On the stage of modern mechanical machining, precision CNC machining centers are undoubtedly a bright star, emitting a unique and charming allure.

A precision CNC machining center is a highly integrated and automated machining equipment. It integrates multiple machining functions such as milling, boring, drilling, and tapping, like an all-round master of mechanical machining.

Multi-Functional Integration: Multi-Process High-Efficiency Machining with One Clamping

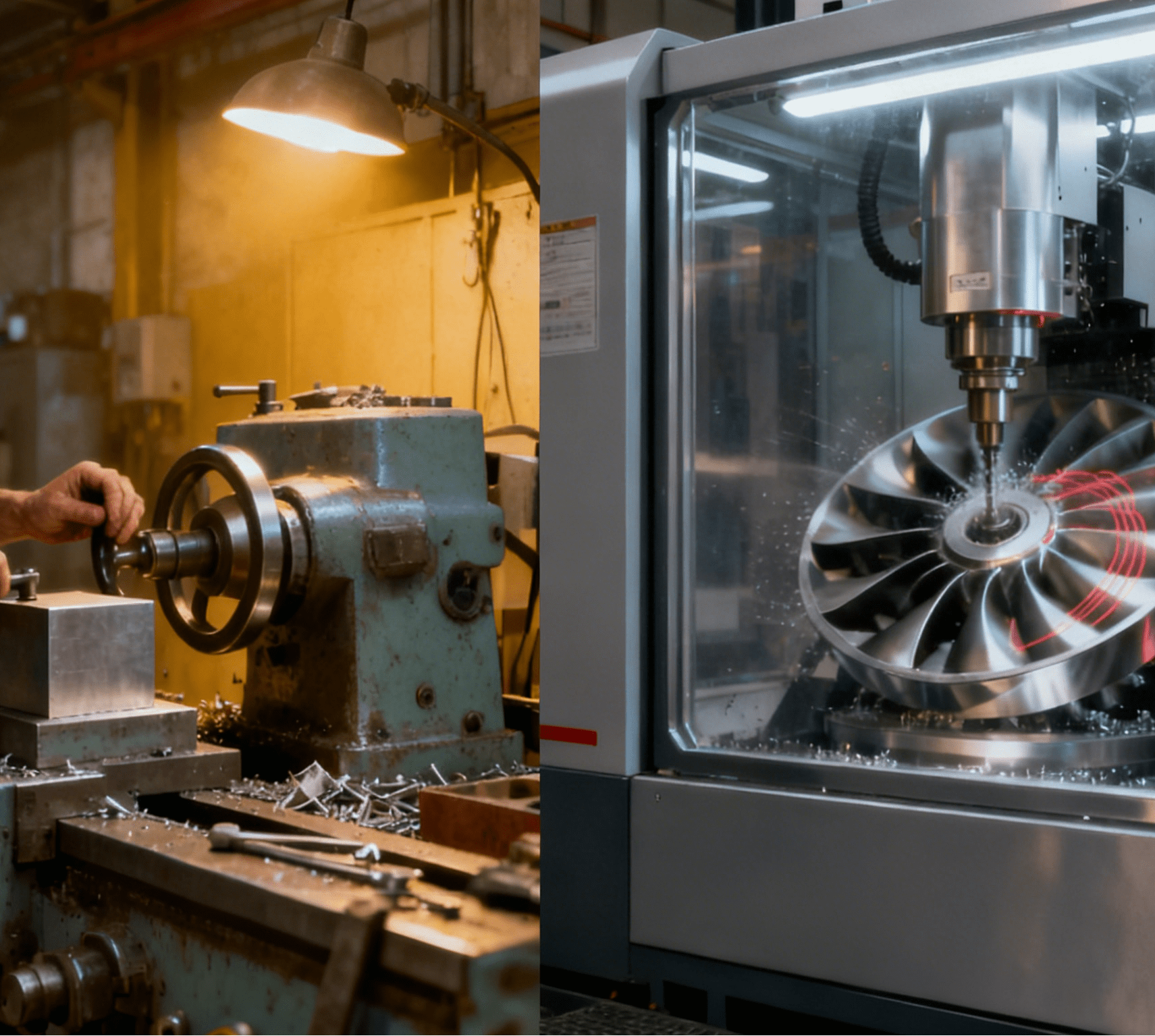

In traditional mechanical machining, to process a complex part, it is often necessary to transfer the workpiece between different machine tools and perform multiple clampings and positionings. This not only consumes a lot of time and labor but also easily introduces errors. However, a precision CNC machining center can complete multiple machining processes on its workbench with a single clamping. For example, when manufacturing a complex mold, it can first perform milling on the cavity to accurately shape the mold, then carry out drilling to reserve holes for subsequent assembly, and then perform tapping to make the threaded holes meet the required precision standards. When processing spring seats that match automatic spring equipment, it can also finish milling the mounting surface, drilling the spring positioning holes and tapping the fixing threads in one clamping, and directly dock with the automatic spring equipment for subsequent assembly. The entire process is efficient and coherent, greatly improving machining efficiency and precision.

Micron-Level Precision: Quality Guarantee for High-End Component Machining

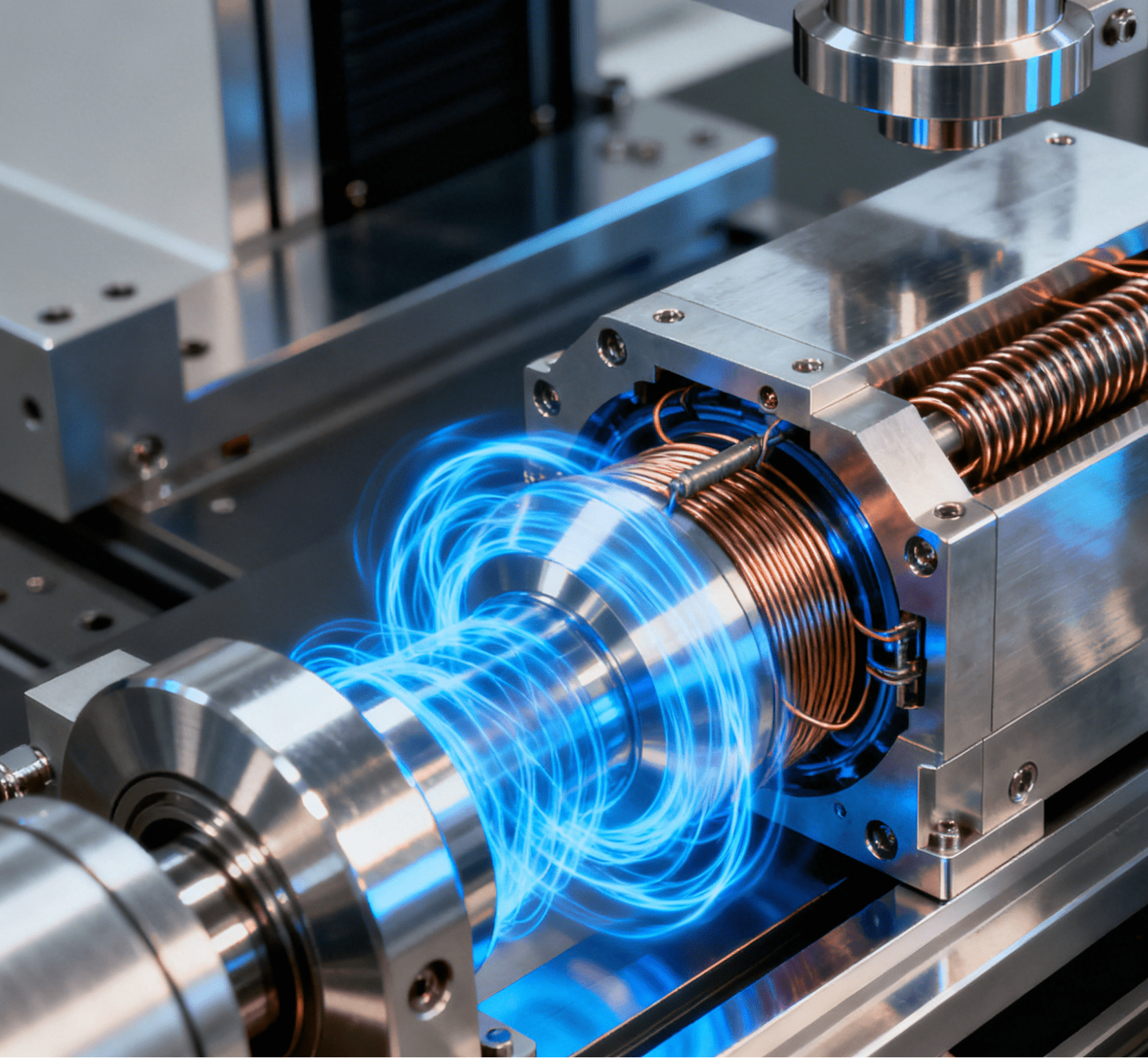

Its high-precision machining capability is amazing. Equipped with high-precision ball screws, linear guides, and advanced CNC systems, it can control the movement precision of the tool at the micron level. When processing some aerospace components with extremely high precision requirements, such as turbine blades of aircraft engines, the precision CNC machining center can ensure that the contour precision, surface roughness, and dimensional tolerance of the blades strictly meet the design requirements. This high-precision machining greatly improves product performance. For example, high-precision turbine blades can improve the combustion efficiency of the engine, reduce fuel consumption, and enhance the flight performance of the aircraft.

High Automation and Flexibility: An Intelligent Core Adapting to Diverse Needs

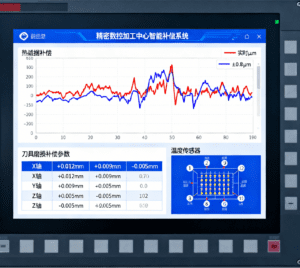

High automation is another charm of precision CNC machining centers. Operators only need to input the designed machining program into the CNC system, and the machining center can perform machining automatically according to the program. During the machining process, it can automatically change tools, adjust cutting parameters, and even automatically monitor and compensate for tool wear and workpiece deformation during machining. For example, when the tool is worn after long-term machining, leading to changes in cutting dimensions, the monitoring system of the machining center will detect it in time and automatically adjust the tool compensation value through the CNC system to ensure that the machining precision is not affected. This automated machining mode not only reduces errors caused by manual operations but also improves production efficiency and reduces labor intensity, enabling enterprises to achieve large-scale and high-efficiency production.

In addition, precision CNC machining centers also have good flexible machining capabilities. With the increasing diversification of market demands and the acceleration of product upgrading, enterprises need equipment that can quickly adapt to different product machining needs. A precision CNC machining center can switch from processing one part to processing a completely different part in a short time just by replacing the corresponding program and tool. For example, a mechanical manufacturing enterprise may need to produce various types of products such as automobile engine parts, medical equipment parts, and industrial automation equipment parts in one day. The precision CNC machining center can easily handle such diverse production tasks, winning advantages for the enterprise in the fierce market competition.

Against the backdrop of the era of industrial intelligent manufacturing, precision CNC machining centers can also communicate with other intelligent equipment through networking, realizing real-time sharing of production data and intelligent management of the production process. Through seamless connection with the enterprise’s production management system and logistics system, it can further optimize the entire production process, improve resource allocation efficiency, and reduce production costs.

With its many charms such as multi-functional integration, high precision, high automation, flexible machining, and intelligence, precision CNC machining centers occupy an extremely important position in the field of modern mechanical machining. They have become an important force promoting the development of the manufacturing industry towards high-end, intelligent, and precision directions, creating more high-precision and high-performance industrial products for humans and continuously expanding the boundaries of modern industry.