah penerapan sistem ini, dengan peningkatan efisiensi perakitan sebesar 300%.

- Teknologi Pengelasan Non-KontakMenggunakan penyolderan laser dengan kontrol ukuran titik 5μm, mesin ini menghasilkan sambungan bebas rongga pada sekring mikro berukuran 0402, mengurangi kerusakan termal pada elemen sekring dibandingkan dengan metode penyolderan tradisional. Teknologi ini memastikan keandalan sambungan solder dengan kekuatan geser melebihi 50N untuk sekring mini.

Inspeksi Visual 3D & Penyaringan Cacat Cerdas

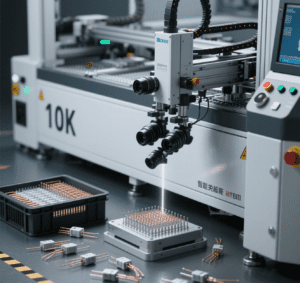

Dilengkapi dengan kamera industri 10K dan interferometer laser, sistem ini memungkinkan deteksi cacat tingkat mikron:

- Analisis Permukaan Tingkat AtomInterferometri pergeseran fasa menghasilkan topografi 3D untuk mengidentifikasi cacat berskala 0,1 μm seperti oksidasi elektroda atau retakan pada bodi keramik. Dalam produksi sekring otomotif, hal ini mengurangi produk cacat dari 2,3% menjadi 0,07%.

- Optimasi Jalur Berbasis AIAlgoritma pembelajaran mesin menghasilkan lintasan perakitan optimal berdasarkan model 3D sekering. Untuk sekering tegangan tinggi yang kompleks, efisiensi perencanaan jalur 20 kali lebih cepat daripada pemrograman manual, sehingga mempersingkat waktu siklus dari 60 detik menjadi 22 detik per unit.

Sistem Pergantian Cepat Modular

Mesin ini dilengkapi modul perkakas plug-and-play untuk peralihan produk yang cepat:

- Transisi Proses 8 Menit:Modul khusus melayani tiga kategori sekering:

- Modul sekering mikro: Mengintegrasikan pengambilan dan penempatan vakum untuk sekering berukuran 01005 dengan desain antistatis;

- Modul sekring otomotif: Termasuk pengujian isolasi dan crimping terminal multi-stasiun;

- Modul sekering tegangan tinggi: Dilengkapi dengan unit penyegelan kedap udara dan pengujian tekanan.

Mekanisme penguncian cepat hidrolik memungkinkan penggantian modul dalam 8 menit, peningkatan 90% dibandingkan pengaturan tradisional.- Adaptasi Parameter Cerdas:Sistem MES secara otomatis mengambil resep proses berdasarkan spesifikasi sekering, dengan AI mengoptimalkan parameter seperti suhu dan tekanan pengelasan menggunakan data historis, menghilangkan kesalahan debugging manual.

Skenario Aplikasi: Revolusi Efisiensi dan Kualitas

Kasus 1: Jalur Perakitan Kotak Sekering Otomotif

Dalam lini produksi sekering otomotif OEM besar, solusi tradisional vs. otomatis sangat berbeda:

| Jenis Proses | Perakitan Manual (15 pekerja) | Mesin Perakitan Sekering Ruizhi (2 unit) |

| Keluaran Harian | 3.000 unit | 12.000 unit |

| Laju Sirkuit Terbuka | 1.8% | 0.03% |

| Resistansi Kontak | Toleransi ±5% | Toleransi ±0,8% |

| Konsumsi Energi | 8.500kW·h/hari | 3.200kW·h/hari |

Khususnya, pemantauan tekanan 12 titik sistem selama crimping terminal mempertahankan deviasi koaksialitas ≤0,02 mm, memastikan konduktivitas listrik yang stabil. Presisi ini mengurangi pengerjaan ulang pasca-perakitan sebesar 95%, sehingga menghemat biaya OEM $ sebesar 1,2 juta per tahun.

Kasus 2: Rakitan Sekering Tegangan Tinggi untuk Kendaraan Listrik

Untuk sekering tegangan tinggi kendaraan energi baru (500V+), mesin ini mengatasi tantangan kritis:

- Titik Nyeri Tradisional: Perakitan manual sekering tegangan tinggi memerlukan waktu 15 menit per unit, dengan kegagalan 8% dalam uji kekuatan dielektrik akibat celah udara dalam enkapsulasi.

- Solusi OtomatisSistem ini menggunakan enkapsulasi vakum dengan kontrol celah level 0,01 mm, dikombinasikan dengan proses curing UV untuk resin epoksi. Waktu perakitan per sekring berkurang menjadi 3 menit, dan tingkat kelulusan kekuatan dielektrik melonjak dari 88% menjadi 99,9%. Sebuah pemasok suku cadang kendaraan listrik terkemuka melaporkan penghematan biaya tahunan sebesar $800.000 berkat berkurangnya limbah material dan pengerjaan ulang.

Dampak Industri: Merintis Manufaktur Cerdas 4.0

Seiring melonjaknya permintaan global untuk sekering miniatur pada perangkat IoT dan kendaraan listrik (diperkirakan CAGR 25% hingga 2027), perakitan sekering presisi telah menjadi kompetensi inti. Direktur Litbang Ruizhi mencatat bahwa sistem data yang kompatibel dengan OPC UA pada mesin ini memungkinkan ketertelusuran parameter penting seperti suhu dan tekanan pengelasan secara real-time, yang sepenuhnya sesuai dengan standar ISO 9001 dan IATF 16949.

Diterapkan di lebih dari 200 fasilitas, termasuk Foxconn dan Delphi, sistem ini telah memangkas biaya tenaga kerja sebesar 70% per lini dan mengurangi luas lantai sebesar 40%. Laporan industri memproyeksikan pasar mesin perakitan sekering akan melampaui $1,5 miliar pada tahun 2026, dengan sistem presisi tinggi terintegrasi AI seperti milik Ruizhi yang memimpin tren menuju manufaktur "cerdas, fleksibel, dan berbasis data".

Catatan TeknisTeknologi kontrol piezoelektrik enam sumbu pada mesin ini telah memegang paten penemuan nasional (ZL2024XXXXXX), dan sistem penglihatan 3D-nya telah tersertifikasi ISO 13849 PLd. Ruizhi akan mendemonstrasikan kemampuan perakitan sekering mikro mesin ini di pameran NEPCON Tiongkok 2025, yang menampilkan operasi presisi hingga tingkat 0,01 mm.

#FuseManufacturing #IndustrialAutomation #PrecisionEngineering #SmartFactory