In the manufacturing of precision components, high-efficiency machining technology of CNC lathes plays a core role. This paper systematically introduces approaches to improve machining efficiency and quality, with a focus on three key areas: micron-level precision control to ensure impeccable dimensional accuracy of components, multi-axis linkage optimization for machining complex structural parts, and intelligent production management to achieve full-process monitoring. Through these elaborations, readers will gain practical insights to meet the stringent requirements for precision components in high-end industries. Next, we will delve into specific technical details in depth.

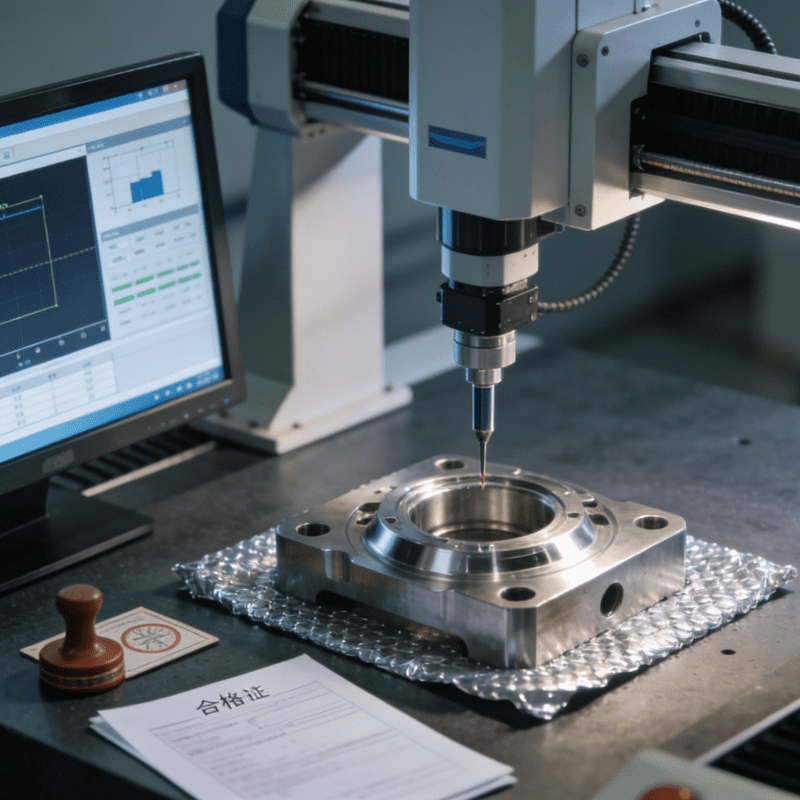

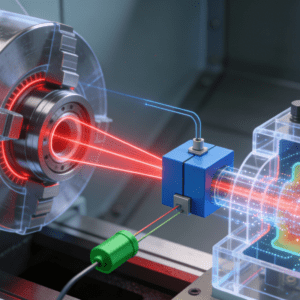

Micron-level Precision Control

Micron-level precision control is of paramount importance in the precision component machining of CNC lathes, which ensures minimal dimensional errors of precision parts. By adopting high-precision sensors and real-time compensation technologies, CNC lathes can automatically adjust cutting parameters to maintain machining accuracy within 1 micron. For instance, in the aerospace field, this control method can reduce scrap rates and elevate product quality. Practical experience has proven that the integration of advanced measurement systems enables effective management of machining errors, laying a solid foundation for subsequent multi-axis linkage optimization. This not only boosts production efficiency, but also meets the rigorous reliability demands of high-end industries.

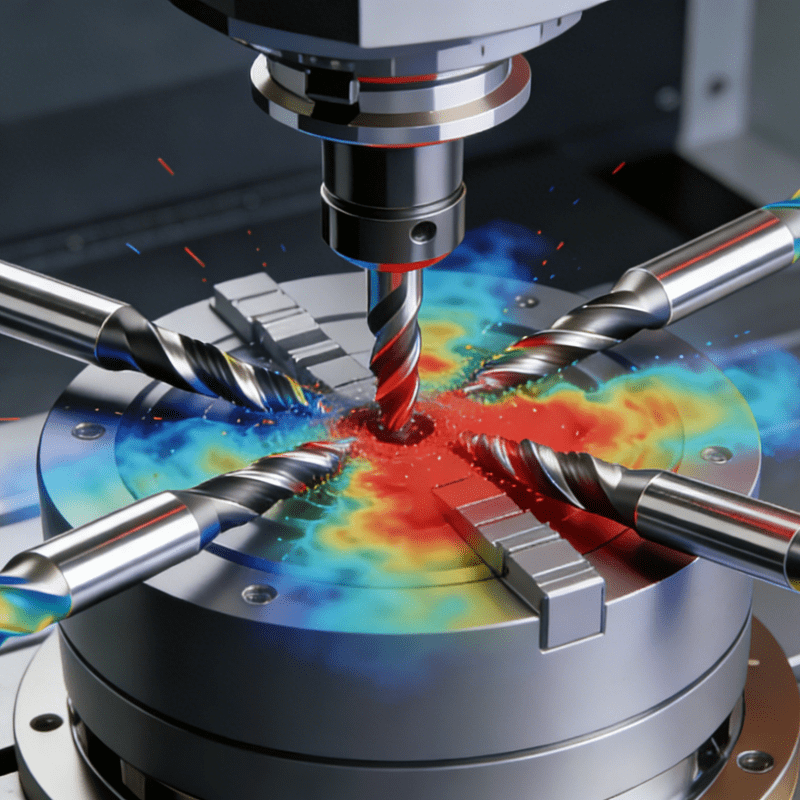

Multi-axis Linkage Optimization

Multi-axis linkage machining technology enables CNC lathes to coordinate the operation of multiple motion axes simultaneously, which greatly enhances the capability of machining precision components with complex geometries. It facilitates the machining of components with intricate structures—such as those commonly used in medical devices and core parts processed by Automatic spring equipment—by precisely synchronizing multi-axis movements. Specifically, Automatic spring equipment relies on multi-axis linkage to achieve high-precision machining of spring spiral structures and end-loop forming, ensuring consistent pitch, diameter and elasticity of springs that are critical for equipment operation. This optimization significantly reduces downtime caused by frequent tool changes or workpiece reclamping during machining. More importantly, multi-axis linkage ensures that cutting tools always contact the workpiece at the optimal angle and position. This not only helps maintain ultra-high machining precision, but also effectively prevents excessive tool wear and workpiece surface damage, thus improving production efficiency while ensuring stable and reliable machining quality.

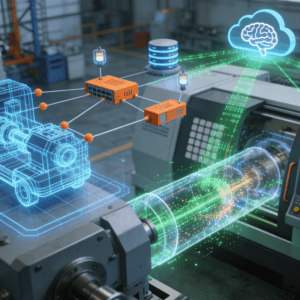

Intelligent Production Management

Beyond precise machining accuracy control and multi-axis linkage optimization, intelligent production process management is also a key driver of efficiency improvement. Automated management systems are now widely adopted in modern CNC lathe workshops to orchestrate the entire production process. Acting as an intelligent supervisor, these systems can automatically schedule component machining sequences, enable efficient collaboration among different equipment, and minimize machine idle and waiting time. What is more, intelligent management is reflected in the real-time monitoring of the production process. Equipped with on-machine detection devices, the system continuously monitors the quality of components during machining. It issues instant alerts once any minor deviation exceeds the allowable tolerance, enabling operators to make timely adjustments and avoid producing non-conforming parts. These integrated measures significantly reduce production downtime, improve equipment utilization efficiency, and ensure the stable and reliable quality of final products.

In summary, the continuous advancement of CNC lathe technology in precision component manufacturing provides robust support for meeting the stringent requirements of high-end industries. Through precise micron-level dimensional control, optimized multi-equipment coordination and the adoption of intelligent production management methods, machining efficiency and component quality have been remarkably improved. In particular, the stable clamping of complex-shaped components and real-time detection throughout the machining process greatly reduce errors and ensure compliance with quality standards for more products. These technological breakthroughs allow high-end industries that rely on top-tier precision components—such as aerospace and precision medical devices—to consistently obtain the high-quality parts they require.