Landmark Industry Deals and Robots’ Shift from “Sci-Fi” to Production Mainstays

Recently, SoftBank Group, a global technology and investment enterprise, announced the acquisition of the robotics business unit of Swiss engineering firm ABB at an enterprise value of $5.375 billion. This landmark transaction has not only stirred the capital market but also set a new direction for talent demand in the industrial robotics sector.

In today’s rapidly developing industrial field, industrial robots have transformed from once “science fiction elements” into indispensable “production mainstays” in factory workshops. With their precise, efficient, and stable operational capabilities, they continuously break through the limitations of traditional production models, serving as the core engine driving the intelligent and automated upgrading of the manufacturing industry. They are profoundly changing the production landscape and competitive dynamics of the global industrial sector.

Cross-Industry Penetration: Robots Empowering Electronics, Food, and Pharma

The application of industrial robots is no longer confined to the traditional field of automobile manufacturing; instead, it has widely penetrated into multiple industries such as electronics, food, pharmaceuticals, and logistics, providing strong impetus for the upgrading of various industries.

In the electronics industry, as consumer electronic products develop towards being thinner, lighter, and more high-precision, industrial robots with micron-level operational precision complete chip packaging (wire bonding, shell packaging) and mobile phone assembly (screen lamination, camera installation), cutting error rates and shortening production cycles.

Notably, in the upstream production of injection-molded components—key to electronics (e.g., plastic connectors, smartphone casing parts) and automotive light-weighting (e.g., small interior plastic fittings)—the Automatic Injection-Molded Part Feeding And Assembly system has become a game-changer in streamlining workflows. This system integrates two core functions: automated feeding (using vibratory bowls with custom tracks to sort and align small standardized parts, or vacuum-equipped robotic arms to handle fragile, irregularly shaped components) and precision assembly (aided by machine vision sensors that calibrate part positions to ±0.02mm). For example, in assembling plastic connectors for electronic devices, the system can automatically feed 500+ injection-molded pins per minute, then align and insert them into housings with zero manual intervention—reducing assembly errors by 90% compared to manual operations and slashing the per-unit production time by 35%.

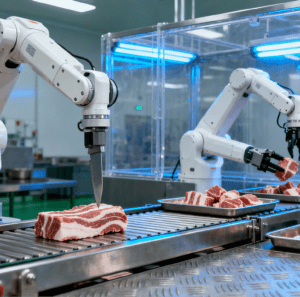

In the food industry, robots address hygiene and standardization challenges: they handle meat cutting, vegetable sorting, and bread baking to avoid bacterial contamination, and execute packaging tasks (box packing, sealing, labeling) to adapt to diverse specifications.

In the pharmaceutical industry, robots operate in sterile clean workshops for drug batching, mixing, and filling—ensuring drug safety—and control vaccine culture parameters (temperature, humidity) while optimizing pharmaceutical logistics (sorting, outbound).

Dual-Benefit Drivers: Enterprise Cost Savings and Social Value Enhancement

The widespread application of industrial robots has brought significant benefits to enterprises and society, with value manifesting in both operational and societal dimensions.

From an enterprise perspective, robots reduce reliance on manual labor for high-intensity, repetitive tasks—lowering labor costs—and minimize scrap rates via high precision, cutting raw material waste. Their 24/7 operation boosts production efficiency, helping enterprises expand scale and respond to market demands faster.

From a social perspective, robot adoption drives the intelligent transformation of traditional manufacturing, spurring growth in related industrial chains (robot R&D, component production, maintenance) and creating new jobs. Additionally, robots replace humans in high-risk tasks (toxic chemical operations, high-altitude construction), reducing workplace accidents and safeguarding worker safety.

Challenges and Future Trajectory: Overcoming Bottlenecks for Smarter Integration

While industrial robots deliver substantial value, they also face hurdles that demand rational solutions—with innovation pointing the way to future development.

Key challenges include technical bottlenecks: robots still lack robust autonomous decision-making and adaptability in complex scenarios (e.g., flexible manufacturing). Moreover, core technologies and key components remain monopolized by a few developed countries, leaving China’s robotics industry with gaps in R&D and high-end component manufacturing, risking “technology bottlenecks.”

With advancing technology and evolving industrial demands, the future of industrial robots lies in greater intelligence and integration—overcoming current limitations to unlock broader prospects for smart manufacturing.

Robots realize the automated assembly of automotive connectors